| Author |

Message |

paulgray

Advanced Member

Username: paulgray

Post Number: 44

Registered: 05-2003

| | Posted on Sunday, January 21, 2007 - 05:42 pm: |

|

Update on the Lackawanna. Got the block back together with new rod bearings and rings and wristpins. I am running it in with a big honkin' drill motor to limber it up. Still need to make more stainless bolts (Oooohhhh stainleeees!) This one is painted with rustoleum pewter gray textured. I like it- looks NOS'y, but hard to find. Wanted something darker than light industrial gray. This appears to match the scraps I found under the grime in corners. |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 220

Registered: 07-2002

| | Posted on Sunday, January 21, 2007 - 08:53 pm: |

|

Looks good Paul, a lot of work in those bolts. Does the stainless thread OK, is it something you ordered or just soemting you had available? |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 221

Registered: 07-2002

| | Posted on Sunday, January 21, 2007 - 08:55 pm: |

|

On the limbering up, have you ever tried Timesaver lapping compound, makes for a nice fit. |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1394

Registered: 11-2001

| | Posted on Sunday, January 21, 2007 - 09:02 pm: |

|

*

Looking Good !

Lackawanna was a very interesting company they were definately a leader in engine design and innovative castings, were well built engines. wonder why we dont see more of them around ??

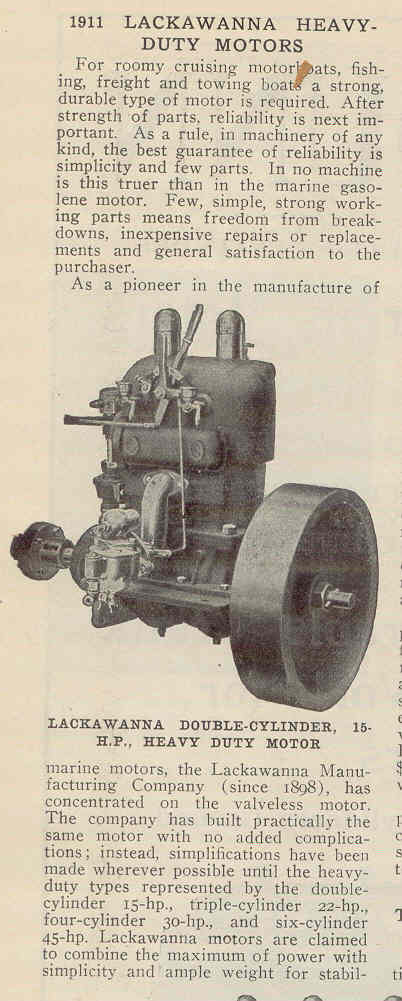

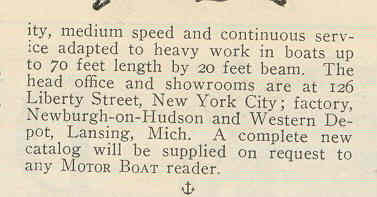

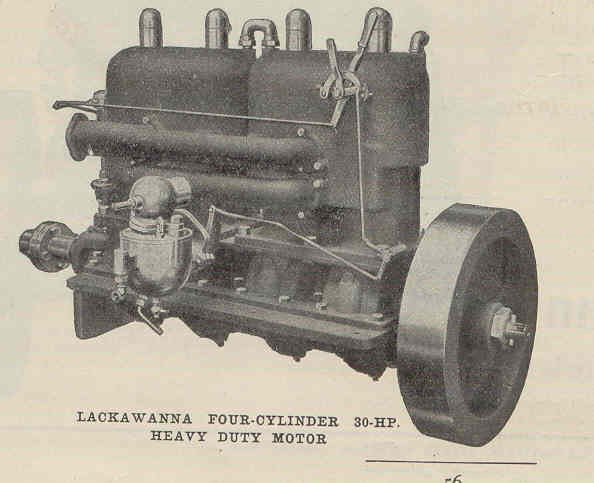

I may have already posted This 1911 article .

1911

|

paulgray

Advanced Member

Username: paulgray

Post Number: 45

Registered: 05-2003

| | Posted on Monday, January 22, 2007 - 08:32 am: |

|

The stainless bolts are something that George Coates Sr. got me doing as they look so nice and stay that way; it is sort of SOP between the two of us on resto projects. I use 303 when I can get it but 304 or 316 also work. Use Anchorlube as a cutting lube and thread 80-90% of the thread with a point tool then chase it with a die to get the root. With carbide and the anchorlube, it is not much more difficult than plain old steel. With a 5C collet chuck and hex collets, the bolt cutting goes fairly quickly. |

paulgray

Advanced Member

Username: paulgray

Post Number: 46

Registered: 05-2003

| | Posted on Sunday, February 11, 2007 - 03:36 pm: |

|

Getting closer- This weekend I attacked the water pump and timer assb'y. Made a new pump shaft, new idler for the driven gear in the pump, re-bushed the bottom timer shaft bearing. Also converted an old 1 cylinder timer to a 2 cylinder model. Still have to make more bolts but not this weekend. Will take some shimming and fitting to get the pump shaft and timer in alignment. Soon as we get some warmer weather, I can start the stand. Want to make out of metal tubing. |