| Author |

Message |

Cameron

Member

Username: cammo

Post Number: 8

Registered: 11-2012

| | Posted on Sunday, August 25, 2013 - 05:26 am: |

|

Hi all,

I had a post about this engine in the unknown engine section.

Since then I have found out what exactly it is.

http://www.oldmarineengine.com/discus/messages/3454/257964.html

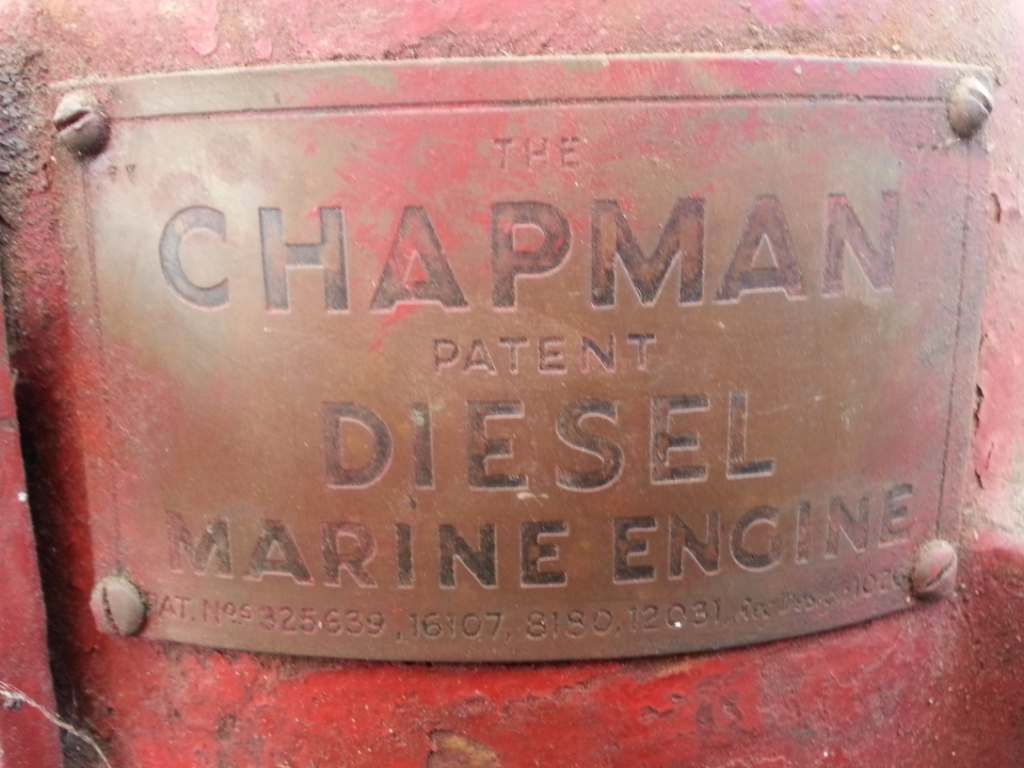

So as the title says its a Chapman diesel.

From what I am told it could be possibly one of 6 ever built!

I picked it up today. Looks like it is missing the magneto for starting on petrol. A sea-dog magneto may fit?

Looks like a bosch injector possibly aided by compressed air? 2 lines going in to the injector.

So I am interested in bringing this engine back to life, would like some input on what should be done first and what to do / what not to do.

Anyway- pictures!

|

Andrew Munns

Senior Member

Username: johnoxley

Post Number: 94

Registered: 04-2010

| | Posted on Monday, August 26, 2013 - 02:15 am: |

|

The second line for the injector is the leak off, whereby a tiny quantity of fuel leaks off to lubricate / cool the injector. Regular fitting for any diesel. Looks like the fuel injection pump is missing, There would not have been a lift pump. Wonderful that the water jacket is not cracked. Need to fill jackets with a preserving oil ASAP. |

Eric Schulz

Senior Member

Username: eric_schulz

Post Number: 82

Registered: 01-2007

| | Posted on Monday, August 26, 2013 - 07:57 am: |

|

Cameron, I often hear stories about the number of products made, sold or imported. A lot of these are guesswork. Chapman was a highly respected name in marine engines, so I would think that they sold more than 6 over the years they were advertised. This is assuming that this is the 10hp diesel as advertised, and not an experimental model I don�t know about.

It looks as if a Seadog magneto drive assembly would bolt straight on, apart from the gear cover.

What to do first is up to you. I would want to look inside to see what condition it was in. It may be in really bad shape and expensive to recondition. On the other hand, because of its rarity, it would be worth it.

