| Author |

Message |

scott_n

Senior Member

Username: scott_n

Post Number: 264

Registered: 02-2008

| | Posted on Wednesday, April 06, 2016 - 01:21 pm: |

|

First let me say you are better working around the flywheel instead of removing it  this will work well with tapered shaft. Clean nut with wire brush and heat using a candle press it ageist the nut till it starts to melt and almost smoke this will work well with tapered shaft. Clean nut with wire brush and heat using a candle press it ageist the nut till it starts to melt and almost smoke |

scott_n

Senior Member

Username: scott_n

Post Number: 265

Registered: 02-2008

| | Posted on Wednesday, April 06, 2016 - 01:31 pm: |

|

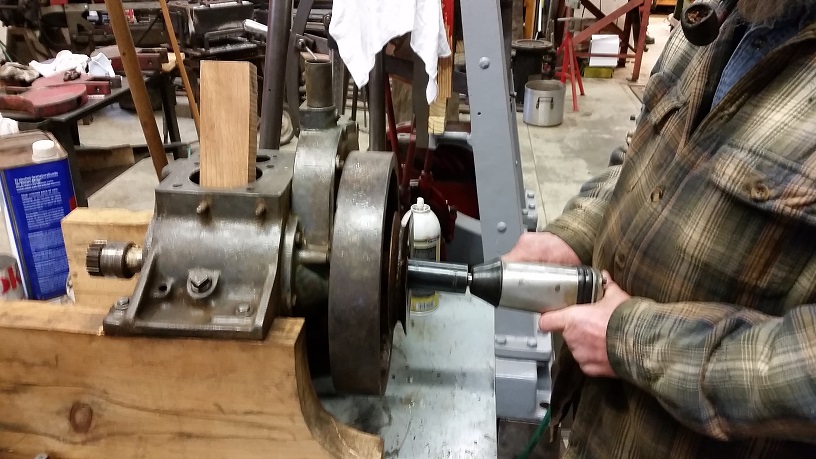

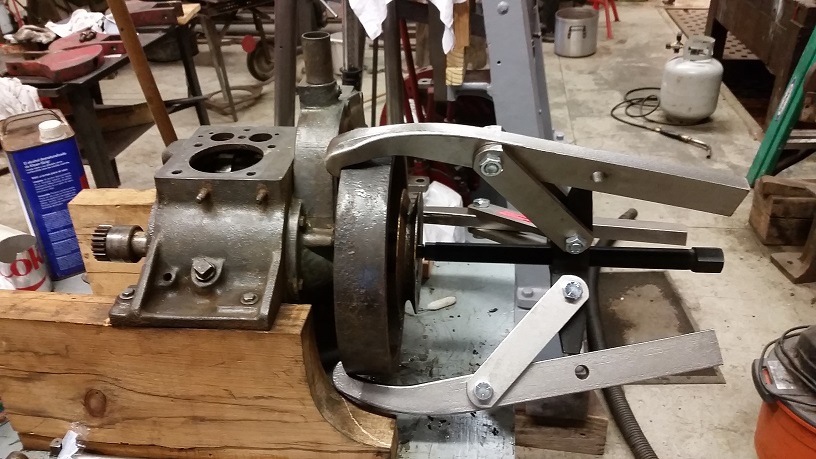

if it is a tough one a impact gun works well if it is a tough one a impact gun works well   then with a big puller lode flywheel with presser then with a big puller lode flywheel with presser  and tap the end of puller and tap the end of puller |

scott_n

Senior Member

Username: scott_n

Post Number: 266

Registered: 02-2008

| | Posted on Wednesday, April 06, 2016 - 01:51 pm: |

|

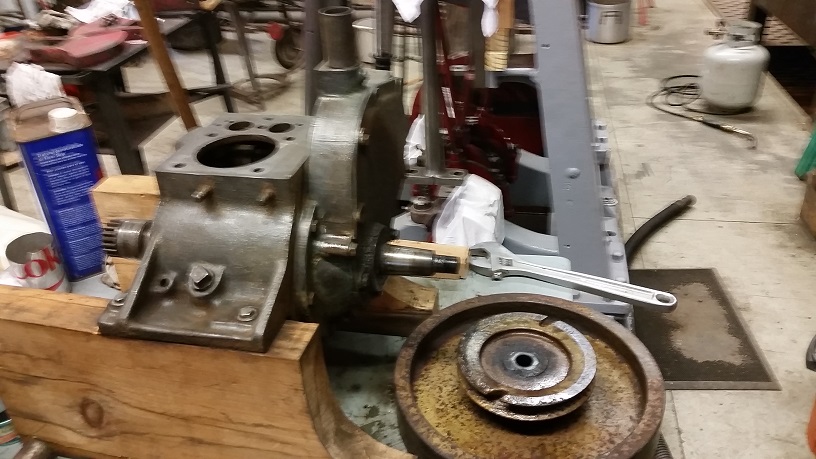

Note a big puller is not recommend for the out side of spooked flywheels. And if you don't have a big puller a good square rap with a hammer using a nut at the end of the threads should work. Just like JB sad on a tapered shaft. And if you have the weight of the engine is supporter you don't have to worry about bending the crankshaft. |

