| Author |

Message |

graynorth

New member

Username: graynorth

Post Number: 2

Registered: 11-2007

| | Posted on Friday, November 02, 2007 - 11:16 am: |

|

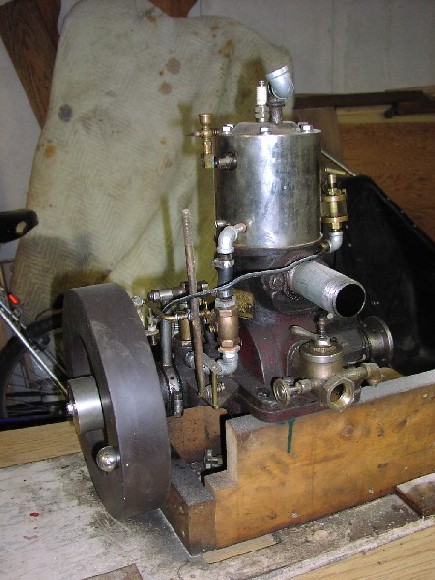

This is a 1902 two stroke engine which no-one can get to run reliably. After 5 years of trying, the latest suggestion is to install a "wet sleave" in order to increase crankcase pressure so as to force more gas into the firing cylinder. Lots of compression, spark, and primitive carb seems to be working. Can anyone suggest a good company to do the work?

Hope you can help! |

graynorth

New member

Username: graynorth

Post Number: 3

Registered: 11-2007

| | Posted on Friday, November 02, 2007 - 11:28 am: |

|

Hopefully the photo will be here! |

barry

Advanced Member

Username: barry

Post Number: 47

Registered: 02-2006

| | Posted on Saturday, November 03, 2007 - 02:32 pm: |

|

As the engine fires but does not continue to run indicates it is only fueled by the initial prime.

The 1902 date suggests this is a two port engine.

Two port engines use a check valve between the carburetor and crankcase.

When piston is moving down, the check valve must seal the crankcase, thus crankcase pressure increases such that fuel is transferred to combustion chamber when the top of the piston uncovers the transfer port.

When the piston moves up, the check valve is pulled open by the negative pressure in the crankcase such that fuel mix enters the crankcase.

If you have not already done so, I suggest you examine, clean, repair or replace the check valve.

Here is a link to a discussion on this board that may be useful.

http://www.oldmarineengine.com/discus/messages/1/10249.html#POST12084

Here is a link to an explanation about the operation of a two cycle engine. This refers to three port design; however you can use the information to understand the function of the check valve.

http://www.stlawrenceengines.ca/technical/twocycle/index.html

Barry |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 304

Registered: 07-2002

| | Posted on Saturday, November 03, 2007 - 04:09 pm: |

|

Two cycles with a lot of blow by can be hard to start. When it fires the blow by fills the crankcase and kills the next cylinder charge. Usually a shot of oil in the cylinder will help for a few strokes. If the oil helps the cylinder will need reworking. |

graynorth

Member

Username: graynorth

Post Number: 4

Registered: 11-2007

| | Posted on Sunday, November 04, 2007 - 03:03 pm: |

|

Gentlemen,

Thank you for your suggestions.

I attach a photo of the carburator side of the engine (which is two port) showing what has been called the carburator( or pop valve ). No other check valve exists. I have assumed that the "popper" is the check valve c/w a dial to adjust the fuel mixture. Changing carburators has not solved the problem.

The photo also shows the oiler which was added in an attempt to reduce blowback (if that is the problem) but it seems somewhat low in the cylinder (in order to avoid touching the water jacket). The cast cylinder walls are somewhat thin, so if a sleeve is fitted, a smaller piston would need to be found. If the cylinder has developed a bell shape, that would explain the good compression at the top of the cylinder but allow blowback at the bottom, but accurate measurement shows no great "bell" present. It seems unlikely that a couple of thou would disable the engine. Thanks again for the advise!

|

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 305

Registered: 07-2002

| | Posted on Sunday, November 04, 2007 - 06:50 pm: |

|

The best way to judge cylinder condition is to try to bounce the engine against compression. It should bounce like a spring. When pulling it over it should resist to the top of the stroke, if you pull it up slow and hear the compression leaking out quickly you may have problems. The carb is a "mixer" it has a check valve in it, you should see the valve pop up and down as you crank it over. |

graynorth

Member

Username: graynorth

Post Number: 5

Registered: 11-2007

| | Posted on Sunday, November 04, 2007 - 07:42 pm: |

|

Thank you, yet again, for your suggestions.

