|

| Author |

Message |

raa

Senior Member

Username: raa

Post Number: 170

Registered: 02-2007

| | Posted on Tuesday, September 19, 2017 - 10:15 pm: |

|

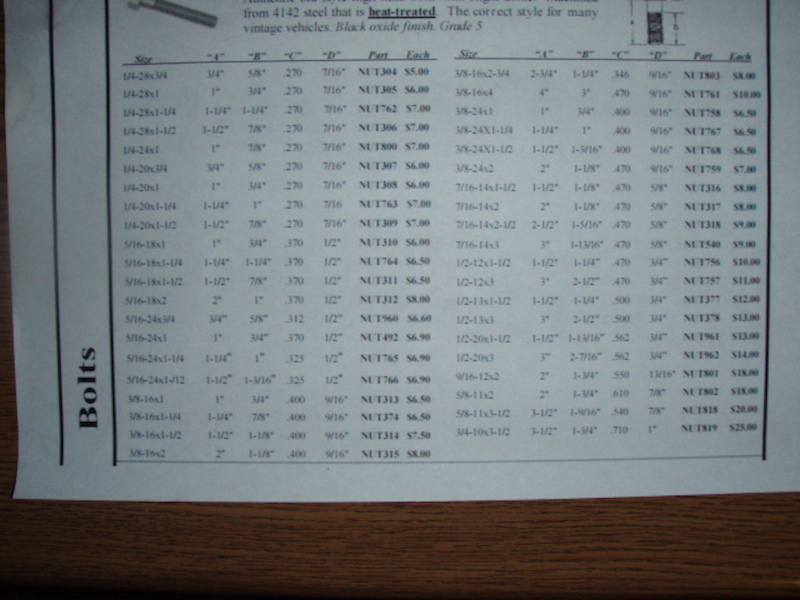

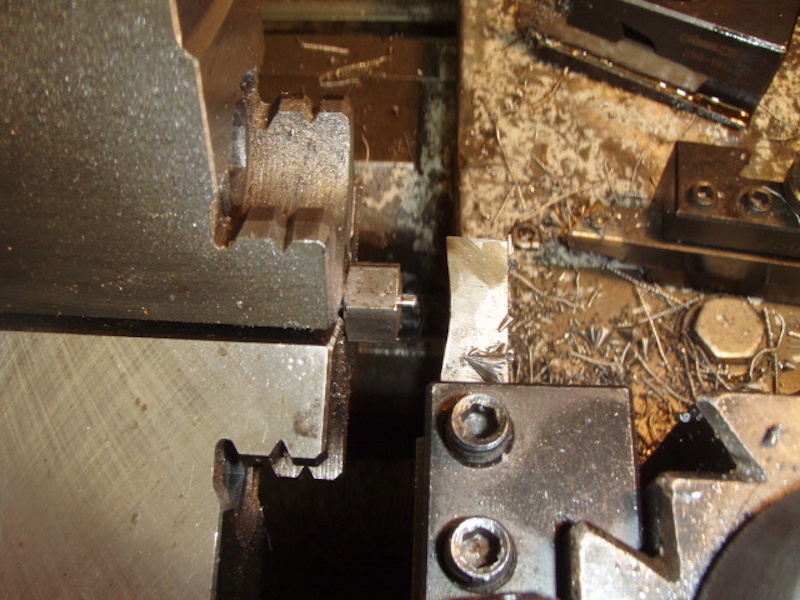

I thought I would pass along how I make my high head bolts. I get 7/16, 1/2, 9/16, 5/8 hex stock in 12L14 or 11L17 stock from Speedy Metal or Metal Express. This is much easier to cut threads on compared to 1018. It takes me about 5 minutes on smaller bolts and perhaps 8 minutes on larger and longer bolts. I use the attached bolt dimension chart since the original bolts seem to be all over the map on dimensions. Once the blanks are threaded and cut off I have a form tool which takes only 20 seconds to cut the rounded head part. One other thing which helps speed up things is to cut only 80 or 90% of the thread and finish the thread with a button die that way you know the thread is to a "modern" dimension and will fit holes which have been cleaned up with a modern tap.

Dick

|

jim_parrott

Senior Member

Username: jim_parrott

Post Number: 151

Registered: 06-2009

| | Posted on Wednesday, September 20, 2017 - 09:34 am: |

|

Dick,

Thanks for the information, I will have to give it a try.

Jim |

dick_briggs

Member

Username: dick_briggs

Post Number: 22

Registered: 02-2015

| | Posted on Wednesday, September 20, 2017 - 06:10 pm: |

|

Thank you;I like the tooling for the crowns. Is the radius of the curvature of the crown the same for all different sizes of bolts?

Best regards, Dick |

raa

Senior Member

Username: raa

Post Number: 171

Registered: 02-2007

| | Posted on Wednesday, September 20, 2017 - 07:32 pm: |

|

I have not a clue. The original bolts were probably made on what we would call a screw machine today where the threads were cut not rolled, the head profile were probably made at the whim of the operator judging by what I have seen just like the way I do my bolts!. I use the same plunge cutter for all sizes adjusting position by eye ball. The engines we mess with were made before SAE came along to standardize things a bit. |

billschaller

Senior Member

Username: billschaller

Post Number: 692

Registered: 12-2003

| | Posted on Saturday, September 23, 2017 - 05:02 am: |

|

I replaced a bunch of nuts and bolts on a Lacrosse farm engine from about 1910, and I figured the nuts and bolts were made either by a drunk, or a 7 year old. Every one was different, the outside sizes, the crown, thickness, etc. No quality control at all. I had fun making every one a little different. |

|

|

|

|