scott_n

Senior Member

Username: scott_n

Post Number: 267

Registered: 02-2008

| | Posted on Wednesday, April 06, 2016 - 01:55 pm: |

|

Then off to the electrologist bath for cleaning.  |

narrabay

Senior Member

Username: narrabay

Post Number: 65

Registered: 02-2016

| | Posted on Wednesday, April 06, 2016 - 02:19 pm: |

|

Thanks Scott, and those are great shots! I think the nut wont be an issue, its clean and not rusted . A big puller, heating the hub a little and care it will either pop, or not. I dont intend to push the issue. But in my experience (my first teenaged job was working on salt water outboards), they either pop, or they dont, and they usually do. |

scott_n

Senior Member

Username: scott_n

Post Number: 268

Registered: 02-2008

| | Posted on Wednesday, April 06, 2016 - 03:02 pm: |

|

this type of cleaning will only leave the clean iron behind and not remove any of the artifact. like blasting or grinding and will only need a light wire brushing to prep for paint. Remember this process only works line of site the cathode has to sea the anode.and will not go behind studs or threads like wax or penetrating oil. this type of cleaning will only leave the clean iron behind and not remove any of the artifact. like blasting or grinding and will only need a light wire brushing to prep for paint. Remember this process only works line of site the cathode has to sea the anode.and will not go behind studs or threads like wax or penetrating oil. |

ernie

Senior Member

Username: ernie

Post Number: 2252

Registered: 01-2002

| | Posted on Wednesday, April 06, 2016 - 03:19 pm: |

|

Scott,

Your were lucky! Pulling like that is the best and easiest way to ruin any flywheel spokes or not!

Narrabay Do NOT ever heat any part of the flywheel as cracks in the hub are almost always the outcome.

Hope this helps

Ernie |

ernie

Senior Member

Username: ernie

Post Number: 2253

Registered: 01-2002

| | Posted on Thursday, April 07, 2016 - 07:15 am: |

|

By the way this is a safety issue. It is the cracks you don't see that get you. |

narrabay

Senior Member

Username: narrabay

Post Number: 66

Registered: 02-2016

| | Posted on Thursday, April 07, 2016 - 11:14 am: |

|

thanks ernie. interesting. would you use a big puller? how would you approach, no heat, puller, light rap on the center bolt? remove crankshaft and use a press? what woukl you say is best approach?

thanks! |

narrabay

Senior Member

Username: narrabay

Post Number: 67

Registered: 02-2016

| | Posted on Thursday, April 07, 2016 - 07:03 pm: |

|

oops just read the part where ernie says

NO HEAT

NO PULLER

So still looking for what Ernie you would do in your shop to get flywheel off...

thanks!

}}} |

marion

Member

Username: marion

Post Number: 14

Registered: 03-2013

| | Posted on Thursday, April 07, 2016 - 08:11 pm: |

|

Consider using the puller not to pull on the flywheel, but only to align the pulling screw with the crankshaft. Adjust the puller until the puller is snug and the pulling screw is straight with the tapered portion of the crankshaft. For several days, periodically squirt BP Blaster at the shaft flywheel junction and wait for chemistry to work. When you�ve run out of patience, wack the head end of the screw with a large hammer, e.g., 5 lbs. The impulse produced will result in the flywheel and puller landing in a jumbled pile.

An analogous approach was used a century ago on Model T Fords to remove rear wheel hubs from tapered drive shafts. |

narrabay

Senior Member

Username: narrabay

Post Number: 68

Registered: 02-2016

| | Posted on Thursday, April 07, 2016 - 10:38 pm: |

|

thanks marion. sounds like your suggesting LIGHT but constant pressure from a puller with PB soaking into the joint for a long period of time...

also hopefully Ernie will chime in with his approach too... |

johnoxley

Senior Member

Username: johnoxley

Post Number: 156

Registered: 04-2010

| | Posted on Friday, April 08, 2016 - 06:28 am: |

|

Noting taper on this shaft looks fairly steep, hence flywheel was released OK. From grim personal experience I once ruined a flywheel that was mounted by a shallow (Morse?) taper. Did not support close to shaft, rather at rim. Took 16 tons + heat to push crankshaft out of rusted flywheel but flywheel hub was distorted and unusable. Next time arranged heavy contrivance to grip at boss. Still took 16 tons but flywheel and shaft undamaged. |

scott_n

Senior Member

Username: scott_n

Post Number: 269

Registered: 02-2008

| | Posted on Friday, April 08, 2016 - 08:21 am: |

|

Ernie Thanks for pointing that out please note in my first picture we are only heating the frozen nut on the out side of the starter pulley and not the flywheel. the flywheel came off with light presser and a light tap on the end of puller. Yes the first two pictures could have bin deceiving. |

scott_n

Senior Member

Username: scott_n

Post Number: 270

Registered: 02-2008

| | Posted on Friday, April 08, 2016 - 08:22 am: |

|

|