| Author |

Message |

2_cycle

New member

Username: 2_cycle

Post Number: 1

Registered: 02-2008

| | Posted on Monday, February 11, 2008 - 11:43 am: |

|

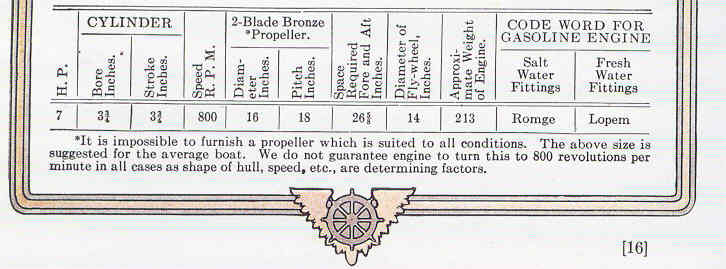

I am in the process of restoring a Fairbanks Morse 2 cylinder, 7 hp Model "E". In order to make the handling and restoration of this heavy engine easier, I want to remove the flywheel. However, I am not sure if the barrel nut retaining the flywheel is a right or left hand thread? Since the flywheel rotation (as viewed from the front) is counter clockwise (right hand propeller), I assumed the thread would be right hand since the torque of the counter clockwise engine rotation (as viewed from the front) would tend to tighten it when turning. Use of the optional crank, though, would tend to loosen it and therefore suggests a left hand thread. Which is it?

Only two parts are missing to acheive an operable engine. 1. A replacement piston ring (one is broken) and the proper gear water pump (missing).

Any suggestions or, does anyone have either item for sale?

Thanks for any help, information or suggestions.

Bill Saunders |

miro

Senior Member

Username: miro

Post Number: 313

Registered: 11-2001

| | Posted on Wednesday, February 13, 2008 - 12:14 pm: |

|

gosh, I'd stay away from the crank if I were you. It will likely backfire when you try to start it the first time and bang - your wrist is smashed.

miro |

johnny

Senior Member

Username: johnny

Post Number: 150

Registered: 03-2006

| | Posted on Wednesday, February 13, 2008 - 07:11 pm: |

|

Bill,

Is there not any thread sticking out of the nut a little? Where you can look at the thread and figure it out? |

richardday

Senior Member

Username: richardday

Post Number: 561

Registered: 11-2003

| | Posted on Thursday, February 14, 2008 - 10:53 am: |

|

It seems to me if the crank dogs indicate a left hand rotation of the engine the threads would have to be left hand as the action of the crank would loosen the nut. In the early years most marine engines were left handed including two strokes with their right handed props. While two strokes would direct reverse on the spark the larger two strokes were typically started by stomping on the fly wheel spokes in the opposite direction one wanted to run. Miro, is also very right better make very sure where the spark advance is before trying to crank the engine. |

2_cycle

New member

Username: 2_cycle

Post Number: 2

Registered: 02-2008

| | Posted on Friday, February 15, 2008 - 09:24 am: |

|

First, thanks to all those who have responded to date. Don't worry Miro. I don't have a crank and the engine is not running yet. The object is to restore the engine to running condition. A crank was available, as an option, when the engine was new. Interestingly, it folded when the engine kicked back in the opposite direction.

To Johnny - No threads are visible. That is the first thing I investigated. The "barrel" nut extends forward from the hub of the flywheel to the end of the crankshaft. In fact, the nut ends even with the end of the crankshaft. So, no threads are visible.

Richard Day - I agree with everything you said. But that is the problem. Is it left hand to counter the power impulses of a counterclockwise flywheel rotation or, is it a left hand thread so the use of the optional crank would not loosen the nut?

For those of you who are not familiar with the flywheel nut used on this model FM engine, it is perfectly round, 1 1/2" long x 1 3/4" O.D.. There are three slots milled into the O.D.,120 degrees apart, equally spaced. These slots accomodate the optional crank or a special spanner wrench to remove the flywheel nut.

