| Author |

Message |

searcher

Member

Username: searcher

Post Number: 16

Registered: 10-2004

| | Posted on Thursday, January 27, 2005 - 09:46 pm: |

|

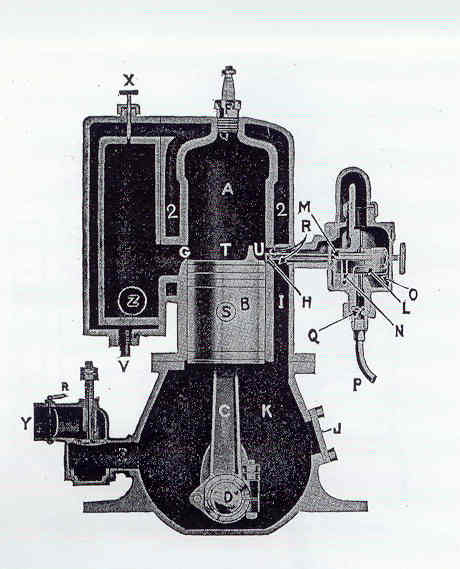

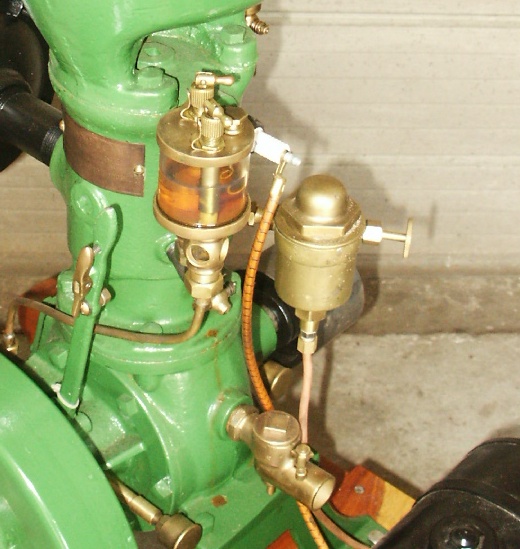

I acquired this Sandow not having a clue about the fuel system other than the seller commenting that it originally used an 'injector'. The 'injector' attached to the small fitting on the cylinder located just to the left of the name plate and just above the check valve (see photo). The rest of this little engine seems original and I am inclined to limit restoration to replacement of the missing part. What do I call that missing part, it seems to be neither a carburetor nor a mixing valve? Where is the best place to advertise for such a part?

The Sandow name plate has a number hand stamped on it (12 876). Is it possible that it is the serial number and the engine was the 876th built in 1912?  |

billschaller

Senior Member

Username: billschaller

Post Number: 113

Registered: 12-2003

| | Posted on Friday, January 28, 2005 - 12:23 am: |

|

go ahead and call it a fuel injector. Detroits had them, too. |

ernie

Senior Member

Username: ernie

Post Number: 462

Registered: 01-2002

| | Posted on Friday, January 28, 2005 - 04:39 am: |

|

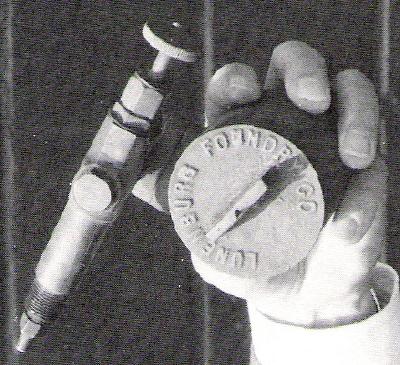

Here is a pic of an injector I made from some old carb/mixer parts. This is a Detroit stationary engine and the check valve is on the other side.

