| Author |

Message |

mirab357

New member

Username: mirab357

Post Number: 1

Registered: 07-2020

| | Posted on Tuesday, August 18, 2020 - 03:56 pm: |

|

Hi,

I bought this engine june 15 2005. It was found in a scrap yard near home, no carb.,no ignition, no muffler. It was very hard to turn. Since there was not much to do these days, I started working on it in july 2020.

Could some one tell me how old it is?

|

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 4176

Registered: 11-2001

| | Posted on Tuesday, August 18, 2020 - 06:17 pm: |

|

*

Entered 723 # St Lawrence twin to master list, its pre WW I estimate is 1913.

# |

mirab357

New member

Username: mirab357

Post Number: 2

Registered: 07-2020

| | Posted on Wednesday, August 19, 2020 - 10:17 pm: |

|

Thanks Richard,

Is it possible to get the master list and possibly update it with my engine.

Two cylinder, bore 3.25", stroke 3.5", 14"flywheel, gear water pump.

This engine does run both direction, but the water pump works only in the clockwise direction looking to the front of the flywheel, which make it a clockwise runner, right ??

What is the power rating ??

Thanks

Roger Legault

Mirabel,Qu�bec, Canada |

miro

Senior Member

Username: miro

Post Number: 1097

Registered: 11-2001

| | Posted on Thursday, August 20, 2020 - 12:49 pm: |

|

In a boat the water pump will work in one direction only.

But for a "show " engine, with a closed cooling system, i.e. a water bucket, the pump will work OK in either direction. After a while though, the water will warm up and you'll have to shut it down, and visit other guys.

I think it's rated a 6 HP - there's lots of good literature on this web site for St Lawrence engines.

miro |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 4177

Registered: 11-2001

| | Posted on Thursday, August 20, 2020 - 03:37 pm: |

|

*

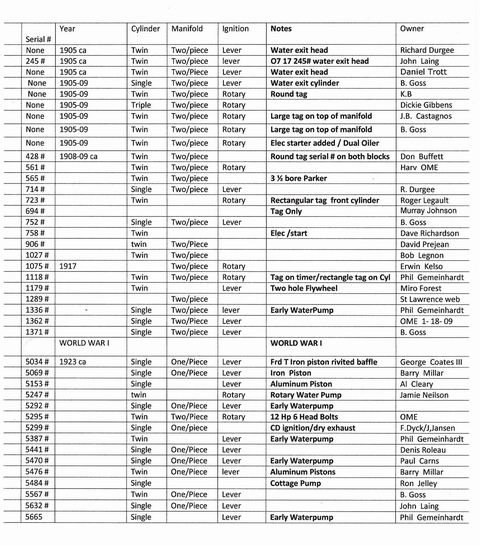

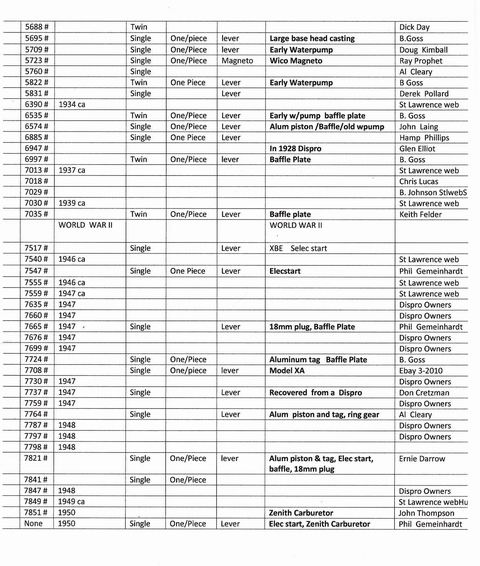

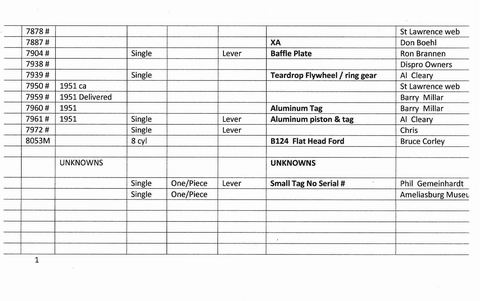

St Lawrence Master List 8/2020

Any changes updates etc let me know !

Anyone known to us here that would like to be the custodian of this list let me know ! I also have a photo list of many of thes engines !

* |

mirab357

New member

Username: mirab357

Post Number: 3

Registered: 07-2020

| | Posted on Friday, August 21, 2020 - 10:57 am: |

|

Hi,

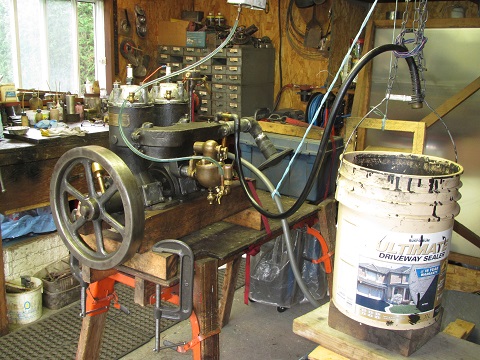

Let me introduce myself. I started doing engines show in 2002, I have 10 stationary engines, a fordson F 1919, a drag saw ... I do most of my repairs myself (99%) and now have this marine engine.

I red most of the post on the St-Lawrence and still have questions.

Here is my preliminary set up shown.

On each side of the center grease cup, there was something that has been removed and open holes capped. Does some one knows what ??

