|

| P60 Water in Oil & Stuck Valve - Bad ... |

| Author |

Message |

Sam Kronick

New member

Username: kronick

Post Number: 1

Registered: 06-2016

| | Posted on Tuesday, June 21, 2016 - 03:17 pm: |

|

Hi all,

I've been fighting with the Palmer P60 in my new-to-me Islander 30 sailboat for the past few months. Trying to nail down exactly what is the ailment and what are just the symptoms... I figured out that most of the poor running and hard starting I've had is indicated by a stuck exhaust valve in cylinder #4 (furthest from the flywheel). I was also getting water in the oil and figured this was a result of 1) overcranking when I tried to start it with bad/old/watery gas last Fall and/or 2) the stuck valve causing that cylinder not to fire, allowing for low enough exhaust pressure for water to back up or something... again, not sure which happened first, because in hindsight the hard starting and overcranking could have been because the valve was already stuck (and I didn't know to turn off the raw water intake until it started back then). If I unstuck the valve with some PB Blaster and tapping it down through the spark plug hole, I could get the engine to run great for a while, so everything else seems to be in good shape. But the valve would always wind up sticking again, sometimes even after sitting for just a few hours while I was out sailing.

So a couple of weeks ago, I replaced all the valves and valve springs, cleaned out the oil a few times until it was clear, and put everything back together. The engine ran fine again at first and there was no sign of water in the oil when I tested running for maybe 15 minutes, but a week or so later, the exhaust valve was stuck again and I had water in the oil! I had made sure to start and stop the engine with the raw water intake turned off every time, so I know the problem wasn't over-cranking this time. It runs well enough to get me out of the marina on 3 cylinders, and after running it for a bit, I pull the spark plug on #4 and it's wet, so it seems like water is getting in to the cylinders somewhere while running, or immediately after I shut off the engine. So my current theory is that the stuck valve was just a symptom of a larger problem with water in the engine.

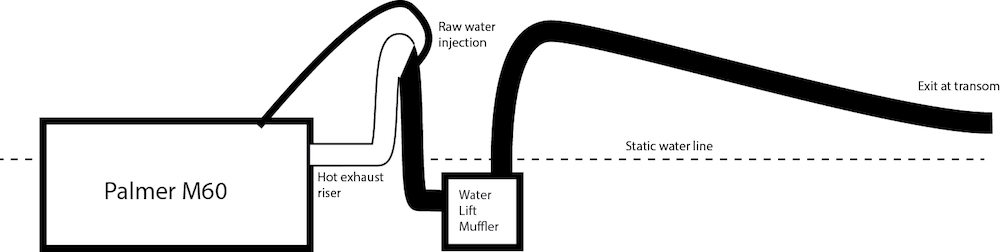

The previous owner replaced the wet exhaust system because it was old and rusted out and then didn't use the boat for years, so there's a possibility he designed it incorrectly and never noticed, though it looks mostly OK given everything I've read (I've attached a diagram of how it's set up). The raw water injection point does seem a little bit close to the top of the exhaust riser (maybe 2"), but that's the only obvious possible problem area to me. The water lift muffler might be another source of an issue but I don't know what exactly (it looks used, not new).

Now I'm considering that the exhaust manifold might be the issue-- it's the original, and if the rest of the exhaust system was rusted out, I guess this could be on its way out, too. Since it was hard to find in the past, I can understand why the PO kept it in. Thankfully David Grosse has new castings available now but at $400 I'd like to be more sure that this is the problem before I take the plunge. Does this make sense as the culprit even though the engine runs great when the valves aren't stuck? How can I test it for sure? If it will fix my troubles, $400 seems like a bargain as I'm about to give up on this engine all together!

Thanks in advance for any thoughts/advice!

