| Author |

Message |

speleausmining

New member

Username: speleausmining

Post Number: 1

Registered: 10-2010

| | Posted on Sunday, October 31, 2010 - 10:31 pm: |

|

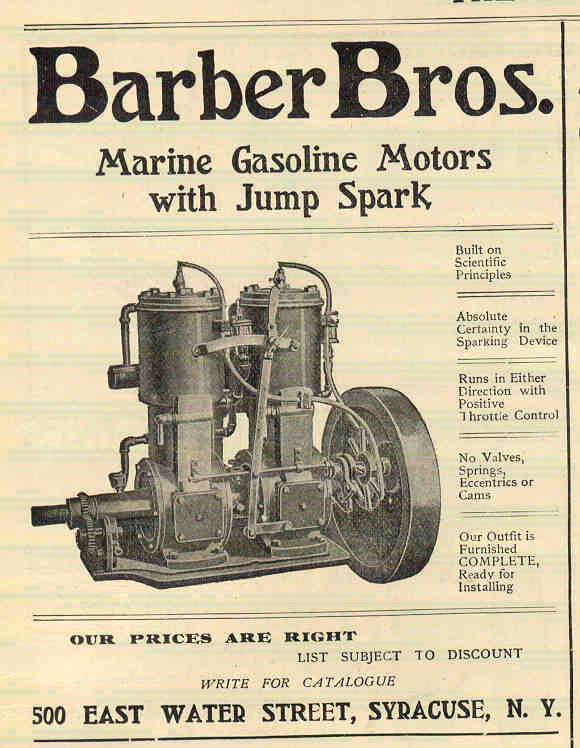

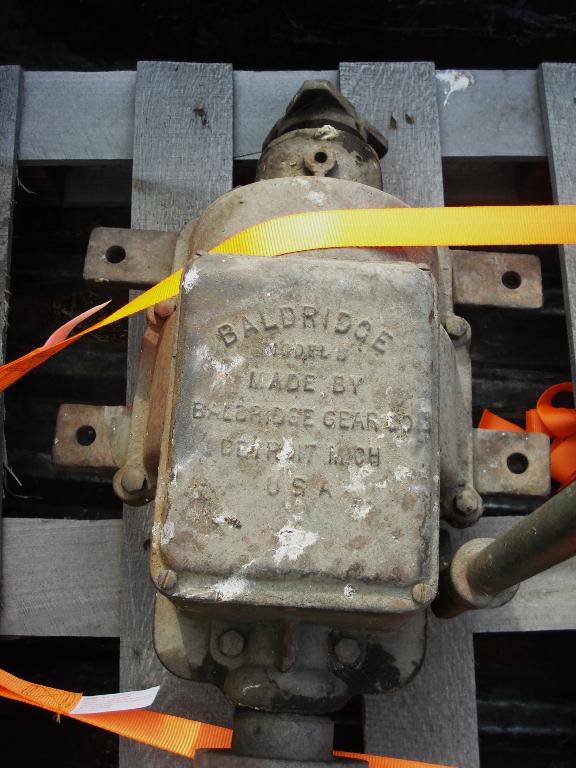

Seems an error occured with my other post so here it is again. I just picked up my first marine engine,stationary farm engines usually being my thing. Its a 2Cylinder Barber Brothers Engine. About 85% original paint which I will be pereserving and keeping. I got a reversing transmission thrown in the deal too. The Transmission is a Baldridge Detroit Michagan which I am not sure is original (though the paint traces match). I do have a few questions. Fistly is there a way to date these engines? I have done some searching here and elsewhere but cannot find anything on dateing these. Possibly the Delco Remy distributer could provide a date but thats come up empty as well. Secondly whats a fair price on these. I am happy with what I paid I am more just curious. Some other thoughts on this one its missing the carb but I have a replacement. If I had to guess given the size of the cylinders I would say 3hp (1.5hp per cylinder). My plan at this point is to put this in a cedar strip boat I am working on (initial planning stages at this point).  |

