| Author |

Message |

bud

| | Posted on Monday, December 08, 2003 - 01:22 pm: |

|

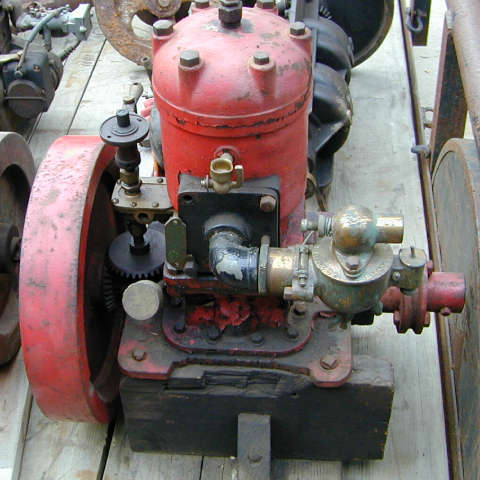

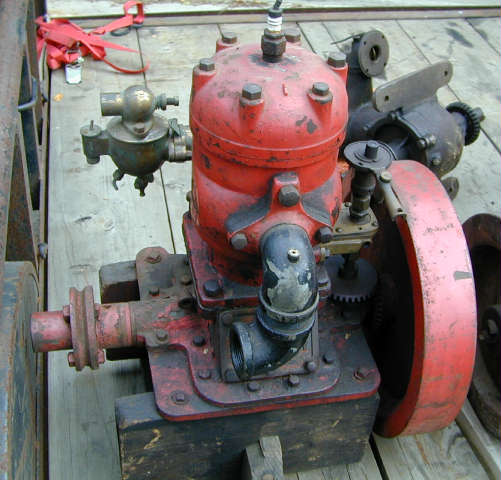

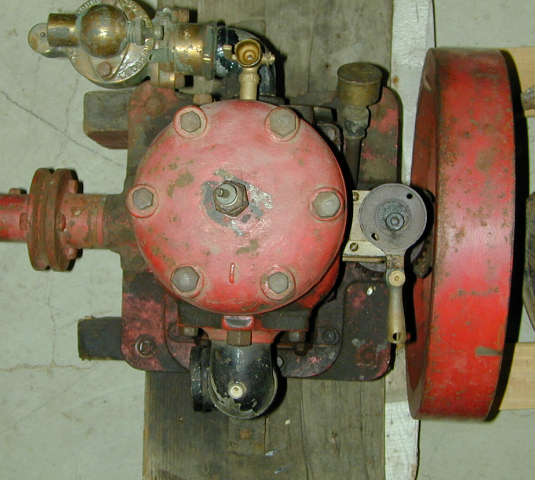

I have an old motor That has the name Purdue University on the plate on the base of the motor.

The only other writing that i can find are the words Lunkenheimer,KRICE, and M.L. Oberdorfer Brass Co. Suracuse N.Y.

I have pics. but dont know how to post them from here. |

solarrog

| | Posted on Monday, December 08, 2003 - 01:52 pm: |

|

This could be a college level project. The Lunkenheimer is most likely the oiler, The Krice

Is the fuel mixer/carburetor make, and the Oberdorfer is the water pump maker. If you can post the pictures here or at a web site and send the link, I will have a look. I hope this helps some

Roger

Fremont,Ca USA |

andrew

| | Posted on Monday, December 08, 2003 - 02:25 pm: |

|

Several of the engineering schools built small marine gas engines from castings. It taught foundry work, machining, mechanical assembly, testing, etc. I have a single cylinder 3(?)HP one that was made by Notre Dame.

Regards,

Andrew |

bud

| | Posted on Monday, December 08, 2003 - 05:32 pm: |

|

This is my web page.

Go to the marine motor link.

I hope it works?

http://www.geocities.com/revbud.geo/ |

solarrog

| | Posted on Monday, December 08, 2003 - 06:28 pm: |

|

I see the Lunkenheimer is on the check valve, not the oiler. This motor doesnt look real old to me.

1940-1950 maybe. can anyone help on this.

Roger |

Tom Stranko

| | Posted on Monday, December 08, 2003 - 07:01 pm: |

|

What a neat old motor. I have a friend in Indiana who has had several of the "Notre Dame"

inboards. They are a sought after thing.

I expect the Perdue is a similar engineering school project (as Andrew stated). Looks like it could run without much effort. |

Bill Schaller

| | Posted on Monday, December 08, 2003 - 07:05 pm: |

|

I have one of those purdue engines, too. goes with my Minnesota Gopher engines. later, I will find and post the pictures, or go out at take some more tomorrow during the snow storm. Andrew, are you sure yours was made at Notre Dame, or does it just have a Notre Dame pump on it? Notre Dame was a company that made water pumps for marine engines, and I have seen unknown engines with this pump. as I remember, mine has a purdue water pump, purdue nameplate, and it says purdue on the piston rod. it surely does not have a lunk check valve and krice carb. the basic engine looks the same. |

andrew

| | Posted on Monday, December 08, 2003 - 07:10 pm: |

|

That engine certainly looks consistent with a "college made" engine. They would have bought the carb, check valve, pump, timer, etc.