|

bcm

Senior Member

Username: bcm

Post Number: 124

Registered: 11-2009

| | Posted on Friday, August 21, 2020 - 11:29 am: |

|

Roger,

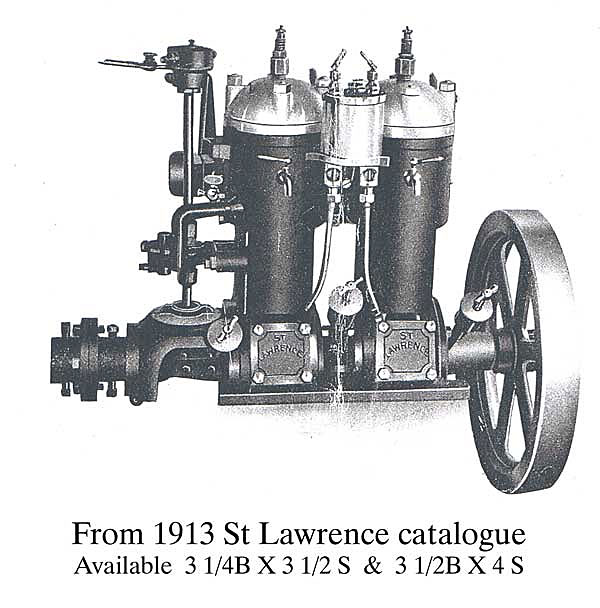

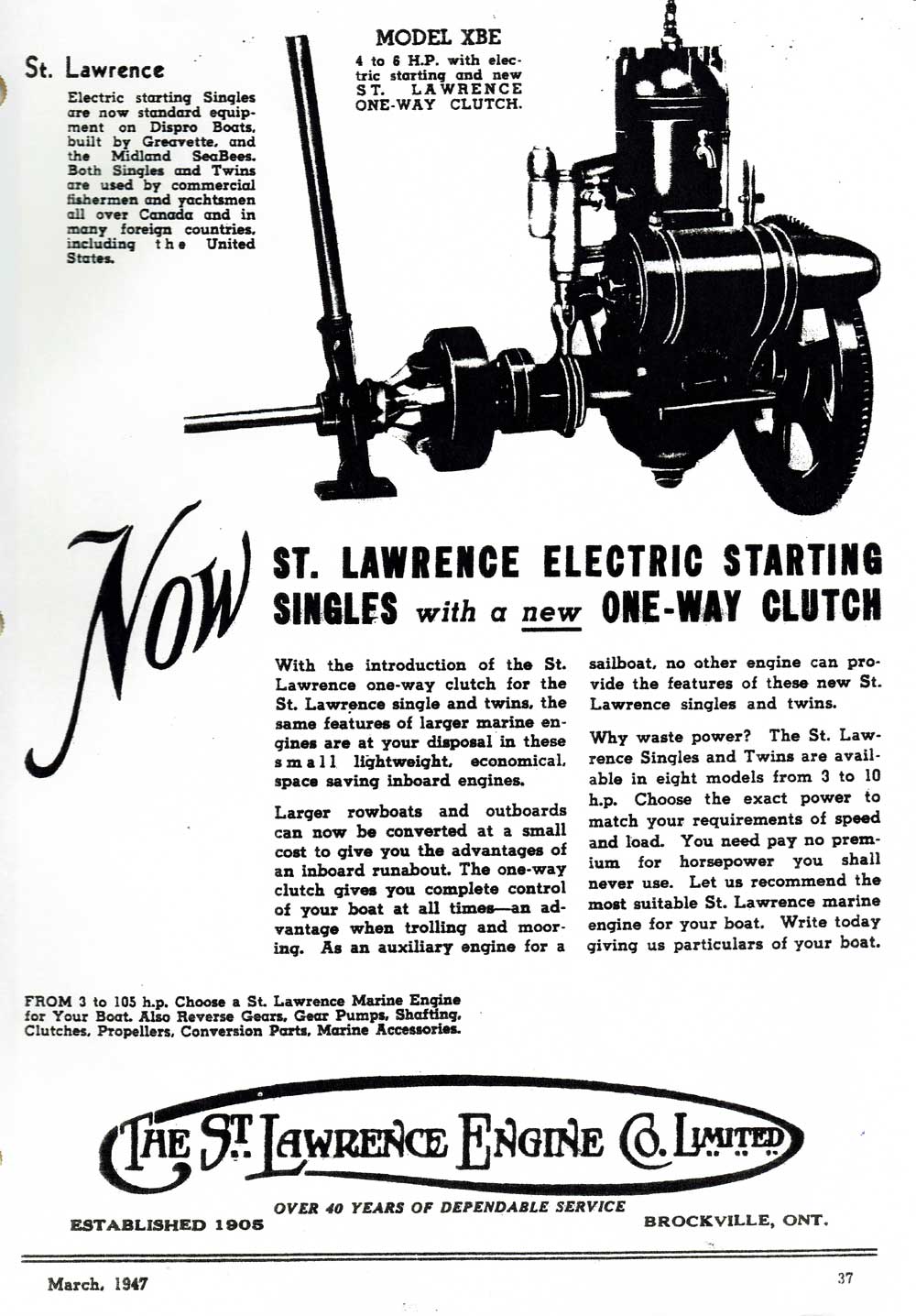

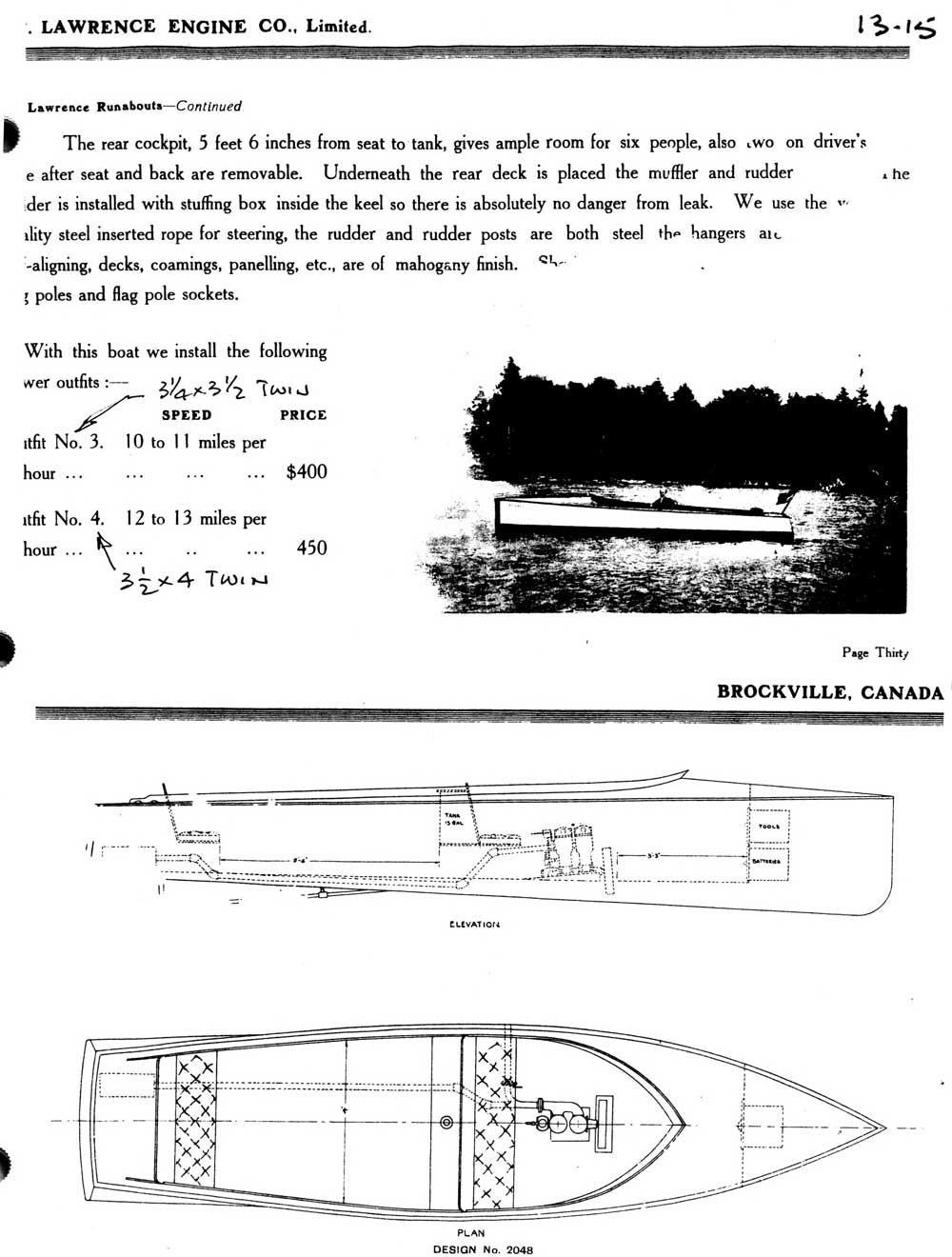

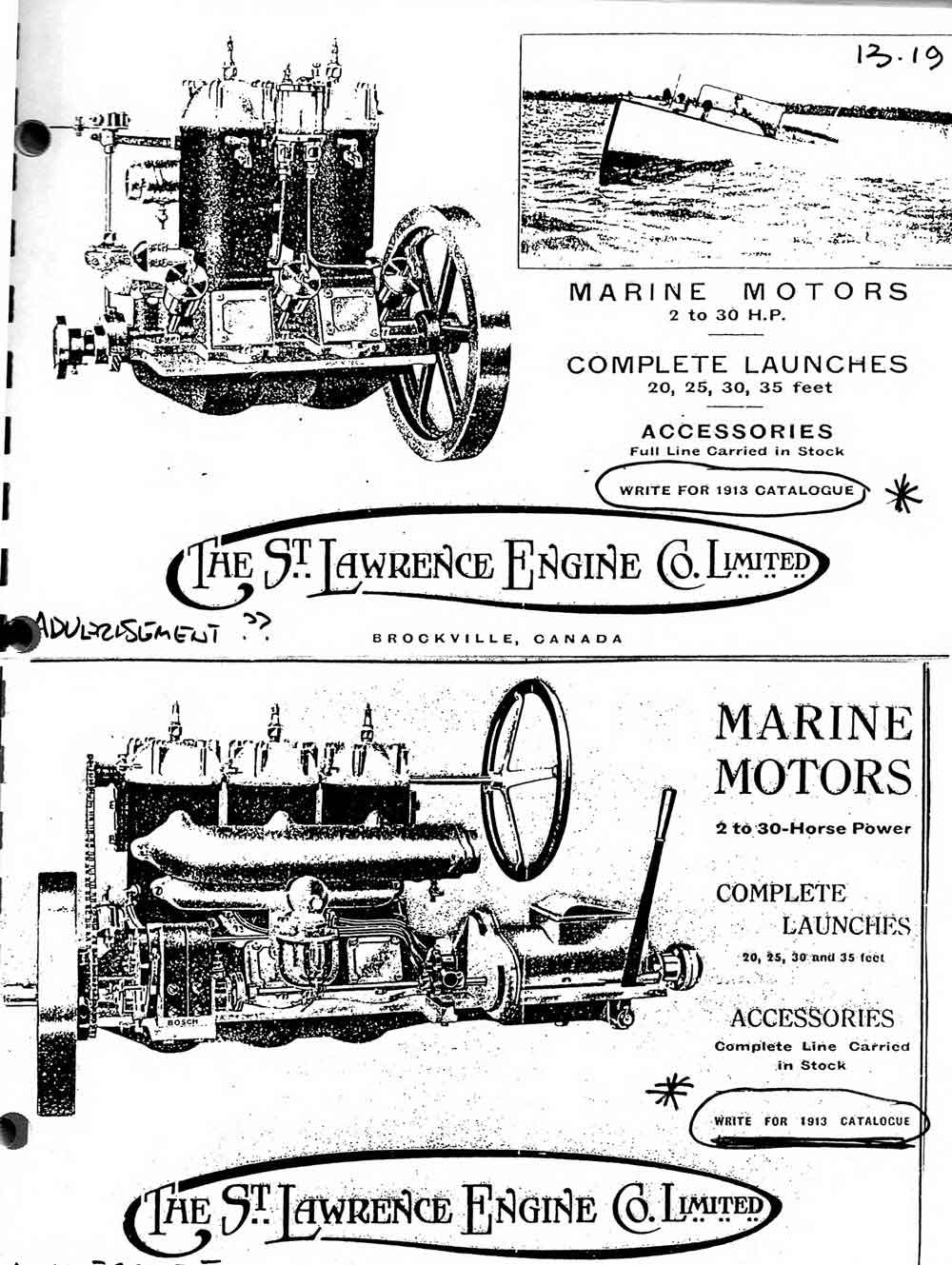

Here is an image of your engine from the St Lawrence 1913 catalogue.

The holes were associated with the oiler that was removed as oil added to fuel was the preferred lubrication method beginning about 1913.