With the decompression tap and primer cup tap closed, I can bounce the engine against compression, although I am uncertain it feels like a spring. The engine counter-rotates about 20 degrees with a reasonable bounce. The "mixer" valve pops up and down but very briefly. The "stem" of the check valve which is visible at the bottom of the mixer bounces 1/16" on each revolution. NEW INFO!!

I have just used my old friend WD40 to lubricate the check valve stem with the result that I have difficulty rotating the engine by hand, and the bounce has increase to 50 degrees. using my hands on the flywheel I am unable to overcome the compression. Still no noticeable movement by the check valve. The spring adjustment on the top of the mixer seems to make little difference.

Perhaps the WD40 has adversely effected the check valve operation.

Comments and suggestions are most welcome!

glen |

john_archibald

Member

Username: john_archibald

Post Number: 27

Registered: 08-2006

| | Posted on Sunday, November 04, 2007 - 08:38 pm: |

|

Glen,

Is the piston in backwards? The vertical fin must face a certain way.

Archibald |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 306

Registered: 07-2002

| | Posted on Sunday, November 04, 2007 - 08:51 pm: |

|

Sounds like you have enough compression, I would look into the check valve. I'm not familiar with yours in particular, but most operate the same. There should be a spring to close the valve, possibly a screw to limit opening of the valve, a mixture needle, and a butterfly or gate to throttle airflow. I would start with the throttle and valve limit wide open. Mixture screw 3/4 turn open. Be sure the valve opens and seats freely. Are you gravity feeding the fuel? If so it should drip when holding the poppet valve open and check when the valve seats. If it continues to drip with the valve on seat, the valve and seat will have to be refaced. With this done, try starting the engine. If it pops a little and dies, it may be flooding, try shutting the mixture needle off and crank a few more times. If it starts and dies it was flooded, try opening the mixture 1/2 turn or so. If it starts on a prime of fuel and dies, try opening the mixture more. |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 307

Registered: 07-2002

| | Posted on Sunday, November 04, 2007 - 08:54 pm: |

|

A new spark plug and fresh gas are a good investment when trying to start a stubborn one. What are you using for ignition? |

richardday

Senior Member

Username: richardday

Post Number: 532

Registered: 11-2003

| | Posted on Sunday, November 04, 2007 - 09:43 pm: |

|

I think the engine wont pass the finger tip test.

Take hold of the flywheel with your finger tips and rotate it quickly. let it go and when it hits compression it must bounce back. If it doesn't it aint gonna run. Probably the big end of the con road is much too tight is a good place to look for stiff rotation. running when primed and then pulled over simply means the energy you added to the flywheel quickly dies away and the engine cannot keep going. Thats my opinion. You know what free advice is worth. |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1564

Registered: 11-2001

| | Posted on Sunday, November 04, 2007 - 10:10 pm: |

|

*

Glen-- 5 yrs of trying to run this one that's a lot of patience!

Thank you for the photos- I keep a list of old marine engine mfgrs and have "The Gasoline Engine Company Ltd." of Toronto listed but have never seen one of the engines or a photo!

You certainly have the best source of info available here. There is a story going around southern Louisiana and as far north as Solomons Isle, Maryland and Mystic, Connecticut That J.B.Castagnos has walked up to a cantankerous old engine and after staring at it a few seconds the engine started right up and ran out of sheer intimidation ?? Others here may be able to vouch for this phenomenon ??

My take on getting the engine running would be:

First- Make sure the deflector on the piston is facing the intake port.

Second- make sure the crankcase is air tight .

Third- if both those are OK then I would take the mixer valve off and borrow one from a known running engine and try it-- Keep fuel tank well above the mixer valve its gravity feed.

Easier said than done -if all else fails next summer bring it to Calvert or Mystic marine engine show and when weekend is over it will either run or you will find out how to get running !!

The engine is definately a piece of turn of the century Canadian history and well worth the time and energy to restore and run, its the only one like it that I know of !