I had been hoping to contact someone who is familiar with this model FM engine, or has maintainance literature, which would pin down the direction of the thread pitch. I have tried to move the nut in both directions and coulden't budge it either way. It has not been off since the engine was new. In had been installed in a launch in Marine City Michigan. I salvaged it in the late 40's and am just getting around to restoring it. (Talk about procrastination!) It sure would help if I could concentrate my efforts, with confidence, that I was trying to break the nut loose in the right direction.

Bill |

iceboater

Member

Username: iceboater

Post Number: 10

Registered: 08-2006

| | Posted on Saturday, February 16, 2008 - 06:17 pm: |

|

Any thought of spliting the nut off the crank.Yes you distroy the nut but you will not take a chance of breaking off the end of the crank. The nut can be replaced. |

2_cycle

New member

Username: 2_cycle

Post Number: 3

Registered: 02-2008

| | Posted on Sunday, February 17, 2008 - 12:45 pm: |

|

iceboater ----- good point. However, I would first like to try screwing it off by knowing I am trying to unscrew it in the proper direction. As a last resort, if all else fails, the nut can be destroyed.

Your user name suggests you may live in the vicinity of the Great Lakes?

Bill |

john_archibald

Advanced Member

Username: john_archibald

Post Number: 42

Registered: 08-2006

| | Posted on Sunday, February 17, 2008 - 01:48 pm: |

|

2-Cycle,

Can you post a close-up digital image of the nut and shaft up here? Failing that, send me an image to: [email protected]

Archibald

Northfield, Minnesota

. |

2_cycle

Member

Username: 2_cycle

Post Number: 4

Registered: 02-2008

| | Posted on Monday, February 18, 2008 - 11:03 am: |

|

Thank you John. Since I do not have the equipment to send you a picture of my engine, I sent you a link to pictures of a beautifully restored, single cylinder version, that appears on the discussion board. I have also e-mailed the owner, Richard, ( [email protected] ) to ask if he removed the flywheel during the restoration process.

Bill |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1612

Registered: 11-2001

| | Posted on Monday, February 18, 2008 - 04:55 pm: |

|

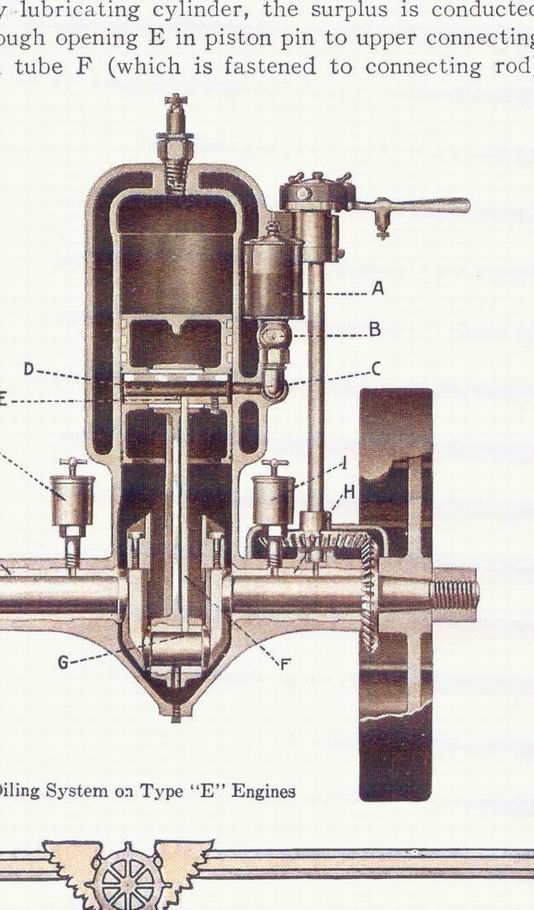

*

I removed the flywheel from crankshaft when I rebuilt it but I cannnot remember on this specific shaft whether left or right thread.

if illustration is not to be trusted I can one day get to it in warehouse and find out for sure !

1911 Fairbanks E single

1911 Fairbanks Twin

* |

john_archibald

Advanced Member

Username: john_archibald

Post Number: 43

Registered: 08-2006

| | Posted on Monday, February 18, 2008 - 06:08 pm: |

|

2-Cycle,

The nut, as drawn, is a right hand thread.

