| Author |

Message |

matt_rigney

New member

Username: matt_rigney

Post Number: 1

Registered: 07-2015

| | Posted on Wednesday, July 29, 2015 - 09:45 am: |

|

Hi--I'm considering buying a 1938 wooden boat (in good shape) with a 100hp Kermath Sea Prince engine. I know nothing about this engine. Can you tell me--does it have a good reputation? It's the original engine and the owner swears by it. It's a flathead-6. Seems well maintained. I'm hoping you can tell me something--'oh, those are dogs' or 'oh, those are great engines', or 'generally, you can do better' or 'plan on replacing it!' Thank you for anything you can tell me. |

ldobbins

Senior Member

Username: ldobbins

Post Number: 173

Registered: 12-2002

| | Posted on Monday, August 03, 2015 - 02:22 pm: |

|

Greetings,

This is a good engine as designed and as built. That said, condition and how it has been taken care of mean everything!

Was it or is it a salt water engine?

Has it ever frozen?

Does it have any cracks or repairs?

Has it ever been rebuilt/restored?

If so, when?

Was it a well known shop for old marine engines?

What parts did they install?

New hardened valve seats for modern fuel?

Depending upon these answers, it may or may not be a good engine today. IF YOU NEED PARTS or a block etc, it will be harder to find than say a Chris Craft engine, but they are around.

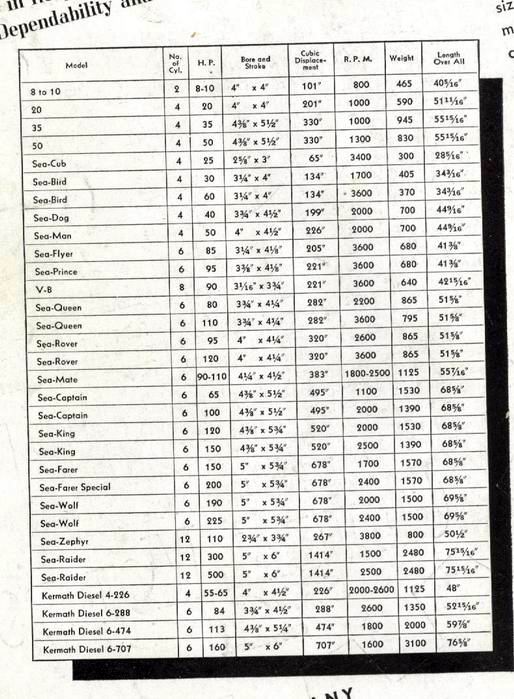

As advertised from Kermath docs, in late 1938/early 1939 this is a 90 HP engine from its 221 cubic inches (3 3/8" Bore x 4 1/8" stroke) developed at 3,600 RPM.

Cheers & Good Luck,

Lew The Left Coast Sterling Guy! |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 3636

Registered: 11-2001

| | Posted on Monday, August 03, 2015 - 07:31 pm: |

|

*

* |

matt_rigney

New member

Username: matt_rigney

Post Number: 2

Registered: 07-2015

| | Posted on Tuesday, August 04, 2015 - 08:45 am: |

|

Hello Lew--

Thanks for that information. The boat spent most of its life on Lake Michigan,

now lives near Portsmouth, NH on salt water. Owner flushes it with fresh

water when he's done for the day. Don't know if it was ever restored, frozen,

etc.

I also don't know about the valve seats.

Is that hard to do--and essential?

Is there any way to combat the effects of modern gas? An additive?

Thank you.

Matt |

ldobbins

Senior Member

Username: ldobbins

Post Number: 174

Registered: 12-2002

| | Posted on Tuesday, August 04, 2015 - 11:48 am: |

|

Hi Matt,

There are fuel additives that can help but may be illegal in some states. Some of them re-introduce lead to the fuel.

Just as the fuel may need help, so does the oil. The flat tappet engines needed the zinc and to a lesser extent the sulfur that use to be in our oils to help the motors survive. There are lots of oil additives out there that do a good job. ZDDP is one of them but ask around in your area.

Lake Michigan was good water for an engine and if he flushes her regularly now, the engine might be in good condition.

But are you saying that a 1938 engine has not been rebuilt? Wow if indeed.

Do or have a compression check done on the engine to start to evaluate her condition. 90 to 110 pounds would be a great number but more importantly, all cylinders should be within 10% of one another. Don't be surprised if you see 60 to 75 pounds compression however.

In order to change the valve seats, you are pulling the entire engine apart and doing machining. A winter project to spend your money on but to also give you peace of mind that you would have a fresh rebuild.