* |

graynorth

Member

Username: graynorth

Post Number: 6

Registered: 11-2007

| | Posted on Sunday, November 04, 2007 - 10:34 pm: |

|

Wonderful information!

I'll try to deal with things point by point.

I believe the piston is oriented correctly. After 4 to 5 complete constructions I am reasonably confident that the fin is in the right orientation.

There is plenty of "bounce" when the piston approachs TDC.

I am encouraged by your collective interest and will rebuild a complete (and secure) test facility in my workshop in order to personally test this old monster. I have been relying on known "experts" in order to avoid doing it myself.

I may have trouble locating another working "mixer". Most of the locals run Dispros with St. Lawrence engines with more advanced carburators.

Many thanks for you interest... I am encouraged.

glen |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 308

Registered: 07-2002

| | Posted on Sunday, November 04, 2007 - 11:37 pm: |

|

An inline check valve and a carb from one of the Dispros will work to test it. |

richardday

Senior Member

Username: richardday

Post Number: 533

Registered: 11-2003

| | Posted on Monday, November 05, 2007 - 06:33 am: |

|

Does it pass the finger tip test??? |

graynorth

Member

Username: graynorth

Post Number: 7

Registered: 11-2007

| | Posted on Monday, November 05, 2007 - 07:52 am: |

|

The finger test results in a good bounce and counter-rotation of 90 degrees. There is suction heard from the mixer valve on the bounce, but no movement of the poppett valve. |

richardday

Senior Member

Username: richardday

Post Number: 534

Registered: 11-2003

| | Posted on Monday, November 05, 2007 - 08:25 pm: |

|

Am I wrong why would there be suction on the bounce? Seems to me when if bounces back the check should snap shut. Am I wrong? |

ernie

Senior Member

Username: ernie

Post Number: 752

Registered: 01-2002

| | Posted on Monday, November 05, 2007 - 08:35 pm: |

|

Just before the bounce the check valve usually opens a bit on a 2 port. It all happens so quick it's hard to tell. However the check valve can't open on the down stroke. Unless its in backwards or leaks

No you are NOT wrong |

graynorth

Member

Username: graynorth

Post Number: 8

Registered: 11-2007

| | Posted on Monday, November 05, 2007 - 09:16 pm: |

|

Apologies...

I have just retried the "finger test" (with the help of my lovely wife) and determined that the noise is not suction, but exhaust output (complete with carbon). No suction was detected on the mixer. No check valve movement occurred.

I suspect thatafter the bounce, the piston retreats and releases the pressure into the exhaust outlet.

Sorry for any confusion.

glen |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 309

Registered: 07-2002

| | Posted on Monday, November 05, 2007 - 10:04 pm: |

|

With the spark plug out you should be able to turn the engine and hear, sometimes feel a puff of air transfering from the crankcase to the cylinder as the piston nears the bottom. If you are getting this on every revolution it should be operating correctly. |

graynorth

Member

Username: graynorth

Post Number: 9

Registered: 11-2007

| | Posted on Tuesday, November 06, 2007 - 09:00 am: |

|

Thank you JB for the suggestion.

With the spark plug removed, and starting at TDC I rotate the engine and just as I see the exhaust port appear, a puff of transfering air is detected at the spark plug opening. This appear o be working as expected. |

richardday

Senior Member

Username: richardday

Post Number: 535

Registered: 11-2003

| | Posted on Tuesday, November 06, 2007 - 12:34 pm: |

|

OK guys get out your cigar boxes if you have one you can spare from your collection. Just don't use a valuable one for this test.

The old time way for determining if the engine intake vaccuum was adequate to run was to place a cigar box (empty of course) up against the intake port. When the flywheel is rotated on the up stroke it should hold the cigar box momentarily. If it didn't it was time to look for crankcase, etc. leaks. Never tried the cigar box approach myself but at this desparate stage Glen will probably try anything to figue out why his engine doesn't want to run on its own. I am surprised his mixing valve doesn't open on the up stroke. Could the spring be too big or the lift adjustment screwed down to too tight??? |

graynorth

Member

Username: graynorth

Post Number: 10

Registered: 11-2007

| | Posted on Tuesday, November 06, 2007 - 01:28 pm: |

|

Well, the cigar box test has been undertaken, and the result is negative. There is a very short bit of suction just as the engine bounces, but insufficent to hold up the box ( or even a piece of cardboard). I tested the suction at the mixer, not at the crankcase and attempted to block the gas line and measured suction at the air intake.

