|

| 2 cylinder Thrall 2 cycle - early 190... |

| Author |

Message |

Mike Adams

| | Posted on Tuesday, November 13, 2001 - 10:39 am: |

|

Andrew, I have the following questions.

1. Do you have any primer cups for this engine? photo#1. I need one,thread is 3/8-24.

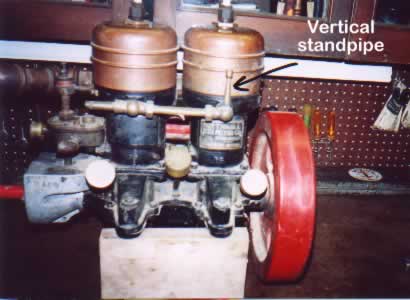

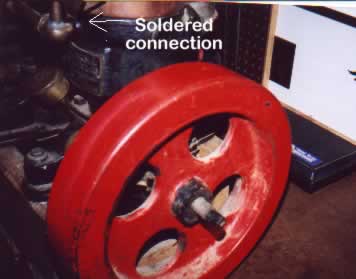

2. In photo#2 you will see the arrow pointing at that vertical standpipe that we talked about. It has a 1/4-20 thread in the top. Can you tell me what it is, and is it supposed to be there? It must have come loose because someone tried to solder it in, as shown in photo#3.

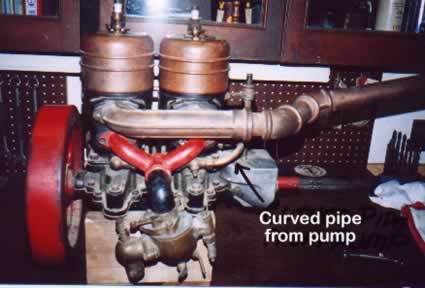

3. Water pump ports-photo#1. Is the 90 degree elbow the intake? The other side of the pump has a curved copper pipe coming out of it,photo#4, which feeds the lower part of the engine. On the other side of the engine, the plumbing(with the vertical standpipe), comes out of the upper part of the engine,photo#2.Now, does the nipple on the left end of this plumbing attach to the exhaust manifold fitting,(circled)as shown in photo#1.

4.Spark Plugs-Where can I find 2 Champion plugs(letter x)with brass caps?

5.Distributor-I have drilled and tapped another hole 180 degrees from the factory hole to accomodate the pin for the second cylinder, as you advised.What are the pins made of? Are they steel or bakelite with steel inserts? Are they one piece, or a large housing with an adjustable pin? What is the diameter of the pin? The body of the distributor has a tang sticking out the side with a hole in the end. What does this attach to?The top of the Bemus cap has a threaded stud in the center which holds a spring, and a 3/8 ball in place.I can't see where this ball makes contact with anything,so I have to ask,what is this for?Youtold me I had to get 2 Model T Ford buzz coils.I have learned that these coils each have their own set of points on them, but do these coils get mounted into some kind of box that attaches to the side of the engine or to the side of the boat?Could you draw me an ignition circuit diagram showing the coils,distributor and all attaching wires?

6.It looks like the cylinder bore stops about 1-1/2 inches from the top of the cylinder.This is how they kept the compression low for easy starting?

7.Facing the flywheel,which way do you spin the flywheel to start the engine?

8.Carburetor-photo#4-Is this the right angle for the carb,or should it be turned to a level position?The adjustable screw on the top of the airhorn,(left). What is it for?

That is the end of my questions for now. If you can be of any help, I would be very greatful. Thank you.

Mike Adams |

andrew

| | Posted on Friday, November 16, 2001 - 10:19 pm: |

|

Here are Mikes photos:

Photo 1:

Photo 2:

Photo 3:

Photo 4:

|

mrbill

| | Posted on Tuesday, November 13, 2001 - 04:23 pm: |

|

Andrew, why don't you just rebuild it for him? |

andrew

| | Posted on Tuesday, November 13, 2001 - 08:24 pm: |

|

Mike has sent me pictures of this two cylinder Thrall that I will post here on Friday.

Anyone that would like to pitch in with help for Mike is encouraged to.

Regards,

Andrew |

miro

| | Posted on Tuesday, November 13, 2001 - 11:18 pm: |

|

The question on the ignition system is a good one especially if you are used to the conventional non-electronic ignition system

The coils produce a (sort of) continuous high voltage current when a 6 volt battery is connected to them ( technically it is a pulsed DC current - for the those in the crowd who remember Fourier series expansions, please argue with me later). The distributor is simply a way of turning the coil on and off at the appropriate time. The distributor contacts usually occupy about 35 to 60 degrees of crankshaft rotation so there is a spark at the plug for that amount of time , that is you'll be getting more than one spark at the gap in the spark plug. I have estimated that at normnal engine speed, there are about 10 sparks evgery time the distributor contact is mafe.Past practice has been to equip each cylinder with its own coil so you'll need two coils. I suspet this was for reliability and ease of maintenance and operation although, I guess in theory one coil COULD do the job. Hae a look at the Technical section of the web site to get more info on ignition stuff.

