| Author |

Message |

jbpelletier

New member

Username: jbpelletier

Post Number: 1

Registered: 08-2005

| | Posted on Monday, August 29, 2005 - 03:14 pm: |

|

I am looking for any photos and information on 2 cycle oil drip lubrication systems. I have found only what may be an oil drip cylinder on a shipwreck and would like to learn more about them. The object I found is corroded, but looks just like the glass cylinder found on the engine on the cover of “Old Marine Engines” by Grayson.

I can be reached either on the list serve or directly at [email protected]

Thanks

J.B. |

billschaller

Senior Member

Username: billschaller

Post Number: 147

Registered: 12-2003

| | Posted on Monday, August 29, 2005 - 07:00 pm: |

|

type in "oiler" on ebay, you will get a hundred a week for the next ten years. |

miro

Senior Member

Username: miro

Post Number: 190

Registered: 11-2001

| | Posted on Tuesday, August 30, 2005 - 01:31 pm: |

|

And , much more to the point, virtually all of the drip oilers were practically useless for providing librication , compared to mixing oil with gas.

miro |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 837

Registered: 11-2001

| | Posted on Tuesday, August 30, 2005 - 06:59 pm: |

|

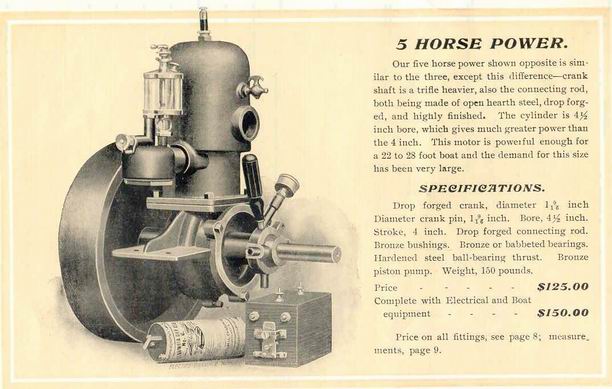

Luricating the old two cycle marine engines was an intersting technology from the beginings to about 1910 or so when the second brass tag on the engines started showing up with instructions to mix the gasoline and oil together for proper lubrication.

The brass and nickel drip oilers, the gear,chain, belt or mechanical arm driven oilers, the internal oil slingers the splash dippers on the connecting rods etc were a fascination and things of beauty to us collectors, in many cases these system were removed from these old egines when the much easier and efficient oil / gasoline mixture was discovered.

Recently I was trying to date an old engine it did not have any drip oiler passages cast into the cylinders and at first I assumed it was probably later than 1910 ca, after researching a bit further i found that the mfging Co. was out of business by 1907 and it perked my interest as to how these engines were lubricated ?

1902-03

This catalog shows a drip oiler on the intake port which was common but most other mfgrs also added the cylinder and or other oilers as well.

The old timer that designed these engines must have been aware that by mixing the oil with the vapored gasoline was by itself adequate lubrication for his engines ! Seems to me he was technologically a few years ahead of his time ? |

searcher

Senior Member

Username: searcher

Post Number: 53

Registered: 10-2004

| | Posted on Tuesday, August 30, 2005 - 09:04 pm: |

|

Richard,

The arrangement with the screwdriver like handle is not one I am familiar with. Is it the spark advance? What are the two projecting tubes and the rectangular ear associated with it? |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 838

Registered: 11-2001

| | Posted on Tuesday, August 30, 2005 - 10:56 pm: |

|

The handle screws into the timer assembly, the projecting tube to port is the wire connector to the coil, the one on the bottom is the friction adjustment and the ear on the starboard top is to connect a rod into to control the timer if the handle isn't used. |

searcher

Senior Member

Username: searcher

Post Number: 54

Registered: 10-2004

| | Posted on Tuesday, August 30, 2005 - 11:52 pm: |

|

Thanks. The reason I am interested is that the timer assembly is missing on my Truscott dynamo and I do not know what the original looked like. It may have had some similarities to this arrangement. I am keeping an eye out for designs I can use as a basis for making a replacement timer that is at least in keeping with the period. |

searcher

Senior Member

Username: searcher

Post Number: 55

Registered: 10-2004

| | Posted on Wednesday, August 31, 2005 - 12:01 am: |

|

By any chance does the handle on this type of arrangement have a spring loaded pin on the other end with the pin fitting into shallow drilled holes that act as predictable stops? |

richardday

Senior Member

Username: richardday

Post Number: 451

Registered: 11-2003

| | Posted on Wednesday, August 31, 2005 - 08:20 am: |

|

It seems to me the main reason dripping oil into the intake failed was the air temp was so low that oil would not readily mix with the fuel. Hence the pooling of oil in the bottom of the crankcase and the need to drain it off from time to time. In fact the air temp without a "oven" over the exhaust line to heat the air piped into the carburetor or mixer throat intake air would drop below freezing and even on a hot day frost can form on the intake. Some early makers such as Smalley actually had jacket water heated intake manifolds but again this water was not particularly hot so the benefit would not approach the heat available from the exhaust pipe. |