| Author |

Message |

np317

New member

Username: np317

Post Number: 1

Registered: 05-2015

| | Posted on Monday, June 01, 2015 - 01:30 am: |

|

Being the new "curator" of a well-preserved Detroit Engine Works single cylinder marine engine (2 h.p.), I had developed questions for which I have not yet "discovered' answers here, and on the DEW history web site. So hopefully someone can help me.

I have not yet made required repairs to get this engine running. I acquired it from an estate, where it languished in a garage in this condition for several decades. It turns over easily, and has good compression.

This is my first foray into this fascinating world of early IC engines, since my days rebuilding 4 different Fairmont speeders with similar 2-cycle engines. And I have an excellent 16' Poulsbo hull to mount this DEW engine in...

I will upload some photos followed by my questions.

Based on the rectangular inspection port for the crank case, is this a late model DEW engine?

What years might it have been produced?

Where might I find more information on this version of engine?

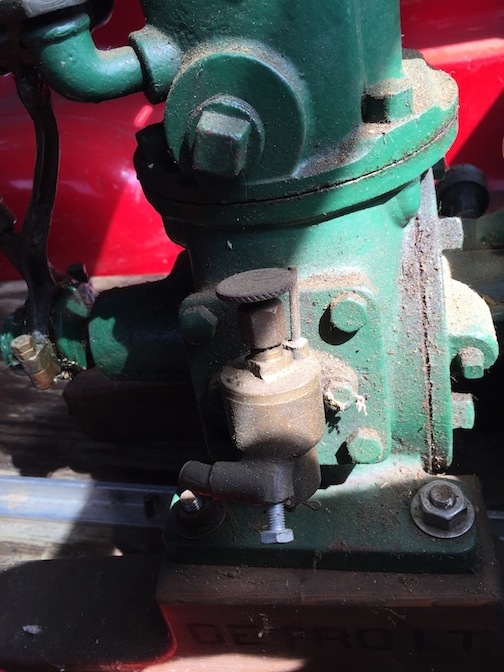

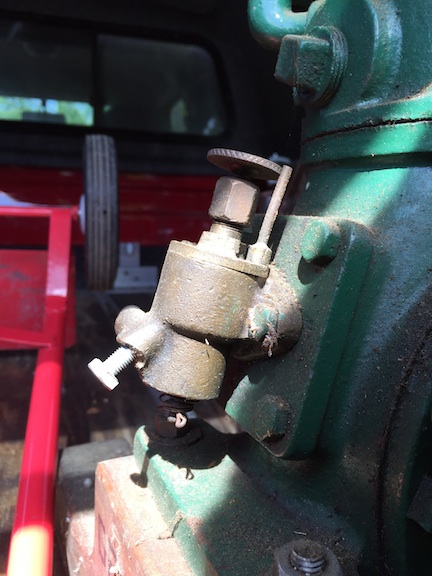

The Mixer is mounted to the crank case inspection plate, instead of the threaded hole above, as on the other DEWs I've seen pictured.

Is this unusual? Perhaps a modification to use a "found" mixer?

Will the engine operate this way, as a "crank case inducted" system? Evidence suggests it has been operated this way. The piston has the deflection ridge in the correct position, near this hole where the mixers are usually mounted.

Should I make an adaptor to install the mixer in this "normal" position?

This mixer looks similar to a Lukenheimer type unit, but with the mounting flange instead of a thread mount.

The mixer fuel needle valve is damaged and requires re-fabrication. Someone screwed in a 1/4"-28 bolt where the needle goes.

Would this have been a DEW-supplied original mixer?

Are there replacements available?

Those are enough questions for my first venture here.

I trust that the demonstrated knowledge base here should be able to assist me getting this marine engine properly running again.

Thank you for your patience so far. And hopefully for your assistance.

~Russ in Seattle |

ernie

Senior Member

Username: ernie

Post Number: 2084

Registered: 01-2002

| | Posted on Monday, June 01, 2015 - 09:33 am: |

|

Yes the mixer is a non Detroit modification.

The mixer looks to be from an Evinrude or Caile.

You are correct. The needle valve for mixture adjustment is missing. The silver bolt is where it should go.

Yes the engine should run the way it is if the needle valve is repaired. |

np317

New member

Username: np317

Post Number: 2

Registered: 05-2015

| | Posted on Tuesday, June 02, 2015 - 01:07 am: |

|

Thanks Ernie.

Any other input, anyone?