Barry Millar

|

bcm

Senior Member

Username: bcm

Post Number: 125

Registered: 11-2009

| | Posted on Friday, August 21, 2020 - 04:19 pm: |

|

Roger,

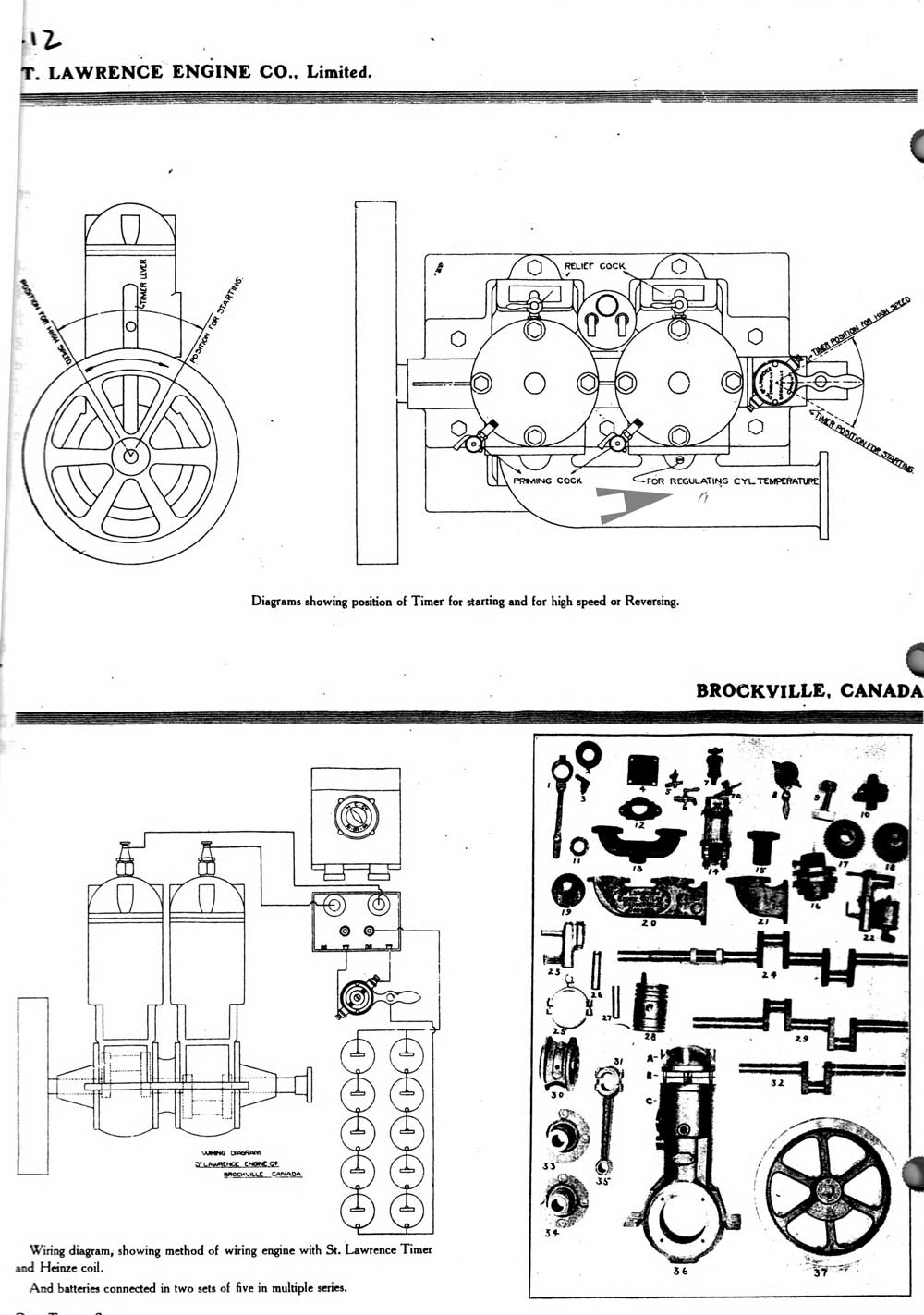

Of interest from the 1913 catalogue.

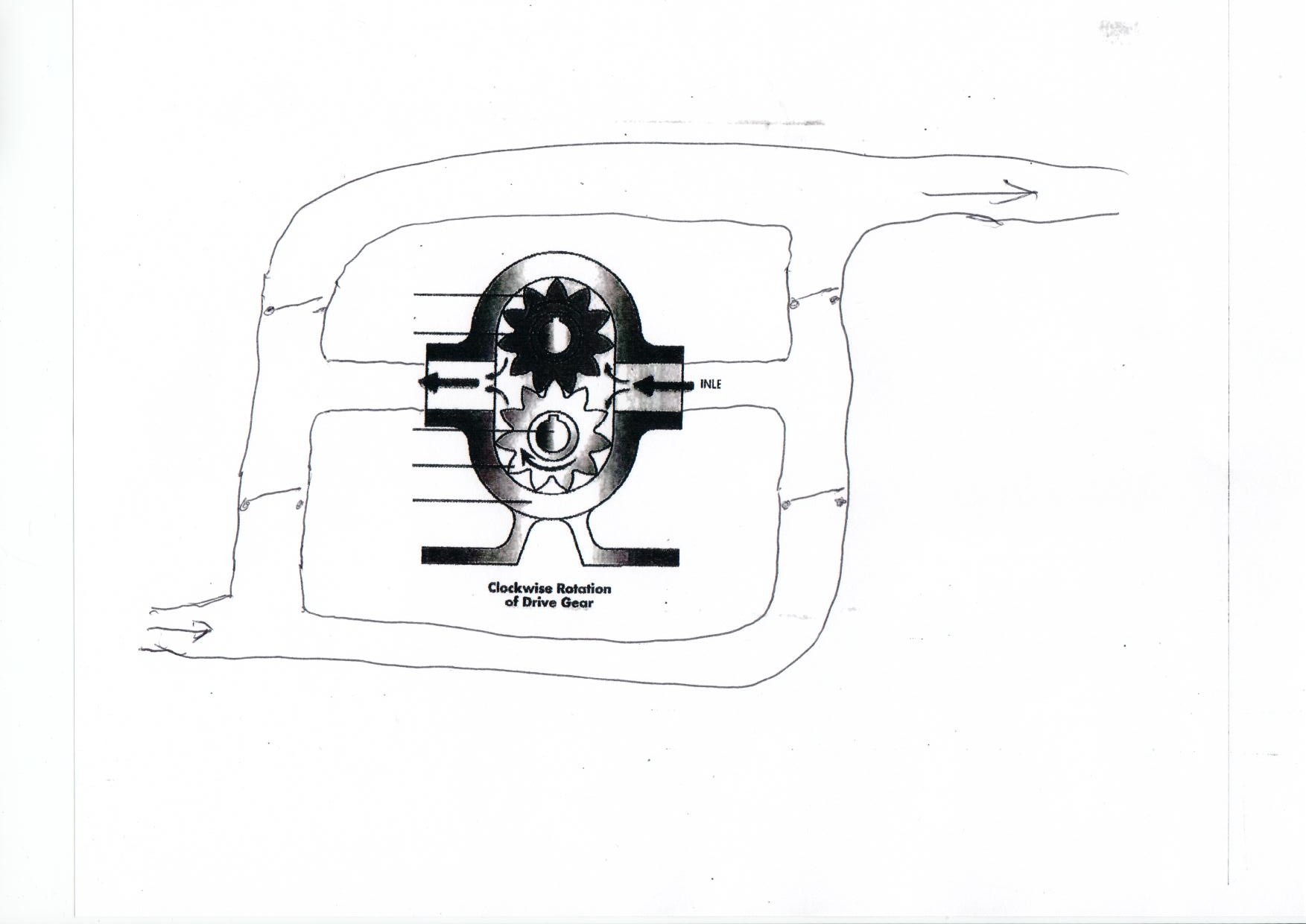

First image

1 Confirms rotation is CCW as would suit a LH propeller.

2 Shows timer position for advanced and retarded timing.

3 Shows a screw for regulating cylinder temperature.

As cooling water exits into exhaust manifold, the screw provides a means to throttle water flow exiting from rear cylinder as this cylinder is closest to pump.

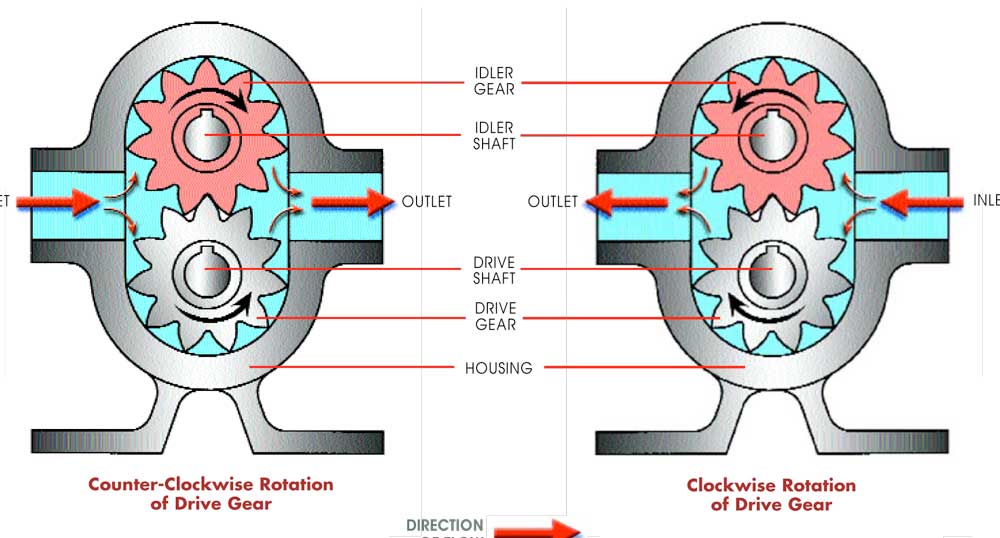

4 After 1913 water pumps were all piston style thus would operate both directions. Your pump looks to be gear style thus only for CCW rotation thus reversing on the fly is not an option.

