|

| Author |

Message |

mac

Member

Username: mac

Post Number: 10

Registered: 09-2013

| | Posted on Monday, January 04, 2016 - 05:01 pm: |

|

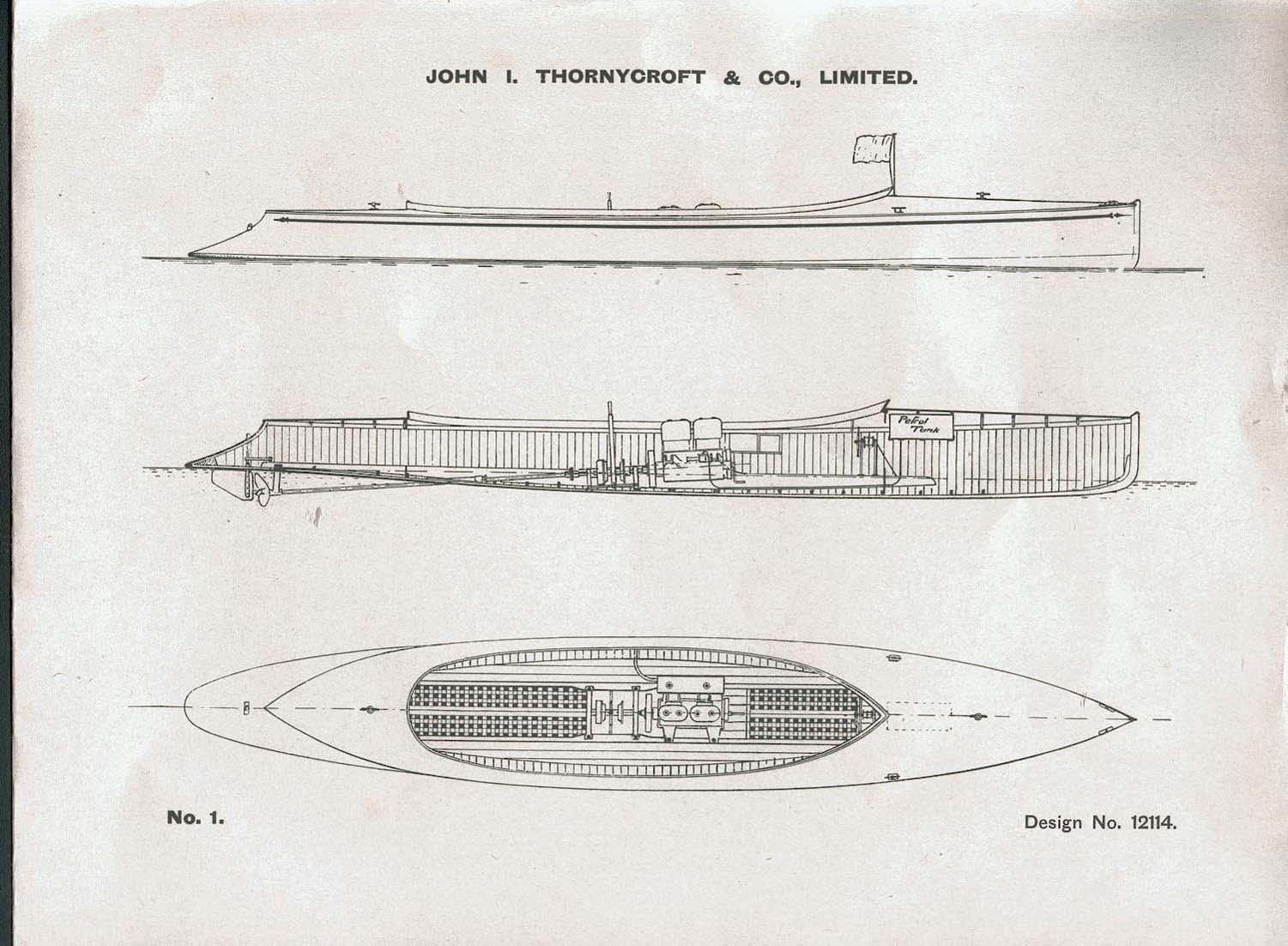

I have a 1903 Thornycroft Racing Launch that I'm restoring as closely as possible to original, built of 3/8" cedar planking on fine timbers. It looks as if it's 4 cylinder engine had an underwater exhaust with no muffler, that was lead straight down to an outlet under the engine, and a water pipe only leading to the side of the boat.