|

searcher

Member

Username: searcher

Post Number: 17

Registered: 10-2004

| | Posted on Friday, January 28, 2005 - 07:35 am: |

|

Ernie and Bill, thanks for responding. Injectors as I know them are pressure driven. The arrangement on Ernies engine seems to be vacuum driven? Can anyone supply me with a source where I might find a diagram of how one of these injectors worked and what they looked like. Hugh |

ernie

Senior Member

Username: ernie

Post Number: 463

Registered: 01-2002

| | Posted on Friday, January 28, 2005 - 08:46 am: |

|

It is actually pressure driven. It works due to the pressure difference related to surface area. The tube off the "T" is to pressureize the float bowl. There is probaly 2 or 3 sq in of surface area on the fuel. The actual fuel delivery tube that almost touches the piston at the intake port is made from 1/16 tube. It runs inside the larger fittings that are screwed into the engine. The needle valve is between the float bowl and the fuel delivery tube. The float bowl gets pressurized during the downstroke of the piston. There is still enough positive pressure in float bowl during the beginning of the upstroke to spray fuel out of the delivery tube into the combustion chamber through the intake port. There is only 1 check valve in the injector and it is in the fuel inlet line to prevent fuel from being pushed back into the fuel tank. The float bowl does see positive and negetive pressure. In fact this one works well with the gas tank sitting on the floor. I don't know of any information on these neat things. |

ernie

Senior Member

Username: ernie

Post Number: 464

Registered: 01-2002

| | Posted on Friday, January 28, 2005 - 09:04 am: |

|

Here is a picture of an Acadia kerosene injector. It worked under the same principals. You can see the small tip on the end. There are hole/s around that to allow positive pressure to go back around the small inner tube into the float bowl above the fuel level. The picture is from Old Marine Engines by Stan Grayson.

|

searcher

Member

Username: searcher

Post Number: 18

Registered: 10-2004

| | Posted on Friday, January 28, 2005 - 08:47 pm: |

|

Ernie, I wrote a response earlier today but I must have pushed a button wrong or something because I see that it never made it onto the discussion board. So, I will try again.

Thanks for the explanation of the injector. Now it is beginning to make sense to me. Yes, that fuel injection system is neat. However, I am not technologically capable of building one and I am getting the feeling that it is very difficult to find an original example. I tried an old engine advertising site and got no response (though I didn't really know what to ask for).

My Sandow is in wonderful condition and the injector is all that I really need to restore it. I wouldn't even repaint it. There is a very good chance my grandfather knew the original owner and may even have heard/seen the engine run or even rode in the boat in which it was installed.

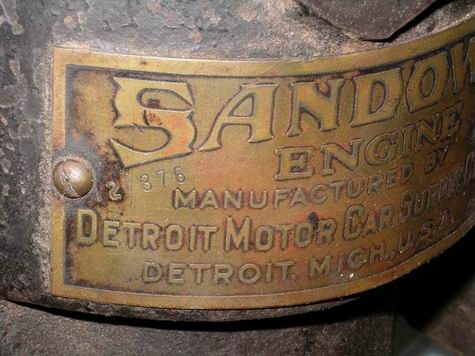

The attached photo depicts the nameplate on the Sandow. Note the 12 376 stamped on the name plate. Any chance that is the serial number and the engine was #376 built in 1912? Or is that wishful thinking?

Thanks for your very helpful response. Hugh

|

ernie

Senior Member

Username: ernie

Post Number: 466

Registered: 01-2002

| | Posted on Monday, January 31, 2005 - 11:30 am: |

|

Hugh,

Very few of the Detroit family of engines even have tags. The one that I have doesn't have an SN. I would not rule out the fact that it could be the SN and year.

What you need to search for is a one piece injector. These injectors were used on Detroit, Sandow, Columbia, Termatt and Monahan and maybe even more engines. For the one piece style I don't think it will matter what size. There was a 2 piece injector that was used on the earlier engines. Due to the style of your engine (marine) the throttle/check valve is where part of the injector was. |

Scott Peters

Visitor

| | Posted on Monday, January 31, 2005 - 02:21 pm: |

|

I think the 1912 date makes sense with the Motor Boating ad cited by Max Homfeld.

Detroit Motor Car Supply Company

Detroit Motor Car Supply Company was one of the conglomerate of marine engine manufacturing firms and boat building companies owned and operated by Hugo Scherer and Frederick E. Wadsworth in Detroit, Wayne County, Michigan. Other firms in the operation included Thrall Motor Company, Detroit Engine Works, Detroit Boat Company, and Columbia Engine Company. They also built automobile tops and traction engines, among other products.

The company was located at 1270-1280 Jefferson Avenue in Detroit.