Many folks test the ignition system before starting by turning the flywheel until you hear the buzz of the coil. While this does not guarantee that you have spark inside the cylinder, it's usually a pretty good indication that things are OK. It's an easy test to do, no tools are needed.

With a 2 cylinder engine, you'll also find that the setting of the timing of the distributor is a bit more finicky than a 1 cylinder but with some practice you'll get good at it.

I hope that helps some |

andrew

| | Posted on Friday, November 16, 2001 - 10:53 pm: |

|

Mike,

I will try to answer your questions in the order you gave them:

1) That is a standard 3/8" pipe thread priming cup that is available from suppliers of antique engine parts such as Lee Pedersen or others.

2) I am not sure what that standpipe is in photo #2. I beleive that piping is your cooling water discharge. Sometimes a petcock would be installed on a cooling water discharge so that water flow could be verified by bleeding off. You don't need anything else there.

3) Yes that 90 degree elbow is the inlet side of the gear driven water pump. The tubing on the outlet side of the pump will feed into the lower portion of the water jackets on both cylinders.

Quote:Now, does the nipple on the left end of this plumbing attach to the exhaust manifold fitting,(circled)as shown in photo#1.

NO...!!! The cooling water discharge should not connect into the exhaust at that location. In many cases the cooling water is piped into the exhaust in order to make the exhaust cooler and more quiet. But is must be done in a way that will prevent water backing up into the cylinders. You can consult any book on engine installations and see that the water always connects at a point lower than the engine, or after a riser type trap that will prevent water flowing back into the cylinders. I don't know what that nipple that you have circled on the left in photo 1 is. It is part of the exhaust piping, not the actual engine or a casting... it could have been added by someone.

4) For spark plugs try Brillman.

5) Regarding the distributor, the pins can be steel because the body is an insulator. The tang on the body is a "handle or lever" to rotate the timer to adjust the timing. Sometimes they were remotely controled by connecting a thin rod to a lever on the bulkhead or elsewhere. The buzz coils are typically mounted in a box and secured to the boat near the engine... a thwart, bulkhead, etc.

6) There often was a "large" gap between the top of the piston and the top of the cylinder.

7) An engine of this type will run either direction... except that you have a gear driven water pump which only pumps water in one direction. Detrimine which way it pumps... that is the direction the engine turns while in "forward".

8) The carburetor looks tilted because it is meant to be level when the engine is installed. The engine will be tilted consistant with the shaft angle in the boat. I think you are installing this in a motor canoe. After it is installed you can adjust the carburetor to a level position. The adjustment on the carburetor that you are refering to is a spring loaded rubber diaphram that is set to allow additional area for air intake at higher RPM.

Hope this helps.... anyone else who wants to pitch in... please do.

Regards,

Andrew Menkart

|

Mike Adams

| | Posted on Sunday, November 18, 2001 - 12:20 pm: |

|

Thank you all for the help, it is greatly appreciated. Mike Adams |

Joe

| | Posted on Sunday, November 18, 2001 - 12:33 pm: |

|

The pictures show a very heavy exhaust pipe hanging on very old cylinders. I would suggest something much lighter and which would absorb vibrations...........also, as you work on the engine u will be tempted to move it around using the long and "handy lever".....but not for long.

....this is a public service announcement.... |

Mike Adams

| | Posted on Monday, November 19, 2001 - 08:12 am: |

|

Andrew, Does Lee Pedersen have an email or website? I could not find any way to access him other than snail mail, concerning primer cups. Also, one of my distributor questions was, what is the threaded stud for in the center of the Bemus cap? The stud holds a spring and a 3/8 ball in place. I can't see where this ball makes contact with anything. Thanks, Mike Adams |

andrew

| | Posted on Monday, November 19, 2001 - 10:11 am: |

|

Mike,

Lee Pedersen has the web site that I linked to in the previous message... but he does not seem to have an email address or phone number. I checked his magazine ad and that doesn't have a phone number either. His "web site" does have an order form which you could use to request what you need. Click here to reach it.

I think that Dick Day wrote an article on the Bemus Timer not long ago that might help you. I will ask him where it was published... if anyone else remember, please post it here.

Regards,

Andrew |

Mike Adams

| | Posted on Thursday, November 22, 2001 - 10:24 am: |

|

Anrew, I would really be interested to get my hands on any information on the Bemus Timers. This is one of my biggest grey areas.

Thanks, Mike |

Ernie

| | Posted on Friday, November 23, 2001 - 10:33 am: |

|

Lee Pederson does not have e mail or a published phone number. (that I know of) However I wish all other suppliers would run their business with the efficency of Lee. I have bought supplies from him for years. Lee must be clairvoient....I mail an order to him and it seems that it was shipped to me before I even sent it. |

|

|

|

|