Second image establishes oiler was in addition to oil added to gasoline. The oiler was not offered after 1913 according to later catalogues.

Barry

|

ernie

Senior Member

Username: ernie

Post Number: 2610

Registered: 01-2002

| | Posted on Friday, August 21, 2020 - 04:58 pm: |

|

Barry,

My 2 cents worth here

Reversing on the fly is fine with a gear pump as long as you don't run it too long in reverse. The Gray U that was in my fantail had a gear pump. I would start it forward then reverse it to back out of the slip. Or reverse it to stop when approaching the slip. Or start it in reverse to back off the trailer. It never even thought about getting hot as it ran cold anyway. Cold as in the cylinder was cool to the touch no matter how long it had been running. 145 deg F max in salt water anyway.

Hope this helps

Ernie |

mirab357

Member

Username: mirab357

Post Number: 4

Registered: 07-2020

| | Posted on Friday, August 21, 2020 - 09:07 pm: |

|

Thanks Barry for the info!

My engine looks exactly the same except for the missing oilers.

As I took the engine apart, I notice that the connecting rods are brass and without bearing inserts to be replaced when worn. I guess that excessive play on the crankshaft has to be remove by grinding the lower part of the connecting rods.

I notice that the pistons are not equally distant from the top of the cylinder at TDC.

Should the pistons be flush with the top of the cylinder or lower and by how much ??

I am trying to find out how much wear there is on the connecting rods.

Regards

Roger |

bcm

Senior Member

Username: bcm

Post Number: 126

Registered: 11-2009

| | Posted on Saturday, August 22, 2020 - 10:11 am: |

|

Roger,

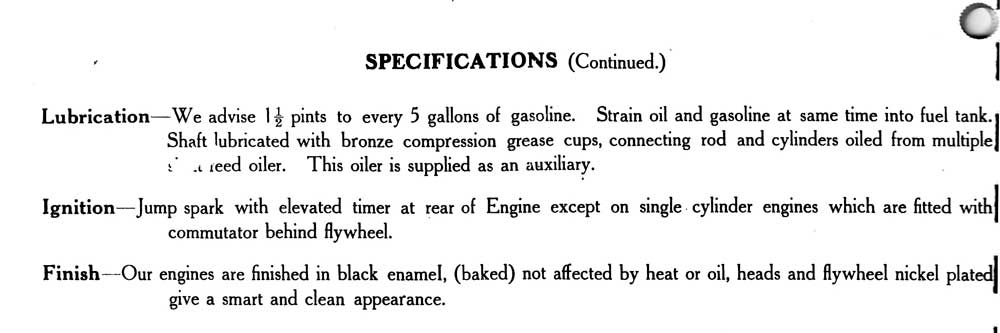

Until about 1925 con rods were bronze, like yours. The only way to refit is to machine the cap piece as you already noted.

When at TDC top of pistons that use bronze con rods are about 1/4" below flush.

In my opinion this reduces compression ratio and in turn output thus there is no advantage. Maybe St Lawrence purchased rods and these were the best fit that was available.

Later, bronze rods were replaced with Ford rods. Then piston was flush, big ends were Babbitt.

Don't hesitate to raise other issues/concerns.

Barry |

bcm

Senior Member

Username: bcm

Post Number: 127

Registered: 11-2009

| | Posted on Saturday, August 22, 2020 - 10:26 am: |

|

Ernie,

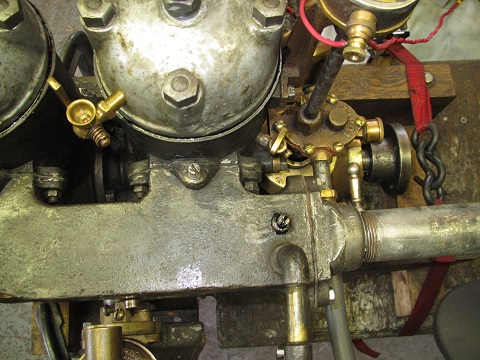

I agree. Gear pumps will operate both directions, note attached image.

However inlet and outlet reverse thus if Rogers engine were reversed cooling water would be pumped out of water jacket, engine would overheat after a minute or two.

Barry

|

mirab357

Member

Username: mirab357

Post Number: 5

Registered: 07-2020

| | Posted on Saturday, August 22, 2020 - 12:09 pm: |

|

Hi Barry,

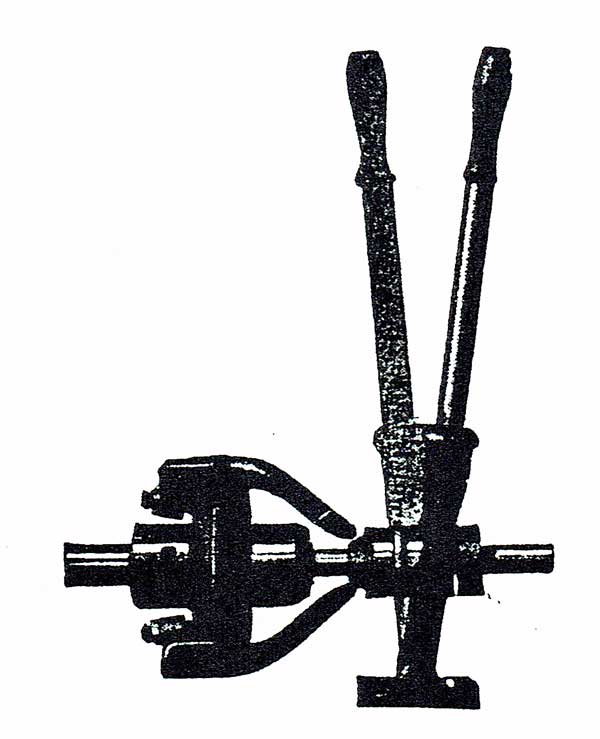

Here is the clutch I believe, what makes it engage?? I am missing part of it ?

I guess you have a catalogue of the St-Lawrence engines. Is it possible to get one of these (PDF files may be)?

Best Regards

Roger

|

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 1454

Registered: 07-2002

| | Posted on Saturday, August 22, 2020 - 02:57 pm: |

|

If you want water in either direction you can do it with 4 check valves.

|

bcm

Senior Member

Username: bcm

Post Number: 128

Registered: 11-2009

| | Posted on Saturday, August 22, 2020 - 03:24 pm: |

|

Roger,

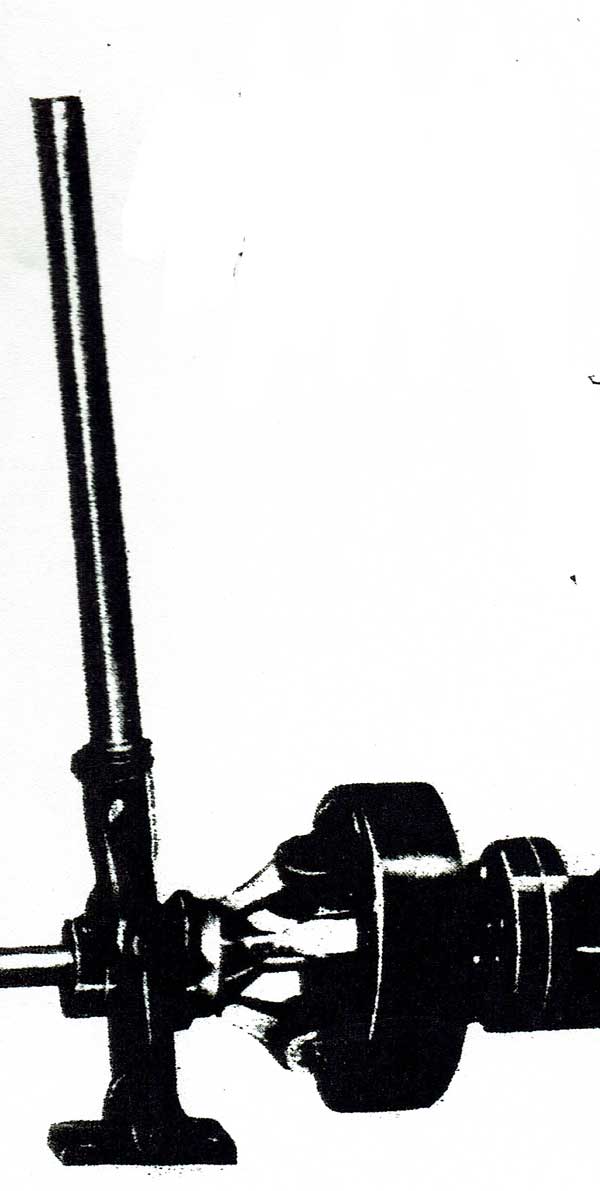

Here are two images of your clutch. This provides the information that you need to make the missing parts.

It's interesting to note that this clutch was first offered in the 1932 catalogue.

Yes, I have copies of St Lawrence catalogues 1913,1925,1932,1936,1945. These are sales catalogues and would be of little use to assist your rebuild. I placed these in a binder 2009, note attached image. The binder includes other interesting information , for example Richard's master list as at that date.

If you want a copy be aware it comprises 70 double sided pages. I could take it to a local print place and purchase a bound copy for you.

Let me know.

Barry

|

bcm

Senior Member

Username: bcm

Post Number: 129

Registered: 11-2009

| | Posted on Sunday, August 23, 2020 - 09:49 am: |

|

Roger,

Of interest,

Here is a full page advertisement for a St Lawrence 3 1/2 B x 4 S single with electric start.