Archibald

. |

2_cycle

Member

Username: 2_cycle

Post Number: 5

Registered: 02-2008

| | Posted on Monday, February 18, 2008 - 10:54 pm: |

|

Thanks guys. John, I have the 1912 version of the same catalog. Those drawings are, indeed, very well done but, by an artist, not a design engineer. Go to page 22 in the same catalog which shows a similar illustration for the model G engine which may very well use the same crankshaft and barrel nut. There the thread is left hand!

Richard, if you could get to yours and check it, that would be very helpfull.

Again, thanks for all your help. I'm sure the mystery will be solved one way or another sooner or later.

Bill |

billschaller

Senior Member

Username: billschaller

Post Number: 146

Registered: 12-2003

| | Posted on Saturday, February 23, 2008 - 01:40 am: |

|

I would think that putting an impact wrench on it, and switching directions every once in a while would get it off. |

2_cycle

Member

Username: 2_cycle

Post Number: 6

Registered: 02-2008

| | Posted on Saturday, February 23, 2008 - 09:16 am: |

|

Thanks Bill. It's a good idea. Wish I could try it but this is a barrel nut. Nothing to grab ahold of. As described earlier, it is perfectly round with three keyway like slots milled into the O.D. 120 degrees apart. Apparently, a special spanner wrench was to be used. I have tried to move it with a 24" pipe wrench against key stock in two of the grooves. I have not been able to budge it as a right hand thread. That does not mean the thread is not right hand - just that I could not move it. Before trying to move it as a left hand thread, or before continuing to move as a right hand thread, I want to make sure my efforts are in the right direction. Yes, I have even heated it.

I am in hopes that someone out there has, or had, a similar engine, or a maitainance manual and can verify the direction of the thread before I try again.

Bill |

john_archibald

Advanced Member

Username: john_archibald

Post Number: 44

Registered: 08-2006

| | Posted on Saturday, February 23, 2008 - 10:32 am: |

|

2-Cycle,

I would make a hefty wrench for the nut first and then rap on it either way until she breaks loose. Alternately heating and cooling the nut with a torch and a squirt bottle of water would help, also. Squirt the water onto the shaft end after heating the nut.

I would also use a few shots of Kroil and let it soak for a day before trying any of the above. Kroil is available online from Kano Labs.

Good luck.

Archibald

Northfield, Minnesota |

2_cycle

Member

Username: 2_cycle

Post Number: 7

Registered: 02-2008

| | Posted on Saturday, February 23, 2008 - 01:08 pm: |

|

Finally, success. The nut came loose after plenty of heat and persuasion. The answer is IT IS A LEFT HAND THREAD!!!!

Thanks to all those who responded to my plight. I hope I can be of some help to someone in the future. Now to "pop" the flywheel off the taper.

Bill |

john_archibald

Advanced Member

Username: john_archibald

Post Number: 45

Registered: 08-2006

| | Posted on Saturday, February 23, 2008 - 03:52 pm: |

|

2-Cycle,

Bravo!

Archibald |

sfsorrow

Member

Username: sfsorrow

Post Number: 10

Registered: 04-2006

| | Posted on Sunday, March 02, 2008 - 10:21 pm: |

|

I just noticed my timing distributor on my Canadian Fairbanks

is run off the other end, drive shaft flange end, of the motor and not like the one illustrated in the period photo.

I was wondering if that is a Canadian quirk or it may be a different model? |

2_cycle

Member

Username: 2_cycle

Post Number: 8

Registered: 02-2008

| | Posted on Monday, March 03, 2008 - 08:53 am: |

|

The engine you described is a model G with removeable head. The timer is at the drive end on that model. If it is a single cylinder, the hp is 6.