I would say that is not 40-50's, but instead it is probably teens to 20's (just a guess, but anything is possible if it was a school project).

I wonder if any of the colleges still have foundry patterns.... ?

Here are a couple of Bud's pictures (I hope you don't mind me posting them here Bud), but you should go to his webpage to see the rest.

|

andrew

| | Posted on Monday, December 08, 2003 - 07:13 pm: |

|

Bill,

You might be right about the "Notre Dame" engine... I don't remember where it says Notre Dame, but it might be on the pump... I will take a look tomorrow.

Regards,

Andrew |

solarrog

| | Posted on Monday, December 08, 2003 - 07:19 pm: |

|

I just went out and looked at some of my engines

fromt the 1920s plus, They use some of the same components that are on this engine. I agree with Andrews 1920s But I also think teens is to early for this motor.

Roger |

Bill Schaller

| | Posted on Monday, December 08, 2003 - 07:31 pm: |

|

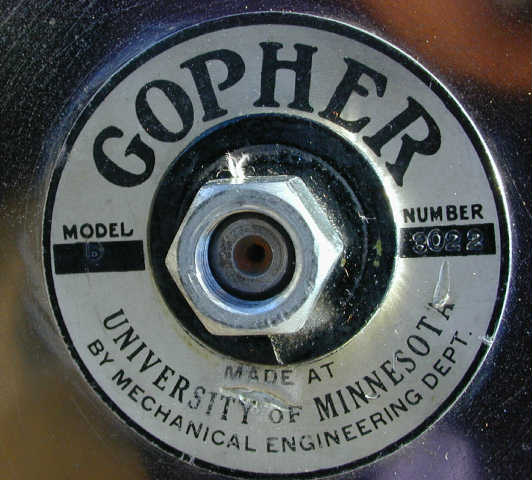

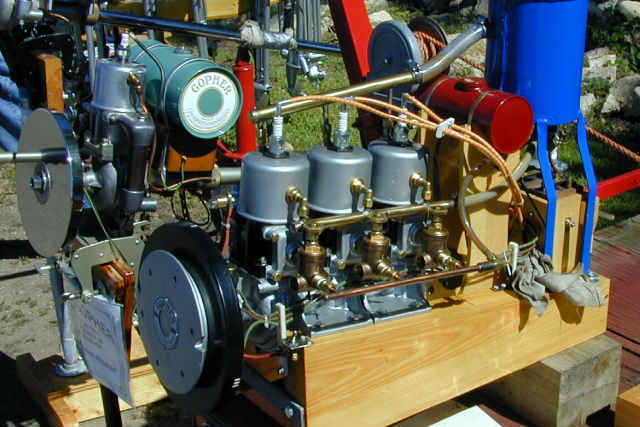

The gopher outboard engines were made at Minnesota about 1926, 1927.

I can find those pictures. |

Bill Schaller

| | Posted on Monday, December 08, 2003 - 07:33 pm: |

|

|

Bill Schaller

| | Posted on Monday, December 08, 2003 - 07:36 pm: |

|

to make up for the screwupin posting pictures, here is aspecial gopher.

|

Bill Schaller

| | Posted on Monday, December 08, 2003 - 07:36 pm: |

|

to make up for the screwup in posting pictures, here is a special gopher.

|

Bill Schaller

| | Posted on Monday, December 08, 2003 - 07:55 pm: |

|

I found a picture.

|

bud

| | Posted on Monday, December 08, 2003 - 07:58 pm: |

|

That looks alot like mine |

Bill Schaller

| | Posted on Tuesday, December 09, 2003 - 12:13 pm: |

|

|

Tom Stranko

| | Posted on Tuesday, December 09, 2003 - 06:36 pm: |

|

So the Gopher came in 1,3,5,7 & 9 cylinder combinations?

Is this something they still make for a project??

Neat engine! |

Bill Schaller

| | Posted on Wednesday, December 10, 2003 - 01:18 am: |

|

The gopher was made in two styles, a model A with a standard outboard layout, and a model B that was a liberty straight shaft outboard style. The model A is much rarer. The 3 cylinder inboard engine pictured above is a one of a kind, originally unfinished project. The engine was not finished due to crank shaft problems. it was restored a couple of years ago, and I do not know if it is running. The gophers are very collectable by outboard engine collectors, and it fits in very nicely with my Minnesota made engine collection, since I did graduate from Minnesota.

|

bud

| | Posted on Wednesday, December 10, 2003 - 06:25 am: |

|

Thanks gies for the help.

