| Author |

Message |

herbertchoover

Member

Username: herbertchoover

Post Number: 9

Registered: 04-2016

| | Posted on Thursday, May 05, 2016 - 03:46 am: |

|

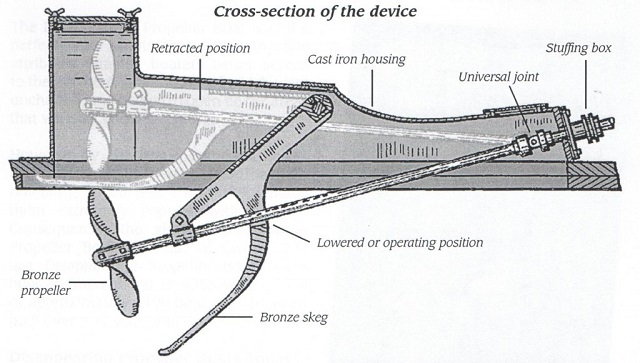

OK, I've searched and searched the interwebs and bought the Dispro book, cant find a clear picture of underneath, the mechanism for lifting the prop. I am looking for the arm which attaches at the "axle" at the fore end and the cutlass bearing at the aft end. I am trying to see how they designed it for rigidity.

So... does anyone here have pictures of a dispro device underside or better yet, taken apart? |

ernie

Senior Member

Username: ernie

Post Number: 2277

Registered: 01-2002

| | Posted on Thursday, May 05, 2016 - 12:17 pm: |

|

http://disproboats.ca/100-years-of-dispro/

http://www.boatdesign.net/forums/boat-design/critical-speeds-semi-planing-21382- 5.html

http://www.oldmarineengine.com/discus/messages/4/263403.html |

herbertchoover

Member

Username: herbertchoover

Post Number: 10

Registered: 04-2016

| | Posted on Thursday, May 05, 2016 - 01:20 pm: |

|

thx ernie, I actually found and saved a lot of pics and bought the Dispro book (great book). BUT, I have not been able to see an actual *photo* of the actual device from underneath. I need to see the articulation pivot point, and the arm itself that has the cutlass on it... I'm hoping someone here has that perhaps Miro does?

|

russell

Senior Member

Username: russell

Post Number: 91

Registered: 08-2003

| | Posted on Thursday, May 05, 2016 - 03:50 pm: |

|

Loved these boats ever since WoodenBoat did that article so long ago. I was in Arcachon on the French coast near Bordeaux last year and had a chance to examine a local boat one of a large fleet of fishing boats and pleasure boats based there.

Being a harbour with numerous sandbars, the boats had a rising propellor arrangement that may have predated Dispros,   |

herbertchoover

Member

Username: herbertchoover

Post Number: 11

Registered: 04-2016

| | Posted on Thursday, May 05, 2016 - 08:09 pm: |

|

BINGO! Found this (after das of searching, and finding many cool pics).

Dispro device maintenance workshop video, it shows the guts and has good commentary from the tech instructor as well:

https://vimeo.com/61385689 |

herbertchoover

Member

Username: herbertchoover

Post Number: 12

Registered: 04-2016

| | Posted on Thursday, May 05, 2016 - 08:35 pm: |

|

And there are more vids on the Vimeo page (Dispro Owners Association) including this one which shows an assembled "device" out of the boat being raised and lowered...

https://vimeo.com/150567324 |

bruce

Senior Member

Username: bruce

Post Number: 558

Registered: 07-2002

| | Posted on Friday, May 06, 2016 - 08:22 pm: |

|

Chris-Did you notice the reverse gear demonstration for the Dippy in the video ?? Made of Spruce... |

herbertchoover

Member

Username: herbertchoover

Post Number: 13

Registered: 04-2016

| | Posted on Friday, May 06, 2016 - 10:05 pm: |

|

Yeah bruce. I guess I'll have to make a Spruce handle for my transmission lever! ;) |

miro

Senior Member

Username: miro

Post Number: 865

Registered: 11-2001

| | Posted on Saturday, May 07, 2016 - 07:03 am: |

|

Sorry for being away so long - no Internet access -

looks like you got your info OK.

Miro |

herbertchoover

Member

Username: herbertchoover

Post Number: 14

Registered: 04-2016

| | Posted on Saturday, May 07, 2016 - 12:05 pm: |

|

Hi Miro, thanks. Actually I would still like to have some actual pics and measurements of the device and especially the through-bolt, and double especially how they seal that through-bolt. Do you own a Dispro?

Chris |

david_doyle

Senior Member

Username: david_doyle

Post Number: 60

Registered: 03-2013

| | Posted on Saturday, May 07, 2016 - 12:25 pm: |

|

I just skimmed the links you posted but I think in the video he said graphite packing available from electrical supplier.

