| Author |

Message |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 725

Registered: 07-2002

| | Posted on Tuesday, October 02, 2012 - 09:21 pm: |

|

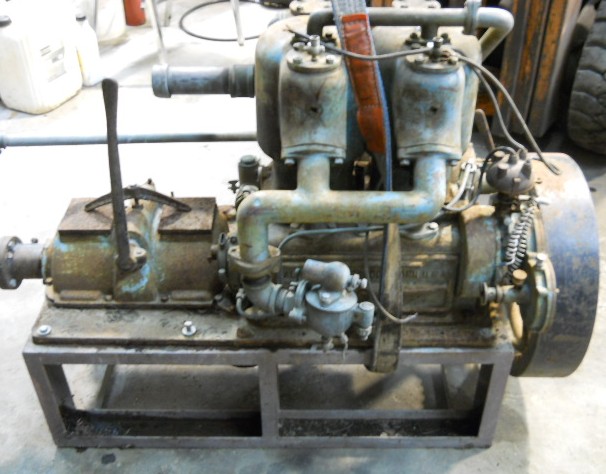

I brought this one home Sunday. It's a 1922 model Palmer RW-2, Dick Day says there's only a couple of known survivors. This one is going to need some cylinder work, salt took it's toll, but George Coates set the bar a lot higher than this with the Barker, so I'll give it a try. I took the cylinders off, going to cook them to try to prevent any further damage. This engine is similar to an NR-2, bigger bore, 12-14hp. |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 726

Registered: 07-2002

| | Posted on Tuesday, October 02, 2012 - 09:26 pm: |

|

|

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 727

Registered: 07-2002

| | Posted on Tuesday, October 02, 2012 - 09:31 pm: |

|

|

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 728

Registered: 07-2002

| | Posted on Tuesday, October 02, 2012 - 09:37 pm: |

|

Things Dick questioned me about were did the cylinders have flats where they meet, flywheel attached with right or left hand threads, it's gibb key, did the water pump have built in check valves. |

qwilkin

Senior Member

Username: qwilkin

Post Number: 76

Registered: 08-2009

| | Posted on Wednesday, October 03, 2012 - 12:19 am: |

|

jb I would like to cook a pair of Blaxland cylinders what is your process please , I have some processes used in Australia and would like to compare

Love the engine and comes with a gearbox thats a bonus

Regards Quinton |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 729

Registered: 07-2002

| | Posted on Wednesday, October 03, 2012 - 06:03 am: |

|

Thanks Quinton, the cylinders will be heated to about 1000 degreesF, kept there an hour or so and cooled slowly, repeat several times. Above 900 degrees the hard rust breaks down and crumbles to a powder. Once the welding is done, the inside will be sealed with an epoxy sealer. I have a 10kw electric kiln, 3 phase, but I haven't wired it up or tried it. We heated another cylinder in a homemade furnace, I have a pallet of fire bricks and some propane burners we made. The fire bricks are stacked to form an oven, holes left for the burners, directed to the cylinder, sheet metal shelving forms the roof. After heating we cover the cylinders with fiberglass insulation and allow to cool. |

seagal007

Member

Username: seagal007

Post Number: 14

Registered: 07-2012

| | Posted on Wednesday, October 03, 2012 - 06:19 am: |

|

I took the jugs from my old Hicks to a foundry to cook them and have the cracks welded. The process worked well but they did get warped and I had to have the cylinders sleeved. Thats a great old Palmer. I would enjoy seeing updates as you restore it. |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 732

Registered: 07-2002

| | Posted on Wednesday, October 03, 2012 - 08:33 pm: |

|

I hope I don't have to do any internal welding on these, but the heat treatment alone can be punishing. If they need sleeving that shouldn't be a problem. |

seagal007

Member

Username: seagal007

Post Number: 15

Registered: 07-2012

| | Posted on Wednesday, October 03, 2012 - 09:28 pm: |

|

Usually its just the outer jackets that need welding but you may have to sleeve the cyls when done. |