Sam |

Eddie Ross

Senior Member

Username: eddie

Post Number: 340

Registered: 04-2003

| | Posted on Wednesday, June 22, 2016 - 07:54 am: |

|

It could be a blown head gasket or crack in the cylinder head or crack in the engine block. Are operating in salt water ? Did the PO ever replace the head gasket ? |

David Grosse

Senior Member

Username: davidg

Post Number: 51

Registered: 11-2010

| | Posted on Thursday, June 23, 2016 - 02:41 pm: |

|

Hi Sam,

Eddie offers some good possibilities.

It concerns me that you are getting enough water to make the plug and valve wet, and foul the oil so quickly without finding the culprit. I suggest cranking the engine with the plugs out and watch what comes out of the sparkplug holes. I still remember the first compression check that I did where water squirted out of the #3 and #4 holes on an atomic 4 engine when it was cranked. In that case it was a hole in the cylinder head that let water into the cylinders.

It seems that you must be passing water through the cylinder and out both the exhaust and down past the piston (to get to the oil). Are you getting any backed out through the carburetor? That is the natural destination for water backed in from the exhaust. It runs down hill and ruins your carburetor.

Walking through your post a few times, and the possibilities, it seems most likely to me that your trouble starts in the combustion chamber in order to get both the sparkplug and the valve wet, but that it would also be prudent to re-design the exhaust to get the cooling water injection at least 4" below the high point in the exhaust riser piping.

Don't give up -- the Palmer 60 is a great engine. Give me a call again if I can help.

David Grosse |

Sam Kronick

New member

Username: kronick

Post Number: 2

Registered: 06-2016

| | Posted on Thursday, June 23, 2016 - 07:47 pm: |

|

Hi David and Eddie,

Thanks for the thoughts. I do have to admit one more thing: I re-used the head gasket because it looked OK and I didn't have a spare (yes, operating in salt water). I know that's a bad idea so I tracked down 2 new copper gaskets from http://www.gasketstogo.com/Palmer.htm but I am still waiting for them to arrive. I will put a new gasket in when it gets here.

Is it possible I've had two distinct problems?

1) when I first bought the boat, old bad gas -> hard to start -> overcranking -> water backed up into engine -> a stuck valve -> hard to start -> more overcranking -> more water in engine.

2) after I replaced the valves but resused head gasket -> blown/leaky head gasket -> water in cylinders

or is a single point of failure more likely... like a hole or crack in the head/block? How would I go about checking for that, or a leak in the exhaust manifold? Do I just inspect things visually when the head is off?

At $60 and a couple weeks of waiting for a new head gasket, I don't want to pull the head again more than once... but it would be great if simply replacing the gasket solved the current issues!

For what its worth, I haven't seen water backing up out of the carb, and thinking about it, that would make a badly designed exhaust system seem less likely the culprit. The water injection point is pretty high up, but it is angled downwards, and the injection tube looks like it might be the kind that extends further inside the exhaust pipe but I can't be sure. It's not just a t-fitting like I've seen in some images.

Thanks for the encouraging words-- I don't want to give up! When the engine has run well, it's very satisfying, responsive, seems well-sized for this boat. Also just feels good to keep an engine older than me alive for a few more years at least :-)

Sam |

David Grosse

Senior Member

Username: davidg

Post Number: 52

Registered: 11-2010

| | Posted on Thursday, June 30, 2016 - 02:32 pm: |

|

Hi Sam,

I mentioned this in my prior, but, while you are waiting for gaskets to come on a boat from Thailand, you could pull all the spark plugs and spin the engine a few times. Watch the spark plug holes while it is cranking. If you don't see water squirting out any of the holes, your problem is not in the cylinders or gasket area. If you do see water squirting out, make note of which cylinder so you can find the problem when you pull the head.

As a temporary, you could also use a fresh water gasket to help you find the leak, and then replace it with a copper one when it arrives and the leak has been remedied.

Backing up a thought, when you replaced the valves, did you clean out the guides, and oil the valve stem before installing it?

