| Author |

Message |

johnny

Advanced Member

Username: johnny

Post Number: 48

Registered: 03-2006

| | Posted on Monday, November 13, 2006 - 07:20 pm: |

|

I picked up A little Detroit at the local engine show this past week. Unlike most Detroits this one uses grease to lubricate the lower con rod not oil. Also has a Lunkenheimer with a built in throttle control.

|

audie_j_taquino

New member

Username: audie_j_taquino

Post Number: 1

Registered: 11-2006

| | Posted on Tuesday, November 14, 2006 - 06:19 am: |

|

My Michigan looks like this one. I'm going to have to look at my crank now for the grease fitting. I'm missing the wet exhaust so if anyone has an extra to part with I'll buy it. Yours is a nice find. Mine is in dire need of restoration. |

ernie

Senior Member

Username: ernie

Post Number: 507

Registered: 01-2002

| | Posted on Tuesday, November 14, 2006 - 07:50 am: |

|

Neat find, looks real original!

Just turn the muffler so it points down at about 45 deg. |

richardday

Senior Member

Username: richardday

Post Number: 425

Registered: 11-2003

| | Posted on Tuesday, November 14, 2006 - 08:19 am: |

|

Don't run the engine without mixing oil in the fuel. The grease cup in the end of the crankshaft too often injects crud into the big end. If you can I would pull the cylinder off and disconnect the con rod so you can flush out the passage from the grease cup to the "big end". Once cleaned out fill with fresh grease and don't use it operationally. Just rely on the oil in the fuel. The idea of the grease cup was to grab it every few minutes and hold it for a couple of turn. Problem is if you forget it will unscrew if the engine is running clock wise. Don't plug the overboard drain in the lower part of the exspansion chamber as water can accumalate and potentially cause catostrophic damage to the engine if it backfires. |

johnny

Advanced Member

Username: johnny

Post Number: 49

Registered: 03-2006

| | Posted on Tuesday, November 14, 2006 - 02:19 pm: |

|

Thanks for the replies everyone. I plan on doing a complete restoration on the engine. So I will clean and blow out the grease ports. I removed the name tag and you can still see the original green paint. Serial # 236 stamped on flywheel hub face and end of crank shaft.

I have a question about the condenser exhaust manifold. The small water pipe that runs down through the middle of the manifold is it suppost to have small pin holes in it that injects water into the manifold or should it have no holes at all?

Thanks for the info |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1330

Registered: 11-2001

| | Posted on Tuesday, November 14, 2006 - 05:06 pm: |

|

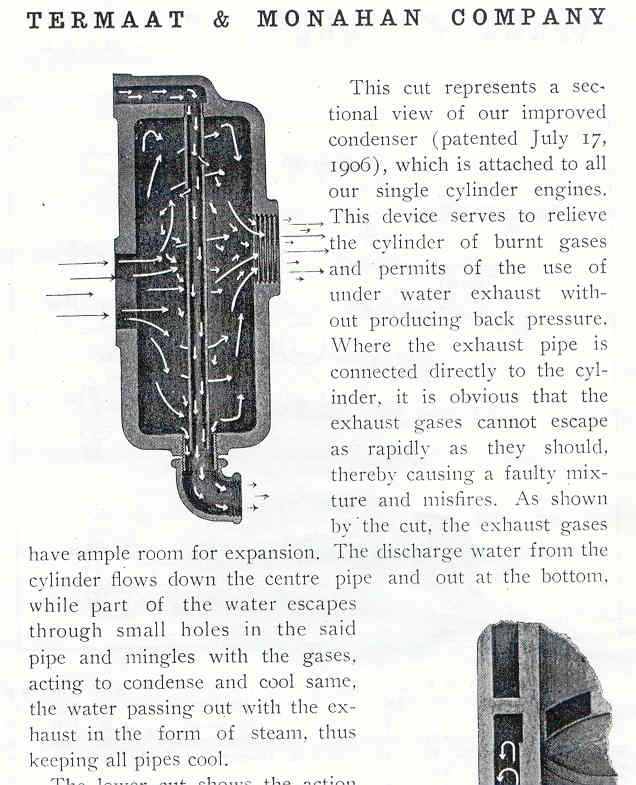

*

1906

|

richardday

Senior Member

Username: richardday

Post Number: 426

Registered: 11-2003

| | Posted on Tuesday, November 14, 2006 - 08:03 pm: |

|

That pipe extends down to the bottom drain but it is not sealed to the bottom drain. There should be two small holes about 1/16" dia as shown on Richard/s diagram. You will see the arrows near the top of the pipe. Their purpose is to spray a little water to cool the exhaust gasses down. Do not seal the bottoem of the pipe to the drain pipe otherwise water can be trapped in the lower portion of the exspansion chamber. There are at least three different versions of this exspanion chamber. One has a bronze needle valve at the top to shut off the water in the tube while the exspansion chamer has a water cooled jacket. Another has the exhaust out the lower aft section of the exspansion chamber. |

johnny

Advanced Member

Username: johnny

Post Number: 50

Registered: 03-2006

| | Posted on Wednesday, November 15, 2006 - 06:27 am: |

|

Thank's for the info everyone.