This highlighted your clutch. It is direct connected to engine flange as is yours. According to the advertisement this is the first time that this clutch arrangement was offered.

The date at bottom of page is 1947. This is the year that St Lawrence ceased manufacture although engines were supplied from stock parts until about 1951.

Appears the 1947 owner of your 1913 engine purchased the clutch.

Probably very few were supplied thus you may have a treasure.

Barry

|

mirab357

Member

Username: mirab357

Post Number: 6

Registered: 07-2020

| | Posted on Monday, August 24, 2020 - 05:53 pm: |

|

Hi Barry,

OK. If you can copy the first tab, the 1913 section and include the Richard's master list. Tell me the price, I shall repay you.

Do you have a PayPal account?

I did start the engine with a drill at first, it does start by hand now but needs fine tuning.

At time it kind of backfire not sure. It is like in the first 50 seconds of this youtube video :

" https://www.youtube.com/watch?v=YCo745UWqQc&t=57s "

Is it possible that the surplus of grease from the main bearings get catch and pushed in the piston chamber with the fuel flow ??

Roger |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 1455

Registered: 07-2002

| | Posted on Monday, August 24, 2020 - 09:57 pm: |

|

Backfiring or sneezing from the carburetor is usually caused by a lean mixture. When an engine is first started cold vaporization of fuel is poor and dry manifolds and crankcases absorb wet fuel adding to the problem. Once everything is wet and and warm the carb will need to be leaned out to keep the engine running smooth. If you lean it out too much it will sneeze, too rich it will tend to 4 cycle. When making adjustments remember that there is some lag time between the adjustment and the result, make them slowly and wait for improvement, it's easy to over correct. |

chris_spring

Senior Member

Username: chris_spring

Post Number: 66

Registered: 02-2019

| | Posted on Thursday, August 27, 2020 - 10:16 am: |

|

With my Adams motor I was puzzled when it would run well for a period then sneeze through the crankcase. When it did I'd adjust the mixture and it would once again run well, but only briefly. The code was broken when it was suggested to me that the engine was getting a lean mix as a result of air leaking past the main bearings. Unless that was fixed an erratic mixture would result. I found that was good advice. I now use a slightly heavier wrist on the greasers and everything works fine. I got to know after awhile how much grease and when, however, if it ever does sneeze in the crankcase, rather that going for the mixture control, I go for the greasers. I offer this as another possibility.

Cheers! |

mirab357

Member

Username: mirab357

Post Number: 7

Registered: 07-2020

| | Posted on Thursday, August 27, 2020 - 10:43 am: |

|

Hi Mr Castagnos,

Yes it is more like sneezing from carb. What would be the initial setting for the needle valve ?

I guest the float height must be critical too.

I notice that the engine run way better in the opposite direction (CCW looking at the front of the flywheel). Any idea ?

Regards

Roger |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 1456

Registered: 07-2002

| | Posted on Thursday, August 27, 2020 - 06:44 pm: |

|

Piston clearance on a three port engine affect performance. In one direction the lower ports are held tight by piston thrust, in the other direction the piston is pulled away from the ports changing crankcase compression and performance. On a single cylinder engine a check valve in the intake will help, twins won't benefit from this. |

mirab357

Member

Username: mirab357

Post Number: 8

Registered: 07-2020

| | Posted on Thursday, August 27, 2020 - 11:00 pm: |

|

Hi J.B.

I never would have taught of that.

That means pistons and chambers are worn out. It would required oversize pistons and re boring.

In my case, if reed valves could be installed at the intake of each cylinder, I think it might do the job just like in a one cylinder engine as you explained.

Would it ?

Roger |

miro

Senior Member

Username: miro

Post Number: 1098

Registered: 11-2001

| | Posted on Friday, August 28, 2020 - 06:45 am: |

|

I found the same thing - the engine ran better with Left Hand rotation.

Initially, I had it Right Hand because I had a Right Hand prop - but it would cough and sneeze and was tricky to get running well .

Then , one day I tried running Left Hand and - wow - so much better.

So then I went hunting for a Left Hand prop - and found one.

One of the observations on this engine, was that with the Left Hand rotation , the crank throws help "sweep" the mixture in the crankcase into the bypass port and up into the cylinder. I don't think it's a major effect, but every little bit helps.

And yes, my experience, is that you do need to tweak the mixture going from cold startup to warm running. Supposedly, the air horn helps this, but I found it really doesn't do very much, mainly because I run more or less at constant speed.

Here's JB's boat and my boat.

https://www.youtube.com/watch?v=r_IKSTqH_Fo

https://www.youtube.com/watch?v=1aBtLjD9v2A

Reed valves would likely mean a re-design of the manifold much more complex than sleeving the cylinders.

miro |

mirab357

Member

Username: mirab357

Post Number: 9

Registered: 07-2020

| | Posted on Friday, August 28, 2020 - 10:12 am: |

|

Hi Miro,

Yes it is, that was a taught (reed valves).

In my case, the gear water pump is also an issue for reversing rotation.

Do you know if parts are still available, ie pistons, connecting rods ?

Roger |

mirab357

Member

Username: mirab357

Post Number: 10

Registered: 07-2020

| | Posted on Friday, August 28, 2020 - 10:30 am: |

|

JB & Miro,

I watched the videos. Both of your boats are very nice. Smooth running engines !!

I currently do not have a boat, makes me dreaming.

Roger |

mirab357

Member

Username: mirab357

Post Number: 11

Registered: 07-2020

| | Posted on Thursday, September 03, 2020 - 04:27 pm: |

|

Hi everyone,

On the exhaust manifold, there is two set screws.

I know one is for adjusting water flow so both cylinder cool down equally.

The other one pass through the first wall of the water channel and close a hole in the second wall.

It seems original, what is it for ?

Thanks

Roger  |

bcm

Senior Member

Username: bcm

Post Number: 130

Registered: 11-2009

| | Posted on Friday, September 04, 2020 - 12:29 pm: |

|

Roger,

Are bosses cast in the manifold that align with the holes. If yes this suggests a factory installation. If no then this is probably an owner modification perhaps for below water line engine installation.

Can you remove the exhaust pipe to determine exactly their function.

Barry |

mirab357

Member

Username: mirab357

Post Number: 12

Registered: 07-2020

| | Posted on Friday, September 04, 2020 - 07:32 pm: |

|

Hi Barry,

There is only one boss on the outside as seen on the picture.

Regards

Roger |

bcm

Senior Member

Username: bcm

Post Number: 131

Registered: 11-2009

| | Posted on Saturday, September 05, 2020 - 10:32 am: |

|

Roger,

That information confirms factory installation. I've checked images of other engines with similar exhaust manifold, these also have the cooling water exit piping. This set up seems to match engines with gear pumps.

Two cycle engine exhaust occurs rapidly when exhaust port is first uncovered causing a high amplitude exhaust gas pressure wave that produces very loud exhaust noise when compared to four cycle engines. Also exhaust gases are much hotter compared to four cycle engine exhaust.

Cooling water is arranged to enter exhaust stream to cool exhaust gases, thus to reduce pressure wave amplitude thus to reduce exhaust noise.

With your engine it seems that the screw regulates the amount of cooling water that enters exhaust stream. Maybe it was thought that too much water would cause back pressure with corresponding power loss.

Maybe gear pumps supplied much more flow when compared to piston pumps that were standard later on. With piston pumps it is normal that all cooling water enters exhaust stream.

Barry |

mirab357

Member

Username: mirab357

Post Number: 13

Registered: 07-2020

| | Posted on Wednesday, September 09, 2020 - 04:57 pm: |

|

Hi Barry,

If some of the pumped water mixes to the exhaust gases at that place, as the engine is stopped, the water present in the manifold will flow back to the combustion chamber until the manifold is empty and flood it ??

Right now, I tightened the screw to close the hole completely.

And yes that pump pushes a lot of water.

