| Author |

Message |

Andrew (Andrew)

Board Administrator

Username: Andrew

Post Number: 779

Registered: 11-2001

| | Posted on Tuesday, July 06, 2004 - 08:14 pm: |

|

I have had email conversation with Richard Crook in the UK about a Lozier engine he has. I thought I would post it here so others might be able to help out. The photo of the tag does say 1-1/2HP, although it may be hard to read below.

Richard

quote:Dear andrew

have just bought a 1.5 hp Lozier 2 Cycle marine engine at the 1000 engine rally over in england. am now looking for information Manual, dating, type of ignition system etc.

Are you able to point me in the right direction regards Richard

Andrew

quote:Are you sure yours is 1.5HP ? I don't recall that size.

Send me a picture of the engine and tell me what info you need.

Richard

quote:Dear Andrew

Please find attatched 3 Photos of the Lozier including the plate.

Yes it is a 11/2 hp speed 420 RPM, This sounds as though it could be rare?

Questions.

I am presuming that the date would be around 1904/1910 could you confirm this?

There is no obvious serial No. on the engine could you guide me to where it would be?

What would the Ignition system be?. At present all I have is a 18mm plug fitted into a brass hexagon headed insert in the head.

The carb is a Holly type N would this be corect?

Would this engine have had a pumped cooling system

Problems

The big end (Wrist Pin?) has some play in it but think there is enough shim in to scrape the bearing

Piston Rings could do with replacing, should be able to source them on this side of the pond.

I could really use a copy of a manual for this engine initially also a copy of the Stan Grayson book on the American 1 lungers.

basically any information that could help me in the restoration.

many thanks again for your help and will look forward to hearing from you regards Richard

Andrew

quote:I think that is the same engine as I have, just labeled differently. I have one that is labeled as a 2-1/2HP, but the same engine was also labeled as a 3HP.

Have you had the head off? Do you know the bore and stroke?

That engine would be 1905 or before.

All Loziers are rare.

There are about ten of the two cycle marine engines like that in this area between museums and private collectors. The 2-1/2 to 3HP castings and then a bigger set of castings that was rated as a 5HP.

Richard

quote:Dear Andrew

Have measured bore & stroke over the weekend, Bore 3.5 inches, Stroke

3.46 inches.

Have had a good look at the Images you have so kindly sent. A difference on my engine id there are no drillings in the Cylinder below the head for the ignition actuator. Could mine have been High tension ignition from new.My carburetter dosn't look the same as yours (mine Holley type N). Would this be correct.

Is there any chance of getting an Operators manual/Shop manual for the engine.

One little twist to the tale I am informed that the Lozier is belived to have come out of a boat at Henley on Thames, nr London, could make it an original import. Will check this out further Will look forward to hearing from you thanks again for all your help regards Richard

