| Author |

Message |

Martin Griffiths

Visitor

| | Posted on Friday, November 18, 2005 - 11:33 am: |

|

I am trying to un-seize a Stuart P55ME. I have removed the plugs and poured in some deisel, and this has drained away into the sump. I have also sprayed in lots of SAS, similar to WD 40.Any suggestions for a more effective lubricant or penetrating solution, and how much pressure can I reasonably apply to the fly wheel? Would there be anything to be gained by heating the sleeve so as to release the pistons? |

Tim Mulvey

Senior Member

Username: timmulvey

Post Number: 174

Registered: 05-2003

| | Posted on Friday, November 18, 2005 - 03:44 pm: |

|

Don't put try to move it by putting pressure on the flywheel as you will break the cone shaped collet that the flywheel slides onto.

Either use a wooden block that is shaped to the crown of the piston then apply some hydraulic pressure eg using threaded rod, a couple of pices of timber and a bottle jack OR hit the block of wood using a small lump hammer but not too hard - just firm repeatedly. I've done two seized Stuart engines via the latter method but it took months. I also kept adding penetrene or diesel but I'm told that vinegar is better though I haven't yet tried it. I've still got two seized engines that are proving very stubborn. |

Bruce Hall

Senior Member

Username: bruce

Post Number: 293

Registered: 07-2002

| | Posted on Friday, November 18, 2005 - 07:30 pm: |

|

A tractor restoration article I've seen recomended Olive oil as a penetrant as the viscosity encourages it to weep by the "traction points" |

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 267

Registered: 07-2002

| | Posted on Friday, November 18, 2005 - 07:56 pm: |

|

Most of the marine engines I've freed were headless, so they had to be worked on from the bottom. I usually try to move the piston inward first, being careful not to go above normal top travel. Rings can expand in the dome and lock the psiton in. I use a piece of pipe that fits the bottom of the piston, put it in the press and apply pressure inward. If it doesn't move I heat the cylinder, through the water jacket if necessary. Pressure alone seldom moves it, but very little heat and you'll hear a pop when it breaks loose. I've seen cylinders split with a grease gun, and pistons broken with a rod through the plug hole, so be careful. |

Serge Harrison

New member

Username: seized

Post Number: 1

Registered: 03-2008

| | Posted on Friday, March 14, 2008 - 01:13 pm: |

|

Un-seizing a seized engine seems to be a popular topic, but almost all the postings I’ve seen are more entertaining than useful. We have the only website and the only product that takes seized engines seriously. Why not visit us www.enginerelease.com |

Mark Deverell

Member

Username: weysail

Post Number: 14

Registered: 01-2008

| | Posted on Friday, March 14, 2008 - 01:42 pm: |

|

Hi Serge,

Useful stuff eh? But as your webpage says, 'only available in North America' Enough said, now just pass me that diesel to soak the piston in........

Mark |

Serge Harrison

New member

Username: seized

Post Number: 2

Registered: 03-2008

| | Posted on Monday, March 17, 2008 - 11:18 am: |

|

Hi Mark:

If Diesel Disolved corrosion, I'd use it too! It doesn't! Engine Release is only available in North America because shipping costs more than the product. Why not find us? even you wouldn't refuse a couple of free kits to try. Would you?

Serge |

Peter Ogborne

Senior Member

Username: peterogborne

Post Number: 254

Registered: 09-2002

| | Posted on Monday, March 17, 2008 - 05:11 pm: |

|

Serge...I'm not doubting your product for one moment but I have seen these sort of things come and go over the years . Now that is not to say that we should not at least try it .Unfortunately here in the south of Western Australia I dont think I stand much chance of obtaining any .I have at the present time about six engines to restore non of which are seized .

In the past I have found water to be the best medium to unseize a marine engine or any engine for that matter that is locked up with rust ,

.Agreed diesel just makes a clugy mess...water in fact disolves the oxide. As I said before your product may well work and thank goodness for inovation! |

Josh Gallant

Visitor

| | Posted on Monday, May 31, 2010 - 12:48 am: |

|

Here's a video that helped me out

http://www.youtube.com/watch?v=Q-Gq8i73gYs |

David Ball

New member

Username: daveincaol

Post Number: 1

Registered: 06-2010

| | Posted on Monday, June 21, 2010 - 05:06 pm: |

|

I've got a siezed Stuart P3M in the pipeline.

