| Author |

Message |

Paul Gray

| | Posted on Thursday, December 20, 2001 - 06:45 am: |

|

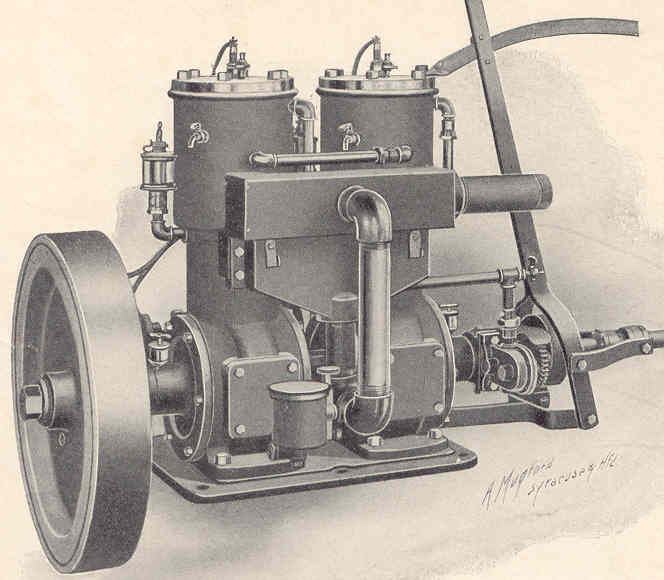

I am restoring a 2-cylinder Barber Bros. (Syracuse, NY) for a friend and am looking for info on these. This one had nickel plated heads and lots of fancy gingerbread on it. I hope to do a "trailer queen" resto on it. Anybody ever remove a flywheel from one of these ? Just would like to know if there are any strange threads/keys I am not dealing with. |

andrew

| | Posted on Thursday, December 20, 2001 - 10:37 pm: |

|

Paul,

I think Bill Schaller has a two cylinder Barber Bros. without a flywheel... so he should be able to tell you what the crank, key, etc. look like. I will see him tomorrow and I will ask him about it. I will post a reply or ask him to do so.

Andrew |

andrew

| | Posted on Thursday, December 20, 2001 - 11:24 pm: |

|

|

Paul Gray

| | Posted on Friday, December 21, 2001 - 06:18 am: |

|

Thanks Andy and Bill. The one in the pix appears to have a mag setup ? Mine has a distributor which I have never seen before. Inside it are two rotors. One distributes the high tension and the other acts as a set of ponts for the primary side. I think it will work with one of those wood-box Atwater-Kent coils I have. The advance-retard mechanism is operated by a lever on the starbord side of the engine. I got the flywheel off AOK today also. Was way easier after the block was removed from crank. The taper/keyway needs a bit of work, but is serviceable. The babbitt is shot as are wrist pin bushings. Exhaust manifold is a complex water-cooled affair with a drip valve for cooling water. Cylinders are in good shape. There is a fiber gear which drives the distributor off the gear on the flywheel which may need replacing. All in all a straightforward resto. |

andrew

| | Posted on Friday, December 21, 2001 - 10:44 am: |

|

Paul,

Glad you got it okay... flywheel removal always makes me nervous!

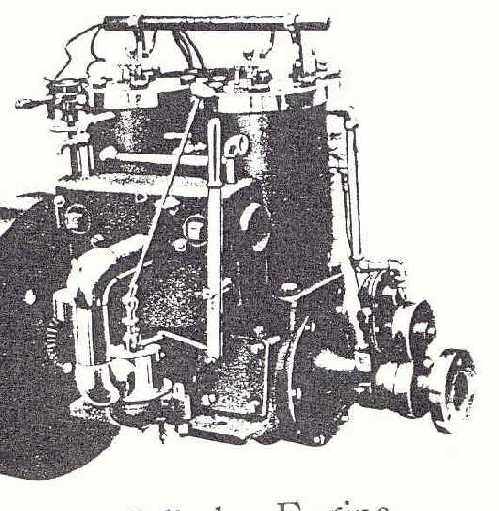

Here are a couple other pictures of Bill's engine.