I have also taken the mixer apart and the photo shows the internal pieces. The mixer lever spins the asymetrical brass collar to adjust gas/air combination and can probably stop the engine completely. There is a spring tensioned screw on top which limits the piston travel.

The interior spring is reasonably substantial.

|

richardday

Senior Member

Username: richardday

Post Number: 536

Registered: 11-2003

| | Posted on Tuesday, November 06, 2007 - 03:32 pm: |

|

It seems to me there is a needle valve on the mixer which is critical to the air/fuel mixture The rotating valve you show in your photo acts principally as a throttle. I grant you as the engine speeds up it will have some interactionon the needle valve setting. It was customary for users to put an approximately 6" pipe nipple in the inlet to the mixer to get better breathing as they called it. I don't understand why you don't get a definite suction at the inlet to the crankcase on the upstroke of the piston. Pls try putting a teaspoon of oil on the top of the piston and see if that increase the suction at the inlet to the cylinder. Leave the spark plug out and crank the engine and see if you don't get a stronger suction with the oil on the piston cylinder walls..

Is the mixer spring a stel spring and do you believe it is origingal? I would expect a phosphor bronze spring. Leave the spring out and crank the engine without the spark plug and see if the poppet valve lifts off the seat. It should very definetly. Make sure the throttle valve is wide open when you are trying to find out if the poppet lifts off the seat. Make sure it has no burrs or bends that could restrict its easy motion. At least we now know you have essentially no apparent intake suction. Have to figue out what the problem is. |

graynorth

Member

Username: graynorth

Post Number: 11

Registered: 11-2007

| | Posted on Tuesday, November 06, 2007 - 04:20 pm: |

|

Thanks Richard for the interest and suggestions.

The interior spring is steel. I have no idea whether it is original. Eleven years ago when I purchased the boat, I recall a very thin large diameter spring inside, but the current spring is sized to snugly fit over the top of the mixer where the piston enters the top.

There is reasonable suction at both the air intake and gas intake of the motor, as measured by my hand, but not enough to hold up a ciger box.

Adding oil into the piston cylinder does not appreciably increase the suction.

Removing the spring results in a bouncing popper valve with more travel.

The needle valve meets the gas line and appears at the hole on the bevelled seat of the popper valve opening. With the spring removed, I start rotating the engine from bottom dead center very slowly. The popper valve starts to bounce when I reach half way up and continues bouncing right to the top. Adding oil into cylinder does not change things.

There was a 6" breather pipe originally attached to the mixer. |

richardday

Senior Member

Username: richardday

Post Number: 537

Registered: 11-2003

| | Posted on Tuesday, November 06, 2007 - 04:54 pm: |

|

Well that is some progress. Why not try to determine the amount of pressure that you need to put on the spindle of the poppet valve to hold it down when someone cranks the engine?? I can send you some phosphor bronze spring wire that you can wind springs from. Don't have the spring wound tight around the spindle. I would make it have at least 1/8" clearance around any post or shaft. You want a loose fit that isn't restricted by such items. I suggest close winding about ten turns 3/4" inches in diameter. Pull the spring out about 1-1/2" Then insert into the mixer and try to see if the poppet valve will rise without bouncing if it does then cut off a turn and try again and see if it starts to bounce. If it doesn't cut off another turn and go through that process until you know what minmum spring pressure you need to overcome bouncing and at that point wind a new spring with a few more turns than the one one you had left and try that as an operational spring. Keep in mind when the poppet bounces on the seat it lets additional fuel into the air stream you don't want that. On the other hand you want the spring weak enough so the intake suction will lift the poppet off the seat and otain fuel mixed with incoming air.

Send me an e-mail with your address and I will put some phosphor bronze spring wire in the mail. I will give you enough to make at least 50 springs so don't worry about cutting it up. Its the only way I can figure how to replace the steel spring with a spring that is close to what the original must have been. |

john_archibald

Member

Username: john_archibald

Post Number: 28

Registered: 08-2006

| | Posted on Tuesday, November 06, 2007 - 07:34 pm: |

|

Is it possible that the spring is acting in the wrong direction???

