|

| Barber Shop- Making a trailer queen |

| Author |

Message |

andrew

| | Posted on Monday, February 10, 2003 - 06:42 pm: |

|

Received the following from Paul Gray....

Quote:Hi Andy-

Working feverishly to get this done for Calvert. The hard stuff is done.

Made 60+ stainless high crown bolts to 'perty this engine up for Mr. Buck.

New rod bearings, wrist pins and bushings, piston rings (thanks Dave), flywheel (cracked hub), welded up taper on crank and re-turned, fancy epoxy paint c'tsy of G+G Coates, heads turned for nickel plating, TIG-welded SS base.

Still a LOT to do- hope to get the brass work + heads to the platers for nickel!

Paul

|

Richard Day

| | Posted on Monday, February 10, 2003 - 07:58 pm: |

|

Beautiful job Paul. |

Bill Schaller

| | Posted on Monday, February 10, 2003 - 08:15 pm: |

|

Hey, can I have the old bolts? Here is a picture of my barber, and I have Paul to thank for providing me with a great flywheel casting so some day I can get mine restored.

|

Paul Gray

| | Posted on Tuesday, February 11, 2003 - 05:36 am: |

|

Bill- And thanks for transporting that Myrick for me !! I am working on the flywheel hub and I must say that making the tapered opening is a challenge. I got the hole finished last night. Now I have to make a male plug with a 3 degree taper and a 3 deg taper on the base to push the broach through. Going to keep the bolts- lots of other projects to use them on... |

Keith

| | Posted on Tuesday, February 11, 2003 - 02:54 pm: |

|

Paul

Looks great! I guess we know who is getting dressed up for Calvert this year. Looking forward to seeing the finished product. |

Richard

| | Posted on Tuesday, February 11, 2003 - 03:12 pm: |

|

Barber, brought out a nifty single cylinder in the 1920s with outside over head valve push rods etc.

The skipper of the Maryland Dove brought it to me to identifye back about 1990. I forget his name but it was a very restorable engine. Complete with a little surface rust. I wonder where it is now. He left the Dove some years ago. Anyone know of this engine? I doubt there are many of that model around today. |

Bill Schaller

| | Posted on Tuesday, February 11, 2003 - 11:27 pm: |

|

Paul, I was joking about the bolts. I am sure all of us wish we could find a few cases of old style bolts, it would save a lot of work.

|

Paul Gray

| | Posted on Saturday, February 15, 2003 - 05:07 pm: |

|

Got the flywheel insert sleeve/plug taper cut and broached...Wheeew, what a job. Had to make

a tapered broach guide with an inclined base to run the broach through in an arbor

press. Going to freeze the plug in liquid nitrogen and it should pop right in

flywheel. Also have to make step key for the crank. |

andrew

| | Posted on Monday, February 24, 2003 - 05:55 pm: |

|

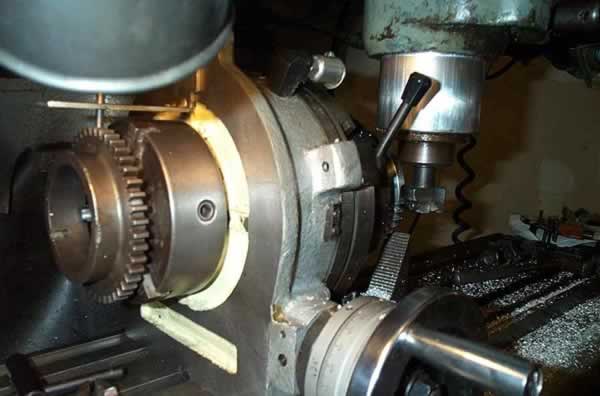

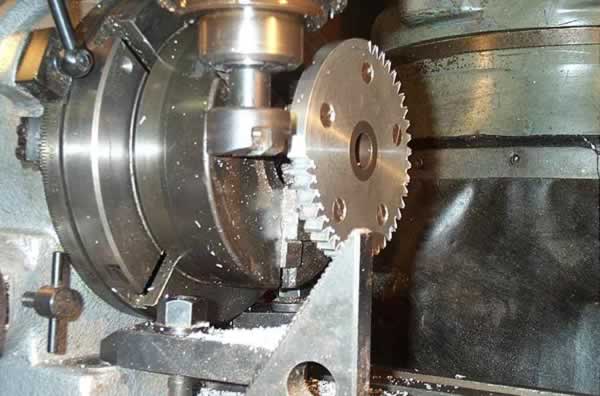

Paul sent in some pictures and description of his progress... very clever way to index!

Quote:Here is the gear for the "distributor" being made. 44 teeth by 4.5" OD.

Used the Regimoto technique; Index off another 44 tooth gear and use a flycutter to make teeth.

Paul

|

|

|

|

|