| Author |

Message |

thomas

Senior Member

Username: thomas

Post Number: 175

Registered: 07-2002

| | Posted on Monday, July 26, 2004 - 08:40 am: |

|

|

thomas

Senior Member

Username: thomas

Post Number: 176

Registered: 07-2002

| | Posted on Monday, July 26, 2004 - 08:41 am: |

|

|

thomas

Senior Member

Username: thomas

Post Number: 177

Registered: 07-2002

| | Posted on Monday, July 26, 2004 - 09:07 am: |

|

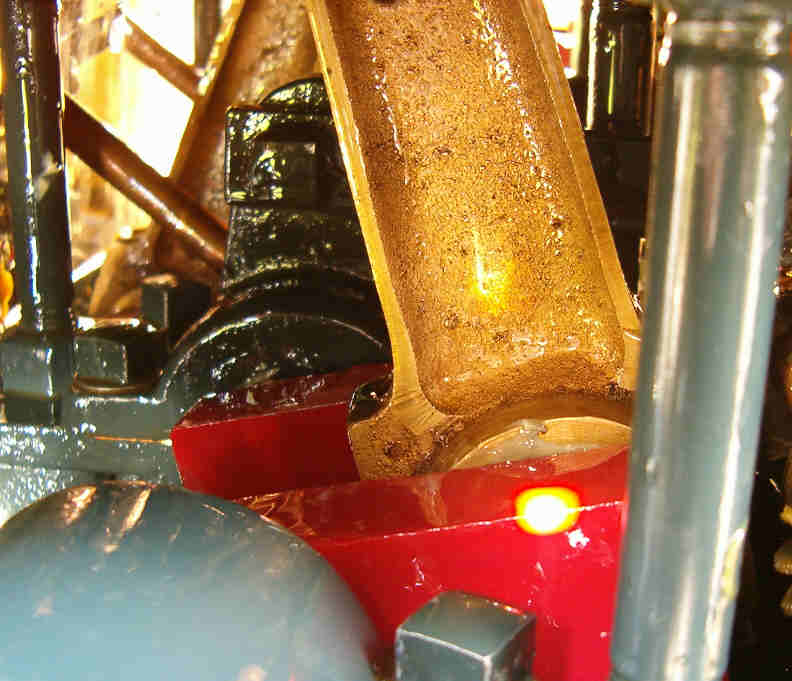

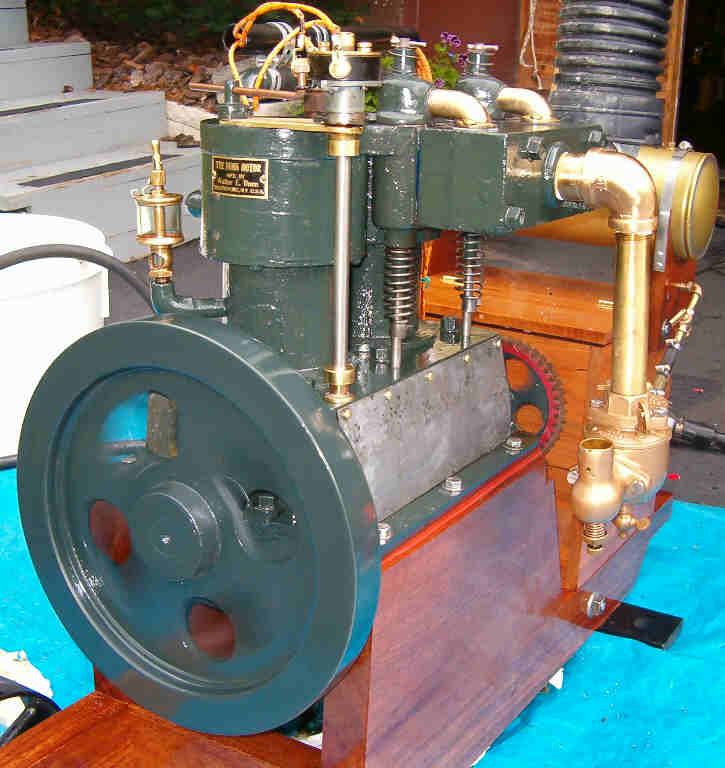

Besides running my Emmons for over an hour on Sat.