Sources:

Homfeld, Max F. 753 Manufacturers of Inboard Marine Engines (St. Michaels, MD: Max F. Homfeld, 1991.) p. 4. Cites Motor Boating, December 1912, p. 30.

Polk, R. L. & Co. Detroit City Directory, 1912 (Detroit, MI: R. L. Polk & Co., 1912.) pp. 186, 3518. |

searcher

Member

Username: searcher

Post Number: 19

Registered: 10-2004

| | Posted on Wednesday, February 02, 2005 - 10:16 pm: |

|

Ernie,

The injector you made for your engine appears to be a self contained, one piece unit and your note indicates I am looking for the one piece injector. However, the note added in the last sentence that the throttle/check valve is where PART of the injector was. So I am not sure whether I need to look for the one piece or two piece.

The note with the photo of your engine indicates your engine still has a throttle/check valve, it is simply on the opposite side of the engine from where it is on my engine. Does part of the injector replace that check valve in that location and the check valve simply moves to the opposite side of the engine?

Thanks for your patience. I have been at this hobby less than a year and have not yet had time to take a two cycle apart to really understand how one works. For example, the throttle/check valve on this engine is the first one I have ever seen though I expect they are actually quite common. I have a long ways to go.

Thanks for your help Ernie.

Scott,

Thanks for your note regarding date of the engine. The references you site are certainly consistent with the date interpretation. Until I learn differently, I am going to assume that my engine is a 1912.

Does anybody have a Detroit brochure from that period that would be willing to make me a photocopy? I would reimburse copy and postage expenses. Or, if such a brochure has been reprinted, where I would make inquiry for a copy?

Hugh |

ernie

Senior Member

Username: ernie

Post Number: 467

Registered: 01-2002

| | Posted on Thursday, February 03, 2005 - 07:10 am: |

|

Hugh,

I will get pics of my stationary one so you know what that style of check valve throttle looked like. You need a 1 piece injector. However does your engine have a 3/4 in pipe plug in the other side of the crankcase? If so you could move the check valve throttle on yours over to that hole and then you could use either the 2 piece or the 1 piece. The one piece would screw into the hole where the fitting is next to the tag on yours. The 2 piece has the fuel injector and needle valve in the small upper hole (by the tag) and the float bowl/pressure chamber would go where your check valve/throttle is now. There would have been a small tube connecting the 2 parts. Does anybody have a pic of a 2 piece injector. I just looked in the Big Yellow Book and all the pics in there are 1 piece.

Hope this helps

Ernie

By the way where are you located. I travel a lot for work. |

searcher

Member

Username: searcher

Post Number: 20

Registered: 10-2004

| | Posted on Thursday, February 03, 2005 - 05:37 pm: |

|

Ernie,

My engine has a 3/4 inch pipe plug on the other side but it is down on the crankcase rather than opposite the 3/4 opening now occupied by the throttle/check valve.

I am in Blue Hill, Maine, near Ellsworth.

Thanks. Hugh |

ernie

Senior Member

Username: ernie

Post Number: 469

Registered: 01-2002

| | Posted on Thursday, February 03, 2005 - 06:57 pm: |

|

Hugh,

Yup that is where is should be. You can move the check valve/throttle on yours to that spot. In fact no matter what style of injector you find that is where the check valve/throttle should should be. That way you can use either style of injector.

Drat the Mazda dealer in Ellsworth is no more. I don't get up that way much. Maybe I need to visit the dealer in Bangor. It looks like it's only about 35 miles or so. Why don't you give Bill Wolfe from Westbrook a hollar. He might know of one. If you need his phone nomber send me an e-mail

Hope this helps

Ernie |

searcher

Member

Username: searcher

Post Number: 21

Registered: 10-2004

| | Posted on Thursday, February 03, 2005 - 09:47 pm: |

|

Ernie, you have been great. If you ever do get up this way, please let me know.

I met Billie Wolf about a month ago and really enjoyed his wealth of knowledge. There is this list of questions I have been keeping since then. Several days ago I arranged to meet with him this coming week. I am sure he doesn't suspect a thing yet as to the number of questions I do have on old marine engines.