Regards,

Andrew

|

PaulGray

| | Posted on Friday, December 21, 2001 - 05:23 pm: |

|

I made the float mold for the Krice carb and put up an ad on this site in the parts FS section. |

andrew

| | Posted on Friday, December 21, 2001 - 05:39 pm: |

|

Paul,

That's great... here is a link to the ad. Do you have a photo you could post with it?

Regards,

Andrew |

Bruce Hall

| | Posted on Sunday, December 23, 2001 - 03:23 pm: |

|

Paul: Can we see the opposite side view please? |

Bruce Hall

| | Posted on Sunday, December 23, 2001 - 03:27 pm: |

|

Paul: Can you show us the mag side?My recently aquired single has the same exhaust manifold but the intake is opposite side!!?? No Barber tag but it's the closest match Iv'e found right down to the gear driven Oberdorfer water pump off the tailshaft. My timer configuration is simular.It has a Monarch "H" carb and check valve - looks like a Schebler clone. |

PaulGray

| | Posted on Sunday, December 23, 2001 - 04:10 pm: |

|

Bruce- Not my engine pix. They're Bills. I hope to have some pix of parts soon to post. Will aslo try to get Krice float pix; pretty boring of a gray plastic donut with beveled edges. |

Joe

| | Posted on Sunday, December 23, 2001 - 09:18 pm: |

|

TO PAUL GRAY....you mentioned Atwater Kent coils. Do u have any extra? I just found an Atwater Kent timer/distributor for a two cylinder Easthope marine engine that I have and need a coil.Thanks....Joe |

Richard Day

| | Posted on Monday, December 24, 2001 - 07:56 pm: |

|

Paul, I think the set up calls for a Ford T coil not an Atwater Kent coil. There were a number of early distributors set up to work with one coil and a distributor to route the spark to the correct cylinder. The AW coil works on a normally open set of point that close for only milliseconds. A long dwell could ruin a good AW coil. |

bill

| | Posted on Monday, December 24, 2001 - 11:30 pm: |

|

Bruce,

this engine does not have a mag, the chain drive is from an engine sitting next to it. |

Bruce Hall

| | Posted on Tuesday, December 25, 2001 - 12:23 am: |

|

Bill: Some bearded old guy in red suit just stopped by delivering stuff.I told him unless it was old marine engines; it probably was for the neighbors up the road!!!!

My water pump mount is the same idea as yours but more elaborate.I have one stud at the bottom of split casting that slides over the rear bearing housing and is secured in place at the desired angle by tightening the stud.The gear pump is fastened to the casting with it's drive gear running on the mating gear on the tailshaft. Both gears are the same outside diameter. Bruce |

Paul Gray

| | Posted on Wednesday, December 26, 2001 - 05:45 pm: |

|

Dick- Thanks for the heads up on using a Ford T coil instead of AK. The way you explain it, it makes sense to me. I would rather not burn up the AK coil too!! Besides I have T coils stacked up like cord wood here. Do you have any info on these distributors ? Who made them or were they made custom ?? What type of water pump did this engine use ?? I have a bronze Oberdorfer gear pump which would work with the right gear on the tailshaft. |

Richard Day

| | Posted on Wednesday, December 26, 2001 - 09:37 pm: |

|

Sorry Paul I have exhausted my knowlege of the type distributor you seem to have. I just know I saw such a unit operating back in the late 1930s on a friends Model T ford saw rig. My memory banks are slowly being vacated. Guess it goes with the age group. |

richarddurgee

| | Posted on Thursday, December 27, 2001 - 11:22 am: |

|

Paul: this is from 1907 Barber catalog  shows oberdorfer type pump mounted horizontaly. ( Pics here of Bills eng show same mount). Have a copy of 1925 Barber catalog that Bruce Hall sent, It shows same pump style but mounted vertically ?? shows oberdorfer type pump mounted horizontaly. ( Pics here of Bills eng show same mount). Have a copy of 1925 Barber catalog that Bruce Hall sent, It shows same pump style but mounted vertically ?? |

