| Author |

Message |

billschaller

Senior Member

Username: billschaller

Post Number: 195

Registered: 12-2003

| | Posted on Thursday, January 15, 2009 - 03:50 pm: |

|

I have seen a couple of mentions that a small metal drip pan was placed under schebler and other carburetors to catch the gas that dripped out. I believe they had a very fine mesh brass screen over the top, I assume to stop flames. Does any one have a picture, or description? I would like to make some, but would prefer it to be somewhat authentic. I suppose just putting a piece of sceen on a period correct tin can would work, too. |

richardday

Senior Member

Username: richardday

Post Number: 706

Registered: 11-2003

| | Posted on Thursday, January 15, 2009 - 08:52 pm: |

|

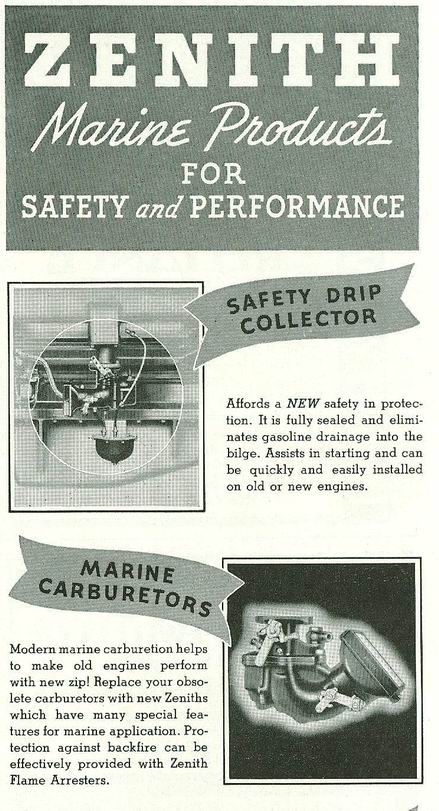

Bill, Somewhere in this page I wrote a short comment regarding the pans we had under up draft carburetors. Looked for it but cannot pull it up.

Back in the period I can remember from visiting various cabin cruisers with big old T head Lathrop and Palmers the carburetors were typical marine carburetor like the the Zenith 63M. They had slant throats with the pick up tube in them. They had backfire traps but beneath the carburetors would be a brass or copper can about 3"W by 6" long by 4" or 5" deep. They had a very fine screen like a Daveys lamp which was soldered or some how attached don't remember exactly how. The fine screen was about 1/2" below the top rim of the can and not removable. I don't remember exactly how it was supported below the carburetor or how the wires were attached to the can. I do remember the owner would simply empty the can over the side if it collected any fuel in it. I don't recall ever seeing any such beast for sale in any of the marine magazines of the time and I have seen a lot of them. I do remember that prudent boat owners all had backfire traps in the early 1930s but they were not required until the safe boating act was passed in 1940. Engine makers were equiping their engine with backfire traps back in the 1920s from what I have seen in old boating magazines. Perhaps Richard will dig up more info from his mountain of information. Best I can offer. |

barry

Senior Member

Username: barry

Post Number: 106

Registered: 02-2006

| | Posted on Saturday, January 17, 2009 - 12:39 pm: |

|

More thoughts on this subject.

It seems to me that a mesh cover over a drip container functions similar to but opposite to a carburetor back fire flame arrestor.

During an engine backfire a flame front may be propagated along the intake manifold out the carburetor air inlet and initiate an engine room fire or explosion should a combustible mixture be present due to previously undetected gasoline leakage.

A backfire flame arrestor absorbs flame heat thus cooling the flame below ignition temperature, as a result extinguishes the flame. The flame is quenched firstly by decreasing the flame front velocity since the area of the arrestor is much larger than the carburetor throat; secondly the mesh flame arrestor screen breaks the flame into a multitude of small flames that, because they are small, are promptly cooled below ignition temperature.

My experience is that Schebler model D when used with St Lawrence engines will drip during operation. I use a rigid plastic tray under the carb to collect drips. Otherwise gasoline drips would destroy and blacken the wood finish. The amount is small, perhaps 2ml after two hours of operation. I use a paper towel to absorb collected fuel and dispose of the towel on land. This should not be confused with carburetor leaking that may occur because of float valve malfunction, refer to a previous discussion about float valves.

http://www.oldmarineengine.com/discus/messages/3433/101261.html

A fine tight mesh tight fitted lid over the drip container would function to extinguish a flame by the same principle as a back fire flame arrestor; it would break up a flame into small flames that would easily cool to below ignition temperature. Since there is no source of ignition within the container to initiate a flame, my thought is the screen is intended to prevent passage of an external flame that would ignite container contents. The screen to work would need to be a tight fit to prevent a flame from passing into the container via any openings.

