|

In my opinion the two most sought after

antique marine engines are the Palmer Bros. of Cos Cob, CT. Models YT-1 and YT-2. The YT

stood for "Yacht Tender" They were widely used in that application but they also

were popular with working watermen. These engines are beautifully running at very low

speed, small, light weight and its fun to watch all the motion. They have exposed overhead

valves and an exposed eccentric and strap operating the water pump plunger. A few have

magnetos but most have Cuno timers with T Ford "Buzz" coils for ignition.

Around the Chesapeake Bay,

the YT-1 was a popular engine for small crabbing skiffs. This was probably due to the much

better fuel consumption of a four-cycle engine over the turn of the century two-cycle

engines that had powered many of the watercraft favored by the watermen.

The YT-1 was released for sale in Dec. 1921 and was made until 1947. By

the 1920s the watermen were replacing their two-cycle engines with new four-cycle engines

as most of the early engines were long since beyond reasonable repair. On the other hand

the two-cycle marine engine with Make and Break ignition held on in the Canadian Maritimes

up until at least the mid 1960s. I believe this was due in a major part to the area

weather conditions and often the watermen had essentially open boats. The proven

reliability of the low voltage Make and Break ignition over jump spark under adverse

weather conditions demanded a waterman stick with proven technology. It is true four-cycle

marine engines were made with Make and Break ignition however I don't believe they were

commonly made after the early 1930s particularly in the sizes needed by watermen. A

two-cycle M&B marine engine is still made in limited production in Lunenburg, Nova

Scotia.

The ignition system was

the most troublesome portion of the marine engine. Dampness and water, particularly salt

water, corrosion were two very active participants in the daily lives of watermen. One of

the ways watermen dealt with with these two very troublesome problems was they would put

the "Buzz" or M&B coil along with the battery in a small wooden box. The

cover or lid was arranged so water would not run into the box. The two or three wires to

the engine would be lead out of the box with the holes for the wires slanted down so water

could not run down the wires into the box. Often the box would have a leather strap which

the waterman could slip over his shoulder so he could carry the box home and put it by the

kitchen stove to dry out during the night. This same set up is also great for running

marine engines at shows.

The YT-1 developed 2 Hsp at 800 RPM. It swung a three blade,12"dia

by 10"pitch prop, Weight 130 lbs. Bore 3" Stroke 3". There were two

flywheel diameters some early YT-ls had flywheels 11" dia. and later units had

12" dia. flywheels.

In 1936 the YT-1 cost $100, Magneto $35 extra, Clutch $45 extra.

Needless to say most watermen bought them without the clutch or magneto.

Only one out of 13 known YT-1 engines has a magneto. On the other hand

3 out of four known YT-2s have magnetos. Apparently YT-2s tended to be bought by more

affluent yachtsmen rather than watermen. That may be the explanation for more magnetos on

YT-2s than on YT-1s. I doubt we shall ever know the answer.

The YT-2 was essentially two YT-1s mounted back to back on one

crankcase. It was made from 1924 until about 1928. Of the four YT-2s known to the author 3

have 1924 manufacturing dates and one has no serial number. The last two digits of Palmer

Bros. engine serial numbers are the year the engine was made. In the late 1960-1973 time

frame only the last digit is the year the engine was made. Considering that engines such

as the Palmer Model C were made from 1900-1930 with very few changes it is not possible to

precisely identify the year of manufacture without the ORIGINAL serial number tag.

The YT-2 sales price is unknown. Trim such as carburetor, waterpump,

priming cups and drain cocks were the same as for the YT-1. Parts such as valves, valve

springs, push rods, waterpump, eccentric etc. were the same as the YT-1. The cylinder head

for YT-ls made before 1924 had the spark plug facing aft at about 45 degrees. Because the

spark plugs would interfere in the YT-2 the plugs had to be placed in a vertical

orientation. This meant that YT-ls made after 1924 have their plugs vertical. Early YTs

had 7/8" spark plugs later YTs had 18MM plugs.

The YT-2 has an oil pump driven off the aft cylinder cam shaft. It

pumps oil to the forward crankshaft bearing from the aft sump. In the YT-1 the forward

crankshaft bearing is oiled by a drip oiler and the crankcase is splash oiled in both the

YT-1 and YT-2.

The magnetos for the YT-l and YT-2 were American Bosh model FX-1 or 2

or FB-2ED-1-lc Remember the YT-1 and 2 run counter clockwise

facing the flywheel and the YT-2 fires at 90 degrees.

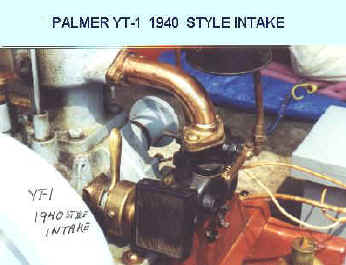

There were basically three different carburetors and intake manifolds

used on the YT-1. The 3/4inch Schebler, Model D was used with the intake manifold shown in

the photo marked

1922-1924. While the Shebler Model D was the standard carburetor offered by Palmer

individual owners may have tried other carburetors such as Kingston 5 ball, Krice, Monarch

etc. These owners were probably trying to get get more speed or better fuel consumption

The Mayer carburetor with an SAE style flange was used with intake

manifold shown in the photo marked 1924-1940 It is believed the Mayer carburetor started

out on the 1914 Buick automobile.

