| Author |

Message |

Richard Alcock

Senior Member

Username: raa

Post Number: 65

Registered: 02-2007

| | Posted on Tuesday, November 26, 2013 - 08:15 pm: |

|

This is a easy way to check to see what the taper angle is on a bore. Pour in Ceroloy(woods Metal) and find a local machine shop to use their shadow graph. It only takes a few minutes to use the shadow graph to find the taper of the Ceroloy plug. In this case it is 10 degrees on a side.     |

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 847

Registered: 07-2002

| | Posted on Tuesday, November 26, 2013 - 08:33 pm: |

|

Learned two things, how to get the taper from the gear and that such a machine exist. |

miro forest

Senior Member

Username: miro

Post Number: 730

Registered: 11-2001

| | Posted on Monday, December 02, 2013 - 08:09 pm: |

|

OK Dick - now that you know what the taper in the bore is, how are you going to do the dental work to fix the broken teeth?

miro |

Richard Alcock

Senior Member

Username: raa

Post Number: 66

Registered: 02-2007

| | Posted on Monday, December 02, 2013 - 08:24 pm: |

|

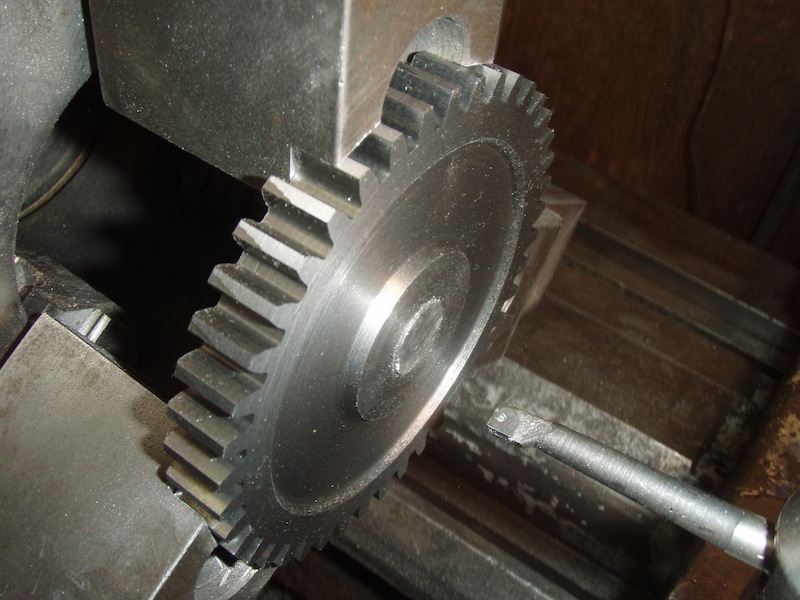

That is the easy part. I picked up two 3.75x .627 class 40 cast iron blanks today for $10. Will turn the blanks asap and take them down to a gear shop in Rockford and for $75 will get them hobbed 12 dp 14.5 pa 42 tooth. After hobbing will finish bore them. One get s a .875/.876 bore and the other get a 10 degree tapered bore. I will mike the ceroloy slug the get the right minor dia. |

Keith Billet

Senior Member

Username: keith

Post Number: 405

Registered: 02-2002

| | Posted on Monday, December 02, 2013 - 10:56 pm: |

|

Dick.

What engine are you working on? |

Richard Alcock

Senior Member

Username: raa

Post Number: 67

Registered: 02-2007

| | Posted on Tuesday, December 03, 2013 - 12:30 am: |

|

These two gears are used on a fire pump which I was told was made in Canada. Sure looks like a Waterman K2 with copper jackets. The carb is a standard Schebler but is mounted under the intake manifold instead a normal K2 position. The gears drive a magneto of undetermined parents. |

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 848

Registered: 07-2002

| | Posted on Tuesday, December 03, 2013 - 05:55 am: |

|

Those gears would have been good candidates for a ring gear shrunk in place. Machine the old teeth off, make a ring, shrink it on and have the teeth cut. You can drill and tap several small holes in the parting line and install screws with loctite for security. |

Keith Billet

Senior Member

Username: keith

Post Number: 406

Registered: 02-2002

| | Posted on Tuesday, December 03, 2013 - 11:15 am: |

|

That's a great idea J.B. I will have to keep that in mind for the future. |

Richard Alcock

Senior Member

Username: raa

Post Number: 68

Registered: 02-2007

| | Posted on Tuesday, December 03, 2013 - 12:11 pm: |

|

In my case the other gear was all busted up so I had no choice. The other issue would be if the gear blank were hobbed it would require a mandrel to support the rings. I shaped probably held on the id with chuck.The ring id would certainly work well if the gear hub were complex. |