David |

Sam Kronick

New member

Username: kronick

Post Number: 3

Registered: 06-2016

| | Posted on Friday, July 01, 2016 - 02:52 pm: |

|

Hi David,

Thanks, I will try that today or tomorrow. By "spin the engine" do you mean crank it with the starter or just turn the flywheel by hand?

The copper gaskets arrived this morning and they look good-- have you considered stocking them on your site from this manufacturer? I would gladly pay a little extra to not have to wait so long if I ever need another one.

And yes, when I replaced the valves I used a nylon brush to clean out the guides and some engine assembly oil to put it all back together. Even though getting the #4 exhaust valve out required a lot of pulling and gentle prying, after I cleaned and oiled the stem, it slid up and down without resistance (I replaced it with a new one of course but it was interesting to see how it was seized from salt water but not rusted in place or seriously damaged).

Sam |

David Grosse

Senior Member

Username: davidg

Post Number: 53

Registered: 11-2010

| | Posted on Friday, July 01, 2016 - 07:20 pm: |

|

Sam,

Sorry, I meant that you should crank it with the engine's starter, not turn it by hand.

I tried to order a batch of gaskets from that supplier, but he cancelled after 3 weeks of waiting. I am now working with other suppliers to have gaskets as well as a few other problem parts readily available for the Palmer 60's.

Good luck with your search for the problem, and Happy Independence Day Holiday Weekend.

David |

Sam Kronick

Member

Username: kronick

Post Number: 4

Registered: 06-2016

| | Posted on Thursday, July 07, 2016 - 10:02 pm: |

|

Hey all,

Here's the update: No water spitting out of the spark plugs when cranking the engine to start. Pulled the head and unstuck the valves, replaced the head gasket with a freshwater one temporarily, put it all back together, rigged up a compression leakdown tester and each cylinder holds 100psi at TDC. I even pulled the small water hose that goes from the head to the thermostat and didn't see any bubbles/water coming out at 100psi, so I think that means the head and head gasket are not the problem (I wish I had done the leakdown test with the old head gasket just to see). Changed the oil 3 times and things were running good at the dock and it idles smoothly and evenly. I can tell the difference between all 4 cylinders firing or not by ear pretty well now.

Then I took it out for a spin in the marina and the power was surging up and down, oscillating between what seems like full power and maybe 1/2 strength. I could only get up to about 3.6-4kts on the GPS (I've seen steady 5.6-6kts when everything is running great). Still, it's good enough to get out of the marina, so I've done this a couple times and gone out sailing, haven't had any problems starting or with the engine dying. This could be a totally unrelated problem, but I figured it's worth mentioning.

Two more things: 1) the valves that have given me problems in the past (exhaust on cylinder 1 and 4) have both been sticking again after the engine sits for a few days. I can easily tap them down through the spark plug hole but I'm getting too good at that-- I've done it hundreds of times now! and 2) I think I'm still getting water in the oil somehow, but if so it's slow and inconsistent. It could be that I'm just washing out the old sludge slowly, as the rise in oil level has been minimal but noticeable (and didn't change at all after I went out and motored for maybe 20min today). I get a thin light grey on the dipstick; maybe if I clean that out a few more times I'll have better luck with sticking valves? Maybe intermittent sticking valves at high speeds are causing the oscillations in power? Just feel like I'm chasing a ghost in this machine from one symptom to the next!

Any thoughts?

Sam |

Eddie Ross

Senior Member

Username: eddie

Post Number: 342

Registered: 04-2003

| | Posted on Friday, July 08, 2016 - 01:34 pm: |

|

Order gaskets for the exuaust manifold so that you can pull it and check for leaks. Gaskets are for International Harvester LoBoy tractor with the C60 engine NOT the Cub Cadet model. Can be gotten through Napa Auto Parts among others but there will NOT be a cross reference for Palmer and you will have to refer to the International Harvester C60 engine. |

Sam Kronick

Member

Username: kronick

Post Number: 5

Registered: 06-2016

| | Posted on Wednesday, July 27, 2016 - 02:35 pm: |

|

Thanks for the tip, Eddie. I pulled the manifold and the good news is that I don't think the leak is there-- I put the city pressure hose from the dock up to the water outlet, plugged the other water holes with my fingers, and didn't see a drop of water inside the manifold. The bad news is I'm still not 100% sure where the problem is...!