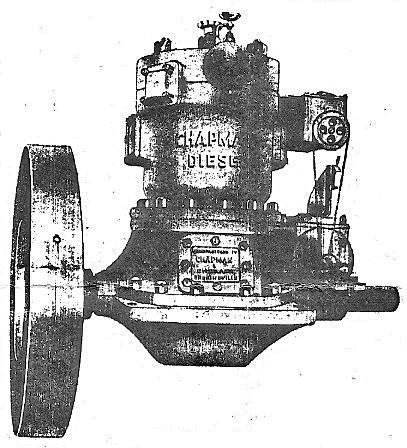

Looking at the photos, the external combustion chamber, used for starting, is missing. The priming tap would not be in its original position, going by the larger fitting screwed into the head. I would suspect that fitting is where the combustion chamber was attached.

These engine didn�t have a starting carburettor, you just put a squirt of petrol in the priming cup which lets the engine start on the spark plug and get enough revs up so that it can be switched over to diesel fuel injection.

The patent numbers on the name plate are the same as those for the 15hp.

The 15hp below shows the petrol combustion chamber with its priming tap/cup.

Eric

|

Andrew Munns

Senior Member

Username: johnoxley

Post Number: 95

Registered: 04-2010

| | Posted on Monday, August 26, 2013 - 05:31 pm: |

|

John Forrest told me the story of a delivery voyage south to Narooma in an open launch with a Chapman diesel. John as apprentice was 'selected' to do the trip. When he was telling the story of this trip, he mentioned that only 6 diesels were built. He did not say which model but we were looking at the brochure for the smaller engine. He did say they started easily on petrol and would run on low quality oils. |

Eric Schulz

Senior Member

Username: eric_schulz

Post Number: 83

Registered: 01-2007

| | Posted on Tuesday, August 27, 2013 - 09:56 pm: |

|

Just had a closer look at a 1940 Chapman ad and noticed they list a "Seadog Diesel, 10 hp", and a "Seadog Twin Diesel, 20 hp". The 15 hp diesel is not listed.

All very interesting.

Eric |

Cameron

Member

Username: cammo

Post Number: 9

Registered: 11-2012

| | Posted on Tuesday, September 03, 2013 - 11:38 pm: |

|

Thank you for the information on the injector Andrew, I wonder if it is the Chapman 10HP diesel advertised?

Eric, if i understand correctly, the external combustion chamber would have bolted to the the head where the priming cup is currently. and the priming cup would have bolted in to the combustion chamber?

i would think the spark plug would then be attached to the external combustion chamber?

yep i am confused!

Yes i thought the first thing i might do was take a look inside, so i got it all apart... well most of it.

the piston is stuck in there pretty good. a few hits from a soft mallet managed to move it down about 20mm

though i am yet to figure out how to get it going the other way...

started paint stripping and polishing the (copper or brass?) parts.

some say i should leave the entire engine unpainted the way it is now. others say i should paint it... i would think painting it would be a good idea.

|

Mark S

Senior Member

Username: marks

Post Number: 153

Registered: 03-2002

| | Posted on Wednesday, September 04, 2013 - 05:16 pm: |

|

Cameron,

Be careful about pushing the piston further down. There is often a wider section at the top of the bore and if you push to far the top ring can expand into it. It's then nearly impossible to remove the piston without destroying things.

If it's moved 20mm it will come out easily. Put it back together and you could use two wooden wedges between the cylinder and crankcase. |

Cameron

Member

Username: cammo

Post Number: 10

Registered: 11-2012

| | Posted on Wednesday, September 04, 2013 - 08:15 pm: |

|

Hi Mark.

Thanks for the heads up. I can see the ring and it is still snug on the piston so I have not gone too far. That is a good idea with the wooden wedges. I will be trying that and hopefully I can remove the piston! |

Greg Y

Senior Member

Username: gregoryan

Post Number: 110

Registered: 09-2004

| | Posted on Wednesday, September 04, 2013 - 08:31 pm: |

|

Thanks for posting such detailed parts pics! A very interesting/ unheard-of engine! Careful with the wedges that they only stay to port and starboard , Not fore and aft, or you could bend the rod. What about a wooden drift [ dowel rod] thru the injector hole!?, maybe cusion the blows with screwed-up rag, and use a wooden mallet, and be gentle. |

Andrew Munns

Senior Member

Username: johnoxley

Post Number: 96

Registered: 04-2010

| | Posted on Wednesday, September 04, 2013 - 08:57 pm: |

|

I once knocked a hole in a Blaxland piston with a wooden dowel down through the plug hole. Suggest a big dowel in bottom end and jack up from the cylinder flange, but not too close to the outer edge. |

Cameron

Member

Username: cammo

Post Number: 11

Registered: 11-2012

| | Posted on Wednesday, September 04, 2013 - 09:01 pm: |

|

I had considered using something to tap it down but quite a lot of force is needed and I wouldn't want to crack the piston. It probably wouldn't though..

Still its another option worth exploring that's for sure

Here is a picture of the primer after I finished cleaning it up and giving it a polish.

|