Archibald

Northfield, Minnesota |

richardday

Senior Member

Username: richardday

Post Number: 538

Registered: 11-2003

| | Posted on Tuesday, November 06, 2007 - 09:02 pm: |

|

In my opinion the spring has to be strong enough to keep the check from chattering and weak enough for the suction of the engine to promptly lift the check off the seat. If the spring were operating in the opposite direction the check would be permanently open. |

barry

Advanced Member

Username: barry

Post Number: 48

Registered: 02-2006

| | Posted on Thursday, November 08, 2007 - 09:48 am: |

|

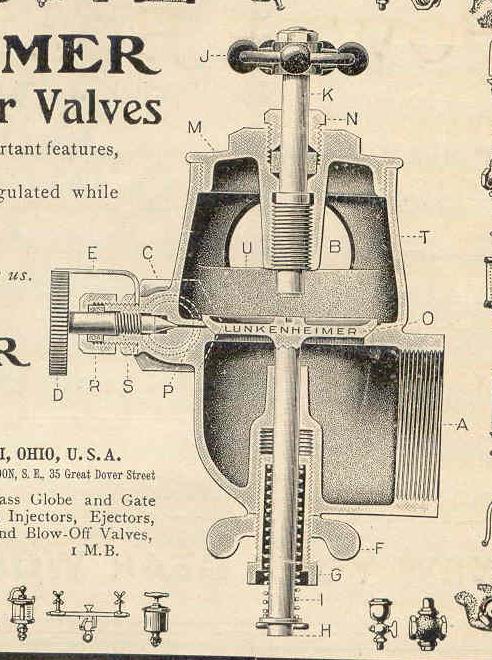

I’m interested to learn about the operation of a mixer of the type used with Glen’s engine. I’ve searched this site without finding a clear explanation with drawings showing internal parts.

Does anyone have this information that could be posted?

Many thanks …

Barry |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1568

Registered: 11-2001

| | Posted on Thursday, November 08, 2007 - 10:25 am: |

|

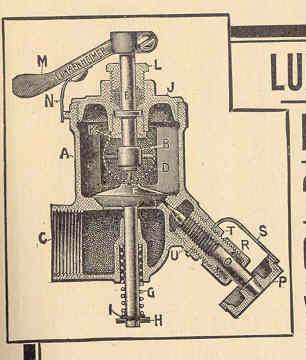

*

1906

1909

* |

barry

Advanced Member

Username: barry

Post Number: 49

Registered: 02-2006

| | Posted on Thursday, November 08, 2007 - 07:11 pm: |

|

Thanks Richard.

This may be an opportunity to compare the advantages/disadvantages of a mixer and carburetor.

The mixer illustrated in Richard’s post is simple and primitive compared to a Schebler model D, yet both perform the same function.

The Schebler as typical of a basic carburetor requires a lot of extra parts associated with the float mechanism. The mixer does not use a float at the gasoline is directly injected into the air stream. As it uses fewer parts it appears to be less prone to maladjustment and problems associated with component wear and subsequent failure.

I am interested in this comparison that suggests the question ….why use a float carburetor when a mixer is less complex?

Barry |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 311

Registered: 07-2002

| | Posted on Thursday, November 08, 2007 - 08:16 pm: |

|

Mixers are very sensitive to fuel level and have to be adjusted as fuel drops. Some were available with a float chamber, but you're right there with the carb. They are nice for show engines, usually start easy and idle slow. |

graynorth

Member

Username: graynorth

Post Number: 12

Registered: 11-2007

| | Posted on Thursday, November 08, 2007 - 09:44 pm: |

|

Oh, the joys of early gasoline engines!

The mixer pictures posted are from the same period but differ significantly from the mixer in question. The 1906 photo is closer to the mark, in that it shows the gasoline input on the bevelled edge. There is no spring below the poppet valve, but rather on top inside the mixer chamber, in order to press the valve down, rather than pull the valve down. Advice to date suggests the pressure of this internal spring is very critical.