|

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 471

Registered: 11-2001

| | Posted on Tuesday, July 06, 2004 - 09:38 pm: |

|

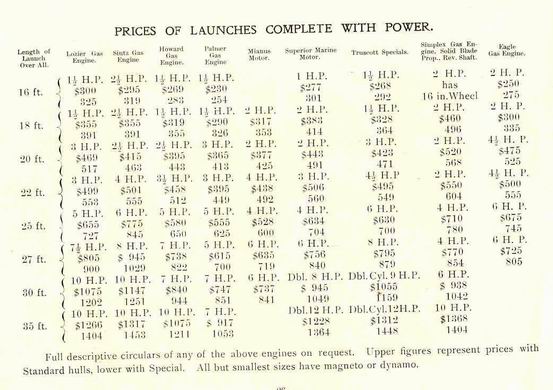

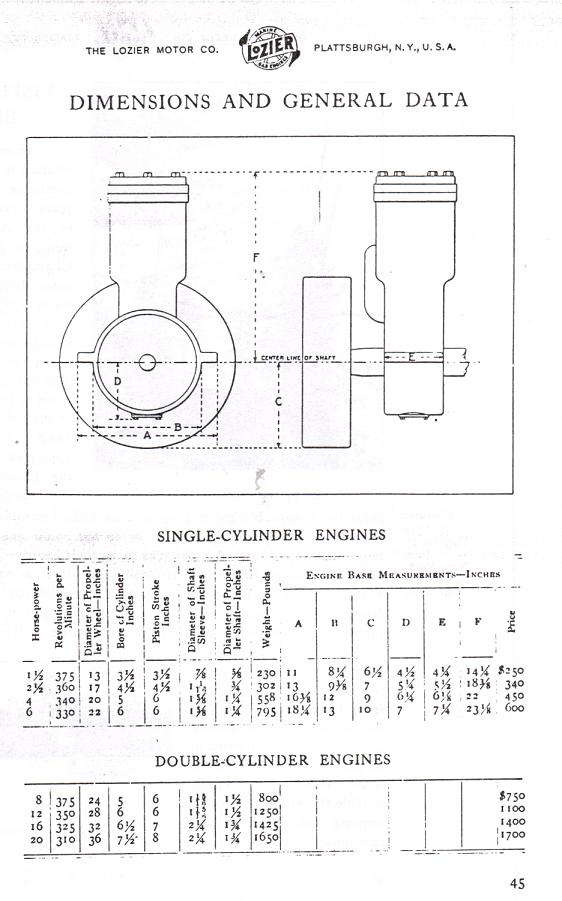

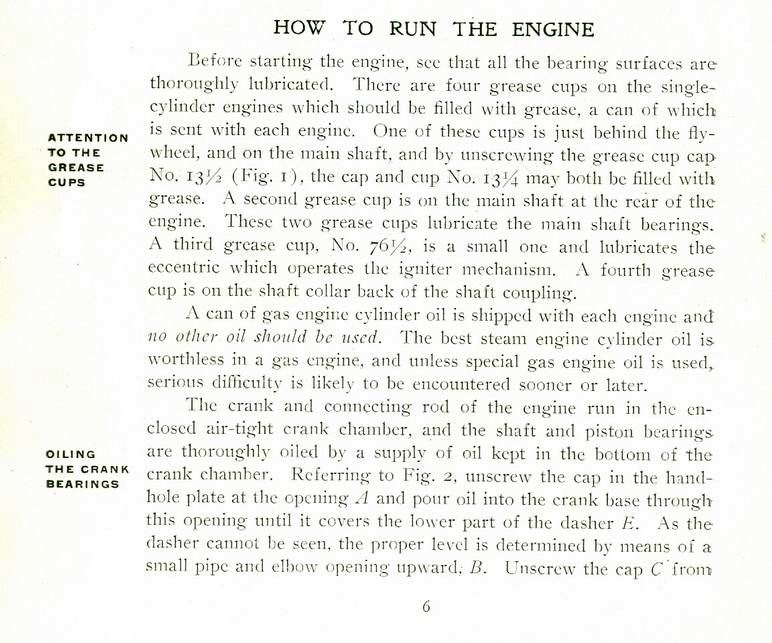

Heckman catalog , not dated but around 1900.

|

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 472

Registered: 11-2001

| | Posted on Tuesday, July 06, 2004 - 09:58 pm: |

|

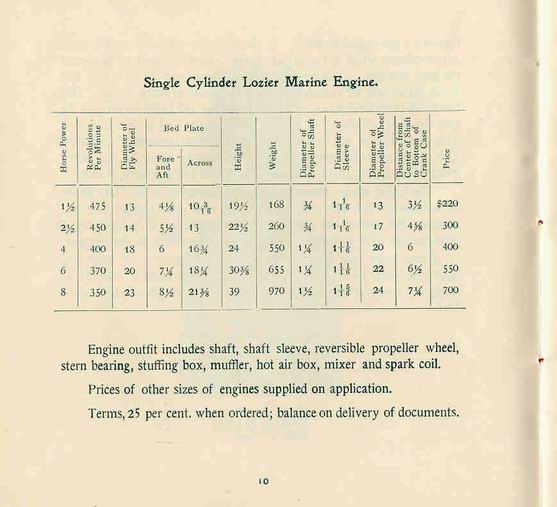

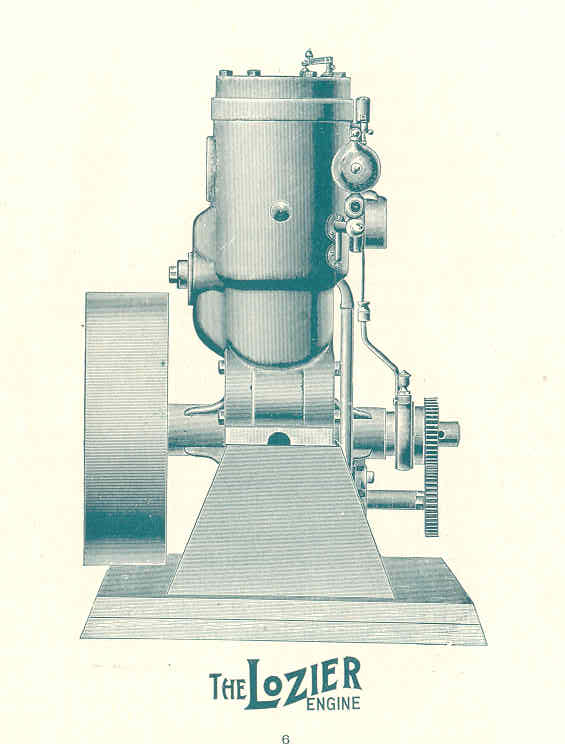

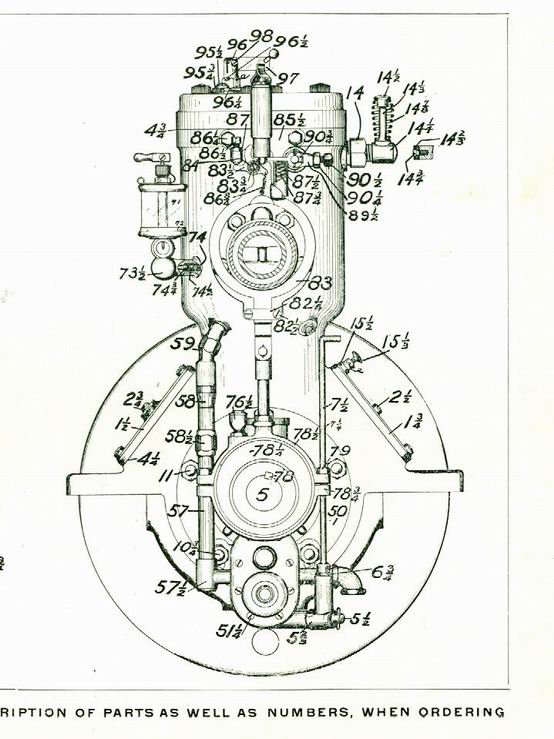

Lozier engine list 1899

|

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 473

Registered: 11-2001

| | Posted on Tuesday, July 06, 2004 - 10:06 pm: |

|

|

Richard Crook

Visitor

| | Posted on Tuesday, July 13, 2004 - 11:12 am: |

|

Dear Richard

Thanks for the images. All information gratefully recieved |

Nick H

Visitor

| | Posted on Friday, August 06, 2004 - 09:55 am: |

|

How are you getting on with the Lozier Richard? I looked at it a number of times at the rally and was rather pleased when the 'sold' sticker appeared - if it had stayed there much longer I fear my resolve not to buy anything heavy might have weakened! |

Richard Crook

Visitor

| | Posted on Monday, August 16, 2004 - 05:08 am: |

|

Dear Nick

Not very far at the moment am really in the information gathering stage. More questions than answers at the moment. And of course the inevitable restoration Q. Will serve me right for having a love of all things smokey. |

robert

Senior Member

Username: robert

Post Number: 140

Registered: 07-2003

| | Posted on Tuesday, December 14, 2004 - 04:49 pm: |

|

I have a not very good photocopy of a 1901 Lozier catalogue here. I was going to post the specifications page, but cannot get it under 50kb and still readable. I'll email it to you now. If someone else wants to try and edit and post it, I can send it to them. |

bartropr

Advanced Member

Username: bartropr

Post Number: 47

Registered: 06-2006

| | Posted on Monday, September 26, 2011 - 07:08 am: |

|

Dear Robert,

Please can you email a copy of your Lozier catalogue, as I have just purchased the Lozier from Richard Crook to use in my Truscott Launch?