Thanks. Hugh |

ernie

Senior Member

Username: ernie

Post Number: 470

Registered: 01-2002

| | Posted on Friday, February 04, 2005 - 07:09 am: |

|

Please say hello to Bill for me. |

searcher

Member

Username: searcher

Post Number: 22

Registered: 10-2004

| | Posted on Friday, February 04, 2005 - 07:26 am: |

|

I sure will. Hugh |

axtion_jim

New member

Username: axtion_jim

Post Number: 1

Registered: 01-2006

| | Posted on Tuesday, January 24, 2006 - 01:12 am: |

|

Hugh I have just registerd on this discussion board. I to am the proud owner of a Detroit 2 H.P. engine. Mine is the farm or industrial type. The water hopper is located on top of the cylinder making a very early model. as any engine manufactured after 1912 used out board cooling system. The fuel vapourizer that is missing from your engine looks like a brass chamber with float inside, a check valve on the bottom,with a fuel line directly to tank. Moulded to the top side of the chamber is the needel valve assembly that is threaded in to the cylinder port next to the oiler. Mine has a threaded top. I have seen some with hinged top that is held down with a thumb nut and a swing bolt on the side of the chamber. I didnt mean to get so long winded,but I get excited when I see an other engine like mine. Shortly I will post some pic,s of the restoration. And after that I am going to cast another brass vapourizer as I have been given another Deroit engine with out one. I hope this is a little help for you. Jim. |

andrew

Moderator

Username: andrew

Post Number: 1356

Registered: 11-2001

| | Posted on Tuesday, January 24, 2006 - 08:34 am: |

|

Jim,

Welcome.

Keep us posted, especially on the casting of a new vapourizer. |

searcher

Senior Member

Username: searcher

Post Number: 82

Registered: 10-2004

| | Posted on Tuesday, January 24, 2006 - 10:35 am: |

|

Jim,

Thanks for responding.

I am still looking for the proper injector for this Sandow (Detroit). I have found two of the type that go on members of the stationary engine family of Detroit/Sandow/Columbia/Termatt and Monmahan/etc. but none of the type that went on the marine engine branch of the Detroit family. I am an optimist and fully expect I will find one eventually.

I would love to try casting something and have gotten as far as to order a two volume 'how to' on the subject. I, too, will be most interested in your casting of the vaporizer.

I have a couple of things on the Detroit family, including an original fold out brochure. Post a photo of your engine and I will send you a photocopy if it matches with your engine.

Hugh |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 977

Registered: 11-2001

| | Posted on Tuesday, January 24, 2006 - 12:33 pm: |

|

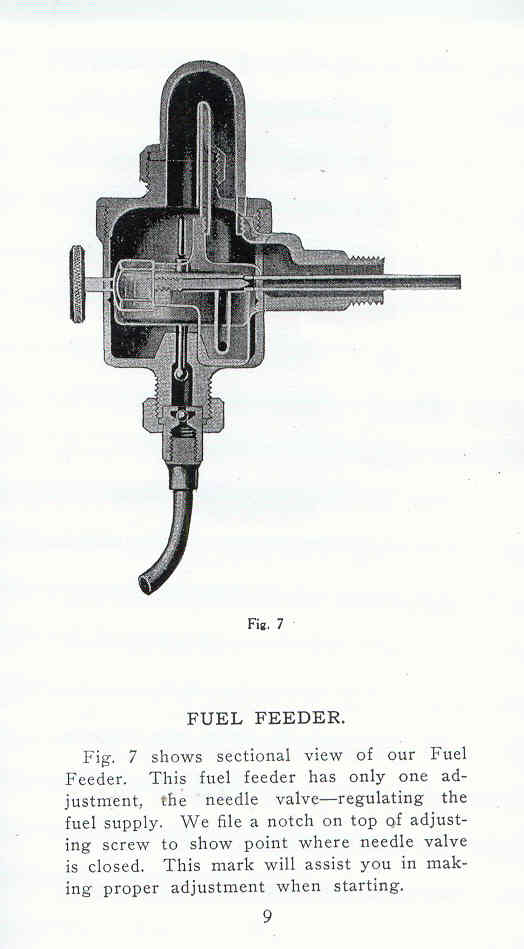

Detroit Engine Works 1913

"Fuel Feeder"

|

searcher

Senior Member

Username: searcher

Post Number: 83

Registered: 10-2004

| | Posted on Tuesday, January 24, 2006 - 04:13 pm: |

|

Thanks for posting the photos. So where the heck do I find one, Richard?

