|

| Chapman Seadog Magneto Problem |

| Author |

Message |

John Treloar

Member

Username: johntr

Post Number: 28

Registered: 10-2005

| | Posted on Sunday, January 15, 2017 - 11:44 pm: |

|

I need some guidance re my magneto and spark for my Chapman 10hp Seadog. I can get it going, but it is not running smoothly. I am sure there is no issue with petrol flow. Checked and double checked that. Good flow from tank to carburettor.

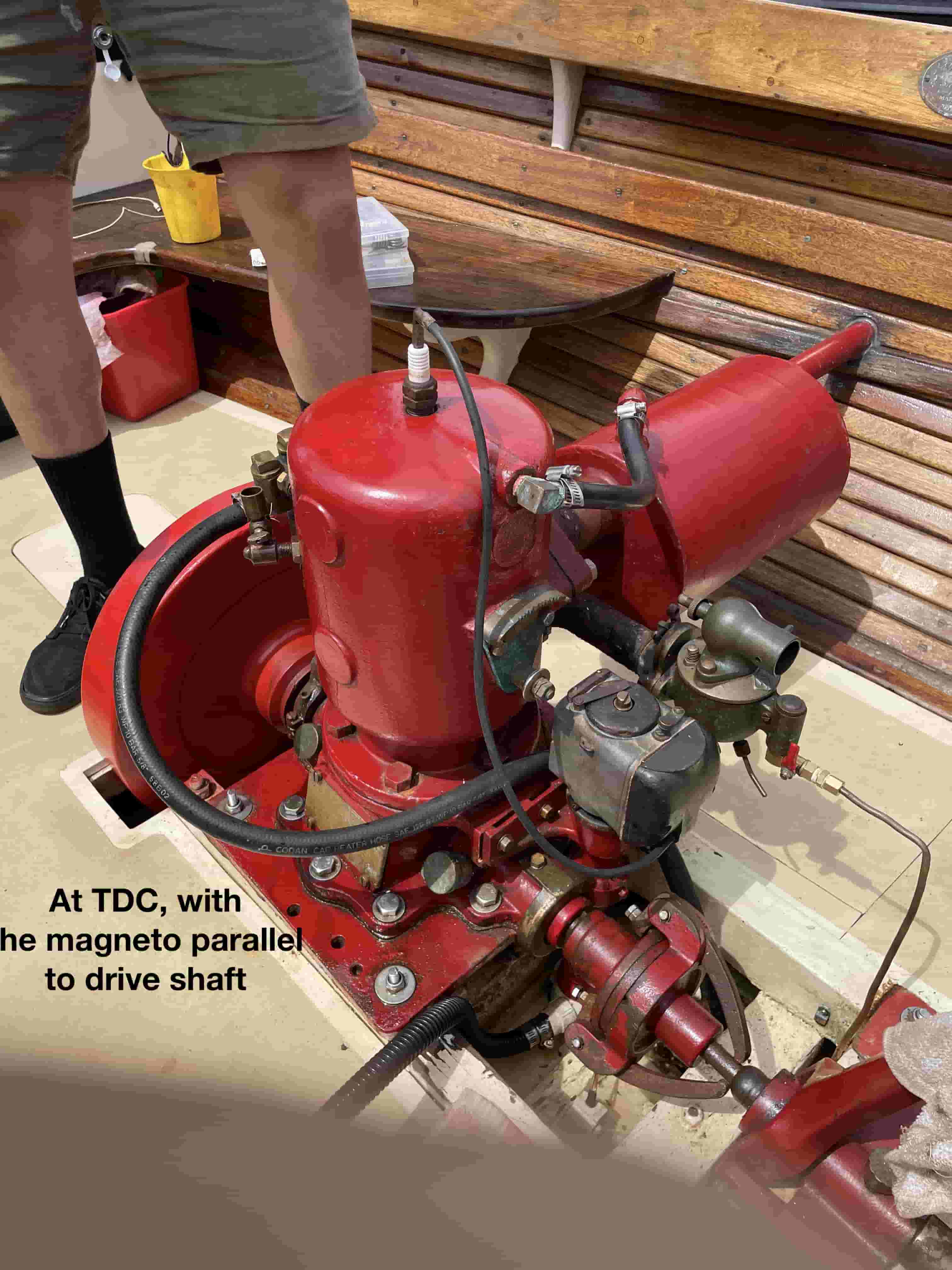

I read other posts on aligning Magneto to TDC. I have two magnetos. I went back to basics and aligned the flywheel to TDC and the magneto holder on the rear of the engine to have the lug pointing to the line on the holder as per pic below.