[email protected] |

bartropr

Advanced Member

Username: bartropr

Post Number: 48

Registered: 06-2006

| | Posted on Monday, September 26, 2011 - 07:14 am: |

|

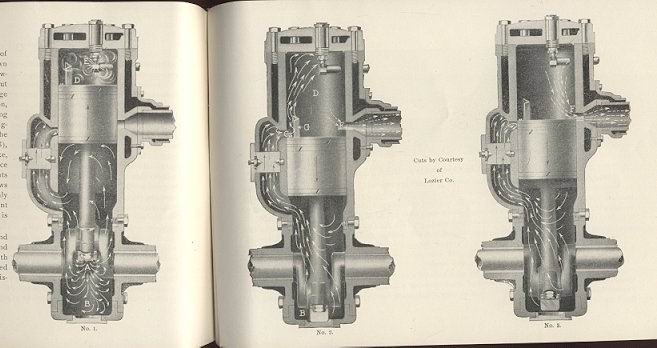

The Lozier 1.5hp engine definitely matches all the measurements in the catalogue I have ("Book 10" - Plattburg N.Y.,on Lake Champlain) for this size.

There appears to be different model types A,B and C from some of the posts on Lozier?

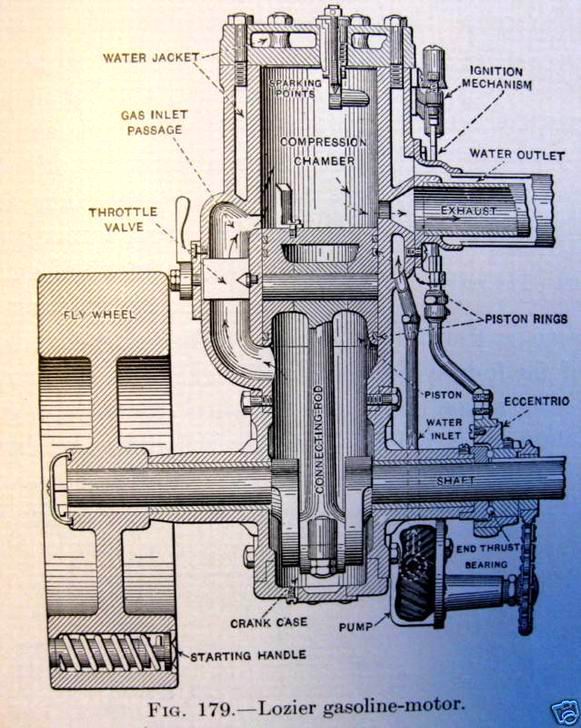

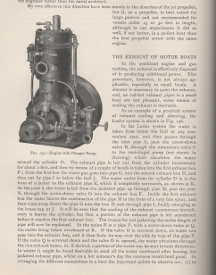

This has a throttle lever on the front - not linked to any timer. Provision for a chain drive pump, and square crankcase access plates on each side. The cross section of the engine from Gardner Hiscock's 1906 edition represents it very well(see New Find-Lozier single cylinder), including the heavy flywheel -13" diameter with a 4" face!

Does any one have a similar engine as I need to copy the spark break mechanism, and will need some close photographs/drawings with measurements. eg, What throw does the eccentric have to drive the mechanism?

Can anyone help? |

robert

Senior Member

Username: robert

Post Number: 447

Registered: 07-2003

| | Posted on Monday, September 26, 2011 - 11:06 am: |

|

Richard, I've just searched my HD and there is no Lozier catalogue there, so I must not have scanned it yet. I'll have to look in my files for that copy I mentioned.

There was a 33 page thesis sold on eBay back in 2001 that I believe one of our members bought ;-)

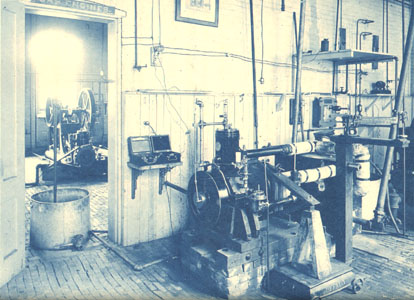

"A Thesis Presented to Sibley College for the Degree of Mechanical Engineer by G. H. Bayne, Jr and E. C. Speiden. 1904. 8 x 11 inch bound carbon copy of thesis. 33 pages plus charts and photos. Binding in quarter leather.

In this thesis the two candidates ran efficiency tests on a 2-cycle 5 H. P. Lozier marine motor. Thesis first compares 4 and 2 cycle engines, then a short history of the Lozier motor is given. The operation and construction of the Lozier engine is then discussed at length. The test setup and test procedures are given followed by test results and charts. There are illustrations of engine components, the Lozier Plant and the test setup with engine in place. All photos and test result charts are blueprint copies. See picture of test setup below.

Condition: Leather spine ends and corners are badly chipped. Front hinge is a bit weak. Interior pages are clean and bright and blueprint copies are particularly clear and sharp.

The students appear to have done a professional job with their testing and the report is well written and detailed. An interesting one of a kind gas engine item."

