| Author |

Message |

jim_parrott

Senior Member

Username: jim_parrott

Post Number: 124

Registered: 06-2009

| | Posted on Saturday, January 21, 2017 - 11:40 am: |

|

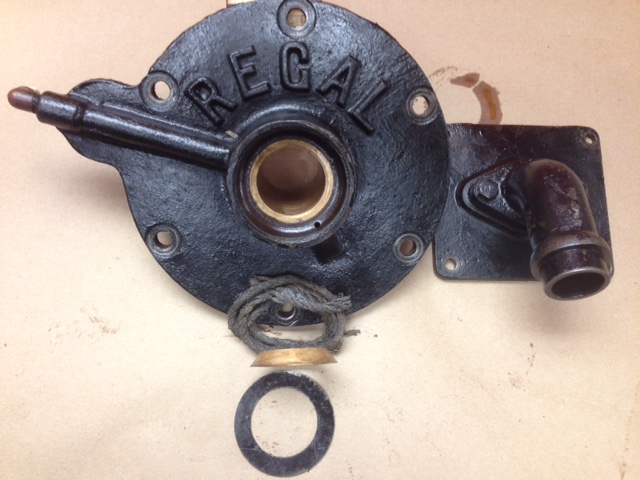

My 2HP Regal leaks oil from the front of the crankshaft. Upon disassembly this was the sealing arrangement. It has a rope packing between the main bearing and a coned spacer held in by a large washer that just snaps in place. Before I adapt to a modern seal, does this look correct for this engine? I also would like a couple pics of the filler cap/breather for this standpipe if available. Any help or suggestions would be appreciated.

Jim |

johnoxley

Senior Member

Username: johnoxley

Post Number: 172

Registered: 04-2010

| | Posted on Saturday, January 21, 2017 - 03:03 pm: |

|

Also need to look at condition of crankshaft stub - Suspect will be corroded/worn, so lip seal will have short life. I usually fit Speedi sleeve stainless shaft sleeve so lip seal has better surface. Have also hard chromed similar problem shafts and this is another option. Expect will need to machine out front cover to take seal, which is a non-reversible action. |

jim_parrott

Senior Member

Username: jim_parrott

Post Number: 125

Registered: 06-2009

| | Posted on Saturday, January 21, 2017 - 03:56 pm: |

|

Andrew,

My shaft is in good shape, and if I put a seal, it will be in an adaptor bushing so I don't have to machine the front cover. Hoping to verify if this method of sealing the crankshaft is original, and if so would like to make it work.

I think a check valve breather cap will help, and maybe turn down the oil pump flow a little.

I saw another Regal Y with a check breather cap, but it had a different filler pipe.

Thanks for your input.

Jim |

jim_parrott

Senior Member

Username: jim_parrott

Post Number: 126

Registered: 06-2009

| | Posted on Saturday, January 21, 2017 - 04:39 pm: |

|

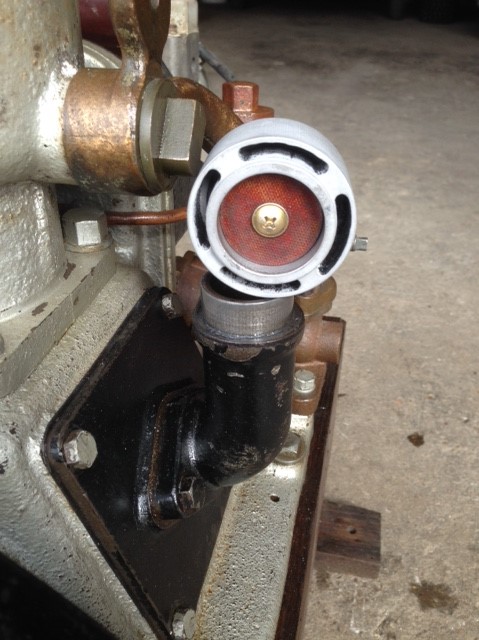

I found a picture of the cap and it should be easy enough to duplicate.  |

robert

Senior Member

Username: robert

Post Number: 828

Registered: 07-2003

| | Posted on Sunday, January 22, 2017 - 03:59 pm: |

|

That does not look like proper graphite packing, which is still available from some marine suppliers.

https://www.google.ca/search?q=graphite+packing&source=lnms&tbm=isch&sa=X&ved=0a hUKEwiT47OU0tbRAhUri1QKHabtB-cQ_AUICCgB&biw=1024&bih=653 |

jim_parrott

Senior Member

Username: jim_parrott

Post Number: 127

Registered: 06-2009

| | Posted on Monday, January 23, 2017 - 03:14 pm: |

|

Robert,

It looks like the packing will also seal the drain passage at the 5 o clock position with this stack up. Is the drain just for the oil wicked from the packing? I may try a new packing, along with a breather cap and see what happens.

Thanks,

Jim |

jim_parrott

Senior Member

Username: jim_parrott

Post Number: 136

Registered: 06-2009

| | Posted on Wednesday, April 05, 2017 - 09:17 am: |

|

I installed an off the shelf lip seal from my local bearing supply. No machining was required. Fabricated a breather cap and the leak is fixed.

|

robert

Senior Member

Username: robert

Post Number: 859

Registered: 07-2003

| | Posted on Friday, April 07, 2017 - 11:47 am: |

|

I have no experience of these engines, but looking at your first photo again just now, I did wonder if the tapered-shoulder "washer" was perhaps meant to seat closely enough on the end of the main bronze bushing/bearing to make the seal without packing?

Does the angle on the "washer" match the angle on the end of the bushing? If the steel spring washer keeps the brass/bronze washer in tension then does it remain stationary or turn with the crankshaft?

If they were aiming at a seal without packing, then having the brass/bronze washer turn with the crank would make sense, since oil migrating along the main bushing would presumably lubricate it, and the drain hole you pointed out (that I missed before) would support that interpretation.

But if the brass/bronze washer did not turn with the crank, then it would need to be lubricated or it would be no more effective as a seal than the main crank bushing/bearing itself, in fact less so as it would wear more rapidly due to the lack of lubrication and perhaps stability between it and the crank.

On the other hand, there is nothing but friction to make it turn with the crank, so the whole concept is a bit illogical!

What do my elders and betters say? |

jim_parrott

Senior Member

Username: jim_parrott

Post Number: 137

Registered: 06-2009

| | Posted on Tuesday, April 11, 2017 - 07:57 am: |

|

Robert

The tapered brass washer fits loosely on the crankshaft. I'm happy with the new seal, but will retain the brass washer with the engine.

Jim |