I've also a relation due in Houston in October, I'll see if I can get some brought over |

Martin Wright

Visitor

| | Posted on Wednesday, July 14, 2010 - 04:50 pm: |

|

Hi, how can I get some engine release here in the uk, my 3ltr Mercruiser has locked up over winter. |

Stephen Gillette

Visitor

| | Posted on Monday, February 07, 2011 - 03:09 pm: |

|

I have a 175hp OMC I/O 4cyl Chevy on a 16ft 1987 Sunbird. Does anyone know the best way to unsieze this engine. Was ran with little or no oil and 0 oil pressure. Will i need to pull engine? |

Todd Vidgen

Senior Member

Username: todd_vidgen

Post Number: 201

Registered: 03-2008

| | Posted on Monday, February 07, 2011 - 09:59 pm: |

|

Yes,and it will need completely stripping,machining

new bearings,pistons etc.The block will need cleaning to remove all the little bits of metal

that will be in all the oil galleries etc etc.

In other words , a full rebuild |

Bryce

Visitor

| | Posted on Sunday, March 13, 2011 - 08:44 pm: |

|

I have a 3.0 merc and i was out today and after running for about an hour the engine stopped, and will not turn. I have plenty of oil and oil presure was good along with the water temp. What shold I try first? I think I may have water in it going to look tomarrow. |

Bruce Hall

Senior Member

Username: bruce

Post Number: 258

Registered: 07-2002

| | Posted on Monday, March 14, 2011 - 08:31 am: |

|

tomarrow.. try marineengine.com This site is for pre-WW2 and older antique marine engines. |

Arthur DeKalb

New member

Username: water_bug

Post Number: 2

Registered: 07-2010

| | Posted on Wednesday, May 04, 2011 - 09:33 am: |

|

Guys, Back to the Stuck Stuart: Does the cylinder unit casting come free of the lower half of the crank case? How can one get at the rods to free ( loosen the caps) them up? If the cyl unit with stuck pistons were then available, maybe the pistons can be pressed out ??? Any information ? art |

Jim Parrott

Member

Username: jim_parrott

Post Number: 12

Registered: 06-2009

| | Posted on Friday, May 06, 2011 - 07:51 pm: |

|

Authur,

I am not sure about access to the Stuart rod caps, but I had a Lockwood Ash that was siezed real bad. After removing the lower half of the crankcase, the rod that was down provided easy access to the cap nuts. The other rod nuts were not accessible, I simply drilled the bolt heads off to remove the cap. Removed the crankshaft, upper crankcase, and put the cylinder in the oven at 210 degrees for about 4 hours. After cool enough to handle was able to push both pistons in 1/2", soaked with penetrating another day. Was able to jack both pistons out using long threaded bolts and nuts through connecting rods. Steel plate was used to jack against and wood blocks added between plate and cylinder as needed til pistons came out.

Jim |

Malcolm Russell Ward

Senior Member

Username: russell

Post Number: 51

Registered: 08-2003

| | Posted on Friday, May 06, 2011 - 10:38 pm: |

|

Sorry Arthur, did I miss something? Which model are we dealing with? |

David Myers

Senior Member

Username: dave_myers

Post Number: 100

Registered: 11-2006

| | Posted on Saturday, May 07, 2011 - 03:24 am: |

|

Arthur, The Stuart does not have Rod End Caps. They use a Split Crank and the big end bearing is a caged roller. You have to take the crankcase ends off and undo (VERY tight) the large nut holding the crank pin to the counterweight.

The best combination I have used to un-seize an engine is either Warm Water or lately I have used Auto Transmission fluid and Acetone (Nail Polish remover)50/50 which works extremely well.

Good luck with the project.

Dave |

Arthur DeKalb

New member

Username: water_bug

Post Number: 3

Registered: 07-2010

| | Posted on Monday, May 09, 2011 - 06:20 pm: |

|

Malcolm Russel Ward, Please see top of thread. The Stuart model is a P-55ME. I asked further regarding that same engine. Looks like I got my unsticking answer from David Myers. Thanks Dave. As to unsticking, I do not have the engine yet, but it looks like MANY solvents and combinations are tried and some help. We will see. Art |

Malcolm Russell Ward

Senior Member

Username: russell

Post Number: 52

Registered: 08-2003

| | Posted on Tuesday, May 10, 2011 - 05:22 am: |

|

Thank you, Arthur. That post being nearly six years back, I thought I'd best check that we were still on the same job. David is right about the anatomy of the nether reaches of the Stuart. If the big end roller bearings are seized and corroded, you do have a big problem. Why did the old beast seize? Salt water ingress? The transmission fluid and acetone unstickem is a novel one. Please let us know how it works. I've never had to dismantle a crankshaft, my P5 was done for me 20+ years back and is still going strong. Best of luck! Russell |