billschaller

Senior Member

Username: billschaller

Post Number: 352

Registered: 12-2003

| | Posted on Sunday, October 31, 2010 - 11:27 pm: |

|

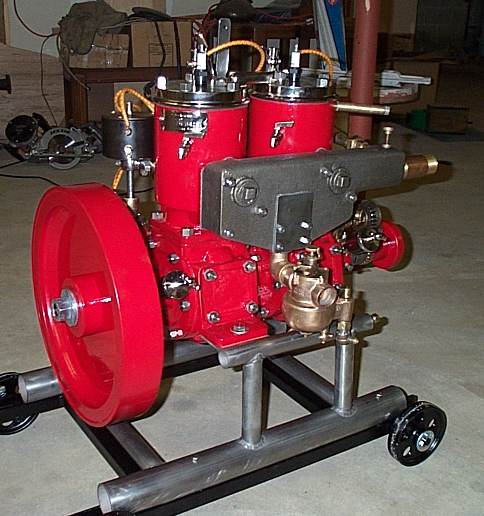

Welcome to the Barber club. Can you post a picture of the name tag, and other views. I don't know the exact year, but it isn't early, because those had this type of ignition.

and, I would put a Krice on it, like this.

|

speleausmining

New member

Username: speleausmining

Post Number: 2

Registered: 10-2010

| | Posted on Monday, November 01, 2010 - 01:13 am: |

|

As Requested here are some additional photos. Personally I am leaning to the late 191X's to Early 192X's for date but Dont really know I do see what you mean about the earlier ignition set up inside the flywheel. I assume the automotive ignition coil is not original? Probably would have been buzz coil. The engine tag is nikle plated Brass.

|

paulgray

Senior Member

Username: paulgray

Post Number: 76

Registered: 05-2003

| | Posted on Monday, November 01, 2010 - 04:34 pm: |

|

That distributor appears to be added later- it may have had a cuno-style timer on it which wore out. Still that engine is probably from the 1912-1918 vintage. The red engine is a 1909 |

miro

Senior Member

Username: miro

Post Number: 513

Registered: 11-2001

| | Posted on Monday, November 01, 2010 - 09:17 pm: |

|

Here's a shot from 2003 starting the red Barber at Calvert. It was the first run after being restored.

George C III is the guy flinging the flywheel

Miro

|

speleausmining

New member

Username: speleausmining

Post Number: 3

Registered: 10-2010

| | Posted on Monday, November 01, 2010 - 11:00 pm: |

|

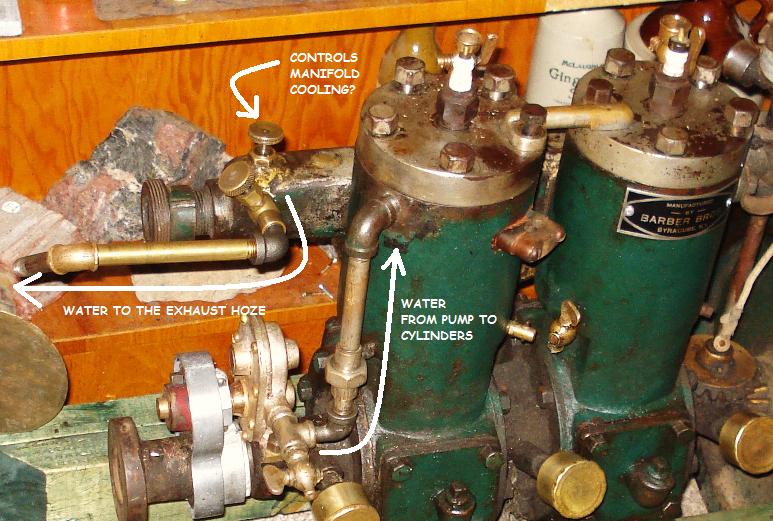

Nice. I was figureing a later date, primarilly because of the distributer but I see no reason that the distibuter couldent be a replacement though if it is it must surely be a replacement provided by the manufacturer. I did a bit more cleaning today The paint is really starting to show itself now. Even whats left of the wireing, though it will need to be replaced, it will be able to be precisely matched for both colour and pattern. Anyone have a clear idea on the plumbing for coolant water on these. I think the setup has been altered on mine. I assume this because there are a couple of black pipe fittings as opposed to the nickle plated fittings used else where. Also there is an unused nickle fitting at the top of one of the cylinders.

