| Author |

Message |

klanger

Senior Member

Username: klanger

Post Number: 118

Registered: 03-2012

| | Posted on Sunday, February 18, 2018 - 08:54 pm: |

|

So I've just gotten another project.

As you can see, needs a few parts!

Hopefully something can be sourced in the future.

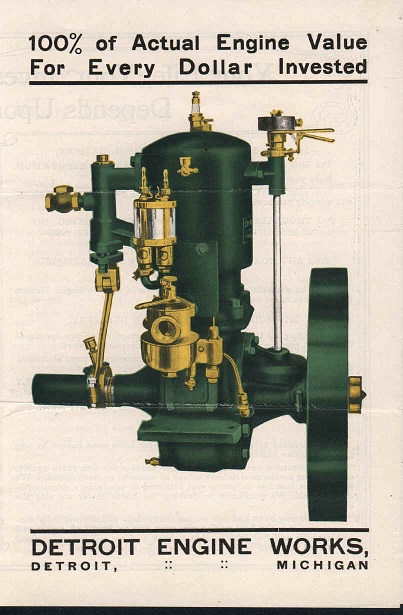

Maybe end up looking like this.

|

klanger

Senior Member

Username: klanger

Post Number: 119

Registered: 03-2012

| | Posted on Sunday, February 18, 2018 - 08:58 pm: |

|

Some more pictures of all I've got.

Its free, turns over and no cracks |

robert

Senior Member

Username: robert

Post Number: 940

Registered: 07-2003

| | Posted on Wednesday, February 21, 2018 - 06:53 pm: |

|

If it takes a Lavigne two feed oiler I can supply one of those. At least you got the tag and fresh water cooled. If you can't find the flywheel wherever the engine came from, there's bound to be another somewhere in this world from an engine that suffered the death of a thousand salts. |

ernie

Senior Member

Username: ernie

Post Number: 2448

Registered: 01-2002

| | Posted on Wednesday, February 21, 2018 - 07:07 pm: |

|

I think I have a flywheel.

I will get dimensions for you in the next few days

Ernie |

klanger

Senior Member

Username: klanger

Post Number: 120

Registered: 03-2012

| | Posted on Wednesday, February 21, 2018 - 09:25 pm: |

|

Hi Robert,

For whatever reason, it seems that a few of the American engines imported down here were used as stationary engines cooling with fresh water,rather the marine engines. This of course saved them from the death of a thousand salts, as is typical down here as well. Not many 100+ year old survivors here.

HI Ernie,

Thank you that would be helpful.

From what I've been able to find out is that it probably about 3 - 4 HP, until I pull the pot and measure the bore, wont know to be sure.

Now if any one has a water pump and strap, shaft coupling, timer, bevel gears for the timer etc.. might just get er done.

Regards

Kev |

klanger

Senior Member

Username: klanger

Post Number: 121

Registered: 03-2012

| | Posted on Saturday, February 24, 2018 - 01:26 am: |

|

Hi Robert,

Please email me details of you want for the oiler.

Let's see what we can work out.

Regards

Kev |

johnny

Senior Member

Username: johnny

Post Number: 579

Registered: 03-2006

| | Posted on Monday, February 26, 2018 - 05:30 am: |

|

Nice looking little Detroit engine. Trick photography because at some point the cylinder magically rotated 180 degrees on the crankcase in between photo's. If I come across any parts I will let you know. |

klanger

Senior Member

Username: klanger

Post Number: 124

Registered: 03-2012

| | Posted on Monday, February 26, 2018 - 08:38 pm: |

|

Hi Johnny,

No trickery, just an illusion because it doesn't have a fly wheel

Kev |

robert

Senior Member

Username: robert

Post Number: 946

Registered: 07-2003

| | Posted on Monday, February 26, 2018 - 11:06 pm: |

|

Email sent Kevin.

Krice carb(?) in the same illustration; not sure where you'll find one, but they are out there. One of our more senior members will know exactly which model they used. |

johnny

Senior Member

Username: johnny

Post Number: 580

Registered: 03-2006

| | Posted on Friday, March 02, 2018 - 07:04 pm: |

|

You are correct just an illusion. When I get a chance I will look and see what model Krice carb is on mine. |

klanger

Senior Member

Username: klanger

Post Number: 125

Registered: 03-2012

| | Posted on Tuesday, March 13, 2018 - 06:36 am: |

|

So I think I have a potential flywheel I can use, but need to know whether it's feasible to have it bored and sleeved to suit the required shaft size? The flywheel currently has a tapered bore.

Kev |

johnny

Senior Member

Username: johnny

Post Number: 585

Registered: 03-2006

| | Posted on Tuesday, May 01, 2018 - 08:51 am: |

|

You could bore the flywheel and put a heavy sleeve in it but flywheel, sleeve & crankshaft would need to be keyed together. Does the flywheel have balance holes in it? Probably will have to be re-balanced to your piston. Although the early Detroit's were not balanced at all and jumped around pretty good. |

robert

Senior Member

Username: robert

Post Number: 957

Registered: 07-2003

| | Posted on Thursday, May 03, 2018 - 11:40 pm: |

|

How's that Lavigne working out for you? As for the flywheel, your best bet might be to have one cast. If someone could send you the measurements you could probably turn up a pattern on a wood lathe and get one cast. Turning one from steel would be another option. With the plasma and waterjet cutting facilities we have these days, things like the holes in the wheel would be pretty easy to cut out. Steel is also the safest option of course. |

klanger

Senior Member

Username: klanger

Post Number: 127

Registered: 03-2012

| | Posted on Friday, May 04, 2018 - 06:14 am: |

|

Hi Rob, email sent.

Still weighing up options for the flywheel and other bits and bobs needed.

Kev |