|

| Author |

Message |

J.B. Castagnos

| | Posted on Monday, December 29, 2003 - 10:48 pm: |

|

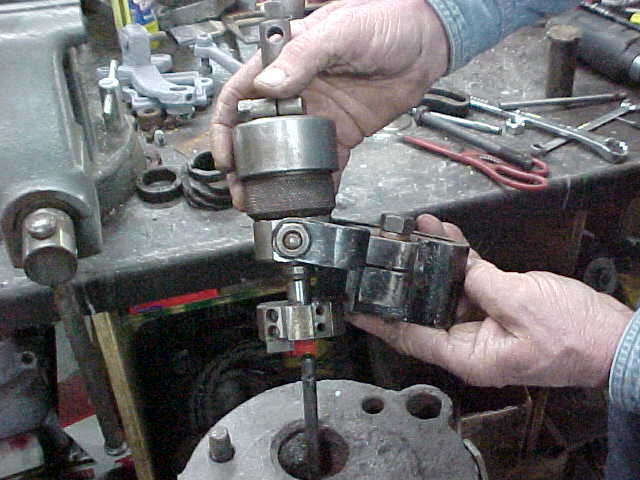

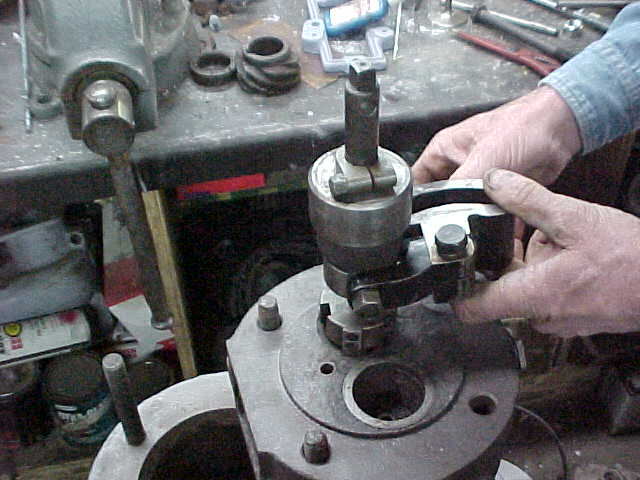

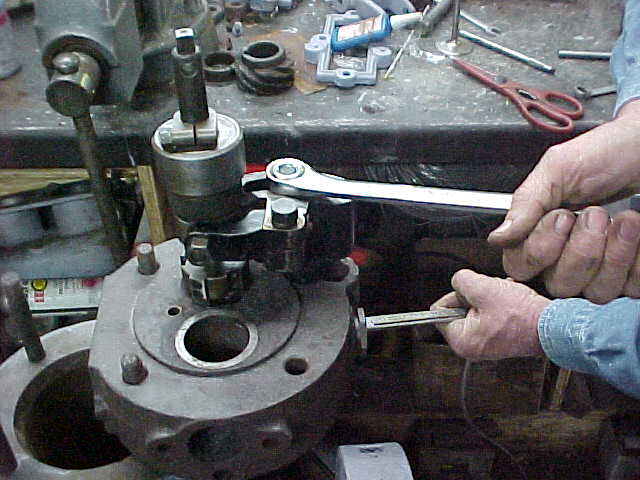

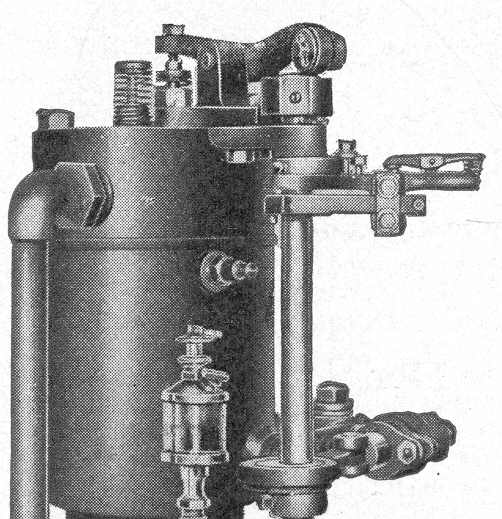

The Fisherman came apart better than I thought it would, had to use the torch on most parts but no broken bolts, even though some of the heads were rusted off. One of the valves stems was rusted away. The seats were nearly gone. Ernest Felterman, the friend that gave me the motor, gave me an old Sioux seat instalation kit several years ago. This is the first chance I had to use it. I installed guides in the head, had valves to fit them. I'll try to attach some pictures, if not succesfull I'll send them to someone to post. |

J.B. Castagnos

| | Posted on Monday, December 29, 2003 - 10:58 pm: |

|

More seat pictures      |

J.B. Castagnos

| | Posted on Monday, December 29, 2003 - 11:07 pm: |

|

The crank and bearings were useable, polished things up and fit shims.  |

andrew

| | Posted on Monday, December 29, 2003 - 11:11 pm: |

|

JB,

Great pictures... good job posting them too! |

Ernie

| | Posted on Tuesday, December 30, 2003 - 07:38 am: |

|

JB,

Nice work! Boy the Souix seat tools sure do bring back memories.

Keep up the good work

Ernie |

Tom Stranko

| | Posted on Tuesday, December 30, 2003 - 06:25 pm: |

|

JB,

I have heard of the seat cutter but only seen the

Black&Decker valve & seat machine my Uncle has (did some old car work with it, no inboards)

I see this tool cuts a deep circle and then you "tap(?)" in a new seat? (hardened?) and then

cut the seat and then grind and fit the valve to match? A very nice tool to have when you need it.