With the passing of the safe boating act in 1940 the Zenith Marine

Carburetor, 61 series was used. See Photo marked 1940 intake. This carburetor is slightly

different from the Zenith industrial version in that it has an intake throat slanted

upward to keep gasoline from running out when "choking" the engine to start. A

gasoline pick up tube to clear the throat once the engine starts is included. Provision to

mount the backfire trap on the inlet to the throat is made. The industrial or marine

carburetor works equally well but DON'T use the industrial

carburetor in a boat.

The photo showing the 1940 intake manifold should be compared with the

photo showing the 1924-1940 intake flange. On occasion the carburetor end flange on the

1924-1940 manifold will be found with the holes slotted out to take the larger flange on

the later Zenith 61 carburetor.

This damage may easily be overcome by filling in the slots with braze and reshaping and

redrilling the flange. Some intake manifolds will be found where the carburetor does not

sit level when the engine is sitting level. This is due to engine angle in the boat had

necessitated bending the manifold to allow the carburetor to sit relatively level in the

boat.

It is interesting to note Palmer catalogs of the period show a

3/4" pipe thread/SAE style flange with the Shebler, Model D connected with a

"close" nipple without an external pipe as shown on the photo of the YT-1 made

in 1998 from N.O.S. parts. This photo also shows the cast iron breather valve of the the

late 1930s and the expanded crankshaft boss of 1937. This boss permitted the use of modern

LIP seals in place of the felt seals the had been in use before the invention of the LIP

seal.

The felt seal had the serious draw back of absorbing water and eroding

the crankshaft. The change to LIP seals took place in 1937. A suitable replacement seal is

Federal Mogul 476838.

It appears most YT-1 applications were without reverse gears. In the

case of the four known YT-2s one has a Palmer made base using a Joe Petrolli, so called

"Navy Gear". The other YT-2 with reverse gear has a Palmer Model YC reverse

gear.

There are a few other changes that will help to roughly date a YT-1

without a serial number. It may be noted that the 1922 engine serial number tag is located

on the forward face of the cylinder just behind the drip oiler. Some time after 1924

Palmer began the practice of placing the serial number tag on the Port crankcase mounting

wing just aft of the carburetor. When the practice of moving the serial number tag off the

cylinder to a location not so easy to be lost if the cylinder is replaced is not known at

this time.

It is believed that a petcock was added to the aft Starboard side of

the crankcase to indicated correct oil level in the crankcase about 1926.

It will be noted on the 1938 and 1947 engines there is a mounting

bracket with a hole bored in it just behind the sector bracket of the Cuno timer. This

seems to have appeared when the YT-2 was released for sale in 1924. This mounting bracket

is cast into the crankcase and is used to mount the magneto gearbox. It should be noted

that when the magneto is used the cam shaft has to be changed from the the one used with

the Cuno timer. The magneto drive bracket is not present on the 1922

YT-1.

There were a number of water outlet changes made on the cylinder head.

The first version exhaust outlet was a 1" NPT boss. Cooling water discharge was a

3/8" NPT out the top of the head. When the YT-2 was released for sale the exhaust

boss was changed to a semi-triangular shape with 5/16" cap screws to hold the exhaust

manifold against the two cylinder heads. Cooling water for the exhaust manifold passed

from the cylinder heads into the exhaust manifold water jacket through 3/8" holes

near the apex of the triangle. In the YT-1 application the cylinder head had the same

semi-triangular shaped boss only in this case an adapter was provided having the same

general shape as the exhaust boss. The adapter was approximately 1" thick and bored

for 1" NPT exhaust pipe. The cooling water discharge was a 3/8" NPT in the top

of the adapter which was changed at some later date changed to the cylinder head.

There were three types of crankcase breather valves. A mushroom style

and a later cast iron unit shown on the "1998" engine replaced a small bronze

check valve that dated back to at least the 1912 period. The purpose of the crankcase

check valve in a one cylinder, closed crankcase four-cycle engine is to keep the oil in

the crankcase from being forced out of any small opening such as around the valve tappets,

crankshaft or camshaft bearings.

When the piston comes down it compresses the air in the crankcase

unless there is a WORKING check valve to allow the air to escape. When the piston

rises the check valve closes and a vacuum is created in the crankcase thus keeping the oil

from leaking out of the engine. I have stressed WORKING check valve because these

valves tend to become dirty and sluggish in operation and while the engine runs well it is

going to lose oil at a rapid rate.

The cast iron breather needs to be cleaned occasionally. It is not as

complicated as will appear on first inspection. there is a bronze valve that moves up and

down with the piston motion, on the top side of the valve is a small piston that slides in

and out of the top cap. There is a small phosphor bronze spring on top of the piston which

returns the valve to the lower bumper. Don't lose it!

Immediately below the valve is a threaded rod with a neoprene bumper

washer that limits the travel of the valve. This rod is extended through the bottom of the

breather and it has a lock nut that keeps the rod from moving once it is locked down. When

operating correctly there is a definite clapping sound. To adjust, loosen the lock nut and

rotate the threaded shaft either way until the valve starts to "CLAP"

The simple old time bronze two part check valve made far less noise and

if one can find one of them they bolt to the same bolt spacing as the cast iron unit.

Don't toss out the cast iron unit as it would depreciate the value of the engine as an

antique.

In conclusion the author is constantly looking for differences in

various early Palmer Bros. engines. It is most helpful if photos of all four sides are

taken and serial numbers provided

if known.

Richard A. Day

40021 Ben Morgan Road

Leonardtown, MD 20650

|