| Author |

Message |

kirk

Member

Username: kirk

Post Number: 8

Registered: 09-2005

| | Posted on Tuesday, June 08, 2010 - 05:39 pm: |

|

Hello!

Haven't been on the board in a while...hope everyone is well.

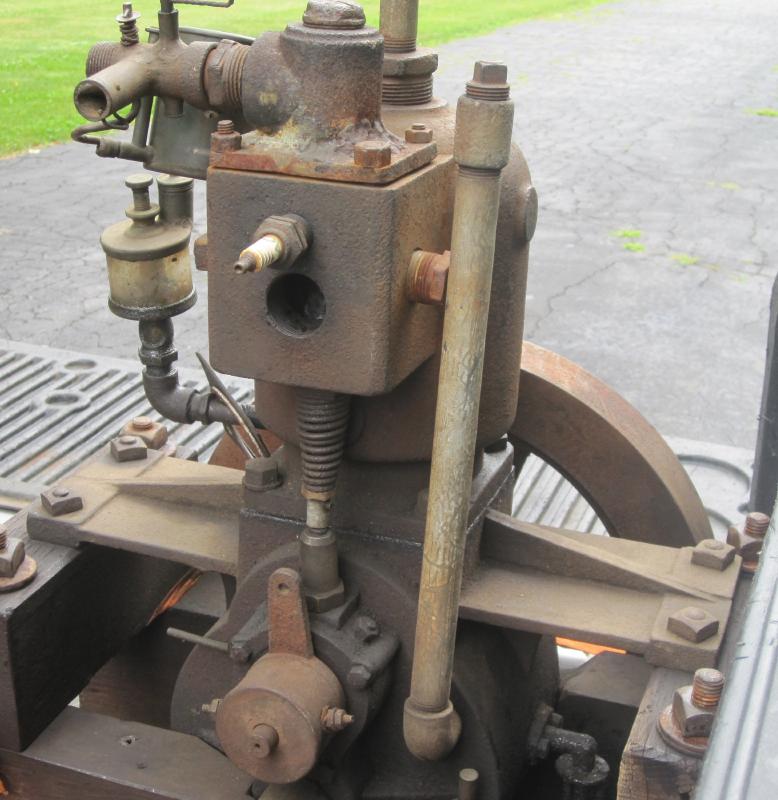

Anyway, I mostly collect hit/miss farm engines, but I do have soft spot for the 1 cyl inboard marine engines. I was at the Bernardston, MA, show, and saw this engine (again). The owner has been trying to sell it for 4 years, and he finally dropped his price to a reasonable number, so I jumped on it.

I have absolutely no idea what it is. I cannot find any casting numbers or tags. I think it may have been a marine design adopted for stationary or automotive use because it has no water pump (thermosiphon cooling), and an oil pump on the bottom of the block with 2 copper oil lines feeding the mains.

Can anyone ID it?

Thanks...

Chris Kirk

Monroe, CT |

john_archibald

Senior Member

Username: john_archibald

Post Number: 140

Registered: 08-2006

| | Posted on Tuesday, June 08, 2010 - 06:00 pm: |

|

Need a better picture. |

ernie

Senior Member

Username: ernie

Post Number: 1205

Registered: 01-2002

| | Posted on Tuesday, June 08, 2010 - 06:01 pm: |

|

Chris,

Send me your original so I can post a bigger pic for you.

Ernie |

kirk

Member

Username: kirk

Post Number: 9

Registered: 09-2005

| | Posted on Monday, June 14, 2010 - 06:01 pm: |

|

Ernie -

Send you some pics today. Email me if they don't work.

Thanks...

Chris |

ernie

Senior Member

Username: ernie

Post Number: 1221

Registered: 01-2002

| | Posted on Wednesday, June 30, 2010 - 08:13 am: |

|

Here are some bigger pics from Chris.

My 2 cents worth are it looks like early atuomotive as the mounts are so high on the sides.

