| Author |

Message |

postal_mechanic

New member

Username: postal_mechanic

Post Number: 1

Registered: 11-2021

| | Posted on Wednesday, November 03, 2021 - 08:59 pm: |

|

Hello, what a great site and forum with a huge wealth of information. I found your site after I came in possession of a DEW marine 2h.p.engine. It was missing parts but I should be able to find them. This marine engine has a 1"NPT manifold opening for the carb. I bought a Schebler model D 3/4" NPT carb on e-bay hopeing it was the 1" which it wasn't.I can make it work with a 1" to 3/4" reducing bushing. Has any one tried this or won't it work because of a reduced fuel mixture. Or will I just have to find a 1"NPT carb. Also on the top of the piston The deflector is facing the exhaust side of the cylinder. Is that right. Thanks |

miro

Senior Member

Username: miro

Post Number: 1164

Registered: 11-2001

| | Posted on Friday, November 05, 2021 - 08:51 am: |

|

No problem, in fact a 1 in carb is probably too much carburetor for a 2 HP engine.

I've used a reducer from 1 in to 3/4 in very successfully. You'll need to replace the cork float with a new one that is resistant to the ethanol n today's fuels. A 25:1 gas oil mix is what I use. Anything else doesn't provide enough oil to lube the con rod bearing and to help provide the seal at the piston rings.

Start with the needle valve about 1 1/4 turns to 1 1/2 turns. That will run a bit rich.

The secret to setting up the carb is having a good ignition - a hot blue, noisy spark is what you need to have. In fact get yourself a modern version of a buzz coil, the old style Ford coils are OK - sort of - but not when you are learning about these old engines.

No, the deflector should face the intake port, to force the new mixture up into the cylinder.

Eventually, you'll learn how to bounce start the engine.

You'll have fun for sure . . . miro |

postal_mechanic

New member

Username: postal_mechanic

Post Number: 2

Registered: 11-2021

| | Posted on Friday, November 05, 2021 - 11:43 am: |

|

Thanks so much Miro. Your information is going to make this much easier. |

johnny

Senior Member

Username: johnny

Post Number: 633

Registered: 03-2006

| | Posted on Saturday, November 13, 2021 - 10:08 pm: |

|

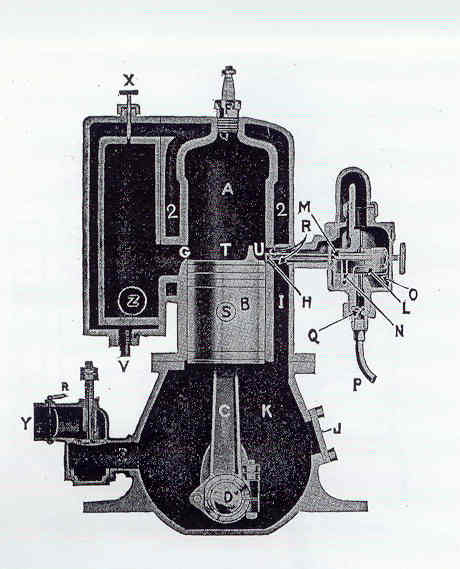

Another tip. Make sure when you rotate the piston a 180 degree's that the lower connecting rod hinged bearing has the bolt and nut side facing your inspection plate/inspection hole. It could also be possible that the connecting rod and piston was not oriented correctly when someone assembled it with the wrist pin. The con-rod needs to be oriented correctly so down the line if the bearing gets a little warn & sloppy you will be able to remove shims from the bottom con-rod bearing by loosening the bolt & nut through the inspection hole to tighten up the bearing some. See cut away view below.

http://www.antiquengines.com/Detroit_Engine_Works_Menu.htm |

johnny

Senior Member

Username: johnny

Post Number: 634

Registered: 03-2006

| | Posted on Saturday, November 13, 2021 - 10:21 pm: |

|

|