Regards

Roger |

bcm

Senior Member

Username: bcm

Post Number: 132

Registered: 11-2009

| | Posted on Saturday, September 12, 2020 - 10:10 am: |

|

Roger,

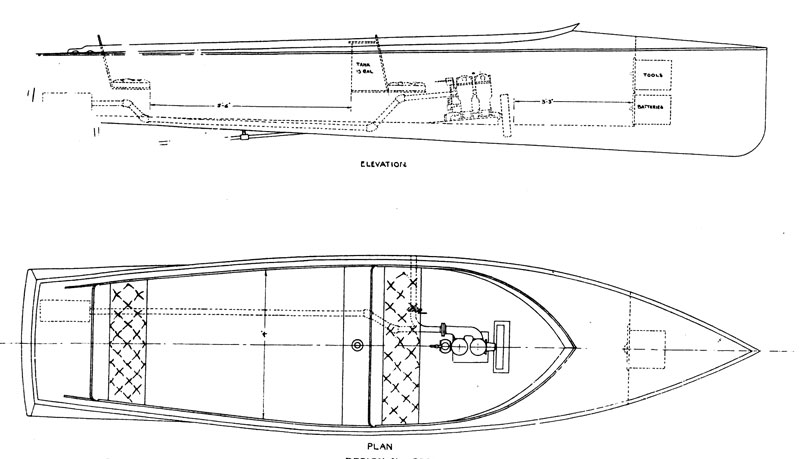

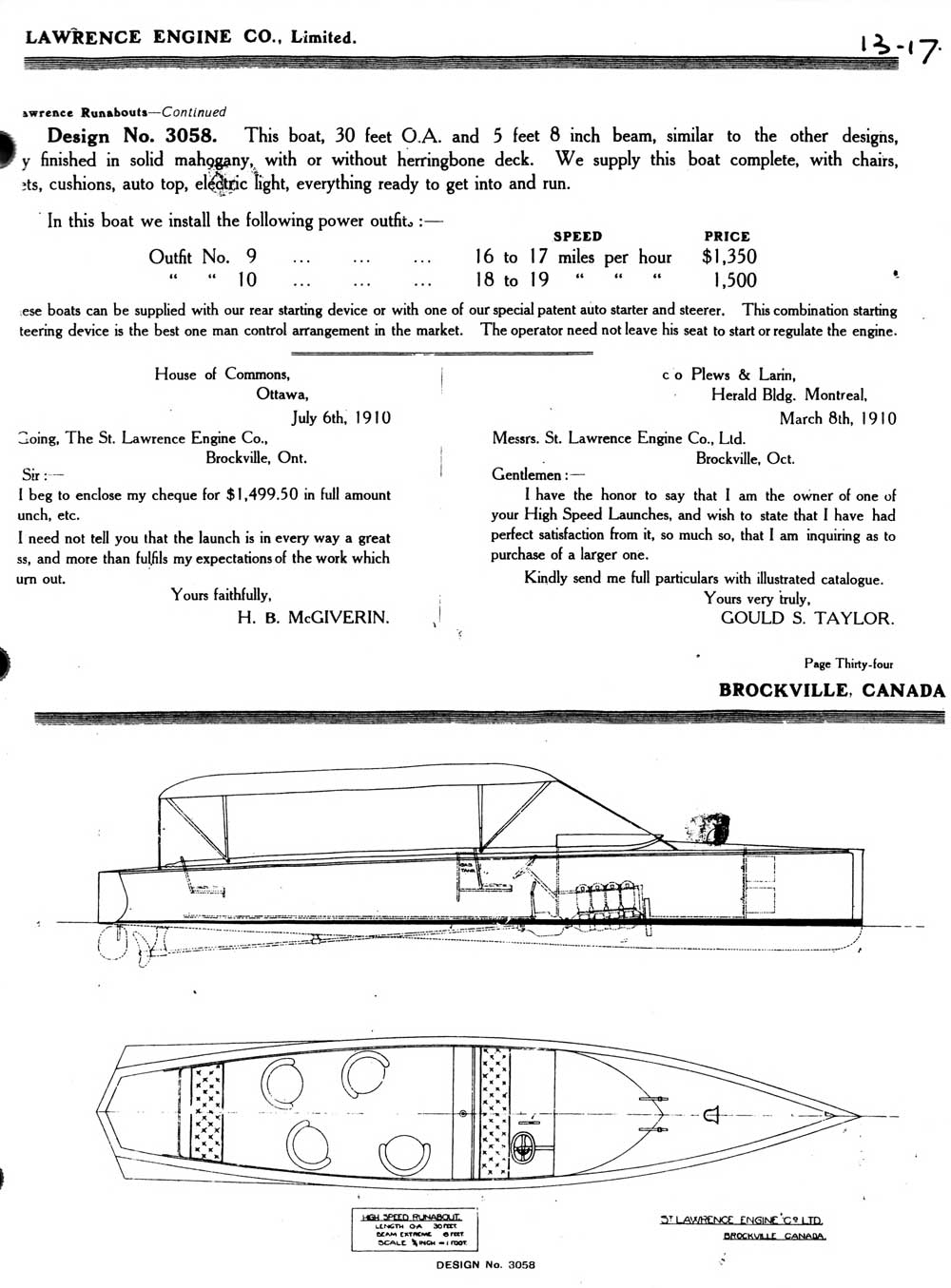

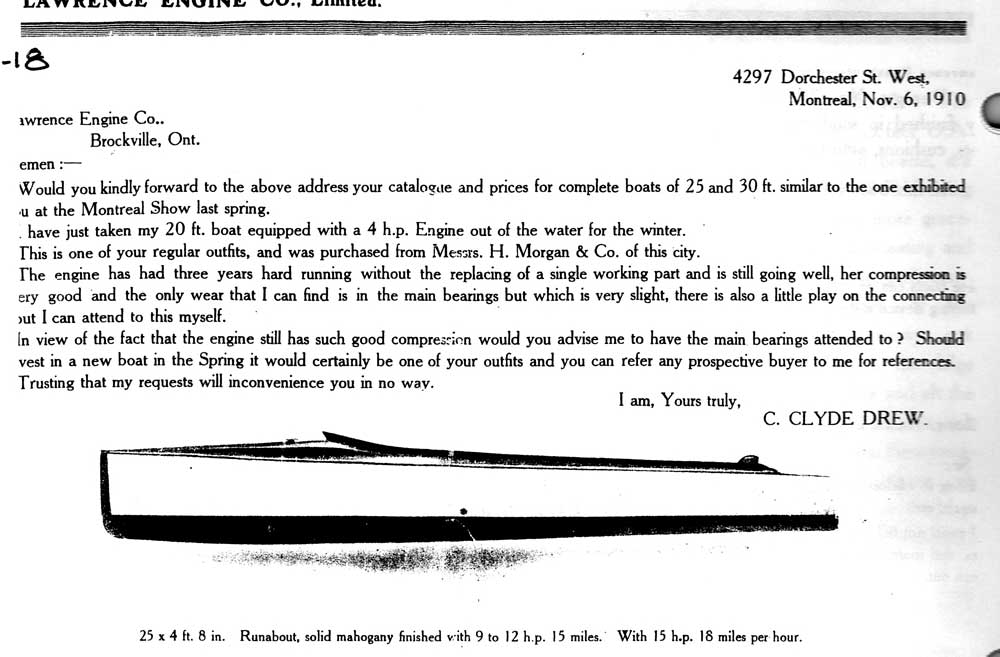

St Lawrence built boats in the early days. Image is a 20 ft St Lawrence launch,looks like your engine.

As is typical for marine engines, engine is installed at angle thus manifold will not collect water at shut down.

Long exhaust pipe would need to be cooled. Too much water might collect in lower section at shut down making starting difficult due to back pressure. Maybe this was reason for screw that adjusts amount of water entering exhaust stream.

I'm guessing rotary timer was used to be convenient for operator. Therefore gear pump was only choice.

I suspect gear pump supplies more water than is needed to cool engine. As gear pump is positive displacement outlet cannot be throttled. I suppose some water could be diverted before entering engine.

Barry

|

mirab357

Member

Username: mirab357

Post Number: 14

Registered: 07-2020

| | Posted on Saturday, September 12, 2020 - 12:52 pm: |

|

Thanks Barry for the info.

Best regards

Roger |

marion

Member

Username: marion

Post Number: 15

Registered: 03-2013

| | Posted on Saturday, September 12, 2020 - 02:25 pm: |

|

Barry, I would appreciate if you could provide more information on the St Lawrence launch you referred to in an earlier post. Thank you. Marion |

bcm

Senior Member

Username: bcm

Post Number: 133

Registered: 11-2009

| | Posted on Saturday, September 12, 2020 - 03:40 pm: |

|

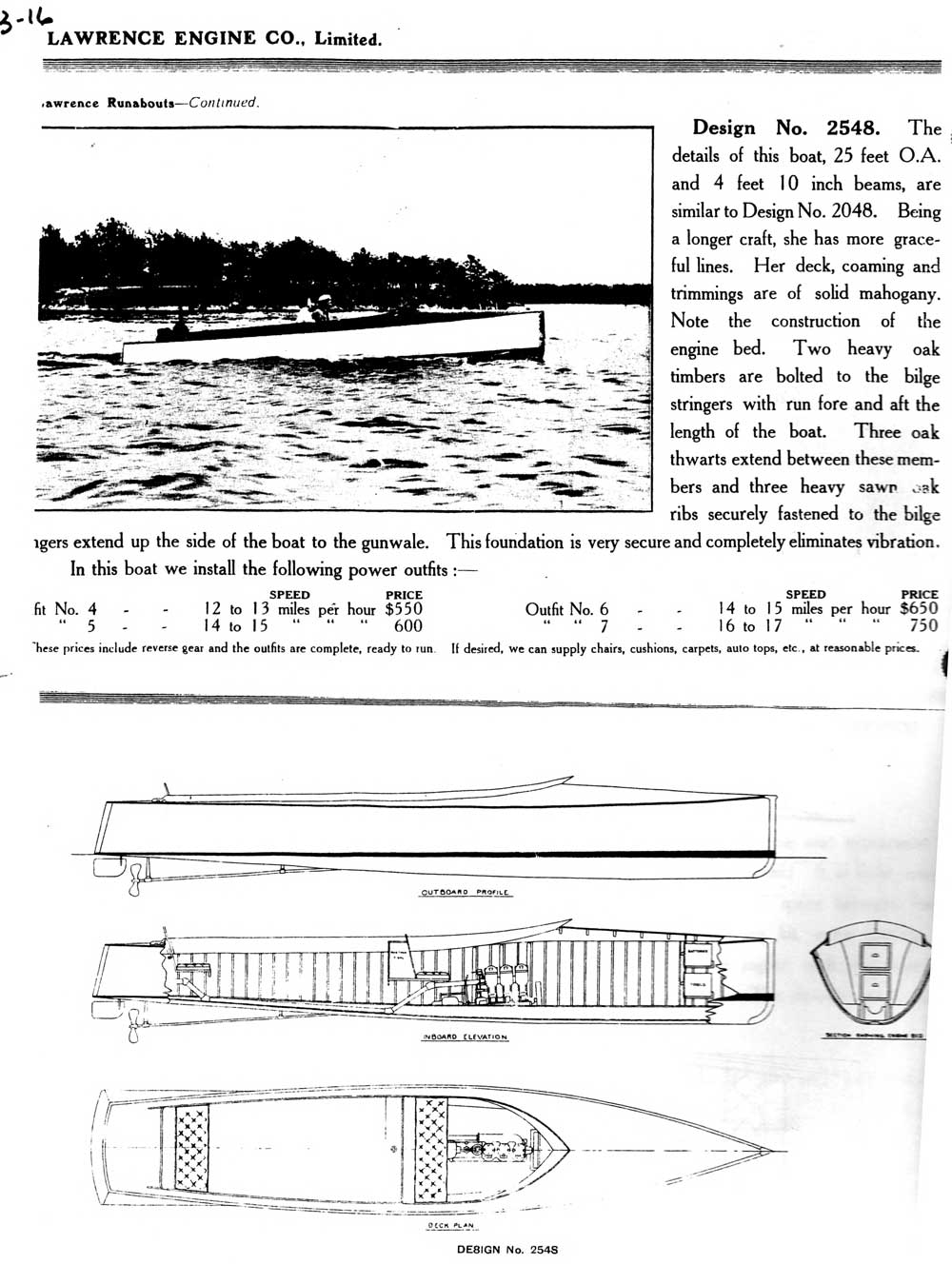

Marion,

St Lawrence manufactured three launches. Here are images from the 1913 catalogue. This is all the information that I have.