He also mentioned that there are 9 'device' versions all different.

Maybe get some heavy cardboard and dowel and start building with that to see how things fit together. Not many successes in the boat building world with out modeling.

What are you going to do for the 'box'/housing? |

herbertchoover

Member

Username: herbertchoover

Post Number: 15

Registered: 04-2016

| | Posted on Saturday, May 07, 2016 - 12:44 pm: |

|

Thanks Dave, I plan to make the husing from styrofoam, cover that in release plastic, and glass over it (heavy, and especially heavy at pivot area), remove the foam.

Great idea on the cardboard in fact I have some 1/4 plywood and jig saw for that. MIGHT make the leg out of mild steel 1/4 plate and then find someone who can replicate in stainless.

Looking for a local home machinist with a bridgeport and lathe, if I can find one, can make the pin-and-block u-joint and center pivot pin. |

david_doyle

Senior Member

Username: david_doyle

Post Number: 61

Registered: 03-2013

| | Posted on Saturday, May 07, 2016 - 01:48 pm: |

|

Good idea on the foam.

The amount of machining required for this job would make it smarter to shop for a cheap lathe then for a cheap machinist. A 9 or even a 7x Chinese lathe will do 90% of it and the rest is a strong arm, hacksaw and file job. If you like playing with this stuff you will never ever, ever regret finding a small lathe. key ways- threading- bushings- tapers- a hobbyist cannot afford to pay someone to do this work nor is it fair to ask someone to work for free on your luxury toy.

Add up the operations required and you will see that even at 30 dollars an hour with no charge for tooling you are looking at a bill that will make this project painful. For less money you can learn a trade, end up with what you want etc.

I am watching with interest as I fell in love with this concept in NFLD 30 years ago and it is on my bucket list of builds. Mine will be a de tuned modern twin cylinder though and not as cool as a palmer. |

bruce

Senior Member

Username: bruce

Post Number: 559

Registered: 07-2002

| | Posted on Sunday, May 08, 2016 - 12:41 am: |

|

I think trading that Palmer YT in for a Caille Liberty single or twin puts all that machinery at the back for more leg room and no need to cut a hole in a perfectly good boat- just sayin... |

david_doyle

Senior Member

Username: david_doyle

Post Number: 62

Registered: 03-2013

| | Posted on Sunday, May 08, 2016 - 02:23 am: |

|

LOL, No a Rudder twin with stern to bow steering ropes is the right engine-that way he could steer from any position and move about the boat to adjust trim. |

herbertchoover

Member

Username: herbertchoover

Post Number: 16

Registered: 04-2016

| | Posted on Sunday, May 08, 2016 - 03:20 am: |

|

an outboard is ruled out. inboard would be cool, but a disappearing propeller even more cool. the housing is easy. the u-joint can be store bought and the lever arm, while maybe tricky, is not rocket science. I like the idea of easy trailering, shallow water usage, and safe beaching. a number of friends have said what a cool engine the YT is. the boat, while a touch small, does look the part. I'd like to get this working solidly, and change the blue to a more "antique" color as Ernie did with his. The only real question is will this be finished this year, or next!

The original post asked for pictures of an actual Dispro "device" and I'm still looking for good pics of the actuator arm, and the pivot bolt and seals. |

david_doyle

Senior Member

Username: david_doyle

Post Number: 63

Registered: 03-2013

| | Posted on Sunday, May 08, 2016 - 04:07 pm: |

|

" easy trailering, shallow water usage, and safe beaching." " easy trailering, shallow water usage, and safe beaching."

Careful you do not talk yourself out of the inboard!

(all in good fun) |

miro

Senior Member

Username: miro

Post Number: 867

Registered: 11-2001

| | Posted on Tuesday, May 10, 2016 - 10:32 am: |

|

There may in fact be DisPro devices for sale - they might need work, but the housings are usually OK.

The so-called - rocker shaft is a tricky part - square drive on lever side and through the skeg assembly.

I'll see if I can get pictures of a disassembled device in a week or so - I think I know where there might be one.

Miro |

herbertchoover

Member

Username: herbertchoover

Post Number: 17

Registered: 04-2016

| | Posted on Tuesday, May 10, 2016 - 12:08 pm: |

|

that would be great to see thanks miro. I am going to speak with a stainless steel fab guy as well about making the arm and shaft.

I recall early on asking here and someo remarked that it would be unlikely to find orphaned device parts so I gave up on that idea. th video does mention 3000+ diepro's were made and 200-300 are left. that leaves 2700 devices discarded. bummer! |