| Author |

Message |

rbprice

Senior Member

Username: rbprice

Post Number: 528

Registered: 11-2001

| | Posted on Tuesday, September 22, 2015 - 09:04 pm: |

|

The bevel gear shown is not from a marine engine but is illustrative of what can be done with today's 3D printing technology. The 25T, 8DP, gear was originally a Zamac die casting well known for it propensity to fail under load. The replacement gear is made from glass fiber reinforced nylon 6/6 which has approx. 1/3 the material properties of 6061-T6 aluminum.

} } |

david_doyle

Advanced Member

Username: david_doyle

Post Number: 42

Registered: 03-2013

| | Posted on Tuesday, September 22, 2015 - 09:26 pm: |

|

Yeah this 3d printing is going to revolutionize restoration/repair.

Have not seen anyone advertising on this continent but I know you can send a file off to India or china and have castings made/machined.

Near as I Can tell our 'maker" revolution with consumer grade printers puts us about 10 years behind the average junior high school trade school over seas. I for one am encouraging my kids to learn to think in X, Y, Z. |

alaskanrocket

Member

Username: alaskanrocket

Post Number: 9

Registered: 09-2012

| | Posted on Wednesday, September 23, 2015 - 01:52 pm: |

|

I agree with you David, my issue is unless people are ok with plastics, Im not sure it will be a huge help to old engines hobbies. Im also afraid that it won't much matter because the interest in such things is starting to die off. Im only 32 and have been collecting for most of my life and haven't met one other person my age or younger interested in this stuff. Granted I do live in Alaska and im sure there is much more youth involvement in the states but I still wonder where my engines will go and who will care for them after I pass away. |

david_doyle

Advanced Member

Username: david_doyle

Post Number: 43

Registered: 03-2013

| | Posted on Wednesday, September 23, 2015 - 02:38 pm: |

|

My thought was that the plastic would be used as a pattern to send to the foundry.

In a few decades once I can turn a 1/4 inch bolt on my lathe and temper a spring with my torch I'll try and learn some of that new fangled stuff.

Yours in Luditery

D |

rbprice

Senior Member

Username: rbprice

Post Number: 530

Registered: 11-2001

| | Posted on Wednesday, September 23, 2015 - 02:58 pm: |

|

Yes to that notion David - only caveat is getting the shrinkage factor correct. And to get a good involute profile, the teeth should be hobbed or shaped or at the very least cut with an involute profile cutter on a dividing head.

When I sent out RFQ's to some gear cutting companies that I deal with, I got prices ranging from US$800 to US$385 for cutting it in aluminum. The polymer gear cost $135 and since the washing machine will only run 20 hours or so each year it should last. |

blue_pearl

New member

Username: blue_pearl

Post Number: 1

Registered: 12-2012

| | Posted on Wednesday, September 23, 2015 - 06:19 pm: |

|

I am a relatively new owner of what I think is a 1906 Gray. I plan to refurbish as a display piece. I have been following this blog site for a couple of years now learning about these types of engines. It amazes me how much knowledge and passion you folks have for restoring these cool old engines. This post caught my interest and I thought I'd contribute since it is a topic I know a little about. This is my first post, so, I apologize in advance if I'm not doing it correctly.

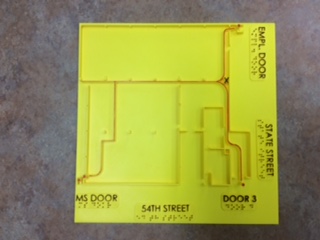

The company I run has a 3D printer and my background is engineering. The printer we have prints a ABS-like material, (similar to the case on our cell phones). It is a relatively tough material. However, it's not a reinforced engineered plastic. I doubt, for example it would hold up as a water pump gear. It might hold up as a distributor shaft gear since I assume the loads are much lower. As someone pointed out, a 3D printed part, could be used as a sand-casting pattern. Or, you could make a plaster mold from it. It is capable of printing almost any geometry. (I think) I attached a couple photos of parts we've printed. If you have a 3D solid CAD model it is very easy to print a physical plastic part. There is laser scanning technology out there to sort of reverse engineer parts. With a scanner you'd be able to scan a physical part, turn that "cloud" of points into a CAD model, and then reproduce it as a 3D printed part. Unfortunately, we don't have a scanner as yet. If anyone has a CAD model that they would like 3D printed, I'd be happy to do it for you.

|

david_doyle

Advanced Member

Username: david_doyle

Post Number: 44

Registered: 03-2013

| | Posted on Wednesday, September 23, 2015 - 07:29 pm: |

|

IIRC there is software to figure shrinkage on files. I.e scan the part to produce a file and the computer figures out how much to resize it (based on methods/materials) so that the printed 'pattern' can be used in a casting process and produce an exact replica.