I have fears that an underwater exhaust bubbling away may not be the easiest to live with. Does anybody have any experience? |

miro

Senior Member

Username: miro

Post Number: 841

Registered: 11-2001

| | Posted on Friday, January 08, 2016 - 04:29 pm: |

|

If you have the exhaust pipe going straight into the lake, then you will have a devil of a time getting the engine to start.

In effect you have 100% blocked exhaust.

For sure on a 2 cycle engine, it will not start.

I've had "fun" with my copper jacket DisPro engine when there was a blob of oily carbon partially blocking the muffler.

Injecting the cooking water into the exhaust stream will help cool the exhaust pipe, and will also make the set up quieter.

Try to configure it, so that you inject the cooling water as close as possible to the engine.

Miro |

rogerd

Advanced Member

Username: rogerd

Post Number: 32

Registered: 01-2010

| | Posted on Saturday, January 09, 2016 - 08:15 am: |

|

Have underwater exhaust in a1909 launch with a 1908 Buffalo 3hp 4cyl engine. An old timer suggested that I install an expansion chamber to relieve back pressure. It looks just like a vintage muffler however no baffles inside. It is above the waterline near the underwater exhaust exit. The exhaust exit has a swinging flapper to direct the exhaust away from the travel direction of the hull. We have run this setup since1987 and starting has not been a problem. One downside is that the exhaust bubbles up the side of the white hull when in neutral . Roger. |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 1133

Registered: 07-2002

| | Posted on Saturday, January 09, 2016 - 09:10 am: |

|

A 4 stroke is like an air compressor, positive displacement, starting would not be as critical. A 2 stroke needs the crankcase pulse to purge the cylinder and induce the air fuel charge, not as positive. My dad ran an outboard repair shop, I remember a customer bringing a motor in, said it wouldn't start. It started first pull. He left it and asked my dad to tune it up, picked it up and brought it back, no start. It started first pull again at the shop. Further investigation revealed that bees had plugged the above water exhaust port, when the motor went under water a positive pressure kept the engine from breathing. |

mac

Member

Username: mac

Post Number: 11

Registered: 09-2013

| | Posted on Saturday, January 09, 2016 - 12:15 pm: |

|

Gents

Very many thanks for the comments, all very useful.

Roger

This flap, how does this work when you are in reverse? You also say one downside is the exhaust bubbling. Are there others, as I understand it can make an unpleasant noise and vibration? I assume you are also putting your cooling water into your exhaust as well -is that correct?

Graham |

johnny

Senior Member

Username: johnny

Post Number: 559

Registered: 03-2006

| | Posted on Saturday, January 09, 2016 - 01:34 pm: |

|

Here's a good story that helps prove what happens when the exhaust gets closed off on a two cycle engine. My father had a Suzuki moped that he use to ride around on at the engine shows. One season it started gradually getting harder and harder to start until finally it just would not start anymore. He could not figure out why it would not start and run because it was getting ignition fire and it was getting fuel and the air filter was nice and clean on the air intake. After working on it for some time he was just about to give up when he noticed the end of the tail pipe did not have a hole in it. After further inspection he discovered that the tail pipe which is only about a 1/2" in diameter was plugged up solid with black carbon. Used a screw driver to punch the carbon out and the moped started the easiest it had in a long time and really ran good had more power also. You live and learn. |

rogerd

Advanced Member

Username: rogerd

Post Number: 33

Registered: 01-2010

| | Posted on Monday, January 11, 2016 - 09:41 am: |

|

Mac. The flap is pinned with about one third above the pin, enough so the top of the flap directs the exhaust in the direction of the flow of the water going past the hull. Will take pics later this week. Downside I mentioned is the somewhat oily exhaust getting on a white hull. Easily cleaned. Vibration and noise are virtually non existent. Almost all water goes in the exhaust with the exception of a small amount from he front of the engin one quarter tap turn going directly down through the inside keel. |

mac

Member

Username: mac

Post Number: 12

Registered: 09-2013

| | Posted on Monday, January 11, 2016 - 02:32 pm: |

|

Roger. Your saying vibration and noise are virtually non existent is VERY encouraging.