~Russ |

johnny

Senior Member

Username: johnny

Post Number: 527

Registered: 03-2006

| | Posted on Tuesday, June 02, 2015 - 10:10 am: |

|

Hi Russ,

That's a good looking little Detroit with a little bit of work it will make a fine engine for your boat. I would agree with Ernie on the info he has given you. A few others details, The Detroit marine engines with the square inspection cover appear to have been manufactured around 1911-1920. If you plan on using the existing mixer with a gas & two cycle oil mix then leaving the mixer mounted down low would probably help lubricate the lower con-rod better seeing as how the drip oiler port for the lower con-rod has been plugged on your engine. If you are not going to mix oil with the gas then you should put a drip oiler in the plugged port. I noticed that Something does not look right about the output drive coupling on your engine. Could it have been cut off? No hole or sleeve to put your prop shaft in and not enough shaft sticking out to put a flange coupling on. You will need to put a one way valve on the threaded port going into your water pump. If you have anymore questions feel free to post or email.

John |

johnny

Senior Member

Username: johnny

Post Number: 528

Registered: 03-2006

| | Posted on Tuesday, June 02, 2015 - 10:23 am: |

|

Russ,

Your output coupling should look like the one in the photo below. Also notice the brass check valve on the water pump.

|

johnny

Senior Member

Username: johnny

Post Number: 529

Registered: 03-2006

| | Posted on Thursday, June 04, 2015 - 11:07 am: |

|

Russ,

Also, I just noticed that your output shaft thrust bearings are missing. they go between the pump eccentric and the main bearing. You do not want to run the engine in a boat with out them. Probably would break the water pump arm. |

np317

New member

Username: np317

Post Number: 3

Registered: 05-2015

| | Posted on Thursday, June 04, 2015 - 04:30 pm: |

|

Johnny:

Many thanks for taking the time to offer your observations on my DEW engine.

Happily, I have studied all the photos I could find and already determined that the thrust bearing was missing, and that shaft connection had been amputated! I already have a new thrust bearing waiting for me to get back home to work on this engine, and I intend to manufacture a new shaft connection sleeve.

Considering that the pump conn-rod had been broken and crudely brazed at both ends, I suspect the engine might have been run on it's stand without that bearing. I'll rebuild the connecting rod so it looks and works correctly.

While making internal inspections, I found that there is no oil slinger mounted to the crank shaft that would channel oil to the main conn-rod bearing. That implies that there might be a grease channel from the front of the crank shaft, outside of the fly wheel. So I plan on investigating further, and cleaning it out and fitting a new grease cup for proper lubrication, as required.

And I will install a new check valve on the water pump input as part of the overall plumbing of the engine. I have already verified that it will pump, and I replaced the packing with modern Teflon rope. It works better now.

The original two-piece spark plug that arrived on the engine had a cracked ceramic top, so I acquired a new equivalent one-piece plug.

?Does anyone know the number of a "proper" spark plug?

And I have already received a new buzz box for the spark.

Now if I can just get my new shop/garage completed (all wiring completed today), and get us move 250 miles south from the Seattle home we have been in for 28 years... Do you think I'll get much shop time this year??? Still, I'm planning ahead, trying to get the DEW engine squared away. I'm enjoying the process, and appreciate the good help I have received from this discussion board.

Thanks All,

~Russ |

johnny

Senior Member

Username: johnny

Post Number: 530

Registered: 03-2006

| | Posted on Thursday, June 04, 2015 - 06:35 pm: |

|

Russ,

That threaded hole to the right of the inspection plate that has a plug in it is your oil port. There should be a small steel tube on the inside of the crankcase that comes from that port and it is aligned with a steel disk attached to the crank, the disk has a rolled lip on it to catch the oil. centrifugal force from the crankshaft turning forces the oil into a small hole that goes to the bearing journal. Your engine is a late model so I'm fairly sure it does not have a grease port through the middle of the crankshaft. If your engine is missing the steel disk then someone probably removed it either because it was rusted real bad or they were mixing the gas & oil and did not need it. The easy way to reproduce the disk is to make it out of aluminum and machine the groove in it rather then making it from sheet metal and having to roll the lip. Autolite makes a one piece spark plug and the number is (3095). |

np317

Member

Username: np317

Post Number: 4

Registered: 05-2015

| | Posted on Thursday, June 04, 2015 - 07:48 pm: |

|

Johnny:

Thanks for that info on the oil port. I was hoping to not remove the crankshaft. I can do further investigation through the inspection plate with my borescope, looking for the oil delivery tube. I can also see if the threaded opening in the front of the crank shaft is deep enough to possibly be a grease gallery. If indeed the oil slinger (motorcycle engine term) is missing, I like your method for turning a replacement. The aluminum would not be so likely to rust away as the original apparently tended to do.

I suspect this DEW engine was a partial derelict that was resurrected with whatever was available, thus the "alternate" fuel mixer. There is a line of water pits across the bottom 3 inches of the flywheel, indicating it was partially under water for some period of time. 'Sure would be fun to learn its history.

And your provided dates of manufacture of this version engine is useful. I have located "Sedro Wooley" stamped on the front face of the fly wheel, but no other marks. Sedro Wooley is a small Washington town on the Skagit River, with access to the Puget Sound. 'Makes sense that a small launch with this engine would be used there in decades past.