Im not a collector or have i ever work on anything like this before. From what you can see in the pics how much of a job would it be to make it run?

The motors turns over freely.

Going to try to link to a pic.

timer |

Ernie

| | Posted on Wednesday, December 10, 2003 - 12:18 pm: |

|

Real neat engines. I see similarities to several manufacturers. Gray for one. As a school engine I would think they looked at existing designs and considered improving on them.

I agree with Andrew in the 20's to 30's time frame. However as a school engineering project it could have been later. |

Bill Schaller

| | Posted on Wednesday, December 10, 2003 - 06:01 pm: |

|

Bud, I would really like to see some pictures of the timer, as you can see mine is missing the top part. your pic link did not work for me, but if you email me the pics, I will post them here.

[email protected] |

Jeff Fay

| | Posted on Friday, December 19, 2003 - 11:09 am: |

|

If anyone could help me identify this two cycle marine engine it would be greatly appreciated. Here are some pictures.

Jeff Fay

Gilford, NH |

Jeff Fay

| | Posted on Friday, December 19, 2003 - 11:24 am: |

|

If anyone could help me identify this two cycle marine engine it would be greatly appreciated. Here are some pictures.

Jeff Fay

Gilford, NH

This is the engine /image{C:/My Documents/My Pictures/Mvc-001l} |

jeff Fay

| | Posted on Friday, December 19, 2003 - 11:26 am: |

|

If anyone could help me identify this two cycle marine engine it would be greatly appreciated. Here are some pictures.

Jeff Fay

Gilford, NH

This is the engine  |

Ernie

| | Posted on Friday, December 19, 2003 - 11:44 am: |

|

Jeff,

E-mail me your pic/s and I will post them for you.

Hope this helps. Just click on my name at the top of this message for my e-mail

Ernie |

jeff Fay

| | Posted on Friday, December 19, 2003 - 01:37 pm: |

|

C:\My Documents\My Pictures

pic2.jpg pic2.jpg |

jeff Fay

| | Posted on Friday, December 19, 2003 - 01:40 pm: |

|

If anyone could help me identify this two cycle marine engine it would be greatly appreciated. Here are some pictures.

Jeff Fay

Gilford, NH

This is the engine \image |

Ed Radtke

| | Posted on Saturday, December 27, 2003 - 08:23 pm: |

|

To help shed some light on the build date of the purdue engine,mine has a last pat. date of 1916 on the Bemus timer. It is a flat top timer, not dome top like in the first post. The water pump looks just like the Oberdorfer in the first post but is cast with Purdue in the top.Mine is missing the comlete fuel system and now I know what to look for [ make ]. I have a one inch schebler D carb. Would that be to much for a 4X4 b&s? Glad to see those pix. Thought I had the only one in captivity. |

J.B. Castagnos

| | Posted on Saturday, December 27, 2003 - 09:42 pm: |

|

My 4hp Lockwood Ash 4x4 b&s uses a 1" Schebler, it idles without closing the throttle, usually have to richen it 1/4 turn. These carbs seem to be easy to get along with. |

searcher

Member

Username: searcher

Post Number: 8

Registered: 10-2004

| | Posted on Tuesday, January 04, 2005 - 11:28 pm: |

|

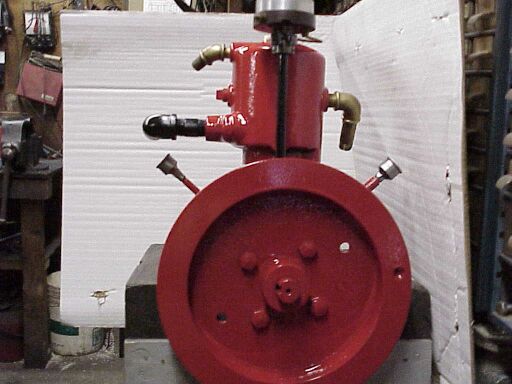

I recently acquired this Perdue University engine from Bud. In the process of cleaning it up a bit, I removed the square cover on which the carburetor/check valve mount. There is a pack of sheet metal plates occupying the space between the cover and the cylinder wall. Does this pack of plates enhance the air/fuel mix somehow?