Bill |

johnny

Senior Member

Username: johnny

Post Number: 158

Registered: 03-2006

| | Posted on Monday, March 03, 2008 - 05:22 pm: |

|

Here are a couple photos I took of a Canadian Fairbanks that was at our January show here in Florida. I believe this engine may still be for sale. The gentlemen was asking $750.00 for it with a schebler carb. The ignition is on the flywheel side.

|

sfsorrow

Member

Username: sfsorrow

Post Number: 11

Registered: 04-2006

| | Posted on Monday, March 03, 2008 - 08:51 pm: |

|

hmmm. interesting Bill.

Mine is a one piece head, single, identical to the

one in the cutaway drawing above, other than the

distributor.

How perchance does one start such an engine.

the only engines I really know about are the ones you stuff wood and water into them and they go choo choo.

nice looking twin, hmmm time to sell my soul, offspring and

grandchildren. |

sfsorrow

Member

Username: sfsorrow

Post Number: 12

Registered: 04-2006

| | Posted on Monday, March 03, 2008 - 08:54 pm: |

|

my C F-M, aside from the reversed distributor,

does not have flutes inside the flywheel rim |

2_cycle

Member

Username: 2_cycle

Post Number: 9

Registered: 02-2008

| | Posted on Monday, March 03, 2008 - 09:59 pm: |

|

Don't have an answer for you. There is no reason why the timer can't be driven by the water pump gear, assuming that the water pump gear has the right number of teeth. Note that the engine picture submitted by Johnny, above, does not show a flywheel fluted on the inside.

Bill |

freshwater

Member

Username: freshwater

Post Number: 16

Registered: 11-2007

| | Posted on Saturday, March 22, 2008 - 06:13 pm: |

|

My C F M has a geared brass water pump on the prop end it also drives the timer on the same shaft it is headless and other than the pump looks like the one in the photo no pictures because I have it apart DEREK |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1663