I did some more digging online and found this thread with pictures from an Islander 30 with a Palmer: http://forums.sailboatowners.com/index.php?threads/muffler-for-palmer-60-on-isla nder-30.140385/ This image looks exactly like how my engine could have been set up before the PO re-did the exhaust: http://forums.sailboatowners.com/index.php?attachments/2012-03-20-17-06-58-jpg.5 1154/ There is even a matching shadow of the bolt pattern for that muffler on the bulkhead on my boat. It looks like it was originally set up with a standpipe muffler, not a water lift, and had the dry exhaust rise ~20" in the port cockpit locker rather than under the cockpit sole where there is only about 8" of space to rise. The only weird thing is that with the exhaust manifold on the starboard side, the dry section of the exhaust runs horizontally about 20" under the cockpit sole. Fortunately there seems to be plenty of room under there for the pipe and good clearance, but does this seem reasonable and safe to you all?

So this brings me back to my suspicion that the problem was caused by the PO's good-intentioned but poorly engineered re-design of the exhaust when the old standpipe rusted out.

I have put together a new black iron pipe with fiberglass lagging and have it rising up 22" in the port cockpit locker, then doing a u-turn down to the water injection point 8" lower. Since the water enters so high up, I currently have it draining straight out the transom without the water lift muffler in the circuit. Is there any problem with this design? I can imagine water flowing forward as I pitch down a big wave, but it would have to be a pretty steep drop and with the engine running, and if the engine is running my guess is this water would turn to steam pretty quickly somewhere along the 40+" of exhaust before it hits the engine. |

David Grosse

Senior Member

Username: davidg

Post Number: 55

Registered: 11-2010

| | Posted on Friday, July 29, 2016 - 10:29 am: |

|

Hi Sam,

I am happy to hear that you are making progress with problems / solutions.

Regarding sticking valves, tamping them down doesn't cure their want to stick again. You may wish to pull those two valves (or all of them) and polish them down with very fine sand paper. Otherwise the stems will just get stuck again.

Good luck,

David |

Sam Kronick

Member

Username: kronick

Post Number: 6

Registered: 06-2016

| | Posted on Friday, July 29, 2016 - 01:56 pm: |

|

Hi David,

Yep, the valves were stuck so bad this time that no amount of tapping them down would get them to move freely. I discovered this after putting the manifold and exhaust back together, but fortunately there was enough room to remove the valve cover and get my spring compressor in there just by taking off the carburetor.

I think the corrosion is on the valve guides, not stems, because when I pulled the valves they looked fine, but they didn't move smoothly until I ran a brush through the guide. And getting them out was not easy-- they required a lot of twisting and pulling with a vicegrips. I'm still afraid there is enough loose rust/crud in the engine that they will gum up again, but hopefully keeping water from coming back in the manifold will be the ticket.

Everything is back together and running fine on all cylinders again at the moment, hopefully I'll be able to get out on the water this weekend and really test it out! Sure sounds like a tractor without a muffler in the circuit though...

Sam |

David Grosse

Senior Member

Username: davidg

Post Number: 56

Registered: 11-2010

| | Posted on Wednesday, August 03, 2016 - 07:09 pm: |

|

Hi Sam,

Good news!

What kind of spring compressor did you use? I am guessing that you had the head, manifold, and carb all off to do the job. If not, please send me a pic of the tool.

Since you brushed the guides and the valves were good, you should be ok for some time as long as you regularly change oil. If you need some more help, you can put in 8 oz of Marvel Mystery oil with an oil change, reducing the amount of regular oil by that much. Marvel is good for lubricating valves where they do not get a dedicated flow of oil from the pump.