A photo would be very useful -many thanks

Is the outlet under the hull, a larger diameter than the exhaust manifold?

My engine has been rebuilt and has oil scraper rings, so hopefully not too oily, especially as the anti-fouling should be white, so fingers crossed!

Why does the small amount of water come from the front of the engine? Is this water that has been cooling the engine? Does your cooling water otherwise mix with the exhaust and go out through this flap? |

foxman

Member

Username: foxman

Post Number: 9

Registered: 03-2008

| | Posted on Thursday, January 21, 2016 - 09:33 pm: |

|

Mac

These boats never used underwater exhaust, with one unusual exception which is now in the Clayton New York antique boat museum and basically didn't work at all well (but it did sort of work and was probably intended as a smoke and noise reducer and the fumes existed through a sort of weird heart shaped step in the hull which causes the boat to be terribly unstable). Napier Major from 1903 (Scolopendra's rival -I couldn't see where the exhaust was but I can't imagine it would have been underwater) You have to be careful with drawings. I have a similar raceboat from 1907 and the original exhaust went out the side. Basically the exhaust manifold simply did a 90 degree turn and exhausted through the hull just above the waterline. HJ Leighton had a big raceboat from 1903 and there were dual exhaust ports at the rear (it was a double ender).

I took a few nibbles at Scolopendra back when it was in Canada, but no go. I do remember checking out the hull which was completely original and I don't remember any exhuast holes in the side. As you know the stern was cut off to make it into a more traditional long deck launch when it came to Canada, so it is likely that the exhaust port was in the missing stern section. Given the precedent of Leighton's boat that would probably be the most reasonable approach, but at the time I'd bet they didn't bother with any special exhaust set up and just put on an smokestack and let it blow right up in the air. They were racing and there was no point or need for niceties.

Good luck on your project. Did you get any nibbles on an actual Thornycroft A-4? |

mac

Member

Username: mac

Post Number: 13

Registered: 09-2013

| | Posted on Friday, January 22, 2016 - 03:40 pm: |

|

Hi Foxman

Thanks for the very interesting post.

I haven�t yet been able to get to the Clayton Museum, but I very much look forward to it, and having a look at this heart shaped step.

One of Scolopendra�s rivals Durendal did have the exhaust exit the stern, but Napier 1�s and subsequent Napier�s I can�t see.

I agree you have to be careful with drawings, and there are details that clearly changed through the build, mostly in this case leaving parts off to save weight, but also ideas were evolving as fast as engines.

The exhaust can only have come out of 3 places in 1903, underwater, side or stern. Stacks in UK didn�t come along for a couple of years and a photo shows an engine box, so that isn�t it. Photos of the stern don�t show an exhaust, and the sides are clearly original and the only exit is as per drawing and is a �� ID outlet, just above the waterline. I�m therefore left believing it has to be underwater, and the very limited period info seems to indicate that underwater was quite normal in UK. There was no tell tales in the planks, but several had been replaced over the years.

