|

| Author |

Message |

J.B. Castagnos

| | Posted on Sunday, May 30, 2004 - 10:07 pm: |

|

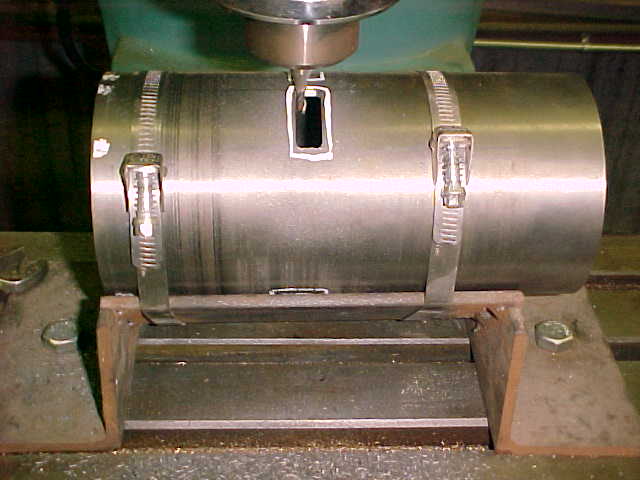

Some of you at the Calvert show saw the cylinder Ken Kaumeyer sent me home with, it needed a sleeve. The wrist pin had been running loose and gouged the cylinder, it was also worn and rusty. I've finished the job and took pictures while doing it, "show and tell". The first picture has the cylinder bolted to the plate on the boring jig, my old Storm boring bar clamps to the top.

The next picture shows the bar going in on one pf the passes, .025" per pass, final bore 4.191" leaving a .001" interference.

Next the cylinder is placed on the bench, a square is used to transfer the port locations to the base of the cylinder. I use a white out pen and a little snap center punch to mark it.

|

J.B.Castagnos

| | Posted on Sunday, May 30, 2004 - 10:26 pm: |

|

The sleeve is then placed on top of the cylinder and the marks are transfered to it.

The square is then placed on the sleeve and the lines drawn down, this shows the location of the ends of the ports.

The square is set to mark the depth of the top and bottom of the ports, this is the most critical measurement, affecting timing.

The sleeve now has a grid marked on it, it's clamped in a v block and the ports are cut in the mill. The cuts are made looking straight down into the cylinder. I use my white out pen to outline the pencil marks, helps to prevent errors while machining.

Once the ports are cut the sleeve is ready for installation, it's been cut to length and the top inner edge has been radiused, on a lockwood Ash the cylinder has a dome at the top and the area bored out looks like a sleeve, i don't like that sharp edge in the cylinder.

|

J.B. Castagnos

| | Posted on Sunday, May 30, 2004 - 10:51 pm: |

|

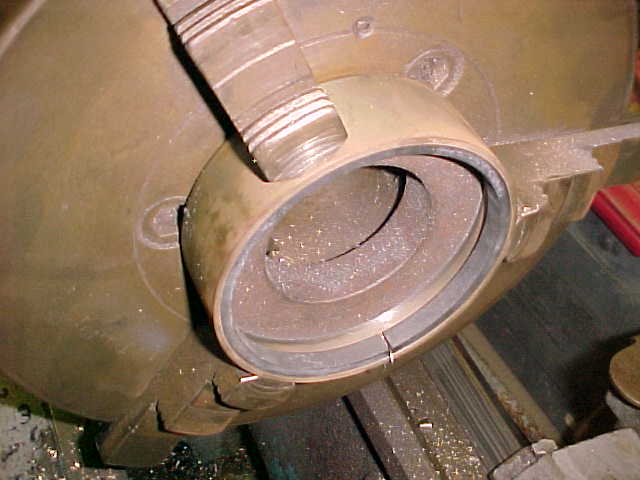

The sleeve and cylinder are coated with Loctite Sleeve Retainer, it's tapped in with a block untill it gets tight and taken to the press and pushed home. It then goes back into the boring bar for the finsh bore and honing, I usually leave it about .005" under and take a light cut on the piston to clean it up. First I clamp the piston from ring area at the top and indicate the bottom, once it's running true a slight bevel is cut on the inside of the skirt at the bottom. Next a cone is placed in the lathe and a light cut is made on it to true it. The piston is turned around and held to the cone by a draw bar with an eye on the end and a pin through the wrist pin hole. The bottom centers up by the bevel on the skirt against the cone. The top is indicated in. A light cut is taken to true the piston and give proper clearance.

The replacement rings are usually too thick and have too much wall pressure. This creates a lot of drag and takes away the bounce, making it hard to start against compression and hard to reverse. A section of the sleeve that was cut off has a disc inserted in one end and it's chucked in the lathe. A step is cut in it to recieve the ring, a hole drilled with a wire insert at the gap keeps it from spinning. A .030" cut is taken, the rings are noticeably easier to compress by hand.

Here's a picture with the sleeve installed and the chamfer cut on the bottom for ring installation. It in shipment back to Ken. We'll wait on a report from him to see how the rest of it goes.

|

Richard Day

| | Posted on Sunday, May 30, 2004 - 11:19 pm: |

|

Beautiful work JB. I am sure Ken will be most appreciative. |

Tim Mulvey

| | Posted on Monday, May 31, 2004 - 05:57 am: |

|

A fantastic guide. Thanks for sharing it with us. I've printed it off to add to my reference folder. |

Dick Gibbens

| | Posted on Monday, May 31, 2004 - 07:13 am: |

|

Good job JB! As is often said, "I'm glad I know you!" Dick G |

Ernie

| | Posted on Monday, May 31, 2004 - 08:37 am: |

|

Real NEAT!! |

rbprice

| | Posted on Monday, May 31, 2004 - 08:59 am: |

|

Not just neat but an example of a really skilled machinist at work. I've spent a lot of time in machine shops and J.B. has got to be one of the best I've ever had the pleasure to know.