Perhaps that would help you as well? This is the photo from the auction page. |

robert

Senior Member

Username: robert

Post Number: 448

Registered: 07-2003

| | Posted on Monday, September 26, 2011 - 11:12 am: |

|

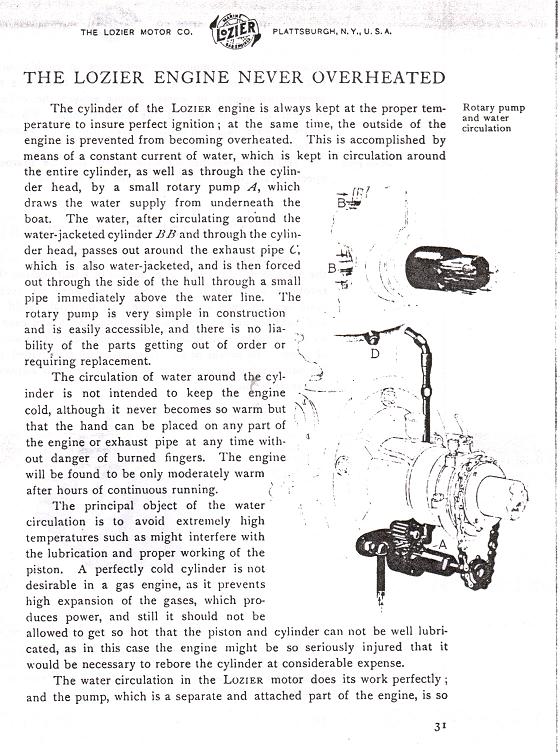

And the only other two Lozier files I found:

I had to shrink the water pump illustration so it would post. I'll email you the full size one now. |

bartropr

Advanced Member

Username: bartropr

Post Number: 49

Registered: 06-2006

| | Posted on Saturday, October 01, 2011 - 05:32 am: |

|

Does anyone know of an existing engine like mine with the chain drive to the water pump and hit and miss mechanism, as both these are missing. What kind of carburettor would it have had - the feed to the crankcase is under one of the engine mounting lugs?

Any suggestions gratefully received |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2678

Registered: 11-2001

| | Posted on Sunday, October 02, 2011 - 07:10 pm: |

|

*

bartrop's Lozier photos

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Cool Old Marine Engine

will look for info !

* |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2679

Registered: 11-2001

| | Posted on Sunday, October 02, 2011 - 09:33 pm: |

|

*

Lozier 1895

Lozier 1900

* |

andrew

Moderator

Username: andrew

Post Number: 1132

Registered: 11-2001

| | Posted on Monday, October 03, 2011 - 10:21 am: |

|

I have two of those engines, but I don't think I have a water pump for either one.

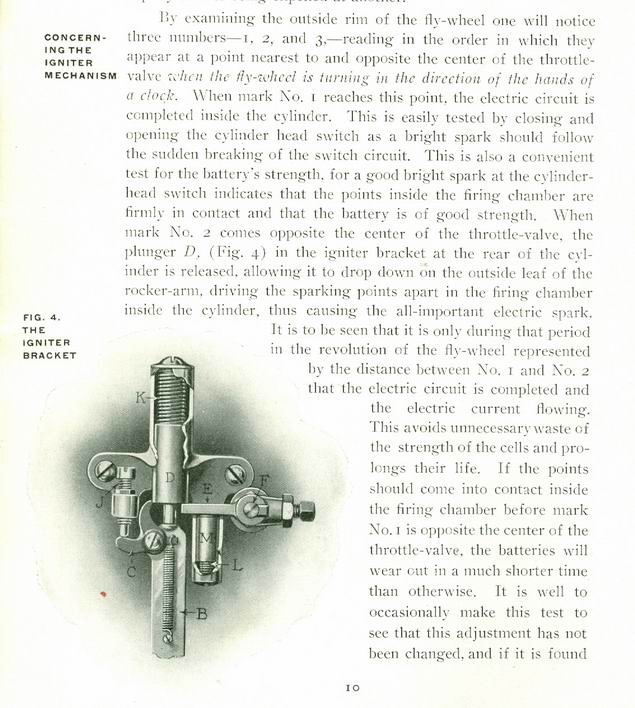

The above photo might help for the ignition.

Richard's cut-away drawing in the previous post is a good one. |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2680

Registered: 11-2001

| | Posted on Monday, October 03, 2011 - 12:35 pm: |

|

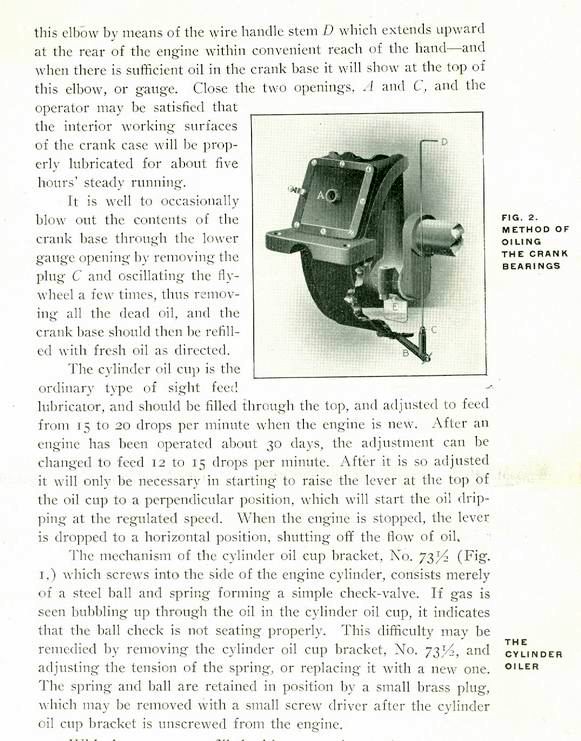

*

For 110 yrs old That engine looks in great condition ! The timer actuater that goes around the exhaust is to me a piece of mechanical art work!

Lozier Aft Illustration

Lozier Ignition:

Lozier Oiling:

These old two cycle engines are one of the very few that required an amount of oil in the crankcase for proper lubrication !

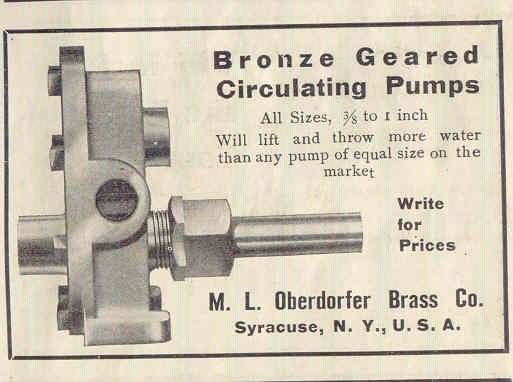

Lozier Water/pump

From the aft illustration above the water/pump looks very much like an oberdorfer made in Syracuse,New York.

