| Author |

Message |

warrene77

New member

Username: warrene77

Post Number: 1

Registered: 04-2013

| | Posted on Sunday, August 16, 2015 - 09:12 pm: |

|

Hello All,

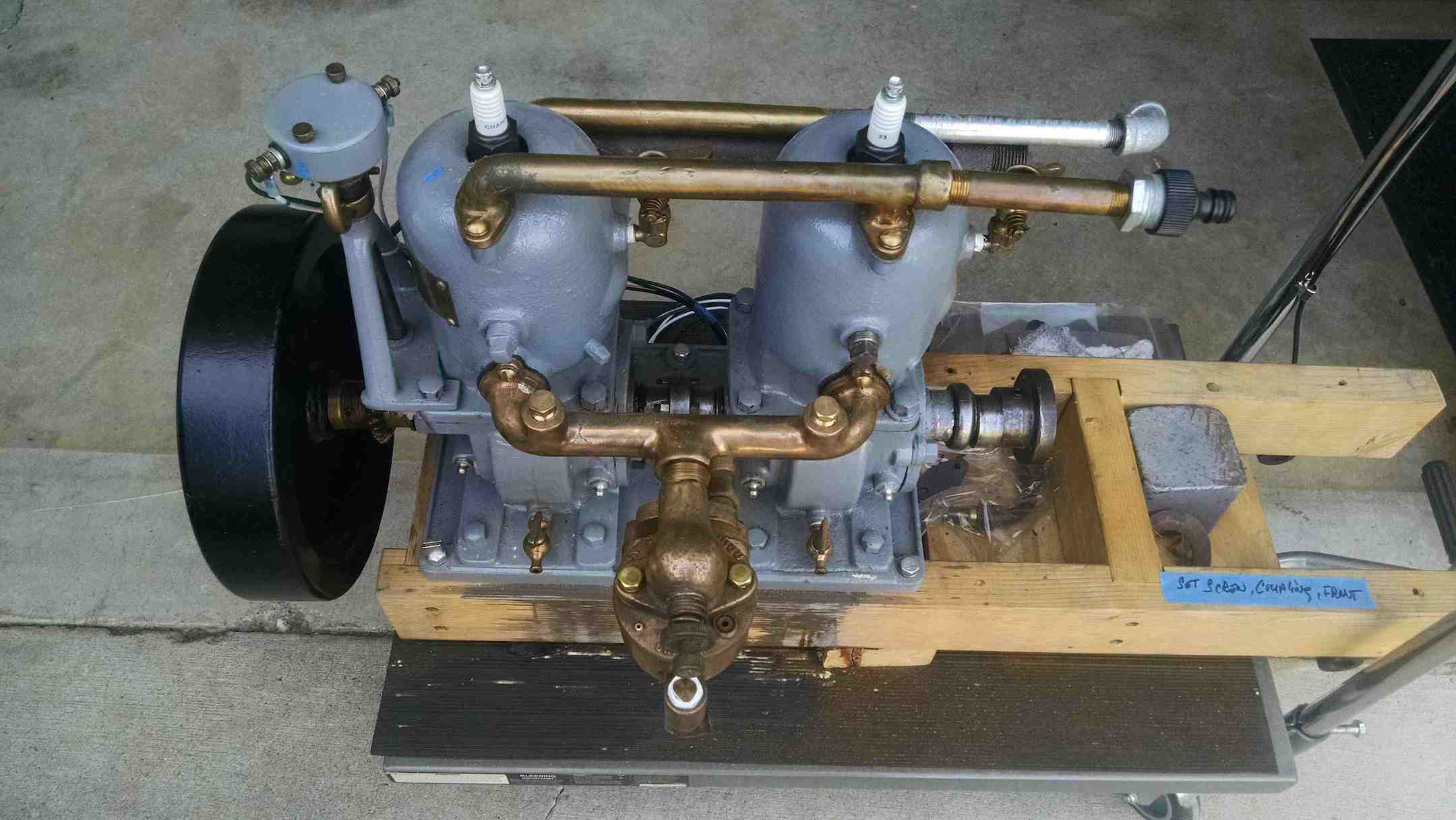

I have a Gilmore-Cragg twin cylinder 2 stroke, 3 port marine engine that I want to get running.