Glad you can go sailing again.

David |

Sam Kronick

Member

Username: kronick

Post Number: 7

Registered: 06-2016

| | Posted on Wednesday, August 17, 2016 - 01:20 am: |

|

Hey David,

This is the spring compressor tool I used: http://www.sears.com/craftsman-valve-spring-compressor/p-00947627000P?plpSellerI d=Sears&prdNo=1&blockNo=1&blockType=G1 I bought it in store at a local Sears. The build quality seems good. It has enough reach that I did not need to remove the manifold to use it-- just the carb and the head, but if I hadn't already done all the valves with the manifold off a few months ago, I would have been totally confused as it's very hard to see what's going on with the manifold in the way. I could do most of the job by touch this time with a little help from a mirror-on-a-stick like this one: https://www.amazon.com/TEKTON-7609-Telescoping-Lighted-Inspection/dp/B0062PBMUY/ ref=sr_1_3?ie=UTF8&qid=1471408656&sr=8-3 But on this Islander 30 Mark II it came down to 1/4" clearance to fit the tool in, so I don't know if it will work on other boats.

Thanks for the tips on MMO. I will definitely make this part of the maintenance routine.

The engine starts up and runs great now, even after sitting for a week without running. So I don't think I'm getting water inside anymore! Give me another month of good fortune and I'll write this one off to the PO's well-intentioned but poorly-designed exhaust setup. He owned the boat for 6 years and never sailed it (I don't get it either!), so he may have had the engine running reliably while level at the dock, ready to destroy itself as soon as I took it out in the wind and waves. I'll post pics of the new exhaust setup when I have a chance.

I did notice some drops of water leaking around the outside of the head, which has caused some rust on the outside of the block (which needs a new coat of paint desperately). I will try to re-torque the head bolts, but maybe this head is just warped now after running it for some time with a cylinder or two not firing. If re-torquing doesn't fix it, I have access to a machine shop and mill for the next few months and might try to re-machine the head, or just buy a new one.

Sam |

Sam Kronick

Member

Username: kronick

Post Number: 8

Registered: 06-2016

| | Posted on Thursday, December 08, 2016 - 02:13 am: |

|

Hi All,

I'm back to having problems with stuck valves on this engine after it's sat for a while. Now it's happening on cylinder #4 (where it was before) and #2 (which is new). It still runs and I can un-stick valve #2 relatively easily, but the problem returns. I changed the oil 2 or 3 times, and while I wouldn't say it looks completely clear, the level is steady and I don't think I'm getting any more water in the oil. It could be residual moisture (from the bad exhaust design) in the valve guides/stems causing issues, or it could be a crack in the block, but I really don't know. I am at a loss for what to do next.

My options as I see them:

1) The engine is as good as dead. Tack on an outboard to keep sailing in the short term. Pull the engine from the boat and replace it with a new diesel or a rebuilt P60 in the long term. I admit defeat on understanding the engine, but get to keep enjoying the boat. An expensive, but final answer.

2) The engine just needs a deep cleaning to get out all the water and re-build. Pull the engine from the boat, look over everything carefully in my shop, and re-install. What if I don't find an obvious problem? How much time will this take? What do I need to/should replace? An inexpensive, but labor-intensive and potentially unsatisfying answer.

3) Pay someone else to figure out any or all of this. The least labor-intensive answer on my part, but potentially the most expensive and mysterious. No satisfaction of understanding what's going on or troubleshooting future issues.

In any case, it looks like I should take the engine out of the boat. Because there is no obvious single problem, I don't think I'm willing to keep trying fixes with the engine in. I measured and think I can get it out if the head and manifold are off. How much does this engine weigh?

I have a week off of work from Christmas to New Years and be getting the standing rigging replaced around that time, so in an ideal world I would figure out a fix I can do during that time frame.

Any advice is welcome!