|

speleausmining

Member

Username: speleausmining

Post Number: 4

Registered: 10-2010

| | Posted on Tuesday, November 02, 2010 - 09:44 am: |

|

My thinking is the line from the pump should go into the far cylinder by the flywheel then circulate to the near cylinder before being injected into the exhaust pipe. It looks like right now it just goes straight to the exhaust pipe, unless of course the exhaust manifold is designed to inject water into the cylinder jackets. |

axtion_jim

New member

Username: axtion_jim

Post Number: 1

Registered: 11-2010

| | Posted on Tuesday, November 02, 2010 - 02:20 pm: |

|

I have a copper top Waterman with the same gear box that you have on Barber Bros engine. Maybe its a Canadian thing to use this box. I had to dismantal mine and clean it up. It has a neat planitary set, but a bit crude. I think that it would be in the best interest to stop the engine then do the reversing. |

miro

Senior Member

Username: miro

Post Number: 514

Registered: 11-2001

| | Posted on Tuesday, November 02, 2010 - 09:59 pm: |

|

The hottest part of the engine is right at the exhaust port of the engine.

I can't see if there is a hole from the exhaust manifold into the water jacket of the engine from the pictures.

If there is, then the cool water should flow first to the exhaust manifold, then to the cylinders and then out to the injection point into the exhaust pipe.

If the cool water goes to the cylinders first, the exhaust manifold won't get the cooling it needs.

The flow of cooling water through the manifold first also keeps the whole manifold at a warm but not hot, temperature, thus warming the incoming fuel from the carb. This helps keep the engine running smoothly when under load.

At a show with no load , getting the mixture right (rich or lean) can be a challenge, because if the mixture is OK for one cylinder, it may not be OK for the other.

miro |

speleausmining

Member

Username: speleausmining

Post Number: 5

Registered: 10-2010

| | Posted on Wednesday, November 03, 2010 - 08:36 pm: |

|

In the manifold there is a hole for cooling water to/from both cylinders. So perhapse the current set up is not too altered.

That leaves a mystery as to what the elbow near the top of one of the cylinder is for.

|

miro

Senior Member

Username: miro

Post Number: 516

Registered: 11-2001

| | Posted on Wednesday, November 03, 2010 - 10:15 pm: |

|

My guess ( and that's all it is) is that the flow is from the water pump, through the manifold, into the cylinders, and then it has to exit from the cylinders somewhere.

Could it be through the un-used elbow.

From there the water would go to the exhaust system injector downstream from the manifold to cool the exhaust gas and quieten the whole thing.

So, maybe the elbow is not un-used.

miro |

axtion_jim

New member

Username: axtion_jim

Post Number: 2

Registered: 11-2010

| | Posted on Thursday, November 04, 2010 - 12:06 am: |

|

Why not hook a garden hose to the elbow and see where the water comes out, my bet is that it will flow through the manifold and out of the elbow or in the proper flow from the pump to the elbow. My easthope dose this.That is why they employ the use of a heat exchanger to make the engine run better on the cold days by regulating the out flow. |

speleausmining

Member

Username: speleausmining

Post Number: 6

Registered: 10-2010

| | Posted on Thursday, November 04, 2010 - 01:58 pm: |

|

My thinking on it is two fold. Either 1) this is where the water from the pump originally was put into the cylinder, or 2) this had a line leading to the exhaust flange in the hull. I am leaning more towards that this is the original inlet. I have hooked up compressed air to this and air flows through the water jacket and out at the exhaust manifold. The needle valve on the exhaust manifold seems to controll the rate at which water from the jacket is allowed to leave. |

paulgray

Senior Member

Username: paulgray

Post Number: 78

Registered: 05-2003

| | Posted on Thursday, November 04, 2010 - 06:45 pm: |

|

Here is a picture of the manifold back-side for the water cooling |

axtion_jim

New member

Username: axtion_jim

Post Number: 3

Registered: 11-2010

| | Posted on Thursday, November 04, 2010 - 11:14 pm: |

|

I believe that the flow is from the pump to the cyls.The valve is to controll the flow of coolant and maintain a temparture in the cyls. to aid in combustion. The valve is adjusted to the heat in the cyls, by touching the outside casting of each cyl. On a cold damp day on the water the carb will freeze up I`ve been told. I sussect this is where expeariance will come into play. |