The engine was complete except for carburetor and spark plugs when I got it.

I've never had a 3 port engine but I do have a Gray, 2 stroke, 2 port marine engine that runs well.

When I first got the engine I took it completely apart, cleaned and re-assembled it.

Comments regarding re-assembly follow:

Replaced piston rings.

Broke original rings while removing them.

Replaced Spark Plugs.

Champion 25

Spacers to prevent piston striking plugs

Got and installed a 3/4" Acadia carburetor (similar to Schebler) and did not install a check valve

Assembled a dual buzz coil ignition box.

Set the Timer to fire spark plugs approximately 10 degrees after TDC for clockwise rotation (viewed from flywheel end). Plugs fire OK.

Pistons are off-set 180 degrees.

Greased crankcase bearings.

Crankshafts appear straight.

Closed crankcase drain petcocks.

Carburetor set to admit air to cylinders.

I can't even get an explosion by putting fuel in the cylinders via the primer cups.

I think my first problem is that the engine is too "tight" which causes failure to produce adequate compression. I'll remove cylinders and pistons, check crankshaft(s) alignment, try to get a free spinning crankshaft and then put things back together (one thing at a time) and try to eliminate "tightness".

I tried to post a picture but couldn't get it small enough.

I would appreciate any advice!

Thanks, Warren |

warrene77

New member

Username: warrene77

Post Number: 2

Registered: 04-2013

| | Posted on Monday, August 17, 2015 - 05:52 pm: |

|

Took engine apart and all was well. Flywheel and crankshaft(s) spin fairly freely. Put pistons and cylinders back and engine spins fairly freely as long as spark plugs out and crankcase drains open. Tight with spark plugs in and drains closed so I must think tightness due to compression. I'll get a proper "O" ring or gasket for carburetor and give another try at starting.

Any advice greatly appreciated!

Thanks, Warren |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 1085

Registered: 07-2002

| | Posted on Monday, August 17, 2015 - 08:06 pm: |

|

Warren, be sure you didn't put the pistons in backwards, deflector goes away from the exhaust. Most of the replacement rings are too thick, increasing wall pressure and drag, we usually have to bore the inside to reduce tension. Are the plug wires on the correct cylinder? Are these tapered pipe spark plugs? Why the spacer? If the the plugs are recessed into the threaded area it will be hard to fire the engine. |

warrene77

New member

Username: warrene77

Post Number: 3

Registered: 04-2013

| | Posted on Monday, August 17, 2015 - 09:47 pm: |

|

Thanks JB.

I'll double check deflectors. Plug wires are on correct cylinders. Spacers are to keep pistons from striking plugs. I'll check plugs for tapered threads. I'll ask about amount to bore cylinders if next start attempt fails. (I've had a "tight" engine fail to start in the past!)

Thanks again,

Warren |

david_doyle

Advanced Member

Username: david_doyle

Post Number: 38

Registered: 03-2013

| | Posted on Tuesday, August 18, 2015 - 12:05 am: |

|

Warren, I read JBs post as boring the inside of the rings not the cylinder (?). Not sure exactly how that is accomplished but makes sense to leave material on the permanent part (cylinder) and remove it from the consumable bit.

If it spins free with the plugs out I'd look elsewhere.

The buzz coil box you built are we sure it produces spark under compression? No boom with fuel direct in the cylinders with compression seems like a spark problem.

Any luck with the pics?