There are six photos attached if I did everything right. I suspect they may not come through in the same order as I originally placed them. Photo 1 is an overall shot of the engine. Photo 2 depicts a closer look at the the square cover where the carburetor/check valve attaches to the engine. Photo 3 shows the square cover removed exposing a pack of thin metal plates. Photo 4 shows the plates removed to expose the cylinder wall. Photo 5 is a close up of the pack. Photo 6 is an edge view of the pack. Approximately a 1/16" air space separates each plate so air could circulate through them. |

billschaller

Senior Member

Username: billschaller

Post Number: 104

Registered: 12-2003

| | Posted on Wednesday, January 05, 2005 - 07:10 pm: |

|

here are searchers photos.

|

billschaller

Senior Member

Username: billschaller

Post Number: 105

Registered: 12-2003

| | Posted on Wednesday, January 05, 2005 - 07:14 pm: |

|

here are 2 more of searchers photos

|

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 227

Registered: 07-2002

| | Posted on Wednesday, January 05, 2005 - 08:10 pm: |

|

The metal pack looks like an attempt to prevent backfire, works like a flame arrester, the flame is cooled as it passes through the thin slots. |

andrew

Moderator

Username: andrew

Post Number: 1007

Registered: 11-2001

| | Posted on Wednesday, January 05, 2005 - 08:11 pm: |

|

I'm not sure if it's similar or not... but see this link to a previous post about ROBERTS "patented anti-backfire devicie". |

searcher

Member

Username: searcher

Post Number: 9

Registered: 10-2004

| | Posted on Wednesday, January 05, 2005 - 09:09 pm: |

|

I am quite new to this hobby and have not yet had the time to totally dismantle a two cycle. As a visual learner, I need to do that in order to understand the flow paths involved. I will take the cover off again in the next day or two for the purpose of seeing how well the plate pack fits the space available and if it could effectively route all backfire through the plates. Sure looks like a plausible explanation. Thanks for the comments. I will post any new observations. |

richardday

Senior Member

Username: richardday

Post Number: 344

Registered: 11-2003

| | Posted on Thursday, January 06, 2005 - 11:34 am: |

|

J.B. is correct. The St. Lawrence has the same sort of backfire trap in the transfer port. In the St. Lawrence the trap is a stack of copper plates that are corregated with V shaped grooves and simply stacked vertically in the transfer port. These systems all work on the same principal as the Davy's miner's lamps reducing the temperature below the ignition point of the burning fuel. |

ernie

Senior Member

Username: ernie

Post Number: 457

Registered: 01-2002

| | Posted on Thursday, January 06, 2005 - 05:25 pm: |

|

These things do two things. Both well!

1 as discussed above they prevent backfire.

2 they also help atomize the fuel.

I have a brand new NOS Gray model "U" it has one in it's transfer port. If I take it out it runs like do do.

It will backfire (sneeze)when it is too lean. (badly)

With it in it runs like a Briggs and Stratton however it will not sneeze to warn you it is too lean. I had to learn how to adjust it by ear. It doesn't sneeze, it just quits.

Also it won't idle well at all with out it installed. No matter how the carb is adjusted.

I have also learned to look for them in the transfer port in any engine. I have seen them made from steel and rusted solid. Also I got an engine from a guy in pieces. It had been sandblasted and was still full of sand. |

searcher

Member

Username: searcher

Post Number: 10

Registered: 10-2004

| | Posted on Thursday, January 06, 2005 - 08:25 pm: |

|

Sounds like that question is pretty well settled, Thank you Bill, JB, Andrew, Richard, and Ernie.

Hugh |

searcher

Member

Username: searcher

Post Number: 12

Registered: 10-2004

| | Posted on Thursday, January 13, 2005 - 09:03 pm: |

|

The timer on the Perdue has an aluminum cap. As you can see from the photo, corrosion has left the surface of the cap covered with rather rough hard deposits. The cap has some lettering along the lower margin but I can make out only the occasional letter. Is there some way to restore this cap?  |

thomas

Senior Member

Username: thomas

Post Number: 242

Registered: 07-2002

| | Posted on Sunday, January 16, 2005 - 10:15 am: |

|

I can't tell if this part was cast aluminum or it was pressed to shape. I doubt there is any way to restore the upper surface and the letters

both. If it was my project,I would either sandblast the cover until all the deposits were off and it had the gray "cast" over-all appearence. Another way would be to mount it on the lathe face plate (remove the center contact and use a bolt?) and carefully take a cut on the 3 major surfaces until they were smooth. This will naturally thin out the part somewhat.

If you had a chunk of aluminum stock you could turn up a duplicate also. Depends on how much time you have.

Tom |

searcher

Member

Username: searcher

Post Number: 14

Registered: 10-2004

| | Posted on Sunday, January 16, 2005 - 01:14 pm: |

|

Thanks for responding. Unfortunately, I think this cover was spun(as opposed to being machined, cast, or pressed)and spun from very thin aluminum at that. There really is no surplus metal there available to remove. However, it was a good thought and I probably would follow your suggestion had there been some thickness available.

I was hoping against hope there might be an electrolitic process where some of the oxide might be converted back to metal. That might have allowed preserving as much as possible of the cap.

I shouldn't be so fussy. It is not a notable engine, simply an interesting one due to its history. However, I do like to have things as original as possible where there is some reasonable way to do it.

Thanks again. Hugh |