I’m unable to come up with a source of an external flame.

I choose not to use a screen as I want to avoid collection of any significant amount of fuel. Also I wish to facilitate removal of drips using a paper towel as previously mentioned. and not be inhibited by the screen.

My engine is typical of a small boat non enclosed installation. If the engine was contained in an enclosed engine room that relied on piped in air for venting, I would be much more prudent.

Barry

|

john_archibald

Senior Member

Username: john_archibald

Post Number: 94

Registered: 08-2006

| | Posted on Saturday, January 17, 2009 - 03:15 pm: |

|

The purpose of the screen is to take the heat away from the flame. If you wrap a piece of copper bell wire around a pencil with in an open helical shape with an "open weave" and you place this over a burning candle flame like a tube, the flame will go out immediately. Even though the flame can get plenty of air it goes out instantly. The open copper helix takes the heat away from the flame and combustion can not be supported.

I showed this to my kids once and they were amazed.

Archibald

. |

rholcomb

Advanced Member

Username: rholcomb

Post Number: 33

Registered: 10-2004

| | Posted on Saturday, January 17, 2009 - 03:22 pm: |

|

http://www.google.com/patents?id=-XhoAAAAEBAJ&pg=PA1&dq=marine+engine+fuel+drip& source=gbs_selected_pages&cad=0_1#PPA1,M1 |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1980

Registered: 11-2001

| | Posted on Saturday, January 17, 2009 - 09:39 pm: |

|

*

I watched a newly made movie the other day it was set back in the early 1950's and when an actor used a modern 4 lettered swear word That was just not used back then, no matter how hard you hit your thumb with the hammer, I was trying to remember the word for the missuse, When I came to this post and saw the old schebler carb on an old engine with an oiler in the intake pipe dating it about 1908 - and then I saw the plastic drip container the word "ANACHRONISM" popped into my head. Same thing when I see modern square cut brass fittings or the use of standard bolts where a high crown was used !!

Now I would think that the quick temporary container in 1908 would probably have been a coffee can, an appropraite one would be a local Company that actually made coffee in those years, I'm not sure but I don't think one that says Decaf, or instant etc would be for that time period either ??

I have searched for info or photos on old fuel drip containers but haven't find anything yet !!

I will say when I need one I'll use tin,brass or copper sheet and form what fits under the specific engine and soft solder the seams. Not to worried about the safety of small amount of liquid gasoline in a metal container, the very object of the drip pan ( besides staining the wood) is to keep the gasoline out of the bilge were it spreads and vaporizes causing the explosive hazard.As for a screen, for a show engine it would look a little fancier, for a running vessel I'd go without it so I can always see any gasoline in it !!

My 8 cents worth ! Up from 2 cents-- infation is everywhere !

** |

billschaller

Senior Member

Username: billschaller

Post Number: 196

Registered: 12-2003

| | Posted on Saturday, January 17, 2009 - 10:17 pm: |

|

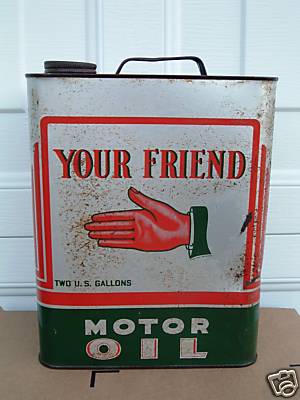

In my grandfather's garage, there were about 140 1 and 2 gallon sized oil cans that were cut in half, and roughly labeled and placed on shelves full of nuts and bolts and nails. I remember looking at them when we had the estate auction, and thinking how great they would have been if they were not cut in half. I know that is the sort of thing my family would have used on the Mississippi and it's backwaters back in the day. Now, those cans in mint shape are worth a lot of money, but in poor shape they would be the perfect thing to cut in half, and use for this. I know it's the sort of thing he would have made, every one of his funnels had fine screen soldered into them. Here are some examples of the type of oil cans he would cut in half, or cut the top off.

|

barry

Senior Member

Username: barry

Post Number: 107

Registered: 02-2006

| | Posted on Sunday, January 18, 2009 - 12:03 pm: |

|

Here is a composite image of the vessel and engine referred to in Richard’s post.

Although the cut-off drip container may be an anachronism, close scrutiny of the images reveals another anachronism, rather blatant. Also the cooling water piping arrangement is interesting.