1906 Oberdorfer ad

This ad shows Type-A, Form-y may be close ? these pumps came in different sizes !

The chain sprocket on the output shaft of these engines are Skip tooth sprockets and from past experience with a 1898 Lackawanna engine I found that none of the modern chains or sprockets would match, finally discovered that turn of the century bicycles used them, I searched ebay and bought an old coaster brake rear hub with sprocket and matching chain $20.00. Had to machine a center hub for the sprocket to fit w/pump shaft !

* |

bartropr

Advanced Member

Username: bartropr

Post Number: 50

Registered: 06-2006

| | Posted on Monday, October 03, 2011 - 03:22 pm: |

|

Richard, Andrew, I never cease to be amazed by the information and details you can lay your hands on! The details are fantastic, thankyou so much. I really can start to visualise many of the constructional details. Hidden under the rust at the top of the cylinder I have found the two holes to support the igniter bracket - the studs had been cut off and smoothed down. You can see from my photos that I have drilled and retapped them.

Andrew:

is the exhaust which brings the cooling water and exhaust gases together made of cast iron or gunmetal?

What is the thickness and width of the yoke/timer actuater which goes round the exhaust?

Do you have a photo of what happens to the yoke/timer actuater underneath the exhaust?

Do you have a photo of the throttle valve-what is inside it, a flat plate?

Many thanks again

Richard Bartrop |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2681

Registered: 11-2001

| | Posted on Monday, October 03, 2011 - 07:19 pm: |

|

*

Only reason I understand the word "Gunmetal" Englands word for BRASS, is from restoring antique English Diving equipment and air pumps !

No gunmetal in exhaust!

* |

gregoryan

Senior Member

Username: gregoryan

Post Number: 86

Registered: 09-2004

| | Posted on Tuesday, October 04, 2011 - 10:36 pm: |

|

it look like perhaps the transfer port's original throttle is not included in the photos - and therefore maybe a throttled intake (with a carby/ mixer/ evaporater) was used at some stage instead!

Looks like the intake is under the baseplate -& thru the eng bed!?

thanks 4 showing the Great photos! |

bartropr

Senior Member

Username: bartropr

Post Number: 51

Registered: 06-2006

| | Posted on Wednesday, October 05, 2011 - 10:18 am: |

|

All photos of the engine are obviously without the flywheel.This is currently being bored and bushed (it had many thicknesses of brass shims to remove the bad fit on the crankshaft which is in good order!)

The transfer port's original throttle inside the cylinder control is missing, no doubt following technological improvements e.g. a carburettor as are the water pump and igniter system.

The photos show the chain sprocket has been pulled off by me(sitting on the end of the crankshaft) It was about 0.5” from the round collar with the slots in it. This is a screwed on collar with packing inside to seal the crankshaft end bearing? The gap between the two would be where the eccentric to drive the hit and miss mechanism would go, following the drawing from Gardner Hiscock's 1906 edition. There doesn’t appear to be provision for a thrust race.

Unlike the Lozier that was found (Posted on Friday, November 12, 2010 - 09:35 pm) mine doesn’t have a number stamped on the end of the crankshaft, neither can I find any numbers stamped on the face of the flywheel(very pitted and rusty) as described in the extract from the handbook describing the Lozier Ignition.

Andrew:

Is it possible for you to measure how far the igniter piston'D'moves in one direction? This will give me the throw of the eccentric.

The engine mounting lugs are 4.25" wide which matches the Lozier specification for their 1.5hp engine (as stamped on the makers plate)

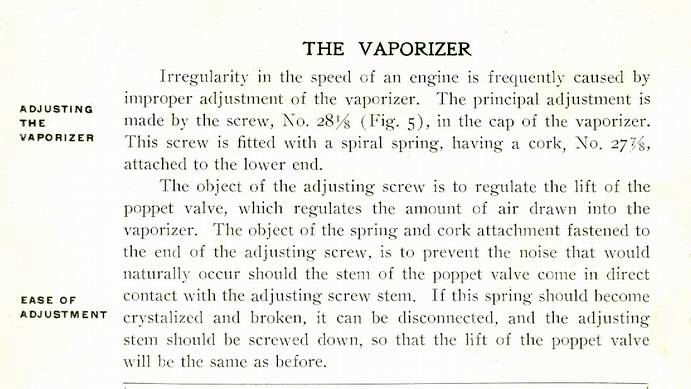

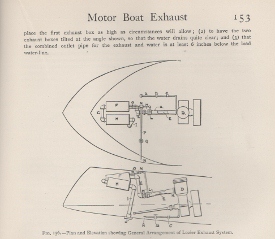

The handbook describes the gasoline running by gravity to a small copper cylinder at the side of the engine. "At the top is a small cup into which the gasoline falls". Heated air passes over it and it vaporises. Any ideas what the mixer would have looked like? Presumably it would be mounted near the crankcase inlet. Would it have had a check valve?

Richard D

Do you have any other views like the "Lozier Aft

Illustration". Is there a list of names to go with the part numbers? Part 14 -the decompression release tap has a wire handle. Are the wire parts available anywhere? All other Loziers seem to have a solid handle, but mine is definitely of this design, and because of its barrel shape is very difficult to wind a coil arond a template as you can't get the template out! What's the secret?

Richard - In the UK Gunmetal is a better quality brass used for castings - like bronze? |

robert

Senior Member

Username: robert

Post Number: 449

Registered: 07-2003

| | Posted on Wednesday, October 05, 2011 - 11:48 am: |

|

Richard, have you been able to trace back the previous owners of this engine? It looks like it must have sat for many years. Sometimes owners take things apart intending to repair them and never get them back together again. Then they pass on or lose interest and the next person does not recognize the significance of the parts and they are not reunited with the engine. Is it possible that the parts you need are still in whatever barn or boatshed etc. this engine was stored in somewhere? |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2683

Registered: 11-2001

| | Posted on Wednesday, October 05, 2011 - 11:56 am: |

|

*

No part descriptions corresponding to numbered engine illustrations ?