Sam |

David Grosse

Senior Member

Username: davidg

Post Number: 73

Registered: 11-2010

| | Posted on Thursday, December 08, 2016 - 01:19 pm: |

|

Hi Sam,

I have read your post a couple times, and the ones before it. It seems like you don't have a water in the oil problem anymore, just sticky valves. So maybe the possibility of a crack in the block, or the bad exhaust design can both be discarded.

It may be that it is sticky lifters, not valves. They can best be cured by removing the engine, and doing a tear down. I have encountered two engines (Atomic 4's) lately where it was the lifters, not the valves that were sticking.

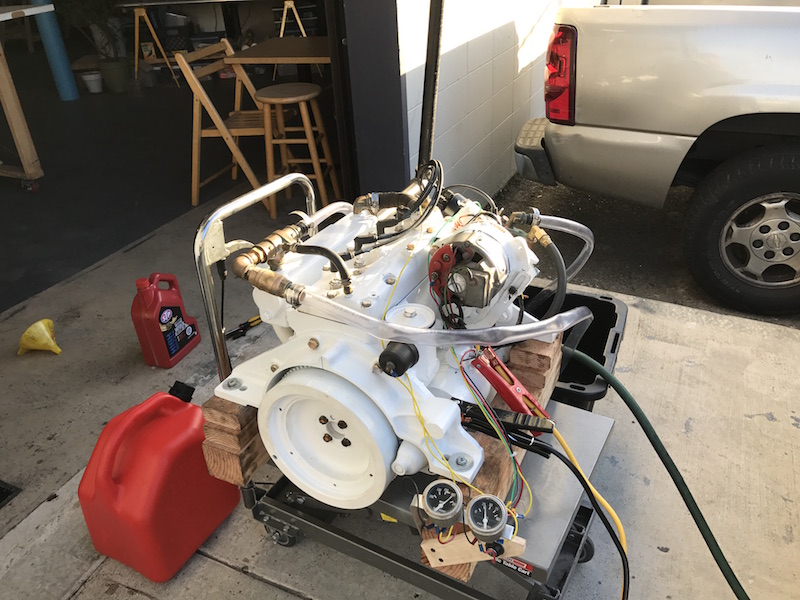

Regardless, I urge you not to delay. Whatever is bad now, will only be worse if left unattended. And from your picture, it looks like it is time for a good cleaning and repaint.

Maybe you could have it pulled when you have the rigging done.

Good luck, and let me know if I can help.

David Grosse

David's Yacht Service |

Sam Kronick

Member

Username: kronick

Post Number: 9

Registered: 06-2016

| | Posted on Saturday, December 10, 2016 - 02:47 pm: |

|

Hi David,

Thanks for taking the time to read into this. I am leaning towards pulling the engine and doing a tear down/rebuild. That way I can see how bad the damage is-- it's been almost a year since I first had water in the oil, but I have thoroughly changed it several times so it hasn't been sitting full of water for that whole time. Hopefully it's not too late.

I'm pretty sure it is the valves, not the lifters, because that's what I could see the couple times I've had the valve cover off. I have new replacement valve guides I got with my valve job kit a few months ago, but didn't put them in at the time because it seemed impossible with the engine in the boat.

Also considering the possibility I have stuck rings on the pistons just because there was moisture in the cylinders. I know to check the head and block for flatness. What would indicated that I should I be thinking about having cylinders or bushings re-bored? What other damage should I look for?

How deep of a rebuild should I prepare for? I see kits like: https://www.tractorjoe.com/parts/p/ik600-in-frame-engine-overhaul-kit-1/mt/tract or/b/international-harvester/m/cub-lo-boy/?c=108&sc=1767 or https://www.tractorjoe.com/parts/p/ok600-major-engine-overhaul-kit-1/mt/tractor/ b/international-harvester/m/cub-lo-boy/?c=108&sc=1767 and don't know which to get.