Keith, Dave does this look like that Baltimore or whatever it was engine? Sort of?

|

kirk

Member

Username: kirk

Post Number: 10

Registered: 09-2005

| | Posted on Wednesday, June 30, 2010 - 12:31 pm: |

|

Ernie -

Thanks for posting the pics.

The crank comes out of the block below the timer. What you're seeing is a sleeve, cast as part of the block, that surrounds that end of the crankshaft. An oil line is plumbed directly into that sleeve from the oil pump that protrudes from the bottom of the block (not in sight), so what you're seeing is very likely a pressure lubricated bearing holder/surface for that end of the crank.

Also, if you look on the very bottom of the lower right hand side of the picture, you'll see a sight glass that's plumbed into the side of the block.

I took some time to go through the engine on Father's day. I cleaned the points and replaced the homemade mixer with a 1" Schebler. After hooking up a buzz coil, I got it to run for a few seconds. Compression is strong, and the engine sounded healthy. Next step is to mount a gas tank so that I can get the engine running for more than a few seconds. After that, I'll put it on a cart and plumb a cooling tank, then it's off to the shows to see if I can get a positive ID.

Chris |

miro

Senior Member

Username: miro

Post Number: 472

Registered: 11-2001

| | Posted on Wednesday, June 30, 2010 - 03:32 pm: |

|

A marine engine needs to have a thrust bearing somewhere to take the push of the propeller.

Sometimes, it is not obvious, but looking at the output shaft carefully should indicate if there is a thrust bearing there.

Many early marine engines are direct drive, especially the smaller ones like this one because the transmissions were more $$$ , hence the need for the bearing.

Except that in this case it is a 4 cycle and non-reversible.

miro |

kirk

Member

Username: kirk

Post Number: 11

Registered: 09-2005

| | Posted on Wednesday, June 30, 2010 - 07:43 pm: |

|

Miro -

Thanks for the reply. The engine does not appear to have any provision for a thrust bearing. I compared the non-flywheel end of the crank to my 1 cyl Detroit marine engine, and there is no dedicated flange for a thrust bearing, as with the Detroit, nor is there any sign of any type of wear on the end surface of the sleeve that surrounds the crank end (I mentioned the sleeve on an earlier post), where a thrust bearing would have ridden.

Chris |

john_archibald

Senior Member

Username: john_archibald

Post Number: 143

Registered: 08-2006

| | Posted on Wednesday, June 30, 2010 - 09:38 pm: |

|

In some boats the use of a thrust block is employed. The propeller shaft terminates in the boat at the thrust block ( just aft of the engine )which contains a bearing, usually a ball bearing that can take radial as well as axial forces. A tapered roller bearing could also be used.

The engine is then coupled to this shaft with a flexible coupling that does not allow any axial forces to be transmitted.

Thus the engine sees no thrust loading and the boat goes merrily to sea.

Archibald

Northfield, Minnesota

. |

kirk

Member

Username: kirk

Post Number: 13

Registered: 09-2005

| | Posted on Monday, July 05, 2010 - 01:04 pm: |

|

UPDATE: Took a few hours today to weld up a gas tank bracket and mount and plumb a gas tank. The engine fired right up and it runs like a swiss watch. Seems to love the Schebler carb. Started up several times after that with one quick turn of the starting crank.

Like most old engines, it not balanced, so it starts to jump around when run at anything over moderately fast idle. Made for an interesting first run, given that I had it sitting on a mover's dolly.

There are open copper lines coming from the mains, and those lines are weeping oil. I thought that they would be to manually oil the mains, but it seems like the exact opposite.

Next step is mounting it on a cart and plumbing a thermosyphon cooling tank.

Chris |

ernie

Senior Member

Username: ernie

Post Number: 1228

Registered: 01-2002

| | Posted on Monday, July 05, 2010 - 06:36 pm: |

|

Neat!

Gonna bring it to Mystic? |