Registered: 11-2001

| | Posted on Sunday, March 23, 2008 - 01:02 pm: |

|

*

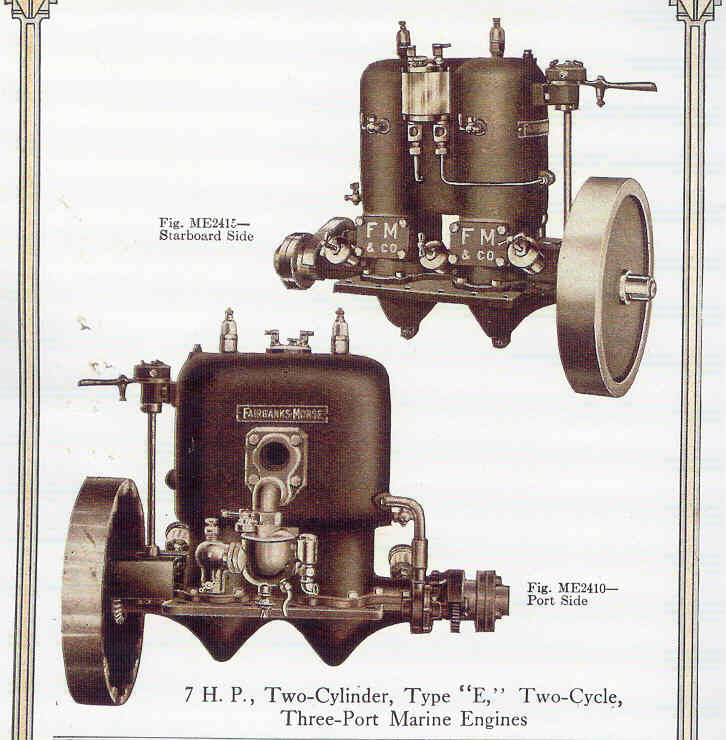

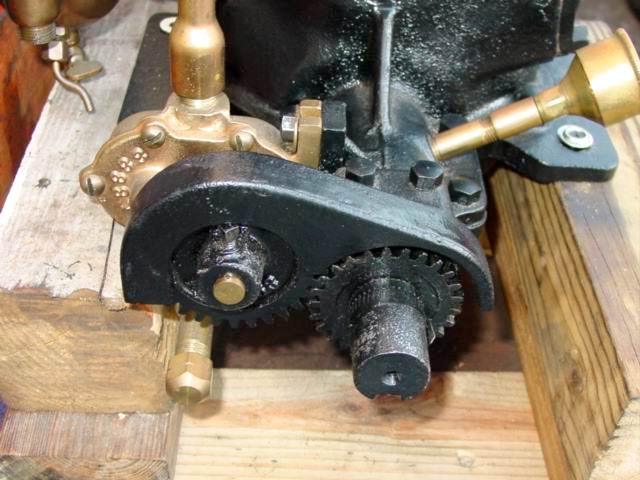

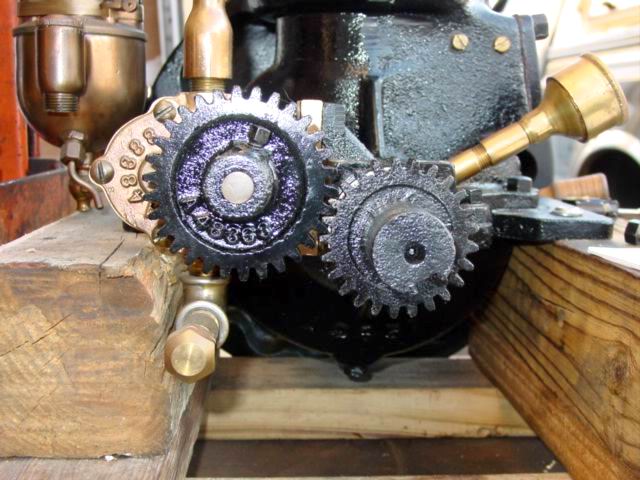

The Fairbanks Model " E " single that I rebuilt a few years back !

* |

2_cycle

Member

Username: 2_cycle

Post Number: 10

Registered: 02-2008

| | Posted on Monday, March 24, 2008 - 10:50 am: |

|

Good morning Richard,

Nice job on your restoration!

Do you have convenient access to that engine? If so, would you mind taking some measurements for me? My 2 cyl., Mdl. E is essentially complete with the exception of the oiler lines, waterpump, waterpump drive gear, piping and gear shroud. I suspect the the chances of finding those parts are slim and none. I am going to have to be creative if the parts cannot be found. So, I have the following questions regarding the water pump assembly: 1. Water pump manufacturer and model No? Is it an OBERDORFER? 2. What is the water pump drive shaft dia? 1/2"? 3. What are the inlet and outlet inside diameters? 1/2"? 4. What is the pump shaft drive gear dia? (I have the crankshaft drive gear.) 5. length and width of the pump?

I expect thatI will eventually have to take another brass gear pump and modify it to fit. I think I can buy a spur drive gear from a mill supply house and fabricate the brass pipe from the discharge to the engine. So, your answers would be very helpfull if I can't find someone who has an engine that is scrap and can be parted out.

Thanks,

Bill |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1666

Registered: 11-2001

| | Posted on Tuesday, March 25, 2008 - 07:35 am: |

|

*

From looking at photos the single and the twin seem to use the same pump, its an Oberdorfer and I see many of them for sale although there are many different models, next time at my warehouse i'll get info and a few close up photos with the gear cover off !

* |

2_cycle

Member

Username: 2_cycle

Post Number: 11

Registered: 02-2008

| | Posted on Tuesday, March 25, 2008 - 09:11 am: |

|

Thanks Richard. I sure would appreciate it. I agree that the pump for the single and twin cyl are the same.