I was lucky enough not to have a callout for work so I got to work on the last things on the Dunn twin (timer and wires/coil)and about 5:30

I was filling up the Scheibler bowl with some gas

and Amsoil left from the Emmons. I did not connect the water because I knew that the oil splash issue could be a problem. I had only put 1/2 a qt of oil in each crank well (just touched the bottom of the crank cheek)WELL! The engine started and ran ok with just a slight advance and a tweak of the needle valve but the oil was

running down the splash shields and back and down the outside--in a word it was a mess. I have

attached a picture of the engine just after the run (please ignore the aluminum nails holding the shield) and one of the inside cavity shot from the front. Notice how EVERYTHING is slick and shiny with oil. Splash must have been how the

interior mechanics were lubed and it does cover all the area but how exectly the oil is recovered

is still a mystery. If anyone has any Dunn running experience I would appreciate their input |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 487

Registered: 11-2001

| | Posted on Monday, July 26, 2004 - 07:53 pm: |

|

Tom, Dunn II looks just "GREAT" ! |

thomas

Senior Member

Username: thomas

Post Number: 178

Registered: 07-2002

| | Posted on Saturday, July 31, 2004 - 01:08 pm: |

|

|

thomas

Senior Member

Username: thomas

Post Number: 179

Registered: 07-2002

| | Posted on Saturday, July 31, 2004 - 01:22 pm: |

|

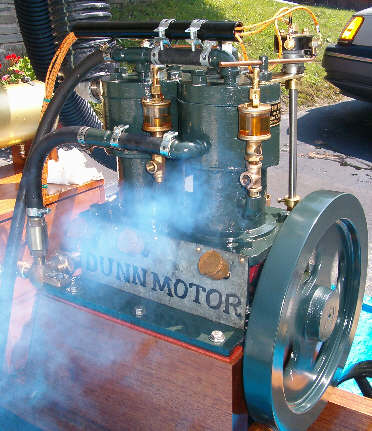

I started the Dunn with water connected and found some leaking head bolts and a old style clamp leak. I fixed those and then the rear cylinder stopped working. The coil needed some "Tweaking" and I found that spark plug is

weak somehow (swapped it and the miss follows the plug). It was pretty loud W/O a muffler so I just put a 10' piece of plastic 6" drain pipe over the exhaust and it was ok.

The oil is still a mystery. The front oiler drops it's whole load in about 5 min regardless of how low the needle valve is set. The rear oiler either drips nothing or it blows out the contents through the fill hole (but not all the time!) It does sound good and I did shoot a few min. of AVI video which is passable.

I took the engine inside because it's really raining now and I want to stare at it and HOPE the solution to the oiler/oiling issues float up to the surface of my brain. |

andrew

Moderator

Username: andrew

Post Number: 837

Registered: 11-2001

| | Posted on Saturday, July 31, 2004 - 03:45 pm: |

|

Tom,

If you want to email me the AVI file I will put it on the server and try linking to it from here. I have never played with video files before... but it should work.

I'm sure we would all enjoy seeing it run  ! ! |

thomas

Senior Member

Username: thomas

Post Number: 180

Registered: 07-2002

| | Posted on Saturday, July 31, 2004 - 07:12 pm: |

|

Andrew,

I am sending you a CD with megabytes of AVI video and also some still photos of both the Dunn and the Emmons. I always wanted to see some videos of a Fay & Bowen and other unusual engines. Maybe this will be the start of something good. |

george_iv

New member

Username: george_iv

Post Number: 2

Registered: 07-2004

| | Posted on Saturday, July 31, 2004 - 09:25 pm: |

|

Wow, pretty engine!!! The oiler deal sounds kinda familiar. My father has a St. Lawrence single with the same type of oiler ooze problem. He put a check balled oiler on it and if the oiler is open, you can't put oil into it. It'll blow it out as fast as you can pump it in. What it appears is that the top piston ring uncovers the hole in the cylinder. No check ball will work fast enough to stop the entire pressure of combustion at the end of the power stroke. It kinda turns it into a ported two cycle. So anyway, you may want to check your connecting rod center distances from the pin to crank.