3D scanners are getting pretty cheap.

I got left behind on alot of this stuff by buying MAC computer, no one writes useful software for it

15 year old boat design software still runs on my windows 98 dell but beyond chined boats I can't 3D anything. (probabley for the best) |

rbprice

Senior Member

Username: rbprice

Post Number: 531

Registered: 11-2001

| | Posted on Thursday, September 24, 2015 - 07:52 am: |

|

Hello Blue Pearl - what other types of materials can you work with on your 3D printer? I have another project that may need to use carbon fiber impregnated nylon to get the needed strength. And where are you located?

Thanks

Bob Price |

blue_pearl

New member

Username: blue_pearl

Post Number: 2

Registered: 12-2012

| | Posted on Thursday, September 24, 2015 - 11:22 am: |

|

Bob:

My name is Jim Kerlin and I'm located in Milwaukee. Ours is a FDM (Fuse Deposition Modeling) machine. It is kind of like a cross between an ink jet printer and a hot glue gun. It is designed to run ABS material. We can do several colors (e.g. whit, black, red, blue, green) only one color at a time.

Your question intrigued me. I am checking, but, I don't think our machine will build parts in nylon. From some online research I found there are machines out there that do run nylon. There are also printer feed stock filament sources that include carbon fiber alloyed nylon.

If you want to pursue your application further I'd recommend you contact a company that specializes in making 3D printed prototypes. They are most likely to have the greatest choices of materials. There are many such sources. One in Wisconsin that I know of is IPPD.

Jim |

blue_pearl

New member

Username: blue_pearl

Post Number: 3

Registered: 12-2012

| | Posted on Thursday, September 24, 2015 - 11:35 am: |

|

Bob:

Sorry. That 3D prototyping house was actually http://www.adcinc1.com/index.html

Jim |

blue_pearl

Member

Username: blue_pearl

Post Number: 4

Registered: 12-2012

| | Posted on Thursday, September 24, 2015 - 11:39 am: |

|

Bob:

Here's contact information:

Advanced Design Concepts, Inc.

N27 W23655 Paul Road

Pewaukee, WI 53072-5793

Phone: 262.523.1010

Fax: 262.523.1011

Mark Schaefer, President

Phone: 262.523.1010 Ext. 206

Cell: 414.405.4066

Pager: 414.222.1969

E-mail: [email protected]

Jim |

alaskanrocket

Member

Username: alaskanrocket

Post Number: 10

Registered: 09-2012

| | Posted on Thursday, September 24, 2015 - 12:05 pm: |

|

I don't know much about 3D CAD programs or 3D printing but after the trouble of drawing it in CAD, 3D printing, making a plaster mold, then casting it, then machining the cast part. Wouldn't it be a lot easier to just machine it from stock based off of measurements?? Maybe the process isn't as difficult as I'm picturing it to be. |

rbprice

Senior Member

Username: rbprice

Post Number: 532

Registered: 11-2001

| | Posted on Thursday, September 24, 2015 - 08:56 pm: |

|

Thanks for the info Mark -

As for the economics of the 3D printing process, like so many things, it depends on what your goal is and what equipment you have. On one end is the toy stuff that has the value of at least exposing kids to the concept. On the other end of the scale are flight worthy compressor blades for both GE and P&W engine.

From the antique engine viewpoint, as I have mentioned there are several part on several of my engines that are do a good job replacing low stress parts with both glass and carbon fiber reinforced nylon. The carbon fiber stuff is 3X more expensive than the glass filled but less expensive than a machined casting or a machined from a block of steel part. Using 3D printing to make a pattern, when you need to make several of the same parts makes sense if the final part is subject to high stresses > 10,000 psi yield. And the nice thing is when combined with CAD, the communication of the final intent is readily transmitted to the final manufacturing facility. } |