richarddurgee

| | Posted on Thursday, December 27, 2001 - 11:34 am: |

|

1925 catalog  |

Bruce Hall

| | Posted on Thursday, December 27, 2001 - 11:13 pm: |

|

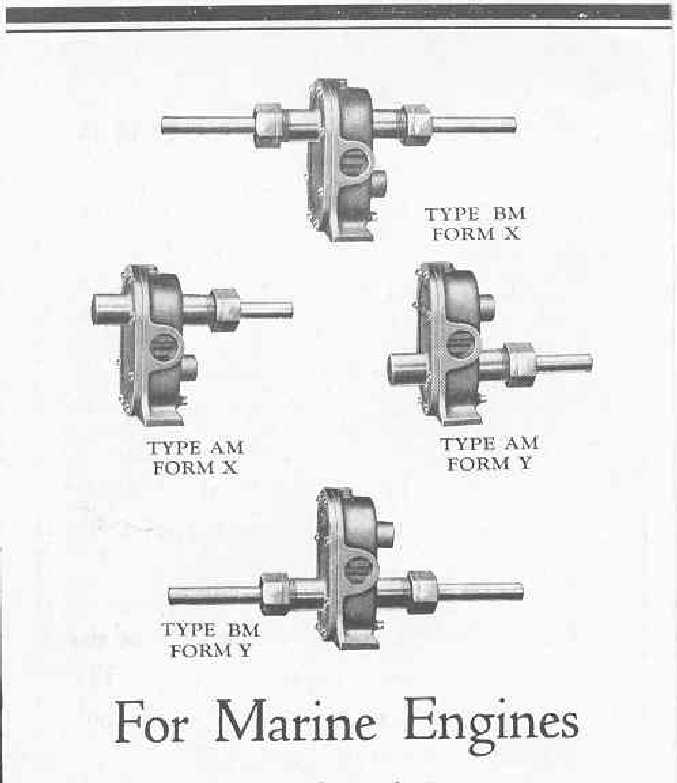

Richard; thanks for posting the Barber catalog shots-I have some interesting news on the bronze Oderdorfer gear pump used on the Barber and other Marine engines.It's still being made in Syracuse in nearly the same casting style it was made a hundred years ago!! Log on to Orberdorfer pump Co. website and go to the BRONZE PEDESTAL PUMP section.Look at the series N-3000 pump spec-It's a pedestal mount 3/8" fpt inlet and outlet.It pumps 1.5 gpm at 400 rpm; at near zero ft. head.Slightly less with ~23 ft head(~10psi);more at greater RPM of course.Other choices such as N-2000 ;etc. have smaller or larger pipe connections and capacities. COOL!! Contact the MFG rep firm listed for your area (info on the web site) for purchase availability. There's a company history profile stating Oberdorfer started building pumps in 1890 on Water street-home to or very near several of Syracuse's engine builders.The profile states they made marine pumps since 1920 which in essence is true but we know they were applied much earlier. |

richarddurgee

| | Posted on Friday, December 28, 2001 - 12:10 pm: |

|

This is from a 20's or 30's oberdorfer pamphlet!

|

andrew

| | Posted on Friday, December 28, 2001 - 12:26 pm: |

|

Here is a link to the Oberdorfer web site as Bruce mentioned.

They also have a maintenance page which looks interesting.

Regards,

Andrew |

bruce

Senior Member

Username: bruce

Post Number: 275

Registered: 07-2002

| | Posted on Tuesday, August 02, 2011 - 09:22 am: |

|

A Barber Engine Co. catalog recently sold on e-bay. It was a 1904 or earlier piece consisting of a very early Barber Co.letterhead and engine data in an envelope marked Brennan Engine company post marked 1904. Did Anyone here manage to purchase this item? I lost the bid at the last minute but would like very much to purchase a photocopy of these items-especially the company letterhead. It listed a fabrication shop in Phoenix NY possibly the steam products fabrication location. |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 3059

Registered: 11-2001

| | Posted on Thursday, August 22, 2013 - 02:02 pm: |

|

*

Oberdorfer Pumps Corporation has a rich history of quality, ingenuity and service. The pump department of Oberdorfer Foundries was formed in 1890 when Moses L. Oberdorfer began manufacturing bronze pumps in a small factory on East Water Street in Syracuse, NY. Oberdorfer pumps were used to provide oil for lubrication of the engine cylinder walls for the very early automobile, aircraft and motor boat industries.

* |