| Author |

Message |

David Roberts

New member

Username: dave_roberts

Post Number: 1

Registered: 10-2008

| | Posted on Tuesday, October 07, 2008 - 07:06 am: |

|

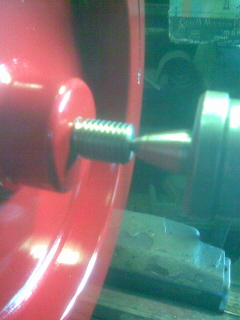

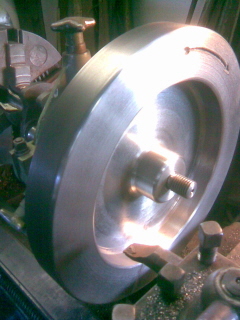

Recent (September) repair of Blaxland STX crankshaft and flywheel. Crankshaft was bent at flywheel end (flywheel was still attached) Straightened the crankshaft, tested on V-blocks, built-up damaged starter pulley thread on crankshaft, turned and screwcut (3/4" Whitworth), machined all diameters and surfaces on flywheel. Epoxy primed.

|

David Roberts

New member

Username: dave_roberts

Post Number: 2

Registered: 10-2008

| | Posted on Tuesday, October 07, 2008 - 07:12 am: |

|

This is the machined flywheel after it has been machined. You can see the "before" above.

|

David Roberts

New member

Username: dave_roberts

Post Number: 3

Registered: 10-2008

| | Posted on Tuesday, October 07, 2008 - 08:11 am: |

|

Excuse the Type-o in first post. Should be SXT.

(Although im sure all of you already know that!) |

Todd Vidgen

Senior Member

Username: todd_vidgen

Post Number: 83

Registered: 03-2008

| | Posted on Tuesday, October 07, 2008 - 04:33 pm: |

|

Why didn't you remove the flywheel?

Then you would have been able to clean off the rust

and stuff that collects on the crank under the

eccentric for the water pump ,also you can then

machine the eccentric,fit it with a stainless

sleave and eliminate 99% of water pump problems

Nice job though |

David Roberts

Member

Username: dave_roberts

Post Number: 4

Registered: 10-2008

| | Posted on Wednesday, October 08, 2008 - 07:44 am: |

|

Appreciate your comments, you are quite right but as the bend was severe (approx. 1/2" total run-out at rear end of c/shaft}I didn't want to open up a can of worms - plus I was only asked by the customer to straighten it and reconstruct the thread that's all.Just couldn't stop myself machining the deeply pitted f/wheel, partly on my own time .....you know that feeling. Have re-machined old flywheels in the past and fitted stainless sleeves for Ray Jacobs at Blaxland Chapman Marine Co. as well as new flywheels over the years before he retired and more recently for his son Brett who took over from Ray as you know. |

Todd Vidgen

Senior Member

Username: todd_vidgen

Post Number: 84

Registered: 03-2008

| | Posted on Wednesday, October 08, 2008 - 04:52 pm: |

|

Yes It is very hard to put a price on certain jobs

as they have a habbit of "growing",and yes the

amount of free time put into a job so it meets

your own standard, I think is not always

perceived or sometimes even appricated

Carry on anyway eh? |

David Roberts

Member

Username: dave_roberts

Post Number: 5

Registered: 10-2008

| | Posted on Friday, October 10, 2008 - 07:27 pm: |

|

re:your last post Wednesday 8 October 2008 Thanks for your thoughts and encouragement, will carry on and look forward to catching up with you all at the Davistown Putt Putt Regatta. P.S. Saw an entry on this site about making piston rings ,very interesting - I would like to make some,I have a heat treatment oven and surface grinder to grind them to standard or o/size thickness after heat treatment. |

David Roberts

Member

Username: dave_roberts

Post Number: 6

Registered: 10-2008

| | Posted on Friday, October 10, 2008 - 07:58 pm: |

|

re:your last post Wednesday 8 October 2008 Thanks for your thoughts and encouragement, will carry on and look forward to catching up with you all at the Davistown Putt Putt Regatta. P.S. Saw an entry on this site about making piston rings ,very interesting - I would like to make some,I have a heat treatment oven and surface grinder to grind them to standard or o/size thickness after heat treatment. |

Todd Vidgen

Senior Member

Username: todd_vidgen

Post Number: 85

Registered: 03-2008

| | Posted on Sunday, October 12, 2008 - 04:32 pm: |

|

You can still buy the blaxland and simplex rings

new.Also there is a mob in Melbourne that claim

to have the largest range of rings in Oz |

David Roberts

Member

Username: dave_roberts

Post Number: 7

Registered: 10-2008

| | Posted on Sunday, October 12, 2008 - 06:36 pm: |

|

I thought that was so but I could use a bit of extra work and depending on the current market price maybe I could make a few and market them locally, could you give me any idea of price? |

Todd Vidgen

Senior Member

Username: todd_vidgen

Post Number: 88

Registered: 03-2008

| | Posted on Tuesday, October 14, 2008 - 04:36 pm: |

|

I think simplex/clae rings are about $55 each

Blaxland rings are about $20 each

The oil ring on the simplex would be a challange

to make |

David Roberts

Member

Username: dave_roberts

Post Number: 8

Registered: 10-2008

| | Posted on Thursday, October 23, 2008 - 09:43 pm: |

|

re:your last post on Tuesday October 14,2008 thanks for the info on the rings - at that price(the Blaxland at $20 ea) I'm thinking I would be better off concentrating on making the Blaxland crankshafts which seem to be not available new ( or very scarce )at the moment but would be interested to ask you about the Simplex rings just for my general knowledge, maybe on Sunday if you have a moment. Brett asked me years ago if I could set up and make crankshafts so I think it's high time I got myself into gear. I have ground the mains from time to time (singles and twins) and without wanting to look like someone trying to "re-invent the wheel" I've often thought the mains could be slightly larger in diameter,particularly on the twin - say 1/32" extra on the single and 1/16" on the twin, as they sometimes flex a little between centres while grinding if you have the pressure on the centres even a little too much, and you have to be very careful(more so on the twin) and keep checking the tailstock centre adjustment.This flexing is also, I feel sure you would agree because of the fact that it is not a through shaft i.e.reduced in rigidity by the crank, and I feel and would like to also increase the crank-pin diameter from 15/16" diameter to 31/32" or even 1" as it affects the flexing too (depending on any feedback I get from further discussions.)I also noticed on the single crankshaft I repaired last month that it was only .005" U/size on the rear and main and .030" U/size on the front/flywheel end. I feel that the a slightly larger diameter crankshaft might also run/wear better on the front main as it is supporting a fairly large and heavy flywheel- I know these are very small points and these engines run practically forever but I have to try to keep my mind working! |