speleausmining

Member

Username: speleausmining

Post Number: 7

Registered: 10-2010

| | Posted on Thursday, November 04, 2010 - 11:44 pm: |

|

I have re-configured the plumbing based on what makes the most sence to me so let me know if I am way off I belive for optimal cooling water has to circulate The dual inlets in the manifold would create dead areas of little to no circulation. In particular if each cylinder had an inlet I fail to see the need for a conection between the cylinder. as with eaqual volume coming into both cylinders there is no reason for the water to travel between them. It is on this reasoning that I proceeded to plumb the pump up to where the elbow was near to top of cylinder 1, From there the water would travel out through the manifold outlets to the valve on the the manifold. This needle valve does not provide enough of an outlet for the incoming water so I have plumbed the old inlet at this valve to bypass and go into the exhaust hoze. As per photo

Thoug I am still unsure of this as The possibility exists the elbow was the outlet for the cylinders. |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2470

Registered: 11-2001

| | Posted on Friday, November 05, 2010 - 12:08 am: |

|

*

Photo in the above post is the correct and factory original water system !

Delco Remy was the name That United Motors came up with when combining Dayton Electric Labratory Co. and Remy Electric Co. in 1926, engine above was mfgd prior to 1920.

Barber Bros was definately a very early marine engine mfgr (1899) and pioneered the design for many of the Central New york engine makers.

Looks good - Thanks for posting the good photos.

* |

axtion_jim

Member

Username: axtion_jim

Post Number: 4

Registered: 11-2010

| | Posted on Friday, November 05, 2010 - 12:17 am: |

|

Well lets put it this way, I think that the rear cyl. will run colder than the front.Also there is no reason to put the water outlet in the exhaust.All of the engines of this type that we run onthe coast exit out the side of the wheel house along with a hose for the coolant separately above the water line producing that famous tune that we all know and love. |

miro

Senior Member

Username: miro

Post Number: 519

Registered: 11-2001

| | Posted on Saturday, November 06, 2010 - 06:19 am: |

|

I agree with that arrangement if you are running the engine at a show - dry exhaust makes a good "noise" and you get the water back into a barrel.

But in a boat, the wet exhaust cools the exhaust gas, making all the exhaust piping cooler ( it can get REALLY hot), plus it takes the bark out of the exhaust sound.

miro |

robert

Senior Member

Username: robert

Post Number: 388

Registered: 07-2003

| | Posted on Saturday, November 06, 2010 - 12:50 pm: |

|

Re your comment on the gear, the Baldridge being fully enclosed won't sling oil around, but it doesn't really look right for the engine IMO. Of course you could box it in so it's not visible. A Gies or Joe's Gear would be another option, but the Joe's have a reputation as oil slingers (probably when worn or not properly aligned). Not sure if the Gies have the same reputation. Either would look better than the Baldridge, which is probably oversize for this engine anyway. |

speleausmining

Member

Username: speleausmining

Post Number: 8

Registered: 10-2010

| | Posted on Sunday, November 07, 2010 - 12:49 pm: |

|

Yes this set up will cause one cylinder to run slightly cooler then the other though I do not belive this will be a significant problem. Water still reaches the exhaust through a needle valve located on top of the exhaust manifold. and I can allways plumb the excess water into the exhaust system as well. I am fairly happy with this cooling arrangemnt now as its as close as I can find to what I see in early advertisements for these engines. It also makes more sence, at least to me, from a flow point of view. Also the whole idea of having the intake air piped through the exhaust manifold is to pre-warm it. IMO if you are putting the coldest water into the manifold you kind of defeat the purpose. It makes more sence to me to have hot water from the cylinders circulating there to warn the air. Of course if this system becomes a problem on running I can always switch it back. |

axtion_jim

Member

Username: axtion_jim

Post Number: 5

Registered: 11-2010

| | Posted on Sunday, November 07, 2010 - 10:35 pm: |

|

You may have a valid point as to plumbing the coolant to the manifold first to aid in heating the fuel.like you said it can always be reversed. Not been said before that is a great engine and I`m looking forward to the day when can be seen powering a cedar strip boat. |