|

| Author |

Message |

dave_carter

New member

Username: dave_carter

Post Number: 3

Registered: 08-2005

| | Posted on Sunday, November 01, 2009 - 05:35 pm: |

|

Could anyone advise me on the construction of the rest of the exhaust for the engine pictured below. 2hp, 1911-1914. Judging by the amount of damage to piston and conrod it seems to have locked up hydraulically either by taking in water back up through the exhaust or through the carb. I presume the venturi effect draws the coolant through the engine as there no provision for a fixed coolant pump.

The coolant joins the exhaust at the base of the muffler and exits through a 1/2" pipe. I am quessing after a short distance of 1/2" pipe, the exhaust should go into a larger diameter pipe (vented to atmosphere) and also over a verticle horse-shoe bend so as to prevent water being sucked back up the pipe on engine over-run.

I won't be putting it in a boat, but would like to show it with the exhaust pumping out coolant.

Does the coolant supply need a non-return valve on the inlet to stop all the coolant draining back out of the engine when the engine stops?

Your suggestions will be greatly appreciated.

http://home-and-garden.webshots.com/photo/2857000630054098493xtklrs?vhost=home-a nd-garden

http://home-and-garden.webshots.com/photo/2074596740054098493wMMJOw?vhost=home-a nd-garden

http://home-and-garden.webshots.com/photo/2270383990054098493GPMEyY?vhost=home-a nd-garden

http://home-and-garden.webshots.com/photo/2123253050054098493DqBnhg?vhost=home-a nd-garden

Regards,

Dave Carter

North Yorkshire.

England |

johnny

Senior Member

Username: johnny

Post Number: 193

Registered: 03-2006

| | Posted on Sunday, December 06, 2009 - 06:27 pm: |

|

Hello Dave,

I'm glad you posted on the forum because it reminded me that I wanted to put a section on my website about this subject. I do not know much about Boulton & Paul engines however this particular engine appears to be a lot like the Detroit two cycle marine engines manufactured by Detroit Engine Works, Detroit Motor Car Supply Co., Termaat & Monahan, Caille perfection, etc..

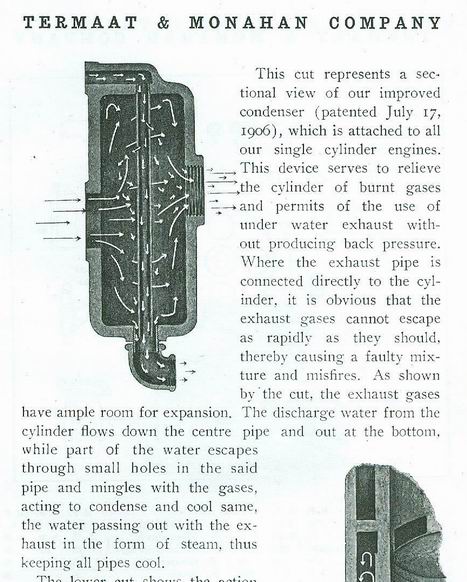

As you probably have already figured out it is very important that you get this expansion chamber manifold working correct or you could have more problems. This is a expansion chamber and condenser not a muffler as a lot of people think. The muffler that was made for this engine is cast round or tubular with baffles inside and attached to the manifold by way of pipe.

VERY IMPORTANT!

Make sure that the pipe that runs down through the chamber is not rusted out or cracked. This pipe should have two or three very small holes maybe about 1/16 diameter for a little water to come out. Also make sure that the drain at the bottom of the chamber where this pipe goes into is not plugged, rusted or carbon up.

See link for patent and details on how the expansion chamber works. You can also visit my website if you like it might help you with your engine rebuild. Good luck...email me if I can help. Regards John

http://www.antiquengines.com/images/Condenser_Muffler_01_825923_Large.gif}}

http://www.antiquengines.com/images/Condenser_Muffler_02_825923.gif

http://www.antiquengines.com/images/Condenser_Muffler_03_825923.gif

http://www.antiquengines.com/Detroit_Engine_Works_Menu.htm |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2250

Registered: 11-2001

| | Posted on Sunday, December 06, 2009 - 08:49 pm: |

|

*

Dave, This is a catalog illustration of the condenser. Also photos of a Detroit Single, Note Water/Pump !

** |

dave_carter

Member

Username: dave_carter

Post Number: 4

Registered: 08-2005

| | Posted on Saturday, December 12, 2009 - 05:52 pm: |

|

Hello Johnny, Thanks for the info and the patent details with working explanation. The casting is in good condition, but I haven't spotted any holes yet. I'll give the chamber a good clean out this weekend.

Being new to the marine engine side of the engine hobby, I didn't realise until I looked at your website, how many makes of engines and their fittings are almost, but not quite, the same.

Rebuilding is slow, as looking for a suitable con-rod to fit, or modify the bearings to suit, over the last six months has drawn a blank. I have commisioned a scale steam man to whittle one from a suitable single piece of steel.

Regards, Dave. |

dave_carter

Member

Username: dave_carter

Post Number: 5

Registered: 08-2005

| | Posted on Saturday, December 12, 2009 - 06:26 pm: |

|

Hello Richard, Thanks for the info and photos. I had looked at the two flat faced apertures and wondered if there was something more than just pipe connections, now I see why there is no sign of any mountings for a pump near the shaft.

Is there a specific time for the pump to push water through the system and into the chamber?

As the pumps look similar, would any one know if they are interchangable?

Regards, Dave. |

|

|

|

|