Richard Alcock

Senior Member

Username: raa

Post Number: 71

Registered: 02-2007

| | Posted on Thursday, December 05, 2013 - 11:43 am: |

|

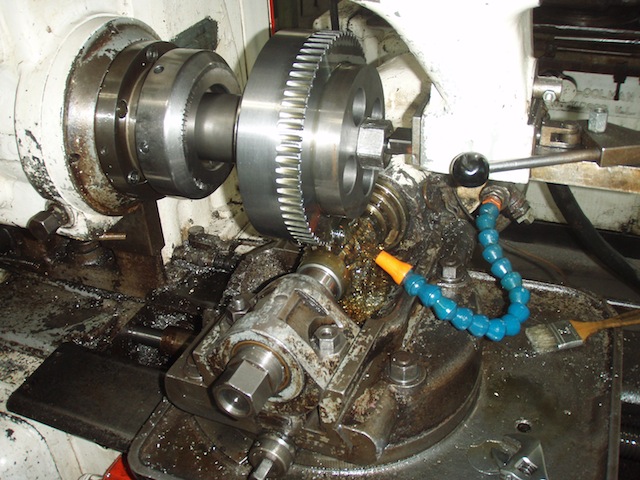

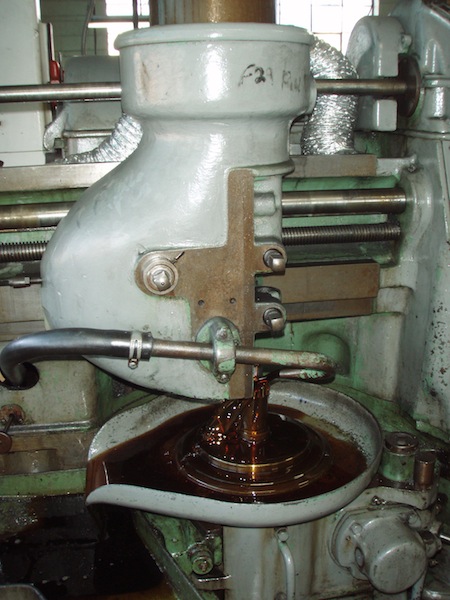

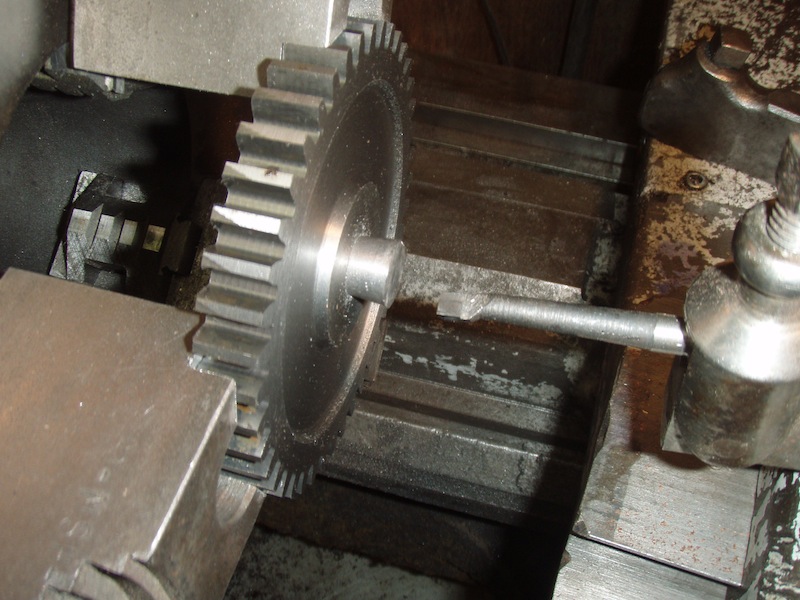

I dropped off the gear blanks this morning and took a few pictures of gear hobbers and gear shapers so that if you have never seen one you can see how the gear tooth is formed. These are old manual machines which helps keep the cost down and are more than adequate for the typical old marine engine.

I thought I would also pass along a good shop to get gears made: Carmona Gear Cutting,2415 Kishwaukee St. Rockford, Il. 815 963-8236 ask for either Robert or Victor Carmona    |

Richard Alcock

Senior Member

Username: raa

Post Number: 73

Registered: 02-2007

| | Posted on Wednesday, December 18, 2013 - 04:38 pm: |

|

I used the Ceroloy plug casting to check as I machined the bore.   |

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 855

Registered: 07-2002

| | Posted on Wednesday, December 18, 2013 - 07:38 pm: |

|

The gear looks good Dick, you're getting full use out of this run of the Ceroloy. |