I have been collecting and restoring Stationary engines sense the early 80's but never really got into the antique marine engines or boats. I believe the bug has bitten me, partially due to this Old marine engine forum and the people here. Very interesting site and people, keeps me coming back for more.

Got to have me a old boat one of these days. |

johnny

Senior Member

Username: johnny

Post Number: 89

Registered: 03-2006

| | Posted on Monday, March 05, 2007 - 08:03 am: |

|

I have a question for everyone, now that I have completly disasembled this Detroit marine engine and now have started rebuilding it. I was thinking about what richardday said about not using the greaser for the lower end con rod. Which brings me to my question. If I mix oil in the gas how does the oil get to the lower con rod? Fuel mix from the carb or mixer enters into the port at the cylinder and is sucked up through the port into the top of the cylinder where it is ignited. I believe very little fuel if any at all enters into the crank case. I would think that if the carb or mixer was mounted on the crank case chances are that the lower con rod would recieve oil. I actually brought this question up back when I first joined this forum but I'm not sure if everyone understood what I was trying to say. I am planning on mixing two cycle oil with the fuel to help lubricate the top end and will also use drip oiler. I'm thinking maybe I need to use the greaser on the bottom end con rod also. I would like to know what everyones thoughts are on this matter if possible.

Thank you |

johnny

Senior Member

Username: johnny

Post Number: 90

Registered: 03-2006

| | Posted on Wednesday, March 07, 2007 - 06:14 pm: |

|

Have any of you engine rebuilders ever balanced one of these old marine engines that never was balanced from the factory? at least this Detroit apears not to be balanced. No balance holes or counter weight to be seen. We are going to check the balance here in a few days and if it's not balanced I'm thinking about balancing it by drilling holes in the back side of the flywheel rim. My Dad say's he has the formula and knows how to do it. The only engines I have ever balanced were a few old harleys and thats been a few years back.

Any thoughts or sugestions on this matter?

John Davis |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 230

Registered: 07-2002

| | Posted on Thursday, March 08, 2007 - 09:59 pm: |

|

We've ballanced several of the single Lockwood Ash engines. I did two 4hp and Bob Legnon and Jamie Hury have each done a couple of 2hp. It helps but it gets to be a trade off. You are trying to balance reciprocating motion with a rotating weight. You eliminate some of the bouncing up and down but start to get a wobble from the base area. The best way to eliminate shake is to go to a lighter piston. The stock cast iron piston in a 4hp L-A is over 4lbs. I had some aluminum pistons cast that are under 2lbs. The formula I use is to counterbalance all of the rotating weight plus half of the reciprocating weight. Nadler single cylinder engines had counter balance holes drilled in the flywheel. The water pump was also timed to counterbalance the piston. |

john_archibald

New member

Username: john_archibald

Post Number: 2

Registered: 08-2006

| | Posted on Thursday, March 08, 2007 - 11:28 pm: |

|

It's impossible to completely balance a one cylinder engine.

If you drill holes in the flywheel, you will introduce a couple.

The best way to "eliminate" ( minimize is a better word ) vibration is to add cheeks to the throws if there is room.

The suggestion above about using a lighter piston is also a good one.

Archibald |

johnny

Senior Member

Username: johnny

Post Number: 96

Registered: 03-2006

| | Posted on Tuesday, March 27, 2007 - 08:52 am: |

|

I have just about finished restoring my little 2hp Detroit thats in the photos above. I have decided to not balance the flywheel until I see how it runs. I did not think of the concentric for the water pump acting as a counter balance as someone had mentioned in the post above. So I will wait and see how smooth it runs. I'm setting it up on a stand with a water tank and fuel tank so I can run it at the shows. Does anyone know how small of a water tank I can get away with using and still cool the engine properly? I wanted to try about a two gallon tank. Is this big enough? I will post some new photos within a week or so.

Ernie,

I was looking at turning the exhaust on a 45 degree down angle like you said but the muffler has baffles in it with one hole in each baffle and some of the holes in the baffles are at the top and some are at the bottom so I'm not so sure if it will make a difference if its on 45 down or straight out. What do you think?

Thanks |

ernie

Senior Member

Username: ernie

Post Number: 624

Registered: 01-2002

| | Posted on Tuesday, March 27, 2007 - 08:29 pm: |

|

I really don't think it matters at idle. Give it a try. You can always change it. In the summer 80 deg f plus air temp a 5 gallon bucket gets pretty hot in about a half hour or less. It's 58 deg F here tonight and I ran my YT 1 for about 2 hours before it got real hot. Havn't put a thermometer in it, however I don't want to put my hand in the water. So I guess it's based on how long you want to run it. 2 strokes get hotter than 4 strokes.

Hope this helps

Ernie |