I have two magnetos and inserting one at a time, I checked to see if at 2.5" BTDC the contact points started to open. I had the magneto in the position I believe it should be in which is at about 45% perpendicular from the engine in one of the slots in the magneto carrier slot.

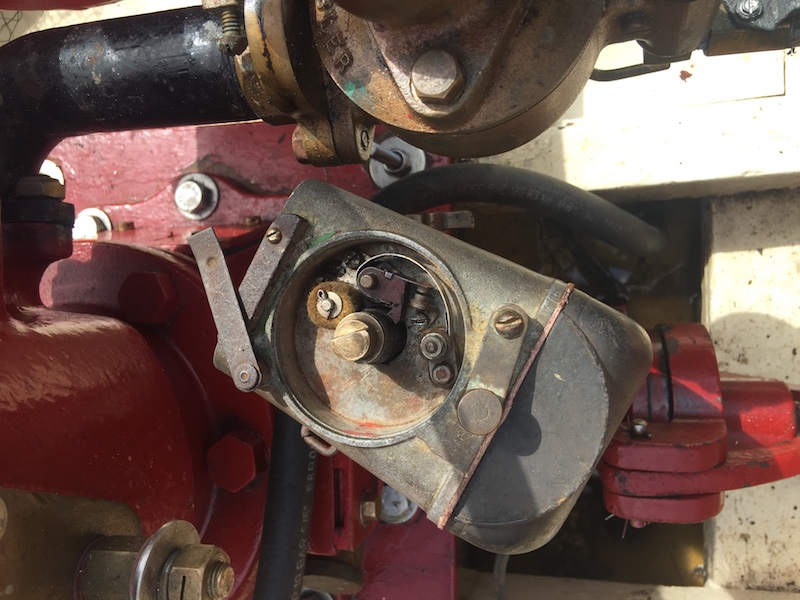

Here it is with the top cover removed.

When I rock the flywheel, the points appear to open early at around 4" BTDC. I assume the magneto should sit in the slots in the magneto holder? Or should I twist the magneto slightly and hold with the locking piece on the side of the magneto holder?

I also put in my other magneto. Very different in relation to the contact gap with flywheel at same position.

I had the motor running but dont feel it is running as best it can and reckon it is running off the second spark from the magneto. What I mean is that it is not running as it should. The engine spins freely, easy to get going sometimes, difficult to idle and I do reckon I have something wrong in the firing sequence and proper alignment of the magneto, the points and therefore not the most reliable engine at present.

The boat is on a swing mooring next to Haberfield (UTS) Rowing club at the bottom of Iron Cove. I can get the boat to the wharf at Le Montage on the other side of the bay if a guru wants to have a look and see what I have done wrong. Of course I'd pay you for the time.

Everything else is in good nick, but I dont have a totally reliable engine. Help please.

Here is a picture of the boat before the new exhaust. The green material along the side is the cover.

John |

Todd Vidgen

Senior Member

Username: todd_vidgen

Post Number: 279

Registered: 03-2008

| | Posted on Monday, January 16, 2017 - 12:13 am: |

|

you have the magneto in the reverse position |

Ross Cook

Visitor

| | Posted on Monday, January 16, 2017 - 01:15 am: |

|

Todd knows what he is talking about but if anyone needs magneto repairs this might come in handy http://www.maggyman.com/default.html |

John Treloar

Member

Username: johntr

Post Number: 30

Registered: 10-2005

| | Posted on Wednesday, April 26, 2017 - 06:20 pm: |

|

Todd, I just need to have it turned to click into the other guide? |

Todd Vidgen

Senior Member

Username: todd_vidgen

Post Number: 281

Registered: 03-2008

| | Posted on Tuesday, May 23, 2017 - 11:33 pm: |

|

Yes . But also check that the piston is at tdc by putting a rod down the plug hole ,sometime the flywheels have been known to slip . Had one a month ago 45 degs out. Also the drive on the maggy can move (its not keyed). So ideally tdc ,maggy parallel to crank .the pin in the drive lined up with the score mark on the maggy bracket .then when you rotate the fly wheel to 5/16 btdc (gauge down plug hole to piston crown).

The points should just start to open .Some folk like to use the fly wheel mark and the 2 and a bit inch btdc .but a lot of flywheels have been machined ,and this then changes the measurement.