The next catalogue is dated about 1925. No launches were in this catalogue.

Barry

|

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 1458

Registered: 07-2002

| | Posted on Saturday, September 12, 2020 - 09:28 pm: |

|

Piston pumps are positive displacement also, to reduce flow you have to restrict the inlet on either. |

bcm

Senior Member

Username: bcm

Post Number: 134

Registered: 11-2009

| | Posted on Sunday, September 13, 2020 - 12:01 pm: |

|

Thanks for info JB,

I've always been of the opinion that restricting either inlet or outlet, gear pumps or piston pumps is not desirable.

Wonder if you would add information regarding your experience as it is not the same mine.

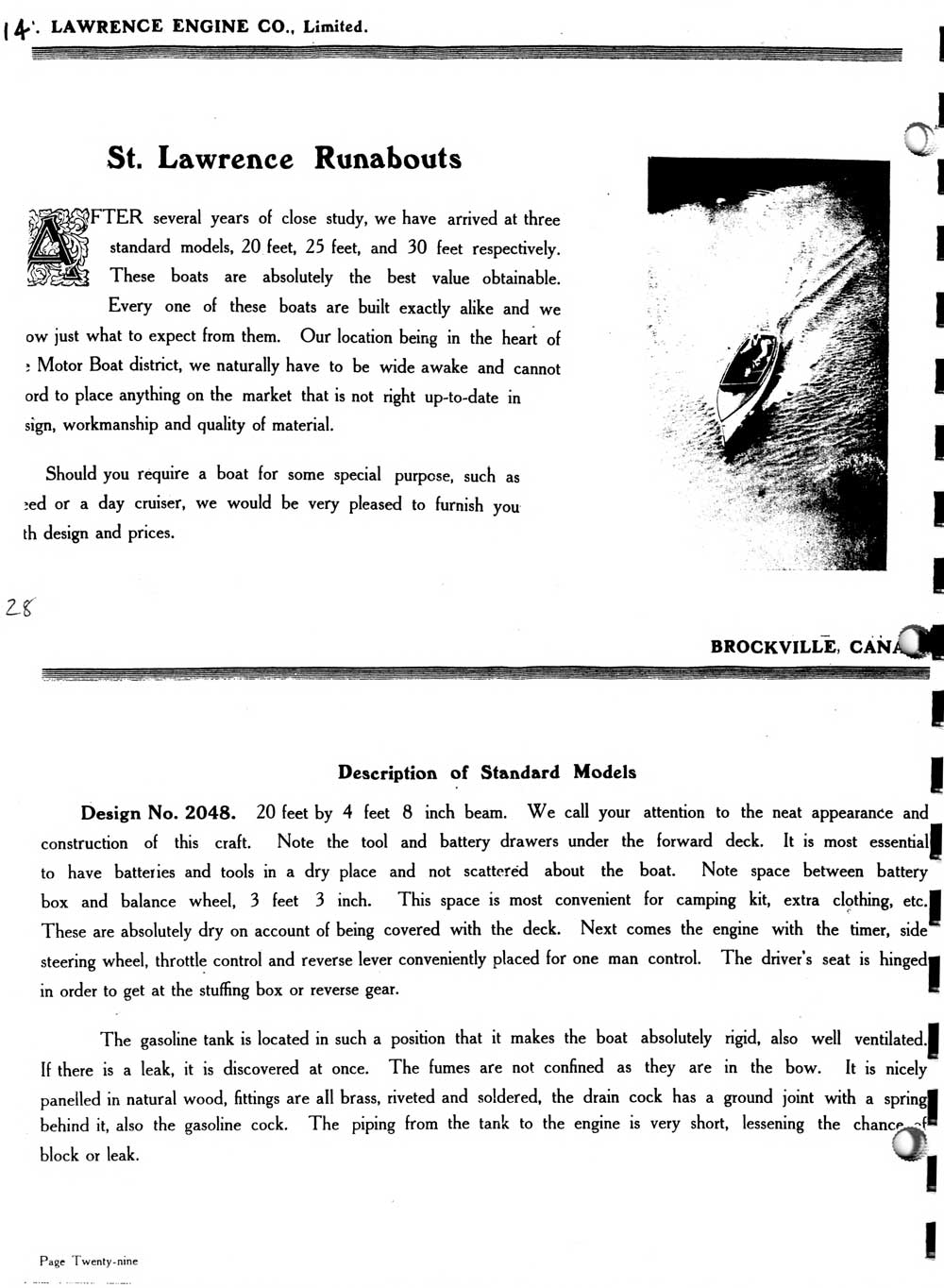

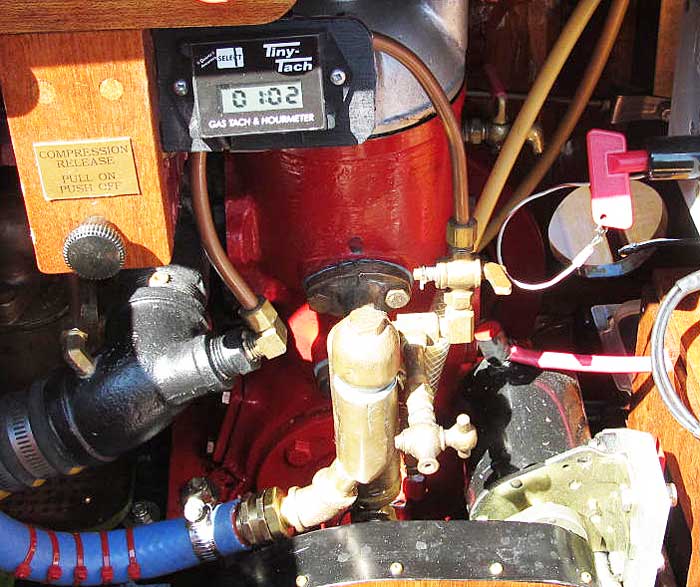

I experimented with diverting some of a piston pump discharge directly to exhaust manifold to reduce cooling water flow through engine to increase engine operating temperature, note image.

Roger could install a tee with valve in gear pump dischsge to divert excess water thus reducing amount of water entering engine.

Barry

|

bcm

Senior Member

Username: bcm

Post Number: 134

Registered: 11-2009

| | Posted on Sunday, September 13, 2020 - 12:01 pm: |

|

Thanks for info JB,

I've always been of the opinion that restricting either inlet or outlet, gear pumps or piston pumps is not desirable.

Wonder if you would add information regarding your experience as it is not the same mine.

I experimented with diverting some of a piston pump discharge directly to exhaust manifold to reduce cooling water flow through engine to increase engine operating temperature, note image.

Roger could install a tee with valve in gear pump dischsge to divert excess water thus reducing amount of water entering engine.

Barry

|

marion

Member

Username: marion

Post Number: 16

Registered: 03-2013

| | Posted on Monday, September 14, 2020 - 04:41 pm: |

|

Barry, thank you for posting this information of St Lawrence launches. My eye is drawn to the illustration of Design No. 3058 with a four-cylinder engine. I am curious if four-cylinder St Lawrence engines ever manufactured, and if so, does any still exist? Marion |

bcm

Senior Member

Username: bcm

Post Number: 135

Registered: 11-2009

| | Posted on Tuesday, September 15, 2020 - 12:00 pm: |

|

Marion,

Check this post Dec 7 2018 by billschaller that shows an image of a 3 cylinder St Lawrence.