Bill |

freshwater

Member

Username: freshwater

Post Number: 17

Registered: 11-2007

| | Posted on Wednesday, March 26, 2008 - 01:38 pm: |

|

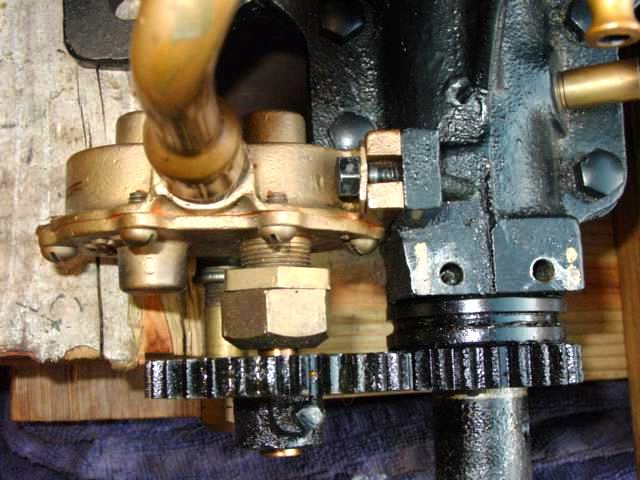

here are a couple of pics of the water pump and timer setup on my CFM notice someone juried a auto distrbutor on it this engine is complete otherwise shebler carb double drip oiler 3 T type grease cups primer etc the tag reads FAIRBANKS MORSE with no place for model or serial can anyone help with model etc. RICHARD ??? thanks derek |

freshwater

Member

Username: freshwater

Post Number: 18

Registered: 11-2007

| | Posted on Wednesday, March 26, 2008 - 03:05 pm: |

|

pictures are to big |

robert

Senior Member

Username: robert

Post Number: 207

Registered: 07-2003

| | Posted on Thursday, March 27, 2008 - 01:58 am: |

|

"I salvaged it in the late 40's and am just getting around to restoring it."

That is beautiful - thank you! |

freshwater

Member

Username: freshwater

Post Number: 19

Registered: 11-2007

| | Posted on Thursday, March 27, 2008 - 05:35 pm: |

|

|

freshwater

Member

Username: freshwater

Post Number: 20

Registered: 11-2007

| | Posted on Thursday, March 27, 2008 - 05:44 pm: |

|

|

freshwater

Member

Username: freshwater

Post Number: 21

Registered: 11-2007

| | Posted on Thursday, March 27, 2008 - 05:48 pm: |

|

Hi I finaly got the pump pictures to go does anybody have a CFM with this setup the motor is headless 2 cyl the pump has no name or no. thanks for any help DEREK |

billschaller

Senior Member

Username: billschaller

Post Number: 148

Registered: 12-2003

| | Posted on Thursday, March 27, 2008 - 06:27 pm: |

|

like this?

|

billschaller

Senior Member

Username: billschaller

Post Number: 149

Registered: 12-2003

| | Posted on Thursday, March 27, 2008 - 06:29 pm: |

|

|

freshwater

Member

Username: freshwater

Post Number: 22

Registered: 11-2007

| | Posted on Thursday, March 27, 2008 - 07:18 pm: |

|

Hey thanks that is the pump as you can see in my pictures it has been modified with a auto distributor rather crudely do you know what year your engine is DEREK |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1683

Registered: 11-2001

| | Posted on Monday, April 14, 2008 - 09:11 am: |

|

*

2_cycle

Bill - Photos of Fairbanks Model E Water pump.

Crankshaft Gear 25 teeth

Pump Gear 30 teeth

Inlet pipe size 1/2 inch

Shaft 1/2 inch

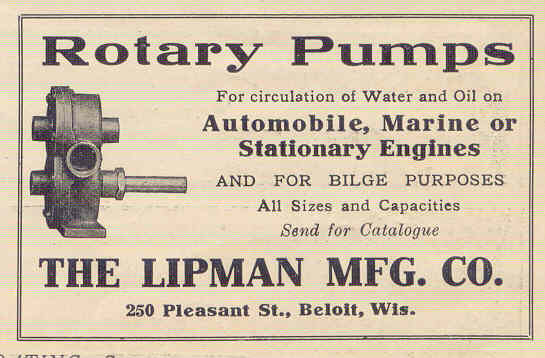

After looking closely at the pump I believe it was Made by The Lipman Mfg Co. Unless you had it side by side with an Oberdorfer it would be hard to tell the difference ?

* |

2_cycle

Member

Username: 2_cycle

Post Number: 12

Registered: 02-2008

| | Posted on Tuesday, April 15, 2008 - 04:49 pm: |

|

Richard,

Thank you ever so much for your trouble. Great pictures! They will certainly be of help.