Hope this helps . Sorry did not answer sooner ,but for some reason , have not been getting posts on my email. (very possible the fault lies with the organic component of the computer. (Me) |

John Treloar

Advanced Member

Username: johntr

Post Number: 32

Registered: 10-2005

| | Posted on Monday, March 08, 2021 - 01:57 am: |

|

Todd,

It has been ages since I spent time on my Boat Sarah. Family and work got in the way. Back to make her shine and run again!

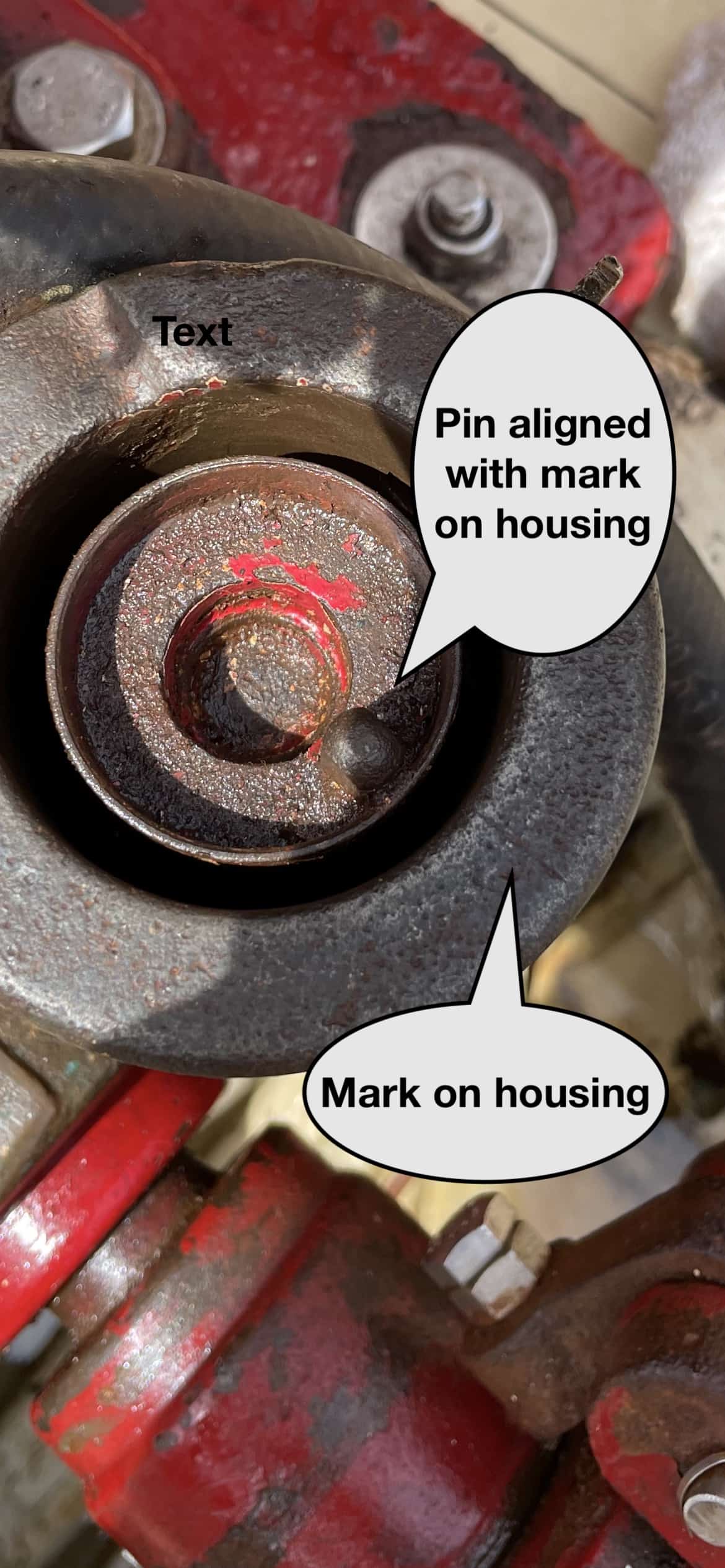

I followed your advice above and checked TDC and aligned the bit in the housing for the magneto to the mark on the side of the housing. See photo attached.

next, we check that the piston when 5/16th of an inch is before TDC the points start to open.

Question is what to do if not opening then? Slightly turn the Magneto?  |

|

|

|

|