And yes, cleaning and painting the engine is definitely on my list. That alone will make this whole process worth it!

Thanks,

Sam |

David Grosse

Senior Member

Username: davidg

Post Number: 75

Registered: 11-2010

| | Posted on Sunday, December 11, 2016 - 01:50 pm: |

|

Hi Sam,

My preference is to not rebore, but just hone the cylinders unless you really have to. You won't know what to buy until you open up the engine and see what you have, other than a complete gasket set.

If you rebore, you need new pistons. You should probably plan on having the crank reground, and get larger main bearings. You will need rings for whatever size pistons you end up with, and probably a few bearings.

Let me know how it goes, and if you need anything special.

David Grosse

David's Yacht Service

SoCal |

Sam Kronick

Member

Username: kronick

Post Number: 11

Registered: 06-2016

| | Posted on Friday, December 16, 2016 - 03:30 am: |

|

The engine is out! I spent about 3 hours a couple nights ago disconnecting everything (including removing the head, manifold, and alternator), then about 4 hours last night to set up the hoist, get it onto the dock, onto a hydraulic cart, and into the back of my car. It's now safely in my shop where it awaits the rebuilding work.

I did this without another set of hands, but it wasn't too bad. One thing that really helped due to the way the engine sits was getting a hydraulic floor jack underneath the port side of the shaft of the shifter on the transmission (see picture). This way I could keep the engine more level as I started lifting it from the front, before I could re-position the lifting strap to be more balanced. Also, building stringers out of 4x4's and 2x4's to mount the engine onto once it was out of the boat made it really easy to slide between the hydraulic cart and the back of my car.

Here are some pictures of the process:

Thanks for the encouragement to go for this!

I pulled off the valve cover just to get a good look inside. The valves, springs, and upper part of the lifters are showing plenty of rust. But peeking down into the camshaft and the lower end of the lifters, things look pretty clean. So my next question is this: if I've only been having trouble with sticking valves and when I could get those running freely everything else with the engine seemed great, is tearing into the bottom end necessary here? If I don't do it, what might I regret down the line? I believe the engine only has 150 hours on it right now, so besides salt water damage I don't think anything is likely to be worn out. I am worried about sticking piston rings because of the water in the top end-- is there a way to check that without pulling the pistons out? I can check piston clearance with a feeler gauge from the top, right? I'm not afraid of tearing into the bottom end, but I'm not 100% sure what I'd be looking for.

Here's a picture under the valve cover:

Thanks,

Sam |

Sam Kronick

Member

Username: kronick

Post Number: 12

Registered: 06-2016

| | Posted on Friday, April 21, 2017 - 03:11 am: |

|

It's been a while, but I wanted to say that I completed the re-build (and re-painting) of this engine earlier this winter. Photos of the process are up here: https://www.flickr.com/photos/kronick/albums/72157679586805264

Wish I had posted sooner, but I've been too busy out sailing :-) (ok, and dealing with a million other tiny projects on the boat)

Here's what I did:

- Cleaned out all emulsified oil

- New piston rings

- Flushed water passages with vinegar

- New gasket set including copper head gasket from GasketsToGo.com

- Rebuilt Zenith Z61 carburetor

- Pertronix electronic ignition conversion (no more points)

- Stripped old rusty paint and re-painted white

- Cleaned engine compartment and re-painted with gray bilge paint

- Cleaned up wiring

- Re-routed exhaust to port cockpit locker to get enough height (>20" when not heeled) before raw water injection (to address original cause of failure and sticking valves)

I would estimate the total time was somewhere around 40-60 hours. Can't put a $$$ value on that but I now literally know this engine inside and out.

It runs and looks better than ever! Thanks everyone for the help in getting this boat back in action.

|

Ernie

Senior Member

Username: ernie

Post Number: 2378

Registered: 01-2002

| | Posted on Friday, April 21, 2017 - 11:27 am: |

|

Looks great! |

David V.