I have two bronze/brass gear pumps. One is an Oberdofer with 1/2" suction & discharge openings & a 1/2" dia shaft. The outside dimensions of the pump body are 2 5/16" wide x 3 3/4" long. However, the drive shaft is opposite the mounting foot & the stuffing box, as well as the extentions for the internal gear shafts, are much longer. In fact, they facilitate small grease cups. If it would even be possible to modify this pump, the modifications would have to be extensive.

The other pump is a Sherwood with 1/2 suction & discharge but a 3/8" shaft. Body length is 2 7/8" and body width is 1 15/16". It does have the cast mounting foot adjacent to the drive shaft. However, it also has grease cups and a long stuffing box and shaft housing extensions. did you note the body size of your pump? Which of the above outside dimensions are the closest to you pump?

I do have the crankshaft drive gear but do need the pump shaft gear, gear shroud and piping. I think I can buy a new pump gear, make a shroud and piping. However the pump itself remains elusive. I have not heard of Lipman gear pumps but agree that the illustration you included does look like the pump I am looking for. If you (or any one else reading this) run across a Lipman pump of the proper size let me know.

Again, thanks ever so much for all that you have done. I appreciate it.

Regards, Bill |

2_cycle

Member

Username: 2_cycle

Post Number: 13

Registered: 02-2008

| | Posted on Wednesday, April 16, 2008 - 01:22 pm: |

|

Richard,

I just observed that there is a major difference between your water pump and those that I described yesterday as well as the Lipman pump whose illustration you sent. Yours has the stuffing box cast into the cover. All the others have the stuffing box cast into the body. A pump like the one on your Mdl E has the advantage of being able to change the position of the drive shaft by reversing the position of the cover & gears. Interesting.

Bill |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1687

Registered: 11-2001

| | Posted on Wednesday, April 16, 2008 - 03:53 pm: |

|

*

The old rotary water pumps on marine engines are similar to the magnetos and carburetors -- several different Companies and many many diferent models !

From 1890's through 1910 there was only a few Companies making the rotary w/pumps, Just off my head - Imperial, Lipman, Lobee, oberdorfer.

I have been searching for yrs for a Lobee for one one my 1898-99 engs .

I don't think many of us are even aware of what some of these old pumps look like - one day as a project I'll try to put together some catalog and ad photos of the different pumps and their mfgrs ! Gives us more stuff to search for at the Flea Markets ?

* |

sfsorrow

Member

Username: sfsorrow

Post Number: 14

Registered: 04-2006

| | Posted on Monday, May 05, 2008 - 01:15 am: |

|

FM E and FM C

I have just discovered that there is such a thing as an

FM C, it looks a lot like an E only a little more muscular.

One cyl, so most is identical.

Now I am really confused between the E C and M.

thanks for the good site.

sfs |

jim_parrott

Senior Member

Username: jim_parrott

Post Number: 210

Registered: 06-2009

| | Posted on Tuesday, August 13, 2019 - 10:59 am: |

|

A Friend has the Fairbanks Model E pictured above. He is looking for a water pump, gear, transfer tube, upper timer parts and double Oiler. Anyone having spares please post or email me thru this site. .

Thanks,

Jim |

bruce

Senior Member

Username: bruce

Post Number: 683

Registered: 07-2002

| | Posted on Tuesday, August 13, 2019 - 08:47 pm: |

|

Looks a lot like my Motor-Go twin |

jim_parrott

Senior Member

Username: jim_parrott

Post Number: 211

Registered: 06-2009

| | Posted on Wednesday, August 14, 2019 - 10:37 am: |

|

Bruce,

Most most Motorgo�s were Made by Lockwood Ash and they do look similar. Do you think your Motorgo was made by Fairbanks Morse? If so, I would like to see some pictures of it.

Jim |

bruce

Senior Member

Username: bruce

Post Number: 685

Registered: 07-2002

| | Posted on Wednesday, August 14, 2019 - 07:30 pm: |

|

Jim, my M G engine has the centered exhaust connection like the FM you show. I think it was JB who said someone there in the cajun posse had a similar config-maybe yours |