Hugh |

bruce

Senior Member

Username: bruce

Post Number: 306

Registered: 07-2002

| | Posted on Tuesday, January 24, 2006 - 09:43 pm: |

|

What does Owls Head museum have in their archives-might be worth asking Hugh. |

searcher

Senior Member

Username: searcher

Post Number: 84

Registered: 10-2004

| | Posted on Tuesday, January 24, 2006 - 10:10 pm: |

|

Bruce, I have a list of things to research at Owls Head. I hope to get over there before my busy season workwise starts up again in earnest in a few weeks. I have visited the museum three or four times over the past 20 years but never with any specific purpose in mind. Now that I have contracted a certain amount of old iron fever, I want to do just as you suggest, some research in the archives. |

thomas

Senior Member

Username: thomas

Post Number: 322

Registered: 07-2002

| | Posted on Wednesday, January 25, 2006 - 02:50 pm: |

|

Searcher, you might try an ad in Gas Engine Magazine want ads. The magazine is published once a month.(they have a web site) They still get a lot of parts sell/buy listings and if you put a photo in the ad you might just get a result. |

searcher

Senior Member

Username: searcher

Post Number: 85

Registered: 10-2004

| | Posted on Wednesday, January 25, 2006 - 05:35 pm: |

|

Worth a try. I sure haven't had much success elsewhere including the antique marine engine classifieds. |

andrew

Moderator

Username: andrew

Post Number: 1362

Registered: 11-2001

| | Posted on Thursday, January 26, 2006 - 09:46 am: |

|

Jim sent the following by email:

quote:Andrew.

Would you please post these 3 photos on your form page for the rest of the group to view,as we have not figured out how to do this posting ourselves.

Thanks again.

Hope you all enjoy these.Jim

|

searcher

Senior Member

Username: searcher

Post Number: 86

Registered: 10-2004

| | Posted on Thursday, January 26, 2006 - 11:33 pm: |

|

Jim,

I am really pleased you posted these photos. This is the first stock injector I have had the opportunity to see. Good photos too. Thanks.

I will find one of these devices but it obviously will take a while. |

steve70

New member

Username: steve70

Post Number: 1

Registered: 02-2006

| | Posted on Sunday, February 19, 2006 - 10:07 pm: |

|

My name is Steve and I just joined this board. After reading the comments on this board, I realized the wealth of information that was shared by all those who posted. I own a Sandow engine that was given to me by a lifelong friend. I have recently started to restore it and in doing so, have realized just how little I know about these engines. My father in law has a couple but he is more interested in restoring old tractors. He is very knowlegable of these old machines, but he to is somewhat stumped about how I should go about getting this engine running. That is my goal to get it running so that the friend who gave it to me can see it run again. In reading these post, I have been able to piece the engine back together again somewhat. I have the same engine as Jim. Those are wonderful pictures. I was wondering if he might be able to post some more that might show some more detail as to where the oilers fit in and of the governor area. Also, the oiler by the injector, does it contain 2 cycle oil for the gas mix or oil for the cylinder? I have also had no luck in trying to find an injector. Any information on how or where I might locate one would be greatly appreciated. Thanks for all of the information. I will try and post some pics of my engine. Just don't laugh at the red color that I have started painting it. My dad thought that would be a good color since I do not know what the original color was. |

johnny

New member

Username: johnny

Post Number: 1

Registered: 03-2006

| | Posted on Wednesday, March 01, 2006 - 10:19 am: |

|

Hello everyone,

Jim very nice Sandow, I would like to post the photos on my website if possible? along with your name and where you are from. My website has a section dedicated to Detroits and related engines. Also a lot of literature that might help some of the Detroit collectors. Please check it out. http://www.antiquengines.com

Thank you...