FYI I am the least knowledgeable fellow on here so everything above is worth about what was paid. |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 1086

Registered: 07-2002

| | Posted on Tuesday, August 18, 2015 - 04:25 pm: |

|

The second to last picture in the link below show's boring the rings.

http://www.oldmarineengine.com/discus/messages/5/3051.html |

warrene77

Member

Username: warrene77

Post Number: 4

Registered: 04-2013

| | Posted on Tuesday, August 18, 2015 - 08:59 pm: |

|

Thanks again JB.

Rings being too thick and having too much wall pressure sounds to be the most likely problem.

There is definitely no bounce in this engine! Do you have any estimate of the cost to bore them and who can do it?

Thanks,

Warren |

warrene77

Member

Username: warrene77

Post Number: 5

Registered: 04-2013

| | Posted on Tuesday, August 18, 2015 - 09:33 pm: |

|

Thanks David, I missed the concept of boring the rings...I can be very thick and I'm not very experienced.

I'll test the buzz coils for spark on an engine that I know will run.

I'm hoping my wife's camera can take pictures small enough to post.

Thanks, Warren |

david_doyle

Advanced Member

Username: david_doyle

Post Number: 39

Registered: 03-2013

| | Posted on Wednesday, August 19, 2015 - 12:19 am: |

|

Jb, great thread you posted a link to. I saved it as a pdf. Pure gold. Still in the setting up phase with my little lathe but look forward to the day I can have such command of round things!

Warren, If you can't resize the pics on your comp send them to me in an email and I'll post them for you. ( I was being selfish asking for pics so if it is too much trouble ignore the bother)

If nothing else comes along you could try contacting Otto Gas Engine Works for help with the rings. I have no experience with them but I visit the site once and a while just to relish in the possible! |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 1087

Registered: 07-2002

| | Posted on Wednesday, August 19, 2015 - 09:35 am: |

|

Thanks. If you can't find someone local to handle your rings, send them to me along with a sample of the old one if you still have it. Check for side clearance between the ring and piston land, this will tell if the piston is worn, .005" or less OK. I take pictures with my phone, email them to myself in medium resolution and generally post with no problems. |

david_doyle

Advanced Member

Username: david_doyle

Post Number: 40

Registered: 03-2013

| | Posted on Wednesday, August 19, 2015 - 06:47 pm: |

|

Thanks for sharing Warren, she certainly is handsome.

}}} }}} |

warrene77

Member

Username: warrene77

Post Number: 6

Registered: 04-2013

| | Posted on Wednesday, August 19, 2015 - 07:53 pm: |

|

I spoke with Dave Reed of Otto Gas Engine Works today and he will bore the piston rings .030" for me. (I lived in Md. before I retired and moved to S.C. and have dealt with Dave in the past - very good guy!) I'll mail them tomorrow.

Meanwhile:

The pistons are oriented so that the deflectors are away from the exhaust.

The spark plug electrodes protrude 1/4" into the cylinders.

The pistons do not appear to be worn.

My phone takes pictures of 3.32 MB and I don't know how to reduce resolution. When I use the re-size application in my computer, the smallest I get the picture is 780 KB. Another thing to learn!!!

Thanks Gents. I truly appreciate the help.

I'll resume this thread when I get the rings back and installed.

Warren |

warrene77

Member

Username: warrene77

Post Number: 7

Registered: 04-2013

| | Posted on Saturday, September 05, 2015 - 04:12 pm: |

|

I installed the new piston rings which were bored .030". The engine is still too "tight" to start.

I'll put this one at the back of the line until I can get means to (power)rotate it so as to get it "limbered up".

Meanwhile, I have a twin Gray that I'll try to get running. |

david_doyle

Advanced Member

Username: david_doyle

Post Number: 41

Registered: 03-2013

| | Posted on Saturday, September 05, 2015 - 04:47 pm: |

|

Once the twin is running you'll have the perfect means to limber it up!

Thanks for sharing your projects. Looking forward to learning abit more about Gray engines. |