Lozier Vaporizer

* |

bartropr

Senior Member

Username: bartropr

Post Number: 52

Registered: 06-2006

| | Posted on Thursday, October 06, 2011 - 11:28 am: |

|

Robert,

I have not been able to find any previous history although Richard Crook the previous owner was informed that the Lozier is belived to have come out of a boat at Henley on Thames, nr London, which could make it an original import.The man he got it from wasn't able to tell him any more, so a dead end here.

A further coincidence is that 'Natalie' a 16' Truscott launch (now in a museum in Munich, Germany)) was used on the Thames in the Henley area most of its life (I have recently spoken to who was possibly the third owner). It didn't have an engine when he got it, but it did have all the original panelling and primitive reversing propeller with long lever,quadrant etc. He fitted the steam plant, using the reversing propellor.

Unfortunately the man he sold it to proceeded to remove some of the panelling and the reversing propellor equipment. This man died a few years ago and all has long been cleared away.Could the Lozier have come from the Truscott? We will probably never know, but my aim is to remake as many of the parts as accurately as possible and install the engine in my 18' Truscott launch.

Richard D

Your further contribution is great - I can't work out what parts 29 etc do at the top of the needle valve, any suggestions? |

robert

Senior Member

Username: robert

Post Number: 450

Registered: 07-2003

| | Posted on Thursday, October 06, 2011 - 12:11 pm: |

|

Interesting Richard, thank you. Please note that it was Richard Durgee who is posting that info and I do believe Richard was the original source of the illustrations I posted as well. With three Richards and Robert on the floor I don't blame you for mixing us up! It sounds like you might have some leads that could be investigated further on the history of boat and engine. I can't make out what No29 does either, or where it fits in.

I would suggest you advertise on Smokstak with these illustrations though, a mixer valve might be out there somewhere. We know how often brass carburetors etc. were scavenged off engines in the past and then sat around for decades afterwards in people's "collections". The Carburetor Shop www.thecarburetorshop.com used to list a huge variety and quantity of antique and vintage carbs in their stock. I see they no longer list their inventory online, probably for "marketing" reasons. Still, they might have what you need. An ad in GEM would be another option. Some more detective work around Henley might be much easier and cheaper though. Good luck! |

bartropr

Senior Member

Username: bartropr

Post Number: 57

Registered: 06-2006

| | Posted on Wednesday, December 28, 2011 - 03:54 pm: |

|

I have been busy with rebuilding my 1902 Lozier, and need help. Have done lots of parts and now I have the cylinder/crancase back from being relined, I can start assembly.

How much movement is needed(in my case provided by the eccentric on the crankshaft) to trip the igniter mechanism. I need to know this to enable me to make the eccentric and strap (both missing) for my Lozier hit and miss engine

|

bartropr

Senior Member

Username: bartropr

Post Number: 58

Registered: 06-2006

| | Posted on Wednesday, December 28, 2011 - 04:29 pm: |

|

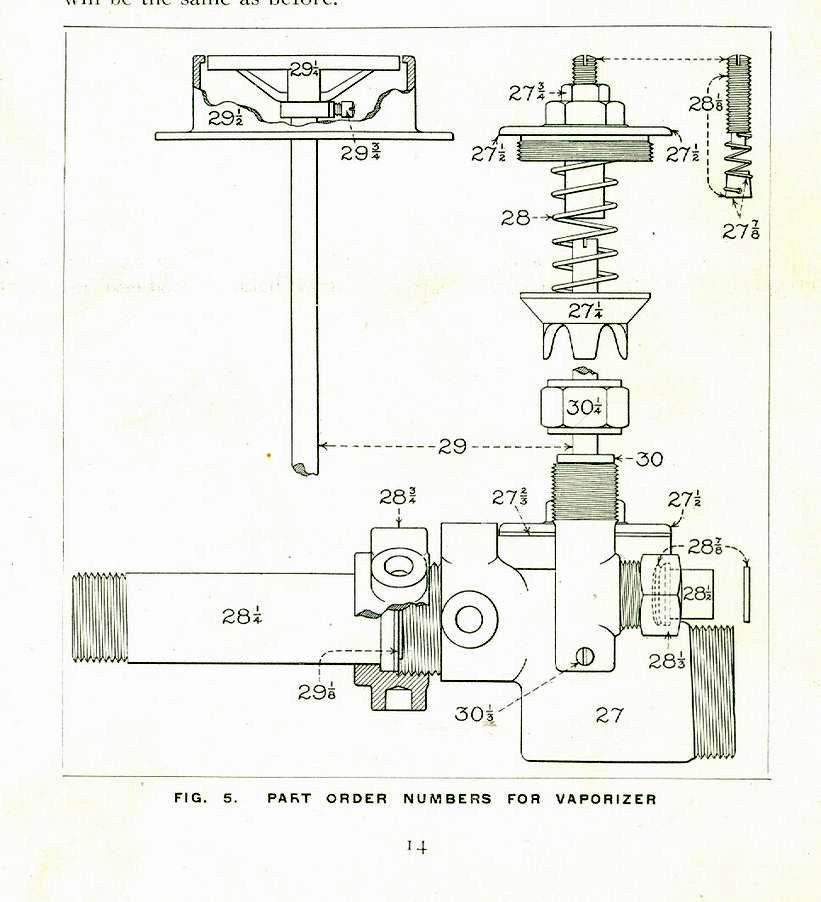

Other parts I have made have included my interpretation of the vaporizer and much more. You can see the petrol feed hole in the seat of the vaporizer body which is closed off each time the check valve seats.

I found the article re Lozier exhaust in Rankin Kennedy "The Book of Modern Engines and Generators Vol 5" The engine illustrtated is a King & Co., of Limehouse London UK

|

bartropr

Senior Member

Username: bartropr

Post Number: 60

Registered: 06-2006

| | Posted on Wednesday, April 18, 2012 - 11:35 am: |

|

An update on recent work. I have managed to make the trip mechanism and the ingniter, and actually got the igniter work to work (mechanically). I am now ready to make the eccentric to drive it all.

