|

| Author |

Message |

Richard Alcock

Senior Member

Username: raa

Post Number: 165

Registered: 02-2007

| | Posted on Saturday, September 02, 2017 - 01:17 pm: |

|

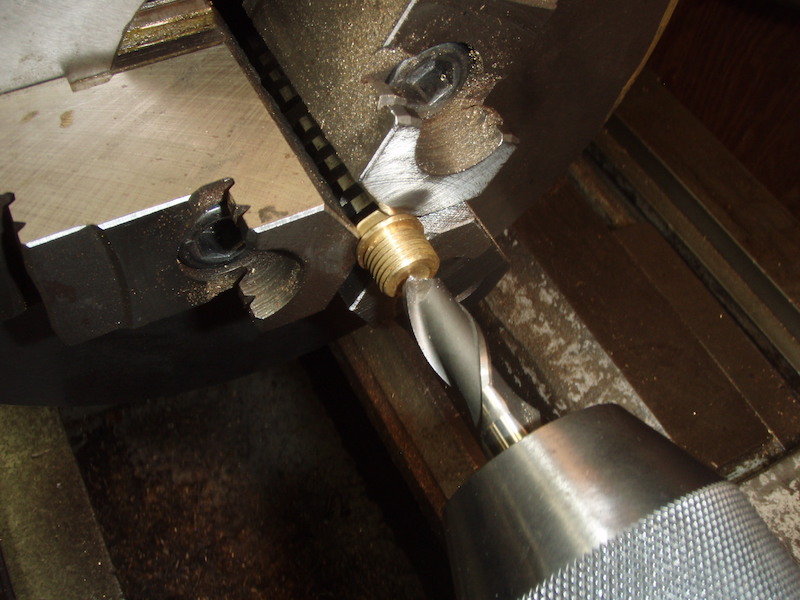

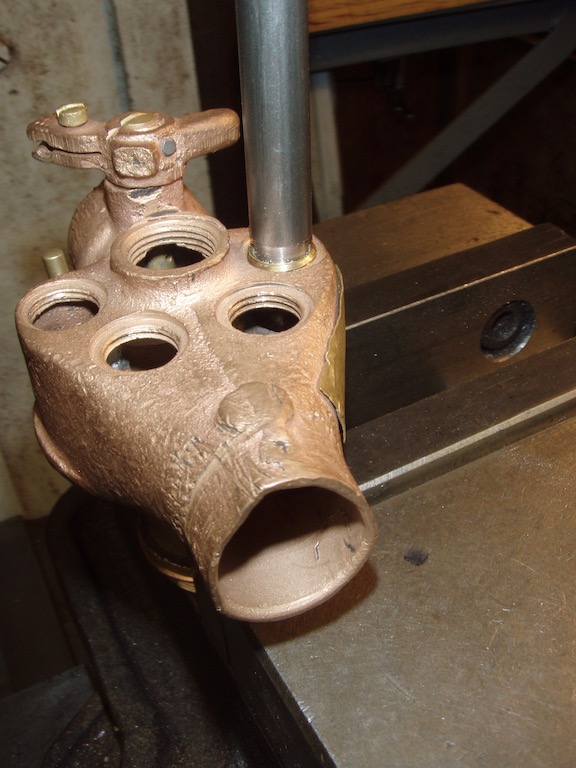

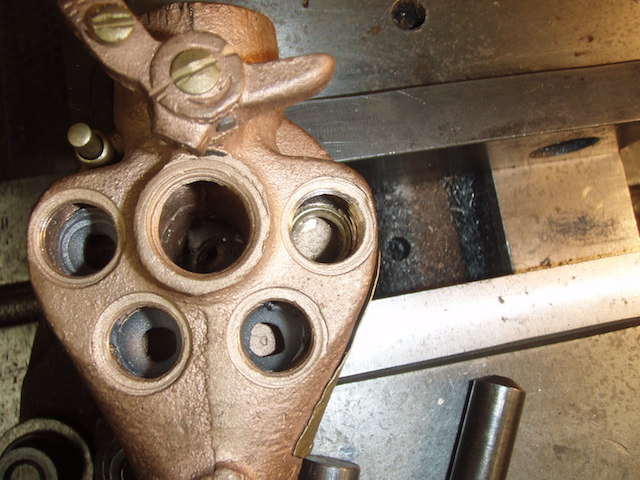

I thought I would pass along what I learned from Paul Doddington and Bob Skinner on Kingston 4 ball carbs. If the seats are not worn too much you can lap them with the ball/tool shown. The caps which retain the balls will/may have to be made new and a little longer. The balls are .437 dia. and should be replaced. If the seats are too far gone then you can make new seats which are .187 long threaded 1/2"-20 on the od .375 dia. hole thru. Use a .4375 ball end mill to make the seat. Locktite in place. Insert with the tool shown which has a 3 degree taper to fit the .375"bore of the seat. I found that the old ball retainers were stamped 1/32 which is the amount the ball is allowed to move when the engine is running. I used a .030" thick piece of cardboard to gauge the correct gap holding it in place with some heavy grease. The little cardboard shows in the last picture and is blue and white sitting on a new yet to be adjusted cap . I chucked the cap up and by trial and error adjust the ball depth in the cap using the ball end mill in the lathe tail stock ,see the first picture. The 3 round things in the last picture is tooling to hold the caps in a Harding collet indexer on my mill.

|

Jim Parrott

Senior Member

Username: jim_parrott

Post Number: 148

Registered: 06-2009

| | Posted on Saturday, September 02, 2017 - 02:23 pm: |

|

Nice work thanks for sharing. How many peppermints were needed? |

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 1330

Registered: 07-2002

| | Posted on Sunday, September 03, 2017 - 10:30 am: |

|

Should run like new, I can see where the worn seats would make it hard to keep adjusted. |

|

|

|

|