I attach some photos of the mixer and timing mechanism

|

richardday

Senior Member

Username: richardday

Post Number: 540

Registered: 11-2003

| | Posted on Friday, November 09, 2007 - 02:23 pm: |

|

One aspect of the mixer is it will pick up fuel from a tank below it by as much as 18" I have been told. It does require a small ball check at the bottom end of the fuel line to function. If you look closly at the springs in the two mixing valves they have a reasonbly large number of turns and relativly fine wire. In other words they are intended tojust hold the valve on the seat without bouncing when the valve is not called upon for fuel. |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 312

Registered: 07-2002

| | Posted on Friday, November 09, 2007 - 07:02 pm: |

|

It's hard to see your timer setup in the pictures, but as Miro said, most fuel problems are due to ignition. Try to set up the plug wire with a little gap that you can watch, be sure the engine is firing until it dies. Bob Price had a problem with his Fero at Mystic, the brush was sticking due to some gummy grease. It would fire every time when cranking over by hand, but when it started the brush wouldn't return fast enough to continue firing. Cleaning it with a little solvent made it run fine. |

art

New member

Username: art

Post Number: 1

Registered: 10-2007

| | Posted on Friday, November 30, 2007 - 08:22 pm: |

|

Might it be a full crankcase and/or leaking seals? |

graynorth

Member

Username: graynorth

Post Number: 13

Registered: 11-2007

| | Posted on Friday, November 30, 2007 - 09:28 pm: |

|

Again, Thanks for your interest.

I have been resting my tired arm for the past 10 days so as to be able to undertake a second attempt at the motor. I have had the beast running for 10 to 20 seconds at very slow speed (less than 100rpm) but it doesn't keep running. The crankcase accumulates a little gas (less than a tablespoon) and the main bearings are quite tight. Is it possible to measure the pressure in the crankcase? How much pressure should there be?

glen |

ernie

Senior Member

Username: ernie

Post Number: 769

Registered: 01-2002

| | Posted on Saturday, December 01, 2007 - 08:24 am: |

|

Turn it over with the spark plug out. If it has a noticable puff! when the piston goes down and uncovers the transfer port in the cylinder the crankcase compression is good enough

Hope this helps

Ernie |

graynorth

Member

Username: graynorth

Post Number: 14

Registered: 11-2007

| | Posted on Saturday, December 01, 2007 - 11:34 am: |

|

The mystery continues. With the spark plug out, I detect a reasonable "puff" at BDC, howegver, I no longer have a spark. The battery is new, and the buzz box no longer buzzes, only a single click. Does the buzz box need to be connected for some time in order to energize the coils?

glen |

miro

Senior Member

Username: miro

Post Number: 299

Registered: 11-2001

| | Posted on Sunday, December 02, 2007 - 07:40 am: |

|

The buzz coil should do exactly that - buzz. If it doesn't then do whatever you have to do, to make it buzz.

I've built myself a version of JB's buzz coil, which throws lightning bolts -up to 3/4 in spark as well as a buzz coil of my own design. I think I might have a spare relay for you if you are close to the GTA.

The single click is a good clue about what might be the problem.

The contact should make contact for at least 10 -15degrees of crank rotation. My Gray engine's contact is about 25 degrees.

miro |

bgoss

New member

Username: bgoss

Post Number: 1

Registered: 12-2007

| | Posted on Monday, December 10, 2007 - 07:24 pm: |

|

Glen, did the ignition fix the problem? If not, it could be this:

It seams to me that you are missing a lever with a damper or butterfly type affair on the intake port (opposite side from the mixer).

It is my understanding that this was used to starve the engine of fuel in order to slow the boat as you approached the dock. Without that piece, you may not be getting a consistant flow of fuel/air mix up to the cylinder.

Just a thought, hope it helps.

Blair

|

graynorth

Member

Username: graynorth

Post Number: 15

Registered: 11-2007

| | Posted on Tuesday, December 11, 2007 - 04:17 pm: |

|

Wow! Thank you for the information and photo!

There is indeed a mechanism as you describe!

And there is no "lever" such as appears on your engine, although the interior hardware appears to be present. How did the beast operate?

The photo appears to be identical to my engine. Do you have any additional information?

My arm is slowly recovering, but the snow shovelling does not help.

My battery has been replaced (it was over-charged) but while I'm now getting lots of Buzz, still no "pop".