Vessel owned any used regularly by John Laing.

Barry

|

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1981

Registered: 11-2001

| | Posted on Sunday, January 18, 2009 - 02:34 pm: |

|

*

This is 1939

** |

billschaller

Senior Member

Username: billschaller

Post Number: 198

Registered: 12-2003

| | Posted on Sunday, January 18, 2009 - 03:11 pm: |

|

Barry, I see the anachronism, they didn't have turn signals like that on trailers in the old days. The Hall effect was discovered in 1879. |

bruce

Senior Member

Username: bruce

Post Number: 191

Registered: 07-2002

| | Posted on Sunday, January 18, 2009 - 03:31 pm: |

|

Just learned about the Hall effect recently when a furnace combustion blower didn't prove run status-changed the Hall effect sensor and back in business. I had to read up on it on the internet-you'd think I would have heard of it before. Bruce Hall |

john_archibald

Senior Member

Username: john_archibald

Post Number: 96

Registered: 08-2006

| | Posted on Sunday, January 18, 2009 - 03:32 pm: |

|

Who built the boat and where was it built? Is it about 14 feet in length?

Archibald

Northfield, Minnesota

. |

capmo

Member

Username: capmo

Post Number: 4

Registered: 06-2008

| | Posted on Friday, January 23, 2009 - 10:12 am: |

|

Avast, the 3X5X3/4 " drip pan under my Hicks Schbler is also coverd in mesh but has a copper pipe in the bottom that goes up and into the arrestor cap so the vacume returns drips to the intake. |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1987

Registered: 11-2001

| | Posted on Friday, January 23, 2009 - 06:56 pm: |

|

*

capmo-- not sure what your refering to "arrestor cap" ? Is a Photo possible ?

------------------------------------------------

Are these drip containers ??

1905

** |

capmo

Member

Username: capmo

Post Number: 5

Registered: 06-2008

| | Posted on Saturday, January 24, 2009 - 12:22 pm: |

|

The cap id matches the spring loaded intake and flares out about 1/2" and is covered with mesh. about half way down is soldered a compression fitting to the return pipe to the drip pan bottom. |

searcher

Senior Member

Username: searcher

Post Number: 277

Registered: 10-2004

| | Posted on Tuesday, January 27, 2009 - 11:49 pm: |

|

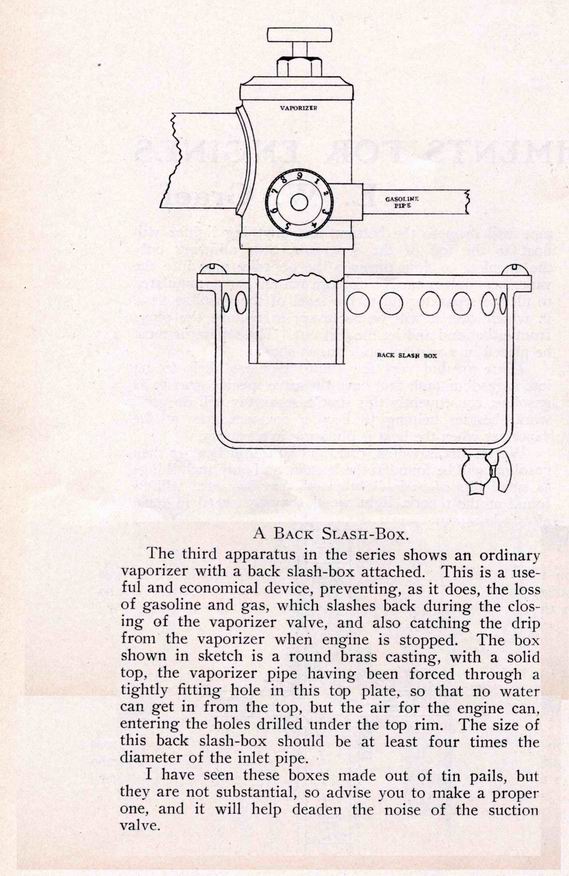

Here is a related device.

|

scott_n

Senior Member

Username: scott_n

Post Number: 78

Registered: 02-2008

| | Posted on Wednesday, January 28, 2009 - 10:10 am: |

|

Hear is a another type  |

bcedrone

New member

Username: bcedrone

Post Number: 3

Registered: 09-2006

| | Posted on Thursday, January 29, 2009 - 01:50 pm: |

|

My 1960's Lathrop engine has a small tray under the carborator with the fine mesh that wes spoken of. It also has a copper tube leading from the tray back into the carburator(or intake manifold). |