J.B. - approx. how much time did it take overall and where do you get the cast iron sleeve blanks? |

J.B. Castagnos

| | Posted on Monday, May 31, 2004 - 09:33 am: |

|

Thanks for the compliments. Bob, The sleeves come from an automotive warehouse, mfg by Ohio. I haven't kept track of the time but I would guess a couple of hours on the sleeve. I had a list of these cylinders I sleeved but lost it in a computer crash, it's over 20. The first one I didn't have a mill so I drilled a series of holes in the drill press, filed them smooth, then went out and bought a little mill-drill. Once it's in the boring jig I can set the cutter and go about my other work, it shuts off at the end of the pass. I started doing boring and sleeving at the Pontiac dealer here in town, it was a family owned business and the old man, John Capone, was a mechanic from the Model A days. I learned a lot from him and his son. Are you finished with the houseboat project? How did it go? |

J.B. Castagnos

| | Posted on Monday, May 31, 2004 - 11:27 am: |

|

Bob, I want to correct myself, after I sent the message I realized I called it a houseboat, It was a yacht or a floating restaurant. |

J.B. Castagnos

| | Posted on Monday, May 31, 2004 - 02:10 pm: |

|

Looking over the steps I forgot to mention, after machining the rings I place a sheet of 400 sandpaper on a piece of glass and deburr the rings. Machining leaves a rough edge that you can feel, this will hold the ring up, keeping it from seating against the ring land. |

rbprice

| | Posted on Monday, May 31, 2004 - 02:34 pm: |

|

The cruise boat is mostly finished and, after a great deal of trouble, is in Lake George. It had to be moved overland 6.7 miles from Lake Champlain, through the village of Ticondaroga, to get to Lake George. The final work is going on to complete the vessel and get it ready for a wedding on 20 June.

The neat trick of sanding the rings to remove the edge burr is one I'll remember.

By the way, how is John doing?

Regards

Bob |

bill schaller

| | Posted on Monday, May 31, 2004 - 05:36 pm: |

|

J.B.,

I just picked up a 1937 Storm boring bar from an old guy at Portland. It was like new until he took it out of the box last year and let it get all rusty. You don't happen to have an instruction manual for your's, do you?

Bill |

J.B. Castagnos

| | Posted on Monday, May 31, 2004 - 07:49 pm: |

|

Bob, glad the boat made the move, hope it's ready in time for the ceremony. John is doing great, I talked to him today, he's planning to make Mystic and Portland. Bill, I do have the manual, will get it copied and send it to you. I don't know the year model of mine, but the manual talks about time saving adapter plates for the Model A&B and 60 & 85hp blocks. I also have possesion of a Van Norman boring bar, larger capacity. It belonged to a club member, Bill Chauvin. He was quite a machinist. He had to bore a block, the bar wasn't long enough so he extended it. If you look hard you can see the joint. I haven't tried this bar yet but that's what we had at the Pontiac dealer, I think it's a better setup because the cat paws are stationary. On the Storm they spin with the cutter so they have to be backed off while cutting. The Van Norman can be expaned once in the bore and support the cutter all the way down, less chance for chatter. |

Tom Stranko

| | Posted on Tuesday, June 01, 2004 - 07:13 pm: |

|

JB,

A fantastic lesson with wonderful documentation!!

However it's nice to know you were once a regular human and had to use a drill & file :-)

I have 2 questions: Do you ever machine the OD of the sleeve at all? 2) Is the sleeve retainer Loktite very slow setting?

Thanks

Tom |

J.B. Castagnos

| | Posted on Tuesday, June 01, 2004 - 09:22 pm: |

|

Tom, the sleeves are available in many sizes, both 3/32 and 1/8 thickness, I've been able to find what I need. The first marine engine I sleeved was a 6hp Caille, I think 4 1/2" bore. The sleeve for this cylinder would have been over the capacity of my bar so I used a thick sleeve from a smaller bore, ended up with less than 3/32 wall. It worked fine. I haven't found the piston and rod for my Fisherman yet. It's a 5" bore, cylinders a little rusty. If I don't find the correct piston I plan to hone the cylinder untill clear, order a sleeve a little larger and machine it to fit. I'll then hone the sleeve and make a piston to fit. The Locktite seems to set pretty fast. I set the press up before starting and tap the sleeve down with a block, usually about half way. By the time I get to the press it takes a lot of pressure to break it loose, a loud thump, and then it moves steady as long as you keep pressing. |

rholcomb

| | Posted on Wednesday, June 02, 2004 - 08:04 am: |

|

Are you using dry ice to cool the sleeve and pre heating the blockup to 200 or so ???? between the 2 you can get about .005 expansion /contraction and drop the sleeve in with little pressure but you have only 1 chance and it is quick bob.... |

J.B. Castagnos

| | Posted on Wednesday, June 02, 2004 - 01:39 pm: |

|

Bob, I'm out in the country, I've only seen dry ice a couple of times in my life. We used to use freon when it was 69 cents a can and didn't realize it was harming the enviroment. I just put a light bulb in the cylinder to warm it up some, the Locktite puts a little limit on what you can do. |

|

|

|

|