|

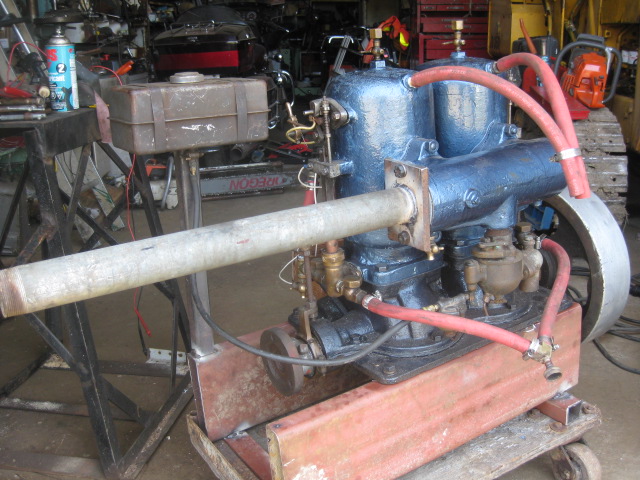

| 14 hp Atlantic make and break |

| Author |

Message |

Ron Bowick

Member

Username: xthreaded

Post Number: 4

Registered: 01-2011

| | Posted on Sunday, May 29, 2011 - 05:19 pm: |

|

After several months of trying to get my hand working again, not very successfull I might add. I have it all together, but, I may have the ring gap too tight as it is an absolute horror to turn over. Looking for advise re ring fitting and starting process. email me at [email protected]

|

Ron Bowick

Member

Username: xthreaded

Post Number: 5

Registered: 01-2011

| | Posted on Sunday, May 29, 2011 - 05:24 pm: |

|

Didn't post the way I wanted If anyone want pix email me at [email protected] If you can advise me re stating methods I'd appreciate it. |

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 954

Registered: 11-2003

| | Posted on Monday, May 30, 2011 - 03:28 pm: |

|

Bob Merriam has had a lot of experience with the Arcadia two cylinder two stroke which is directly transferable to the Atlantic two stroke. Note the Atlantic heart shaped spokes are not suitable to stomping on the spokes to start. Our Canadian friends would tightly wrap line around the pull out handle so it stuck out permanently about an 1"or a little more. Prime the engine set the spark retarded and stomp on the handle so the engine will backfire and run in the direction you want to go. Don't forget to advance the spark once it starts. Another approach is prime the engine setting the piston near the top of the stroke in the direction you want to go (forward/reverse) and as the old timers would say "Snap the Garter" meaning the igniter. With a little practice you should have no problem getting the engine to run. Just remember your priming bottle should have an oil/fuel mix so you don't wash the cylinder walls with raw gasoline. I have a "Double Six" Atlantic and like your engine it can walk all over the area when it runs. I would immediately through bolt some timbers say 4" X 6" by 6' long thwart ship to deal with the incredible torque you develop when the engine starts and reverses on the spark. The through bolts should be at least 1/2" 13 thread. With the engine sitting high on your current mounting I would worry about breaking the crankcase mounting flanges. There seems to be no real thwart ship control with the engine sitting so high on the for and aft "timbers" To operate on a hard surface I would cut 4 each 6" square sections of old tire tread to keep the engine from walking all over the place. These big old two strokes are high torque engines and when they backfire they can really jump around. I think your exhaust pipe is much too heavy and will possibly destroy the cast iron exhaust manifold. Get a 4' piece of 3" copper pipe and aim it upward to ease the torque at the manifold junction.

The engine stiffness is probably good as it shows there is plenty of life left in the brute. I would try putting a tea spoon of SAE 30 in each cylinder to see if that doesn't loosen up the stiffness. Run something like 16 to 1 two stroke fuel mixture until you get the engine running well. Won't hurt it and it will make it easier to pull over. What ever you do get that engine down closer to the thwart ship timbers or I think you can ruin a perfectly good engine and maybe hurt someone. Yeah I am preaching and I learned the hard way. so please take my advice. |

|

|

|

|