And amazingly, I acquired a 3095 spark plug for the replacement! A "guided" guess, for sure. Thanks for the verification.

~Russ |

johnny

Senior Member

Username: johnny

Post Number: 531

Registered: 03-2006

| | Posted on Friday, June 05, 2015 - 06:09 pm: |

|

Russ,

The gentlemen on this forum that actually have boats with the two cycle flywheel engines can give you better tips on what to use for oil. I think most are running either two cycle oil mixed with their gas or 30 weight oil mixed with the gas. This way you don't have to worry about something going wrong with the drip oiler and the engine ceasing up while your cruising the water ways. Leave the drip oilers on the engine with oil in them but don't turn them on. Let the two cycle oil do the job. Just a suggestion. If you are going to run the engine just at shows then the drip oilers are fine for just running slow with no load. |

ernie

Senior Member

Username: ernie

Post Number: 2086

Registered: 01-2002

| | Posted on Saturday, June 06, 2015 - 08:58 am: |

|

Johnny is correct

In our world today oilers are really just a decoration unless you have a fuel injected 2 stroke made by one of the Detroit family of manufacturers.

I use the same fuel and oil mix for my 3 hp Gray in a 20 ft fantail launch (and my show engines) as I do in my older (non 50 to 1) outboards. The ratio is 16 to 1 or a quart of oil to 6 gallons of gas. 30W non detergent oil is easily available at most auto parts stores as well as Tractor Supply.

By 1910 most marine engine manufacturers had started using pre mixed fuel and oil.

1 cheaper no oilers to supply with the engine

2 better lubrication as the fuel and oil mix gets everywhere inside the engine

3 easier to operate (no oilers to adjust or maintain)

4 no added oil to worry about. When it ran out of gas it ran out of oil. Not like an oiler that can run out of oil and not be noticed.

The reason oilers MUST be used on the fuel injected 2 strokes mentioned above as the fuel is injected directly into the combustion chamber and does NOT pass through the crankcase to lubricate the connecting rod and wrist pin. |

np317

Member

Username: np317

Post Number: 5

Registered: 05-2015

| | Posted on Saturday, June 06, 2015 - 10:49 am: |

|

Ernie and Johnney:

Interesting info on oiling the DEW engines.

Is my Detroit 2-cycle an "injected" version? Or an "inducted" engine, because there is no air-check valve on the opposite side from the "fuel mixer?"

Also, the advice to leave the mixer mounted on the crankcase side inspection plate sounds like a good thing for lubrication.

And if used under load in a boat, is the 16 to 1 gas/oil mix ratio what you recommend for this 2 h.p. Detroit? If all works as desired, I plan on using this engine to push a 16' Poulsbo hull around.

Thanks again guys. As a retired teacher I really appreciate you sharing your knowledge.

~Russ |

johnny

Senior Member

Username: johnny

Post Number: 532

Registered: 03-2006

| | Posted on Saturday, June 06, 2015 - 12:50 pm: |

|

That's a good point Ernie brought up about the Detroit two cycle fuel injected engines. Like he says they have an injector nozzle that goes through the intake port and directly through a hole in the cylinder wall. The injector hole is located two or three inches higher then the larger intake hole so if you used oil & gas mix there would probably not be much lubrication for the piston & cylinder much less the upper & lower con-rod bearings. Russ, most of the Detroit 2 cycle engines were manufactured so that you had the option of running a carb, mixer or fuel injection. Your Detroit appears to have a small port for adding fuel injection. Looks like it has a threaded plug in it. There would also have to be another plugged hole on the crankcase for the air-intake valve. Fuel reservoir/injectors are not easy to find and have been going for $300 or more on Ebay. Your probably better off with the mixer. |

johnny

Senior Member

Username: johnny

Post Number: 533

Registered: 03-2006

| | Posted on Saturday, June 06, 2015 - 01:00 pm: |

|

Here's a cut away view of a stationary Detroit engine so you can see how the injector goes straight through the cylinder wall. The marine engines are the same. The large port (D)&(E) are air, the small port (I) is the tip of the fuel injector nozzle.

|

np317

Member

Username: np317

Post Number: 6

Registered: 05-2015

| | Posted on Tuesday, June 09, 2015 - 11:58 am: |

|

Ahh. Good drawing cross-section. That explains the "other" plugged hole in the cylinder wall. And this engine does have a plugged hole on the opposite side of the crank case where the air check valve would be installed for F.I. I can see the DEW design providing options for either fuel injection or mixers. Pretty smart!

In my situation, the mixer appears to be the best solution. I would like to eventually locate a proper mixer as originally supplied with this engine, as I suspect it may provide more controllable operation then the simpler one that it came with. But you are correct: They seem unobtainable.

More good info, and Thanks.

~Russ |