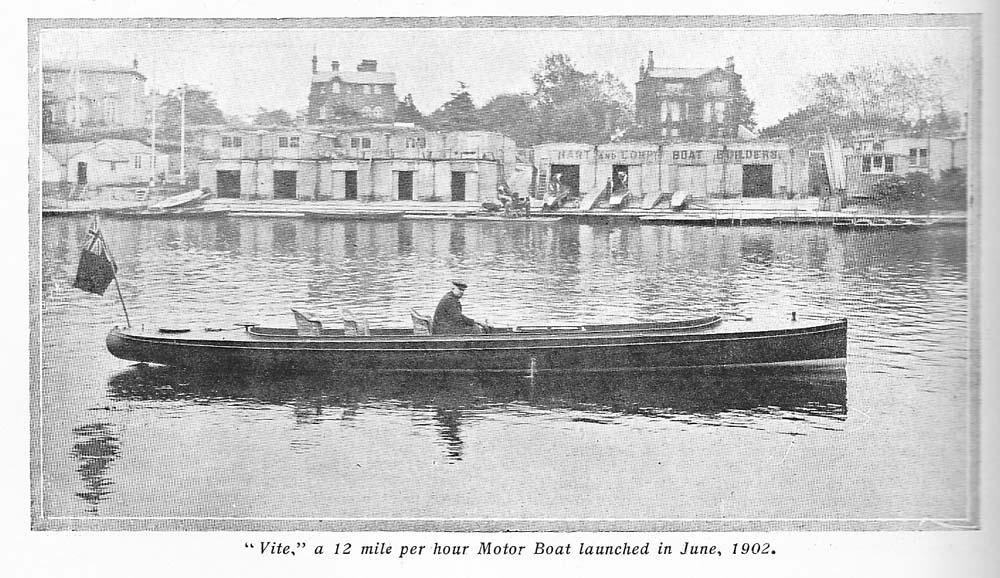

Looking at local UK history, in 1902 a launch called Vitesse was said to have been the fastest on the Thames, and was built about 10 miles from Thornycroft�s. I include the whole article in case it�s of interest.

We are enabled to give the design of this launch, which was built last year by Messrs. Hart, Harden & Co. Kingston Bridge, Hampton Wick, and which has attracted considerable attention on the river. She was not built for a speed-boat, though her dimensions and beautiful construction are eminently suited to obtain good speed results. She was built with a view of introducing on the Thames a fairly speedy boat with a moderate h. p., and without sacrificing the necessary amount of comfort required for a river pleasure launch. The estimated speed on a given displacement was for 12 miles, which she well exceeds. There is an entire absence if vibration, and taking Into consideration that she has an open well of over 20 feet without a seat or tie of any kind, and her very light scantling, speaks well for the construction.

The planking is 3/8 in finished mahogany, teak covering boards, kauri pine decks, American elm coamings, bent round with circular ends and teak mouldings, flush cockpit floor taking nine lounge basket chairs. She is fitted with motor bar steering wheel aft, and an additional wheel on brass column near motor, so that she can be handled easily by one person. The motor is a 4cycle, 4-cylinder .Blake motor, developing 12 b.h.p. at about 800 revolutions, with electric ignition and which can be timed to run the engine down to 200 revolutions and increase to 1,000 If required, or speed of engine can be reduced by using the throttle-valve. The engine is fitted with free wheel starting gear, and is covered with a blue steel casing and polished brass mountings. The exhaust is water cooled and carried out below the waterline, which effectually prevents any noise, and has been found to tax the engine very little.

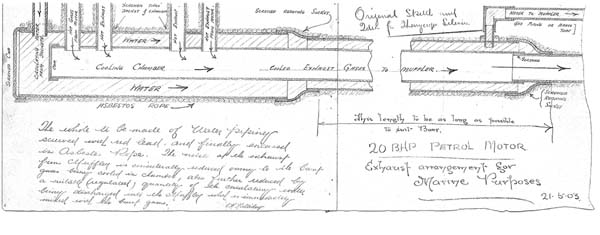

I�ve also seen a drawing by Higley Halliday (who worked for Thornycroft at the time) of a water cooled exhaust also dated 1903, though the water just jackets the exhaust and doesn�t mix with the exhaust gases. Although this could have been for Scolopendra they also sold the same engine for a launch for King Edward VII, and later for other launches.

I�m therefore thinking that the �� side water outlet which is per drawing, must have been the outlet for a water jacket after cooling the exhaust, and still wondering if the exhaust needs an expansion chamber to deal with backpressure. I�ve reconciled myself to authenticity and not having a �rorty� exhaust!!!

Roger shared with me a photo of a flapper for the exhaust on his wonderful period Minette. Looks a great idea, though I�ve no idea if it is relevant to this side of the pond.

It seems to have been a time of rapid innovation, and racing rules still dictated a crew of 2, the Helm and a Mechanician. In 1904 after Scolopendra was sold to Polsons in Canada, Thornycroft built a replica, though the Steering position moved to the aft end of the engine so she could be managed by 1 person, and I think the cooling water mixed with the exhaust, though I am still inclined to think it was underwater. When �The Motorboat� magazine started in 1904 there are few mentions of under or over water exhausts, though it does state underwater were common, but lots on silencers and water cooled exhausts

I�d be very interested to hear more about your 1907 Race-boat. Any photos, esp of the exhaust?

|

|

|

|

|