Any additional info on the engine/damper would be greatly appreciated. Does your engine run?

glen |

ernie

Senior Member

Username: ernie

Post Number: 775

Registered: 01-2002

| | Posted on Tuesday, December 11, 2007 - 07:35 pm: |

|

The valve in the transfer port was used with a mixer with no throttle. Sice you are using a mixer with a throttle just make sure the valve in your engine is open all the way. A lot of mfrs put a valve in the transfer port in the days of the early mixers. As in before carbs. Or you can try putting a handle on your valve and set the throttle in the mixer wide open.

Good luck

Ernie |

bgoss

New member

Username: bgoss

Post Number: 3

Registered: 12-2007

| | Posted on Tuesday, December 11, 2007 - 08:28 pm: |

|

Our engine above hasn't run in years, but it should. More snow to shovel tonight...real wet stuff. I think it's going to be one of those years. I'll take a look on the weekend for some more details on this engine. I think that we have a piece of some old literature that shows the engine. I think I need to shovel a path out to the shop to see if the cylinder on our engine was nickled at one time.

Blair |

graynorth

Member

Username: graynorth

Post Number: 16

Registered: 11-2007

| | Posted on Tuesday, December 11, 2007 - 09:05 pm: |

|

Thanks everyone!

I opened up the spot where the valve was and discovered that it is completely open with no mechanical internal parts. I suspect that the throttle on the mixer eliminated the need for the damper, so that the handle was removed.

Never a dull moment!

glen |

graynorth

Member

Username: graynorth

Post Number: 17

Registered: 11-2007

| | Posted on Thursday, June 26, 2008 - 08:25 pm: |

|

Well, I'm back from my winter in the south.

I've decided to ignore the damn engine, and convert the boat to electric power.

Does anyone have a good idea for a good home for the "beast"?

My shoulder is killing me.... it's been sore for the past six months! |

ernie

Senior Member

Username: ernie

Post Number: 841

Registered: 01-2002

| | Posted on Friday, June 27, 2008 - 12:47 pm: |

|

Glen,

I sent you an e-mail

Ernie |

Ron Mutch

Visitor

| | Posted on Thursday, August 28, 2008 - 12:36 am: |

|

Guys, this is a little off topic but could really help with several two-stroke issues (and others). Our company (an over the road trucking outfit) that hauls asphalt got turned onto a fuel transformer from the asphalt company i might add that works wonders. I used a tiny bit to mix with my two-stroke and it was night and day. They are also selling jugs of the stuff and I now run it in my boats, trucks and RV - the results are amazing, and my oil is lasting much longer.. I suspect the power increase coming from the increase in efficiency, lowers the blow-by..

you will have to google it to find the online store but the site is

www.econal.com |

keith

Senior Member

Username: keith

Post Number: 201

Registered: 02-2002

| | Posted on Thursday, August 28, 2008 - 11:25 am: |

|

Ron,

Do they have any bridges For Sale? |

Ron Mutch

Visitor

| | Posted on Saturday, September 13, 2008 - 02:35 pm: |

|

Keith,

O man that is funny. I laugh every time I pass the pumps too then I reminisce about the mileage I used to get. Admittedly I am enthusiastic about econal and am eager to pass the good word. I understand your ridicule but being a senior member of old marine engine you ought to understand the inherent inefficiencies of fuel and engines (especially two strokes) and if you did you would understand then how a product like this actually works.

Best Regards.. |

keith

Senior Member

Username: keith

Post Number: 203

Registered: 02-2002

| | Posted on Saturday, September 13, 2008 - 06:58 pm: |

|

See Ron,

I do understand. If the product made great economical sense, if would be making national news. Rather, it is being promoted on a site with a relatively small audience, hoping to find a sucker, by a snake oil salesman. I'm still interested in a bridge, but it has to be big. |

Ron Mutch

Visitor

| | Posted on Sunday, September 14, 2008 - 12:42 am: |

|

Well Keith,

Small audience or not I am a patriot not an oil man. I am not trying to sell it and nor am I trying to make national headlines. Just passing on the good word about my positive results.

And... I am willing to put my money where my mouth is. If there is anyone out here that knows Keith and is willing to try Econal, I will pay for it. |

DickieGibbens

Visitor

| | Posted on Sunday, September 14, 2008 - 09:04 pm: |

|

Could it be the asphalt hauling company cleans up with MEK then sells the wash out fluid? |