Johnny |

steve70

New member

Username: steve70

Post Number: 2

Registered: 02-2006

| | Posted on Thursday, March 02, 2006 - 05:24 pm: |

|

Johnny,

I have an engine just like Jim's. You are right, it is a great looking engine. I have also been to your website and it to has been a great resource in trying to get my engine back to running condition. I am in need of a carb / fuel mixer. I am hoping that I will find one. In the meantime, I am looking at trying to run the engine on propane. I have found quite a bit of info on doing this, but want to make sure I do it right. I would hate to do something that would render the engine useless. It was given to me by a lifelong friend and I would love for him to see it run again. Any info that you could offer would be greatly appreciated. Thanks again for your website and the information that it offers. |

richardday

Senior Member

Username: richardday

Post Number: 303

Registered: 11-2003

| | Posted on Thursday, March 02, 2006 - 08:24 pm: |

|

Running a two stroke on propane that seems to need a solution to injecting oil for lube anyone have any suggestings how to do it?? |

solarrog

Senior Member

Username: solarrog

Post Number: 130

Registered: 03-2002

| | Posted on Thursday, March 02, 2006 - 09:33 pm: |

|

I do not see the point, your still going to have the need for oil, Or a liquid lube of some type.

If you have to enter lube, it might as well be with the fuel |

steve70

New member

Username: steve70

Post Number: 3

Registered: 02-2006

| | Posted on Friday, March 03, 2006 - 05:55 pm: |

|

Solarrog,

I would rather run the engine on a gas oil mixture. If I could find the injector or maybe be able to retrofit a different carb such as a Schebler, I would do that. In reading a post on running engines on propane, the person suggested putting an oiler on the engine side of the propane feed for lube. Any suggetions on how I might carb the engine would be greatly appreciated. I have really enjoyed reading the post and learning about these engines.

Thanks |

solarrog

Senior Member

Username: solarrog

Post Number: 131

Registered: 03-2002

| | Posted on Saturday, March 04, 2006 - 01:58 am: |

|

I would log on to ebay.com and at least once a week search for the needed parts, You will not believe the needed items I have picked from ebay

Not to mention a complete Detroit for my collection.

Roger on the left coast. usa |

johnny

New member

Username: johnny

Post Number: 3

Registered: 03-2006

| | Posted on Monday, March 06, 2006 - 11:35 am: |

|

Steve,

You can run your engine by putting a threaded plug where your injector used to be. Then remove the air intake valve and put a lunkinhimer carburetor in its place. You will still use two oilers or a double oiler to lubricate the engine. One oil line to lubricate the cylinder and upper con rod and a second oil line to lubricate the lower con rod. Gease cups to lubricate the mains. I have seen this done more then once and it does work. There is a guy that reproduces the carburetors in two or three different sizes and does a very proffessional job. If your interested e-mail me and I will find the man that reproduces the carbs for you. I believe he has a website.

Have Fun!

Johnny

[email protected]

http://www.antiquengines.com |

johnny

Member

Username: johnny

Post Number: 4

Registered: 03-2006

| | Posted on Monday, March 06, 2006 - 11:43 am: |

|

Steve,

You can run your engine by putting a threaded plug where your injector used to be. Then remove the air intake valve and put a lunkinhimer carburetor in its place. You will need to add a butterfly in the pipe that attaches the carb to the engine or you can use a carburetor that already has a butterfly. You will still use two oilers or a double oiler to lubricate the engine. One oil line to lubricate the cylinder and upper con rod and a second oil line to lubricate the lower con rod. Gease cups to lubricate the mains. I have seen this done more then once and it does work. There is a guy that reproduces the lunkinhimer carburetors in two or three different sizes and does a very proffessional job. If your interested e-mail me and I will find the man that reproduces the carbs for you. I believe he has a website.

Have Fun!

Johnny

[email protected]

http://www.antiquengines.com |

steve70

Member

Username: steve70

Post Number: 4

Registered: 02-2006

| | Posted on Monday, March 06, 2006 - 09:18 pm: |

|

Thanks Johnny!!