Arthur DeKalb

Member

Username: water_bug

Post Number: 4

Registered: 07-2010

| | Posted on Tuesday, May 10, 2011 - 07:23 am: |

|

Thank you all for the responses. I am rather jumping the gun, as I do not have the engine yet. When I get it and take a look, I will report back. Mid may or so. You all have been very helpful already. Art |

Arthur DeKalb

Member

Username: water_bug

Post Number: 6

Registered: 07-2010

| | Posted on Wednesday, June 08, 2011 - 07:35 am: |

|

Hello Malcolm and all, I now have the Stuart P-55 ME AND a beyond repair stuck (and rusty crank ) parts motor. I will be trying by heroic means to salvage the cylinder from the stuck part, as the Non stuck Engine has a hole through the water jacket into one bore. Having been used in Salt water... Is there anyone in the North East USA that has a complete P-55 Stuart that I can correspond with? I have several boxes of spares (parts) to identify. Will post a few pictures if I can figure out how to do that. Art DeKalb |

Paul Gray

Senior Member

Username: paulgray

Post Number: 96

Registered: 05-2003

| | Posted on Wednesday, June 08, 2011 - 07:38 pm: |

|

Lately I have had luck with Tap-Magic Pro-tap fluid. You saturate the bore and ring area and heat it until it smokes and re-apply several times. This stuff appears to dissolve the rust as it contains: Aliphatic Organic Acid: CAS# 112-80-1 >75% mixture

Aliphatic Organic Ester: CAS# 112-62-9 <15% mixture

Organic Polyol: CAS# None Assigned <10% mixture. I'd try bumping it in like JB said. I just unstuck a 6" inverted compressor this way and used a chain and port-a-power to pull it out by the rod. |

Paul Gray

Senior Member

Username: paulgray

Post Number: 97

Registered: 05-2003

| | Posted on Wednesday, June 08, 2011 - 07:41 pm: |

|

BTW- Diesel and ATF and petroleum products do not dissolve rust. Do not use plain Tap-Magic! |

Arthur DeKalb

Member

Username: water_bug

Post Number: 7

Registered: 07-2010

| | Posted on Thursday, June 09, 2011 - 06:49 am: |

|

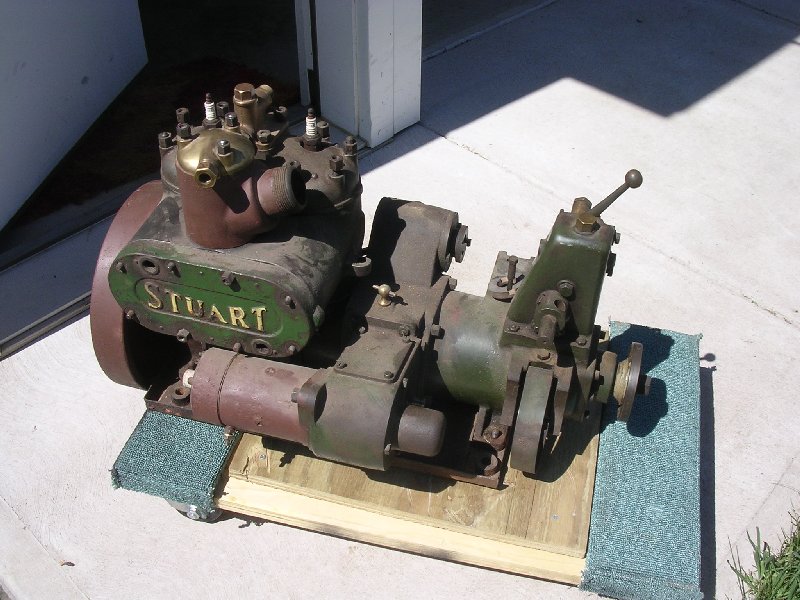

If I can manage it , here are a few pictures of the stuck engine. NO Solvent , molasses or any other goop will free it. I plan to use mechanical means to separate the cylinder block from the crankcase/crank. Then push out the pistons with a hydrolic press. The third picture is of the NOT stuck engine with the hole in the cylinder wall, I am restoring. Art    |

George Martin

Visitor

| | Posted on Thursday, June 09, 2011 - 07:48 am: |

|

Hi Arthur, I had one of those and they are damn heavy!. You have one in a very bad condition, its a pity you cant get a better example. They are not very popular to UK collectors, so you could pick up something for < £100 if you can get it shipped over.