New gudgeon pin and little end bush done, so the piston is ready to go back in.Also ready to braze up the water cooled exhaust (a pipe in a pipe) which is shorter than the 24" mentioned in the article in previous post.

|

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2801

Registered: 11-2001

| | Posted on Wednesday, April 18, 2012 - 07:38 pm: |

|

*

Looks Great, You've come a long way toward getting this old engine back to its original

classic form !!

Appreciate the photos,keep them coming !

* |

bartropr

Senior Member

Username: bartropr

Post Number: 63

Registered: 06-2006

| | Posted on Wednesday, August 29, 2012 - 05:35 am: |

|

http://www.oldmarineengine.com/cgi-bin/discus/show.cgi?tpc=1&post=38838#POST38838

It's nearly a year since I had the engine so I thought you may be interested to hear what I have been doing, and my comments below re the attachments.

Yesterday I actually coupled up the eccentric to the ignition mechanism I have made, and by turning the eccentric on the crankshaft �eureka � it works! Got to assemble all the engine now, get a low tension coil from somewhere (any suggestions), and put some petrol in it!

(See previous posts)

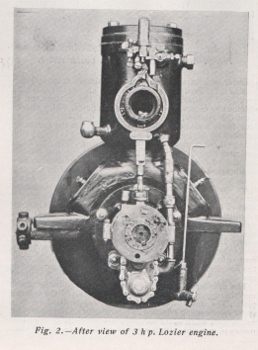

Subject: The Motor boat - Volume 1 1904

Fortunately there is very little difference to how I interpreted the original �spare parts� drawings, but what is strange is that the single cylinder engine is shown in the article with lubricator, pressure release valve (on side of cylinder) and vaporiser � where the round capstan thing is-missing.

The main change is in the �polo mint� ring round the exhaust has a bend in it to allow it to pass over another part of the ignition above it.

When I put mine together I realised there was a problem, so with some difficulty moved the part backwards and added bits to other parts to enable it to function, as there was no indication in anything I had to show the curved/kink . I also couldn�t get it to work with the very short return spring, hence the diagonal one.

|

robert

Senior Member

Username: robert

Post Number: 598

Registered: 07-2003

| | Posted on Friday, September 06, 2013 - 12:50 am: |

|

How's it coming along Richard? |

bartropr

Senior Member

Username: bartropr

Post Number: 66

Registered: 06-2006

| | Posted on Tuesday, September 10, 2013 - 03:24 pm: |

|

Thanks for the enquiry. I've been busy with most of the engine, and have taken it to "offer it up to my Truscott launch in preparation for the cutting, shaping and fixing of the engine bearers. I have also made a bronze tiller, found a five spoke steering wheel for fitting in the bow area, and sorted out a fuel tank and low tension coil. I still haven't tried to start it, so MUST do this!! Searcher was asking about flywheels. This engine is 3.5"bore x 3.5"stroke.

The flywheel is 13" diameter x 4" face, so is very heavy!

Received an award from the Transport Trust here in England at the Brooklands Museum and Race Circuit in the summer in recognition of the work I am doing on the engine and boat.

Will put some photos up of how it all looks now. |

paulgray

Senior Member

Username: paulgray

Post Number: 145

Registered: 05-2003

| | Posted on Wednesday, September 11, 2013 - 11:47 am: |

|

Robert- What is the engine-looking device in the back room of the Thesis picture to the left of the Lozier. Is it a pump or an inverted gas engine? |

robert

Senior Member

Username: robert

Post Number: 601

Registered: 07-2003

| | Posted on Wednesday, September 11, 2013 - 12:01 pm: |

|

I don't know Paul, but there is what appears to be a small marine engine facing towards the camera in front of the device you mention. It could be a larger upright engine that is partially disassembled; in fact I suppose it must be partially disassembled as there is no con rod on the crank. Probably part of the testing and experimentation process that was going on at that time; maybe someone other student's thesis!

Richard, thanks the update. It looks magnificent. |

bartropr

Senior Member

Username: bartropr

Post Number: 72

Registered: 06-2006

| | Posted on Saturday, February 22, 2014 - 12:24 pm: |

|

Getting towards putting the engine in the hull - actually managed to get it running for about a minute. Engine bearers in and frame to mount engine and gearbox on done. Am making couplings for prop shaft etc. once done then can start on the floors, bulkheads, seating etc.

The propeller for the 1.5hp Lozier is stated to be 13" diameter (same diameter as flywheel). It is two bladed and originally would have been reversing. Any suggestion to what the pitch should be? the engine turns at around 450 rpm |

bartropr

Senior Member

Username: bartropr

Post Number: 73

Registered: 06-2006

| | Posted on Sunday, February 23, 2014 - 02:45 pm: |

|

I forgot to post a picture of the engine bearers and frame, so here it is.  . The bearers run across the hull as per the original ones, and then I decided to fix them together with the angle iron frame. This narrows to match the hull as it goes towards the prop shaft. . The bearers run across the hull as per the original ones, and then I decided to fix them together with the angle iron frame. This narrows to match the hull as it goes towards the prop shaft. |

bartropr

Senior Member

Username: bartropr

Post Number: 74

Registered: 06-2006

| | Posted on Sunday, February 23, 2014 - 02:59 pm: |

|

And the engine in its working form

|

robert

Senior Member

Username: robert

Post Number: 644

Registered: 07-2003

| | Posted on Sunday, February 23, 2014 - 04:55 pm: |

|

Well done! Quite a journey. We'll look forward to seeing it in your launch. |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 3237

Registered: 11-2001

| | Posted on Monday, February 24, 2014 - 08:02 am: |

|

*

Hard to imagine this post started 10 years ago,

That's the definition of persistence !

It looks great !