Can you buy the seats still?

Tom |

J.B. Castagnos

| | Posted on Tuesday, December 30, 2003 - 08:47 pm: |

|

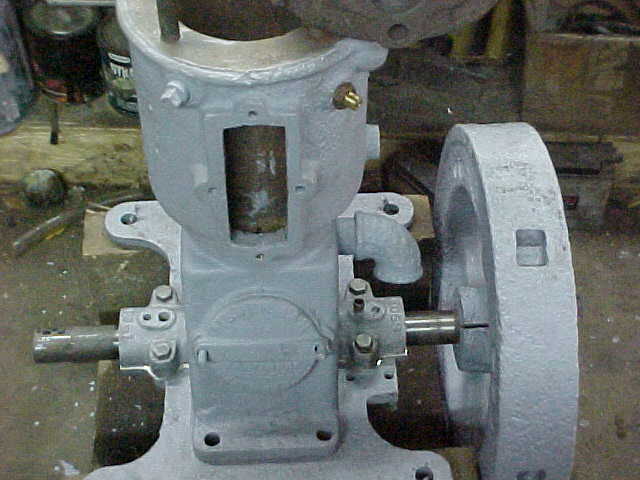

Tom, the seat should be a drive in fit. Most of this work now is done on a mill type machine, the cylinder head shop that does my work has one and probably wouldn't charge me, it's fun to do it yourself. In the last picture behind my engine you will see a box, it's full of assorted seats, was given to me. If anyone needs some just ask. |

newf

| | Posted on Wednesday, December 31, 2003 - 08:29 pm: |

|

Hi There

It is nice to see what u are doing with your engine. I also have one mine is called {COAKER} so this company must of made engines for several differant dealers. My engine is identical to yours so lots of luck hope she works well |

J.B. Castagnos

| | Posted on Wednesday, December 31, 2003 - 09:17 pm: |

|

If your engine has the reverse roller on the rocker arm I would like to get a picture, I have the rocker arm but the roller and shaft were missing, any help would be greatly appreciated.

Thanks, J.B. |

Tom Stranko

| | Posted on Thursday, January 01, 2004 - 11:52 am: |

|

|

Tom Stranko

| | Posted on Thursday, January 01, 2004 - 11:55 am: |

|

JB,

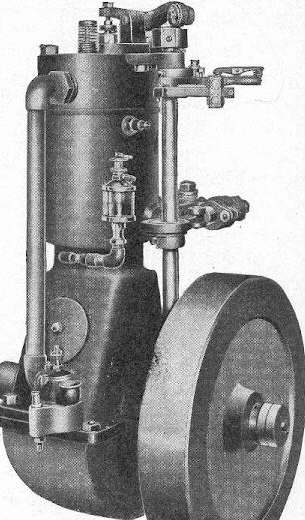

I could email you a scan of this 1907 engraving

if it would help? |

Tom Stranko

| | Posted on Thursday, January 01, 2004 - 12:01 pm: |

|

|

miro

| | Posted on Thursday, January 01, 2004 - 07:05 pm: |

|

WOW JB - that's a real good rig.

But how do you know ( exactly) - how big to make the hole for the new valve seat?

How much fussing around with the adjustment of the cutter diameter did you do?? Did you do a dry run on another victim ?

How did you press fit the seat - dry ice to cool the seat??

Happy New Year too!

Miro |

J.B. Castagnos

| | Posted on Thursday, January 01, 2004 - 08:53 pm: |

|

Tom, my engine is like the one in the 1916 ad in the previous Fisherman thread. The roller appears to be on a shaft that slides in and out, there are two ramps on the cam 1/4 turn apart. The remains of what appears to be a leaf spring detent was screwed to the rocker. I can fabricate something to work but would like to make it as original as possible while doing it. Thanks for the help.

J.B. |

J.B. Castagnos

| | Posted on Thursday, January 01, 2004 - 09:07 pm: |

|

Miro, the cutter is pre set, not adjustable. If you look at the tool you'll see differnt slots, all on a different radius. They're marked 2 3/8, 2 1/2 etc. The seats are oversize, the 2 1/2 I used measured .008 over. I just went for it, the seats were frozen and a a drive in fit, but not as tight as I remember when we did them at the Pontiac dealer where I used to work, they had a similar tool. The knurled nut on the supporting fixture is threaded and feeds the cutter down as you turn it. Placing a seat between the nut and the fixture you set the depth of cut, drop the cutter to the head and lock it at the pinch collar at the top, start turning and advance the cutter until it bottoms. |

keith

| | Posted on Thursday, July 01, 2004 - 01:57 pm: |

|

J.B. If you give me a mailing address I will send you a cam. I borrowed one to copy and made an extra.

\image |

keith

| | Posted on Thursday, July 01, 2004 - 02:01 pm: |

|

Lets try this again

|

J.B. Castagnos

| | Posted on Friday, July 02, 2004 - 07:35 am: |

|

Excellent. It really looks good, my cam lobes were rusted off. I machined it flat and made some ramps to screw on but it would have been a patch job.

Thanks Keith. |

gregoryan

Member

Username: gregoryan

Post Number: 4

Registered: 09-2004

| | Posted on Friday, November 05, 2004 - 04:59 pm: |

|

something back there suggests that this is a direct reversing 4-stroke !!?? I heard that big ships had that gear. Now i see 2 lobes but only one actuated valve. Cool. I used to prefer the 2 strokes for their reversability. |

|

|

|

|