Dont let me put you off though, you deseve credit if you succeed.

The big end bearings are not available (new) so you would have to make them.

Best of luck.

G. |

Arthur DeKalb

Member

Username: water_bug

Post Number: 8

Registered: 07-2010

| | Posted on Thursday, June 09, 2011 - 09:33 am: |

|

George, Maybe I was not clear. I DO NOT plan to save this rusty one. Just to try and extricate the cylinder only. The third pic was of the engine I will restore. That is not stuck, just has a hole from the water jacket into one bore. If I can save the cylinder block on the rusty one, I can avoid having to sleeve the bore. Art |

John Archibald

Senior Member

Username: john_archibald

Post Number: 178

Registered: 08-2006

| | Posted on Thursday, June 09, 2011 - 10:03 am: |

|

Looks like a candidate for the "fill it full of grease and add more".

Make an adapter for the spark plug hole from an old spark plug and then insert a grease fitting in it. Then follow instructions above.

This will only work if the port is not uncovered by the piston.

Archibald

Northfield, Minnesota

. |

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 598

Registered: 07-2002

| | Posted on Thursday, June 09, 2011 - 11:29 pm: |

|

I would get a couple bags of charcoal and put it in a pit and cook it. Art knows the dangers of using grease to remove a stuck piston. If you get it above 900 degrees or so, George Coates can give a better idea of the temp, the rust will powder, coals will heat and cool it slowly. |

Arthur DeKalb

Member

Username: water_bug

Post Number: 9

Registered: 07-2010

| | Posted on Friday, June 10, 2011 - 06:45 am: |

|

JB, Thanks for the suggestion. I am considering band sawing the whole thing thru just below the cylinder casting, then use a hydrolic press to push out the pistons. No need to save the crank and rods. Now I have to find a saw with big enough throat. Art |

Arthur DeKalb

Member

Username: water_bug

Post Number: 13

Registered: 07-2010

| | Posted on Monday, June 13, 2011 - 06:03 pm: |

|

Hi ALL: Major progress on the stuck ST. After removal of the cylinder studs, the front crankcase half came off with lots of persuasion by a lead hammer. Then a hand hack saw parted the con rods, allowing the VERY rusty crank to come off. Then with great persuasion ( a 10 lb maul) one piston was driven out. Will try a hydrolic press on the other tomorrow. Art  |

Arthur DeKalb

Member

Username: water_bug

Post Number: 15

Registered: 07-2010

| | Posted on Wednesday, June 22, 2011 - 06:59 am: |

|

The ST P-55 Block has been fully extracted from the rusty mess. First piston was driven out in one piece. second piston had to be hammered and chiseled out in many pieces. Cylinder bores honed. Both bores have blemishes, as expected, but will be usable. More clean up to proceed. Thought all might be interested.   |

Thomas P Montagu

New member

Username: tom_montagu

Post Number: 1

Registered: 12-2011

| | Posted on Thursday, December 29, 2011 - 01:41 pm: |

|

Hi; a trick I learnt from a person who was faced with the problem of freeing off a seized and VERY rare earo engine was to heat up some old engine oil in a (old, check with wife first!!)saucepan on the cooker and then CAREFULLY pour it down the bores above the piston. It seemed to work as the aircraft is now flying--with its original engine |

Roger DiRuscio

Senior Member

Username: solarrog

Post Number: 508

Registered: 03-2002

| | Posted on Saturday, December 31, 2011 - 04:16 pm: |

|

Another trick I have seen used is concrete cleaner has Sulfamic acid in it in a weak formula. It will dissolve the oxides, but not the base metal. I have seen this used and it worked in a couple days. Do not add oil before trying this product as it will not work with the oil blocking the path |

David wisotsky

Visitor

| | Posted on Wednesday, January 24, 2018 - 09:30 pm: |

|

WE just freed our boat motor using Kano Kroil Penetrating Oil, 8 oz. liquid

got it on amazon then took the rocker arm rack off so all valves were closed and used an air compressor

to pressurize the cylinders forcing the oil into the rings then ran two battery's in series and and hit the start short bursts it worked !!!!!!!!!!! |