http://www.oldmarineengine.com/discus/messages/1/119388.html

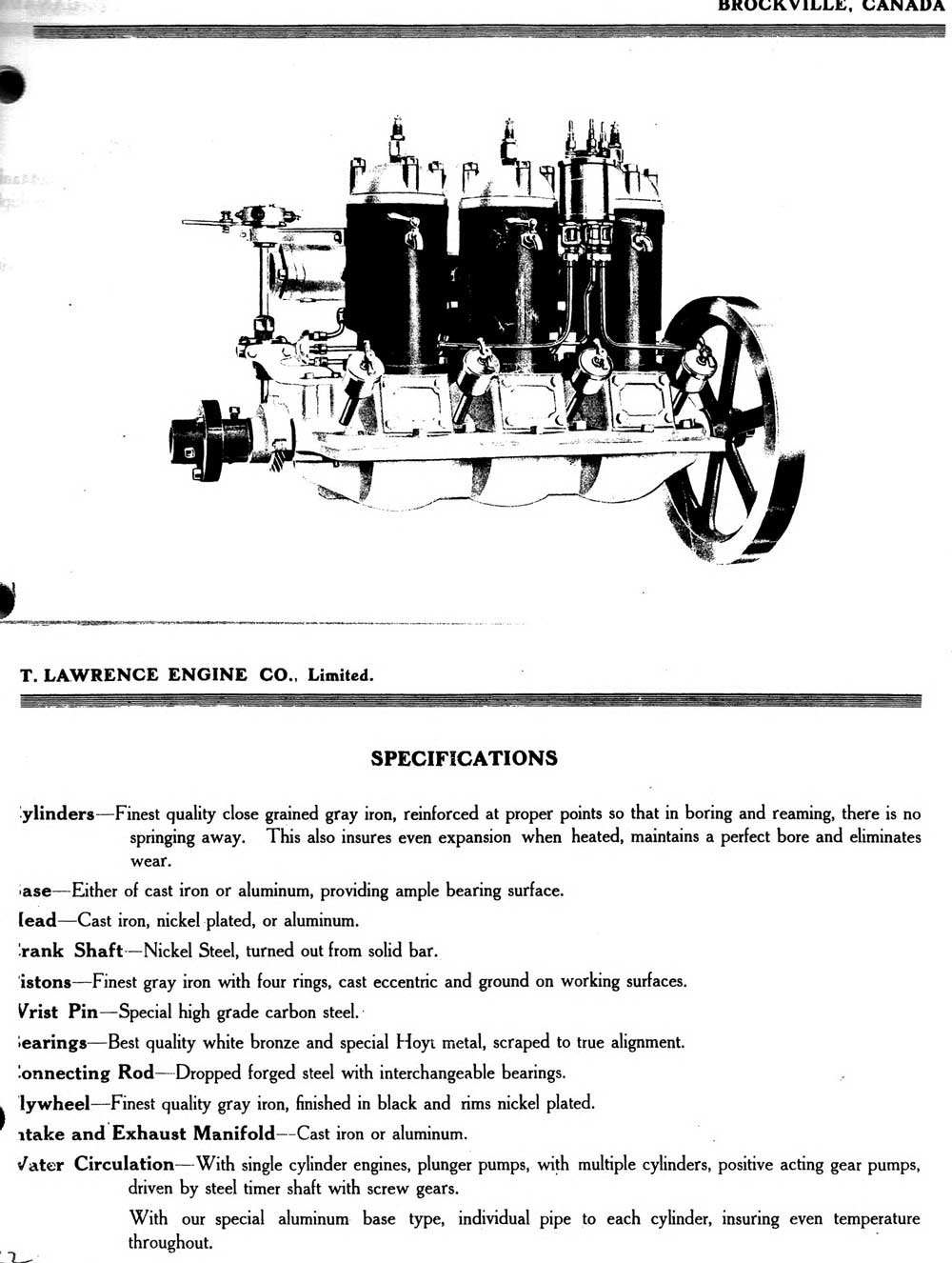

I'm attaching several additional images from 1913 catalogue.

1st image is letter dated Nov 1910 stating boat was operational for 3 years. Rather impressive considering St Lawrence stated in business 1905.

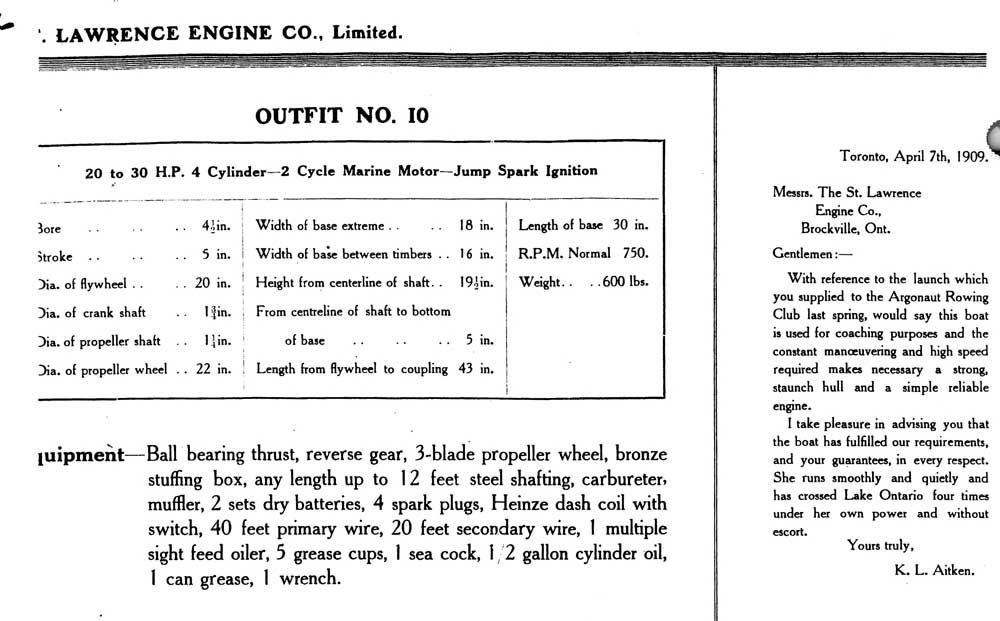

2nd image lists specifications for outfit 10 used for powering design 3058. This is huge four cylinder engine.

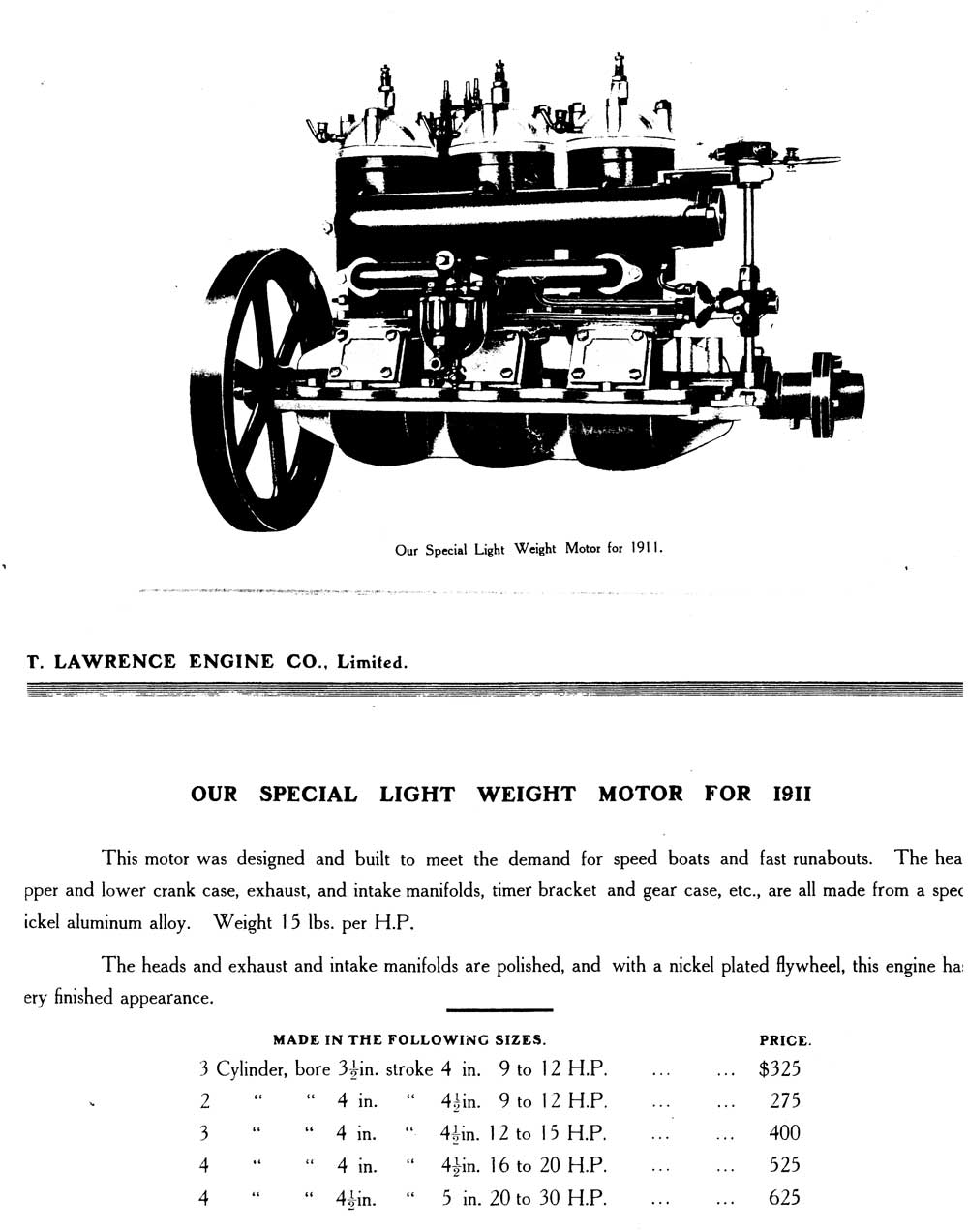

Image 3 and 4 and 5 is information about light weight engines available 1911 also 4 cylinder units were offered. I suspect the image in Bill Schaller's post is a three cylinder version.

St Lawrence were very ambitious in the early years offering many engine sizes up to four cylinders.

regards, Barry

|