Hope this helps,

George |

thomas

Senior Member

Username: thomas

Post Number: 181

Registered: 07-2002

| | Posted on Sunday, August 01, 2004 - 02:51 pm: |

|

I've got all kinds of running problems. The front clyinder seems to be running hotter or else firing more regularly than the aft cylinder. The

exhaust area is getting hotter and the hi-temp engine paint is brown. The other cylinder is also

over heating the paint in that area but only 1/4

as much. I put an elbow in line with each oiler to see if that opening would stop the spitting back into the oiler. When running, those 1/4" elbow openings are like miniture exhaust ports; there is just a steady blast of (?) blow-by and oily smoke. I tried my IHC muffler but it seems that the smaller 1-1/4" opening and maybe the muffler itself is choked up and the engine won't run as good with it on.

I made a little oil "dip stick" (no jokes here)

so I can refill the crancases before each start

and not over fill them.

When I put the engine together I had to estimate the valve timing because the gear on the crankshaft had been disconnected and I could see no obvious factory type marks between the cam gear or the drive gear. I looked in several old auto maintenance manuals but I settled on a friends advice to have the power stroke go as long as possible before opening the valve and then be sure it was open as far as possible in the upstroke but closed before TDC to allow the suction stroke to have all it's necessary time.

The engine has great compression and I wonder

where the blow-by is comming from.

The oiler ports into the cylinder are way down

below the top of the piston and probably below the rings themselves. (the rings are all above the wrist pin. I did put new rings in the engine

but I can't see the rings as an issue).

MAYBE with the long down stroke before exhaust opening is letting the combustion pressure to get a little too close to that oiler port?? |

thomas

Senior Member

Username: thomas

Post Number: 182

Registered: 07-2002

| | Posted on Sunday, August 01, 2004 - 02:55 pm: |

|

|

thomas

Senior Member

Username: thomas

Post Number: 183

Registered: 07-2002

| | Posted on Sunday, August 01, 2004 - 05:42 pm: |

|

I measured the piston at BDC and I see the oiler port is open at BDC. I did replace each of the old single big rings with two smaller ones. I wonder if that 1/2 ring gap is allowing this to happen? I did advance the cam gear one tooth but it was late in the day and my arm is shot; could not get it to start (yes, I did reset the spark timing). I think the coil is on the fritz again.

I'll have to try next week after work.

It does sound nice running!! With my odd ball drain pipe muffler it sounds like a John Deer twin. |

keith

Senior Member

Username: keith

Post Number: 144

Registered: 02-2002

| | Posted on Monday, August 02, 2004 - 07:49 am: |

|

Tom

Most old books that talk about valve timing recommend the exhaust opening 30 degrees before BDC and closing 15 degrees after TDC. Your short and late exhaust cycle could be part of your heat problem. Are you using oilers with the vent tube and ball check? You need to get Dick, Ernie and B.J. to address this problem.

Keith |

thomas

Senior Member

Username: thomas

Post Number: 184

Registered: 07-2002

| | Posted on Monday, August 02, 2004 - 11:08 am: |

|

The oilers were without check balls but I machined some small threaded plugs and added brass check balls that seem to work at least as well as factory units.

In mulling this over I'm starting to think (as Keith surmises) that the exhaust timing needs to be advanced (open valve sooner) (1)to allow the gas to be pushed out earlier and for more of the stroke , which gets rid of heat, (2) to get rid of the gas while all the rings are still between the oiler port and the port opening itself. The set of auto mechanics books I have (copyrights 1906 to 1920) stated that the average of 120 auto makes had the exhaust opening

45 degrees before BDC. |

thomas

Senior Member

Username: thomas

Post Number: 185

Registered: 07-2002

| | Posted on Monday, August 02, 2004 - 07:12 pm: |

|

I ran the Dunn for long enough just now to see that we are on the right track in advancing the exhaust timing. MUCH less back pressure in the cylinders (as per what comes out the oiler port). I have noticed there is a 100% difference between the 2 cylinders for some reason; the aft cyl. has twice the back pressure of the forward one. However, They are both reasonable now and I will be trying another long run with water and muffler later in the week. |

RichardDurgee

Senior Member

Username: richarddurgee

Post Number: 1340

Registered: 11-2001

| | Posted on Monday, November 27, 2006 - 10:36 am: |

|

*

Chuck

This old post shows the side plates, some were brass some were galvanized.

My Dunn II and Toms have the oil pan in one casting as you see in the other postings, I have never seen one like yours with the frame for the crankshaft and cylinder pedestal supports and yet open like a pan was a seperate piece ?? Will be back home next week will search Dunn info !

I had emailed you some info as to the mfg date of your engine its a few years older than Mine and Toms and may be the difference in the style of crankcase ?? |