Thanks for the update

* |

miro

Senior Member

Username: miro

Post Number: 743

Registered: 11-2001

| | Posted on Monday, February 24, 2014 - 09:41 pm: |

|

Assuming that your launch will be traveling about 5 mph, and that your prop (typically for this kind of application) would have about 20% slip and your engine is putting out its rated HP at 450 rpm, then a pitch of 12 - 13 in. is about what your should have.

If you find a prop that has 14 in pitch - use it - it will probably be OK.

I would not suggest a prop with a larger diameter though.

Remember that HP = Torque ( ft-lbs) x speed ( rpm) so a lower speed means lower HP.

Since your launch speed is very likely below its terminal speed for a displacement hull ( a function of the square root of length at waterline) you should be OK and your engine doesn't over speed.

My experience has been that it is better to slightly over load an engine than to under load it and end up having to throttle it back to prevent over speed.

I also assume that it will be direct drive (no FNR gearbox) i.e. you start and you go. Leaving the dock is the easy part - it's coming back in that's trickier.

You have to figure out at what speed you want to hit the dock at.

miro

miro |

bartropr

Senior Member

Username: bartropr

Post Number: 75

Registered: 06-2006

| | Posted on Wednesday, February 26, 2014 - 10:01 am: |

|

Thanks Miro, that's really helpful. I had seen a slightly larger prop with the correct pitch you suggest, but will keep looking for one with the correct diameter. Probably will have to buy a new one.

I agree about the slight overloading of the engine. It works well with my other boat 'Diana', stopping the engine from over-revving.

Richard |

bartropr

Senior Member

Username: bartropr

Post Number: 85

Registered: 06-2006

| | Posted on Thursday, March 16, 2017 - 04:58 pm: |

|

Just a picture to show the engine (without flywheel) in the hull |

bartropr

Senior Member

Username: bartropr

Post Number: 98

Registered: 06-2006

| | Posted on Monday, August 03, 2020 - 07:53 am: |

|

I have been busy getting the 1902 Lozier engine which I rebuilt to run smoothly, after I had to take it out of the Truscott, as the chain driven water pump just kept throwing the chain off. I seem to have managed to get it aligned, and all now works well.

https://youtu.be/BmjiSXAI0S4 |

miro

Senior Member

Username: miro

Post Number: 1092

Registered: 11-2001

| | Posted on Tuesday, August 04, 2020 - 10:11 pm: |

|

Looks like it's running steady - that's the thing to get into a boat.

I'm sure that the hull will love that engine - virtually no shaking on the test stand.

miro |

chris_spring

Senior Member

Username: chris_spring

Post Number: 62

Registered: 02-2019

| | Posted on Wednesday, August 05, 2020 - 07:27 am: |

|

Very nice! Well done!

Cheers! |

bartropr

Senior Member

Username: bartropr

Post Number: 99

Registered: 06-2006

| | Posted on Friday, August 07, 2020 - 12:28 pm: |

|

I'm using a Schebler model 'D'carburetor, and have discovered that although the fuel level set by the float is below the main nozzle, the engine only runs really smoothly when I close the needle valve (at the bottom of the bowl) almost completely.

Is this because the float isn't working properly? The carburetor is also getting very cold.

There is no easy adjustment for advance and retard except by rotating the eccentric on the crankshaft. At the moment ignition is virtually at TDC. How far should I advance it to ignite before TDC as I certainly think it should be? |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 1451

Registered: 07-2002

| | Posted on Friday, August 07, 2020 - 08:56 pm: |

|

Can you post detailed pictures of the ignition? Could something be missing? Most ignitors had a provision for adjusting timing. In the factory drawings it looks like a little lever at the top right side. |

bartropr

Senior Member

Username: bartropr

Post Number: 100

Registered: 06-2006

| | Posted on Saturday, August 08, 2020 - 10:09 am: |

|

Hi JB. I thought I had posted three pics yesterday, but they obviously didn't save or post? These four are of the engine, and the last of the ignition as shown in the catalogue and the actual parts before I put them all together.

The lever operates the opening and closing of the points in the cylinder head, so that you can have a greater or smaller gap. The actual timing comes from the eccentric on the crankshaft which converts the rotary motion to vertical motion? I can adjust the position of the eccentric

|

miro

Senior Member

Username: miro

Post Number: 1094

Registered: 11-2001

| | Posted on Saturday, August 08, 2020 - 03:20 pm: |

|

I think your carb is set about right.

I have found that the Schebler works slightly better if you connect it to the top of the carb and the intake is at the side.

I posted pictures of my re-done carb manifold here

http://www.oldmarineengine.com/discus/messages/3433/423885.html

And I found that when running the intake manifold actually has condensation on it. That's good because the fuel is actually vapourizing (not just atomizng) and taking in heat to do so.

It looks like you might have the room to get your carb lower to get better flow from your gas tank.

I think you'll find that once installed in the boat and the engine is under load, you'll need to run with a slightly richer mixture - not much, but some.

If it's too lean , it will backfire.

Instructions - at lest to get it set about right - are here

http://www.oldmarineengine.com/technical/carburetor/scheblerD.html

miro |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 1452

Registered: 07-2002

| | Posted on Saturday, August 08, 2020 - 08:09 pm: |

|

The screw on the left in the picture that the trip arm hits is your timing adjustment. The farther you screw it in the sooner it will trip, advancing the timing. The rocker hits the screw, closing the points. as it continues to rise it trips and the points snap open, the engine fires. If you are going to run the engine in both directions you want the eccentric to fire it near tdc with the screw backed out. Running in both directions near tdc is the latest you can hope for. If you are running in one direction only you can retard the eccentric and fire after tdc. It looks like your scew has a lock nut, I would replace it with a knurled head screw with a tension spring under it, allowing you to adjust timing as you desire. |

bartropr

Senior Member

Username: bartropr

Post Number: 102

Registered: 06-2006

| | Posted on Monday, August 10, 2020 - 06:14 pm: |

|

Thanks for your advice. I will try adjusting the screw while the engine is running and see if it helps.

Regarding fuel flow, the little brass pot on the carb., is just for testing. When in the boat there is a fuel tank under the front deck to supply the carburetor |