I think that I have followed you on most of what you described. Are you saying that I would put the carb where the check valve is located on the crankcase? I will send you some pics of my engine and see what you think. I get a little down when I try to find parts and don't seem to have much luck. My wife says that I am obsessed. She just doesn't understand!!!!! |

axtion_jim

New member

Username: axtion_jim

Post Number: 2

Registered: 01-2006

| | Posted on Thursday, March 23, 2006 - 11:29 pm: |

|

Hi Bill

The photos on the web page show the fuel tank mounted on the pedestal that are on top of the skids.The pulley is nothing special,it is about 5 inches on the face & 5 inches in diameter.There is a square head set bolt that clamps it to the flat spot on the crank.The fuel line going into the tank does not have a check valve on the end,it is located on the bottom of the injector.I don't have the muffler,but that is not a hard project.I only have a bit more to do on my engine and it should crank up.I am going to show it on the May long weekend in Fort Langley,B.C.Then i plan to take the injector off and cast a new one for my other Detroit engine,that a good friend of mine Sid gave me.If it works out that the new casting doesn't take 500 hours to make.I will cast a few more.I will take some more photos with it running and have them posted for all to enjoy.

Jim |

axtion_jim

New member

Username: axtion_jim

Post Number: 3

Registered: 01-2006

| | Posted on Friday, March 31, 2006 - 11:07 pm: |

|

THANKS to all who submited the ton of info on the sandow engine. My engine ran for the fist time at 3:00 P.M. Pacific March 31 2006. It is a marverless thing to behold. I still have some details to work out but nothing serious.I made a muffler from a four inch pipe, drilled 1/4 inch holes in the out baffle and welded a 1 1/4 nip on the in side it makes a real nice puk puk sound. The next thing on the agenda is to show it then I will make up and cast some injectors. |

axtion_jim

Member

Username: axtion_jim

Post Number: 6

Registered: 01-2006

| | Posted on Sunday, March 04, 2007 - 11:59 pm: |

|

Well , the casting are finally done , and now is the task of maching .It will have to be a manual process , C&C will be to costly to makeup all the fictures for the movments. As near as I can determan it has 15 defferant proccess,unless someone can suggest something easery. Stay tuned as Im going 6 of them. Jim |

richardday

Senior Member

Username: richardday

Post Number: 469

Registered: 11-2003

| | Posted on Monday, March 05, 2007 - 09:42 am: |

|

Just a point you might consider. They didn't discover mixing oil in the fuel until 1909 and by 1910/1911 most makers of two strokes quit draping drip oilers on their engines as they really didn't work very well and were a pain to clean so one could see the amount of oil in the reservoir and making sure the drip rate was ok. Manufacturers continued to supply drip oilers if the customer requested them but most switched to a 40:1 gasoline/what we now refer to as SAE30 weight non-detergent oil. My practice at a show is to partially fill the drip oilers, make them appear to be dripping but don't actually drip as that adds too much oil to the mix and just adds more oil to be burned. These engines run slow and cold in comparison to weed whackers and chain saws. The two cycle oil for these modern engines won't hurt these old timers but it can fly through the engine and out the exhaust pipe making a big mess. Ernie uses 30:1 modern two stoke oil with no problems so there is no reason not to use it just cut down the amount.

I might add Old man Lathrop never believed in mixing the oil in the fuel but his customers did particularly with working watermen as they didn't have to clean and worry about the supply and drip rate. I am not suggesting one remove the oilers from an antique just leave them there for shows and preserving authenticity. |

johnny

Senior Member

Username: johnny

Post Number: 571

Registered: 03-2006

| | Posted on Saturday, March 18, 2017 - 10:44 am: |

|

I realize that this post is a few years old but was wondering if Jim every finished machining the Detroit fuel reservoir/injectors and how they came out? Below are a few pic's of the fuel reservoir/injector and air intake valve that my father and I produced for his Sandow Detroit. They both work very good although we did have a little trouble with porosity in the castings. When we finished making them we realized that making more to sell would be very very expensive so much that most would probably not purchase them. So we never made anymore.

Just a quick comment to Richard about mixing oil in gas and not turning on the drip oilers. Remember on the Detroit fuel injected engines they depend on a drip oiler to lubricate the bottom con-rod. The fuel never enters the bottom crankcase it is injected straight into the combustion chamber. So I would use a drip oiler to lubricate the lower con-rod. You can still run the fuel oil mix to help better lubricate the top end but also run the drip oiler for lubricating the lower con-rod.

|