|

| Crankshaft/Compression seals on P5ME |

| Author |

Message |

Neil Critchley

Visitor

| | Posted on Tuesday, June 16, 2009 - 05:18 am: |

|

I wonder if anyone can help me or share a similar experience? My P5ME has gradually been losing power over several years, and having (I believe)eliminated all other possible causes, I've been advised that the likely cause is worn crankshaft compression seals. I've now stripped the engine down, but I'm a little puzzled at what I'm seeing, and there don't seem to be any particularly clear manuals or exploded diagrams available. Really, I'm trying to identify the crankshaft/compression seals, so I can replace them. On the flywheel end of the shaft there's a compressible split bronze ring. On the gearbox end, there's a bronze ring pressed into the crankcase hole, and either side of this, 2 steel discs, one with an "oil thrower" shape, which fit either side of the bronze ring and mate with flat surfaces in the middle. There's a great deal of play in this arrangement. I apologise if this explanation is unclear, and would be very happy to supply any photos, or indeed to receive any pics or diagrams, which might help me understand what to check for and replace. As you will have understood, I'm not an engineer! The main bearing ball races seem to be in good condition. Many thanks in advance for any advice or guidance. |

George Martin

Visitor

| | Posted on Tuesday, June 16, 2009 - 09:41 am: |

|

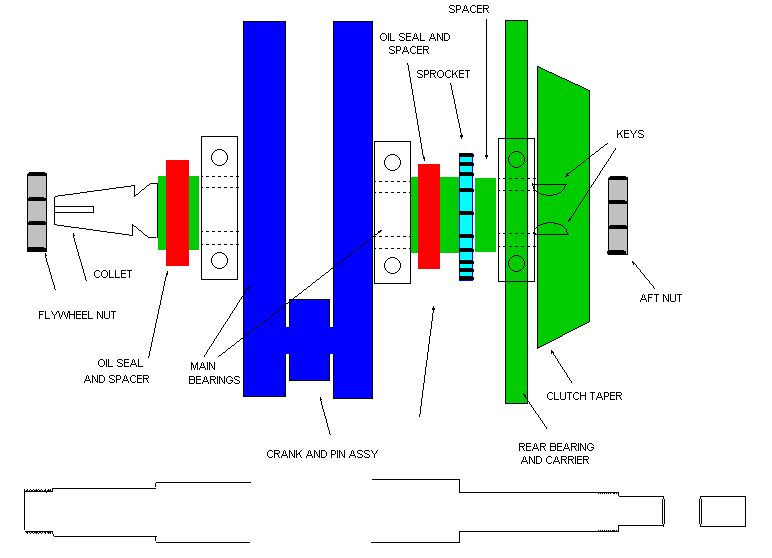

I have several dismantled p5m's and they all have the more conventional seals, though I believe they used to rely on the oil to form a seal between sufaces. I did draw up a block diagram of the crankshaft, i'll see if I can find it. Basically mine have :-

crankweb- main bearing- steel collar- flywheel taper -flywheel -nut in that order. |

Neil Critchley

Visitor

| | Posted on Tuesday, June 16, 2009 - 10:09 am: |

|

Thanks very much George, I can't believe you came up with this so quickly. I'll study what you've sent, and hopefully things will become clearer. I'll let you know how things proceed. All the best, Neil C |

Peter Ogborne

Senior Member

Username: peterogborne

Post Number: 296

Registered: 09-2002

| | Posted on Wednesday, June 17, 2009 - 05:45 am: |

|

Neil....why dont you use one of the modern synthetic seals.If you can measure the OD of the bearing and the shaft diam .Go to any bearing sales business .Once you fit these you can forget any seal leaks. |

Neil Critchley

Visitor

| | Posted on Wednesday, June 17, 2009 - 09:13 am: |

|

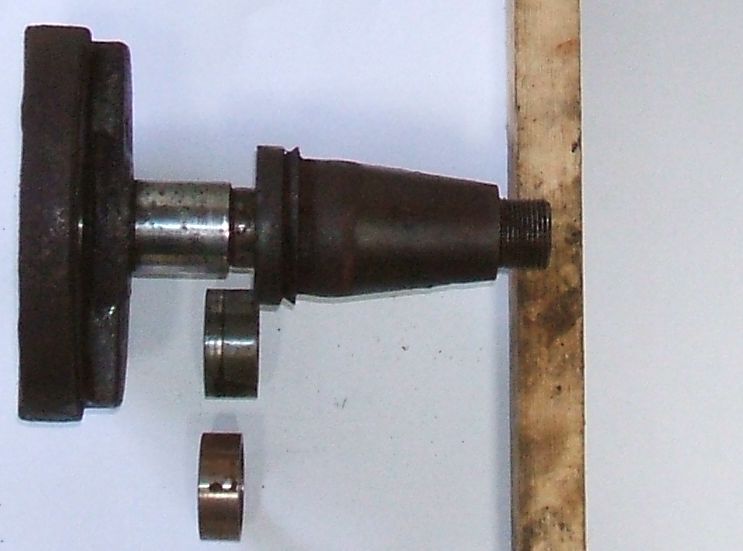

Thanks to everyone. Here's a link to some pictures I've taken of the dismantled crankshaft assembly:

http://picasaweb.google.co.uk/ncritchley/Crankshaft# |

George Martin

Visitor

| | Posted on Friday, June 19, 2009 - 07:39 am: |

|

I agree with Peter. the seals are standard imperial types, I'll measure one up if you like. You will need 2 extra collars, maybe available from fairways etc. Otherwise I can just measure them up if you are going to get some turned (2 sizes). The second hand ones that have been standing can become pitted quite badly. You need a small gap between flywheel collet and shaft shoulder- see photo.

|

Neil Critchley

Visitor

| | Posted on Saturday, June 20, 2009 - 05:04 am: |

|

Thanks George. It looks to me as if the seals should be 2" O/D, 1 1/8" I/D, and 5/16" width. I've got a friend with a lathe, so it would be handy if you could give me the sizes for the extra collars.

I've noticed that my flywheel collet has a hairline crack on the taper. I'm wondering how critical this is, since as far as I can see it's just carrying the flywheel, and has no sealing role. Also, it's going to get crunched up tight by the flywheel nut, and held in place on the shaft by the key. Any thoughts on this? |

George Martin

Visitor

| | Posted on Saturday, June 20, 2009 - 08:26 am: |

|

Seals should be 1 3/8 internal to match collars.

Collars are 1 3/8" O/D, 1 1/8" I/D for both.

wide collar width 21/32"

narrow collar width 1/2" flywheel side I think.

Feel cofidant that the cracked collet will have no effect when clamped. |

|

|

|

|