|

| How to fix exhaust outlet stud |

| Author |

Message |

Matthew Balkwell

Senior Member

Username: matt

Post Number: 120

Registered: 04-2006

| | Posted on Wednesday, September 29, 2010 - 01:15 am: |

|

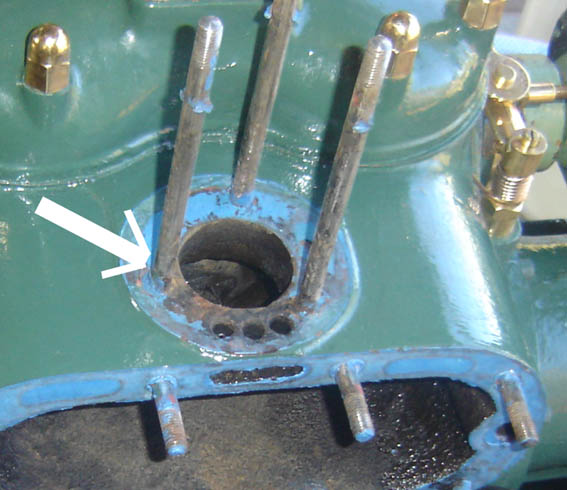

Our spare p55 developed a water leak around the exhaust outlet which also doubles as the water inlet, the cast iron around the stud has given up and there is not enough metal for a helicoil fix.

I have thought about drilling and tapping through to the expansion chamber and using a longer stud with a nut and washer on the bottom of the stud to seal and fix the stud.

Any other ideas?

Ps i have posted a pic of another engine just to show the stud and expansion chamber.

Matt and Ron

|

Andrew Munns

Member

Username: johnoxley

Post Number: 10

Registered: 04-2010

| | Posted on Wednesday, September 29, 2010 - 03:25 am: |

|

Hi - I would make and fit a stepped stud - access to lathe/machinist needed - a simple job for a turner. Turn up rod one size larger thread into engine block and existing size for remainder. Cylinder block must be drilled and tapped. New stepped stud should be sealed in Loctite or similar to keep out the saltwater. |

David Myers

Senior Member

Username: dave_myers

Post Number: 91

Registered: 11-2006

| | Posted on Wednesday, September 29, 2010 - 03:26 am: |

|

Matt, Thats exactly what I did with my P55. Drilled through and tapped what was there and sealed with Loc-Tite and a nut and washer on the end in the expansion chamber. Works ok with no problem.

Off to Taree this weekend and then to Tweed Heads the following weekend.

Cheers, Dave. |

|

|

|

|