Member

Username: cdsailor

Post Number: 14

Registered: 09-2016

| | Posted on Friday, April 21, 2017 - 12:07 pm: |

|

Looks good. Congrats. Which Pertronix ignition kit did you install - part #?

Thanks,

David |

Ned Lloyd

Senior Member

Username: ned_l

Post Number: 125

Registered: 08-2012

| | Posted on Friday, April 21, 2017 - 11:08 pm: |

|

Good to hear. Nice little engine. |

David Grosse

Senior Member

Username: davidg

Post Number: 88

Registered: 11-2010

| | Posted on Tuesday, May 09, 2017 - 03:55 pm: |

|

Sam,

Congratulations, and great work. I am glad that you took the time to do it right, including the painting and installation. Hope she serves you well for lots of good sailing.

David Grosse |

Sam Kronick

Member

Username: kronick

Post Number: 13

Registered: 06-2016

| | Posted on Thursday, May 18, 2017 - 03:06 am: |

|

David V- the part number I have down is "#1548 IGNITOR PRESTOLITE 4 CYL - IAY 4401" from pertronix.com. I think the distributor changed over the years but mine is a Prestolite IAY 4401.

Thanks for the kind words everyone. The engine is still running strong, starts great, and purrs along. Makes sailing so much more fun knowing I can depend on the engine when I need to! |

David V.

Member

Username: cdsailor

Post Number: 15

Registered: 09-2016

| | Posted on Saturday, June 24, 2017 - 09:47 am: |

|

Sam,

Thanks! That's the one I ordered and installed.

I'd love to see a picture of your exhaust riser setup. Do you have one? I've made my own riser and converted to a water lift muffler system. I haven't trialed it yet, so I'm hopeful it's ok: https://1.bp.blogspot.com/-1k0dXpNYkKM/WUw-2ZBUPFI/AAAAAAAAF-w/TMoUM8Ecxwo5ojbD9 _MagjW95apuUGppwCLcBGAs/s1600/IMG_6598.JPG

David |

Bob Ashforth

New member

Username: aenlic

Post Number: 1

Registered: 10-2017

| | Posted on Tuesday, October 17, 2017 - 04:00 pm: |

|

I'm new to the Palmer 60, which is in the Islander 30 I just purchased. Since I believe the issue mine is having is sticky/stuck valves, I thought it preferable to tag along on this thread instead of starting a new one.

The info posted already is awesome and much appreciated.

My situation is this: The engine was running fine two years ago before the PO was absent for two years. When it didn't run as she prepared to sell the boat, her brother replaced a number of parts, including all ignition components and a new carburetor. Per his information spark is not confirmed... though he didn't know if the ignition is off by 180 degrees, as he didn't check that the TDC was set on the compression stroke.

Apart from confirming/correcting that, advice I've found online is that the valves may in fact be the culprit WRT not starting, and that MMO (Marvel Mystery Oil) could fix that. If it's the case, the most likely scenario would be that the last person to start the engine let water into the enginer, perhaps opening the through-hull for water inlet too soon.

My intent is currently to (a) add MMO 'ultimate' to the fuel tank in the recommended proportion and (b) to add a couple of ounces of MMO to each cylinder through the spark plug hole.

I am open to being told just how far off the mark my intent is... all info from the hive mind appreciated!

Thanks-

aenlic |

David Grosse

Senior Member

Username: davidg

Post Number: 96

Registered: 11-2010

| | Posted on Wednesday, October 18, 2017 - 01:43 am: |

|

Bob,

A good start is to check compression, since valves tend to get stuck when the engine is not run.

After that, fuel can go bad sitting around for a few years, and you can check that or bypass it with a new tank tapped into the carburetor.

If you have compression and spark, and you are anywhere near the right timing, you should be able to hear it try to run.

Feel free to call me if you want to discuss or kick things around.

David Grosse

David's Yacht Service

949-933-9613

SoCal, USA |

|

|

|

|