If you pull the spark plugs, you may be able to see the exhaust valves and if you see a ring around the valve head on the block, it could be a replacement valve seat. Originally, the block was ground to create the valve seats for the valves to seal against. When rebuilt or to change and put in harder exhaust seats, the block is ground down and a large ring with sealing surface is pressed into place. The edge of the ring can usually be seen just off the edge of the valve.

Please keep us posted!

Cheers,

Lew |

boilerbob7

New member

Username: boilerbob7

Post Number: 1

Registered: 11-2012

| | Posted on Tuesday, August 04, 2015 - 11:07 pm: |

|

The valves used to be occasionally "lapped". The head was removed along with the manifold, and a spring compressor was used to remove and "lap" the valves with grinding compound. You have to be every careful to not drop the spring retainers into the oil pan. A device similar to a kids rubber arrow was used to lap the valves. I just did that to my Atomic Four. |

bruce

Senior Member

Username: bruce

Post Number: 501

Registered: 07-2002

| | Posted on Wednesday, August 05, 2015 - 08:29 am: |

|

pure-gas.org lists ethanol-free gas stations nationally in the US by state. Seasonally idle engines using 10% ethanol fuel are in danger of corrosion in the fuel system. Marina's and small air ports are sources to look for ethanol free fuel |

david_in_ma

Advanced Member

Username: david_in_ma

Post Number: 35

Registered: 03-2010

| | Posted on Wednesday, August 05, 2015 - 10:19 am: |

|

Matt, No lead valve seats can be accurately installed w/o complete engine disassembly in the hull if there's decent access. No metal chips or other debris need fall into engine during process. Marine engs aren't typically used much. If a proper compression test shows fairly equal numbers, I wouldn't bother with any repairs initially. Use Marvel Mystery Oil in fuel and A ZDDP in oil. This eng is new to you. A local shake down may reveal its condition. My experience w/ older engs is bearing Babbitt breakdown aggravated by acids in the oil that have been sitting in the eng for a long time. Obviously a complete, thorough disassembly and rebuild will provide the best results. Have you considered a heat exchanger? The flush out idea doesn't impress me unless it's done w/ hot water. Salt was circulating in the hot block. Running the eng at 160F or less is very inefficient plus there are places that are very hot around exhaust seats and ports that plug w/ salt any way. David |

ldobbins

Senior Member

Username: ldobbins

Post Number: 175

Registered: 12-2002

| | Posted on Tuesday, August 11, 2015 - 05:35 pm: |

|

Hi Matt,

David is correct in that it can be done in the boat without removing the engine. It has been done this way for decades and as long as cleanliness is observed, it can work there saving money.

That said, it may be difficult to find someone qualified that is willing to do the job in the boat.

And his point about amount of usage is generally true. Through additives, the damage can be reduced or even removed.

All of this can be done and the engine may run for decades to come. But knowing what the compression of each cylinder is must be done to know if the engine is in decent shape to begin with. It it is not, then doing this work is partially wasted.

If it is actually a reasonably low hour engine. Then go for it and play with it! Enjoy!

Cheers,

Lew |

matt_rigney

New member

Username: matt_rigney

Post Number: 3

Registered: 07-2015

| | Posted on Tuesday, August 11, 2015 - 06:42 pm: |

|

Hi all--you guys are great! Thanks for this great information. The owner of the Richardson is considering a better offer from another buyer so I may be looking at a 1972 Bertram 28 (with flybridge) with twin Chevy FWC 305s, with only 570 original hours on the engines. Perhaps a safer boat in a squeeze, though the style is not there. I'll keep looking for any more in put on the Kermath. |

skippy

Visitor

| | Posted on Tuesday, August 11, 2015 - 09:34 pm: |

|

As the owner of a Federal Truck with a JXE engine, my advice is to see what kind of oil pressure you are running when the engine is hot. If it only shows 20-25 lbs. when hot I would consider a rebuilt. Cold mine shows 60 lbs and hot about 45 after a rebuild 14 years ago. These engine also tend to leak oil around the water pump (at least on dry land models ...another thing to look for. |

matt_rigney

Member

Username: matt_rigney

Post Number: 4

Registered: 07-2015

| | Posted on Monday, August 24, 2015 - 09:05 am: |

|

This is very helpful information. If I am in the running for the boat, I'll check all these things.

How difficult would it be to rig a fresh-water cooling system to an engine like this? |

ldobbins

Senior Member

Username: ldobbins

Post Number: 178

Registered: 12-2002

| | Posted on Monday, August 24, 2015 - 06:20 pm: |

|

Hi Matt,

Not too difficult, but the hardware to do it is not inexpensive. The hardest thing to do is find a location on where to drive a second water pump from. One pump circulates water/antifreeze through the heat exchanger (to cool) and through the engine and oil cooler. The other pump circulates lake water through the heat exchanger.

Cheers,

Lew |