|

| Clift and Termatt Monahan |

| Author |

Message |

andrew

| | Posted on Friday, January 02, 2004 - 09:38 am: |

|

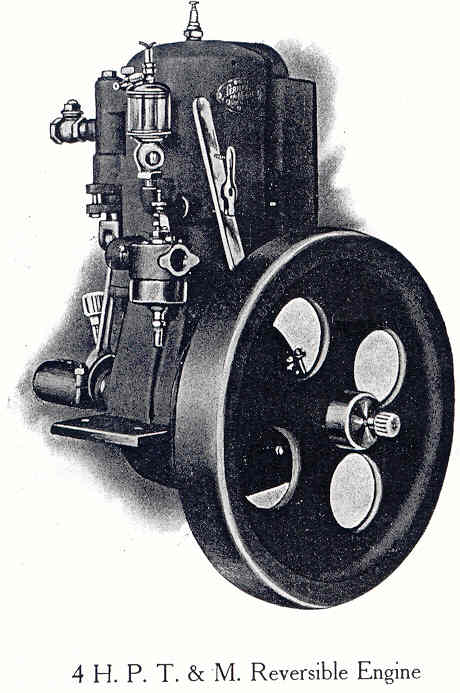

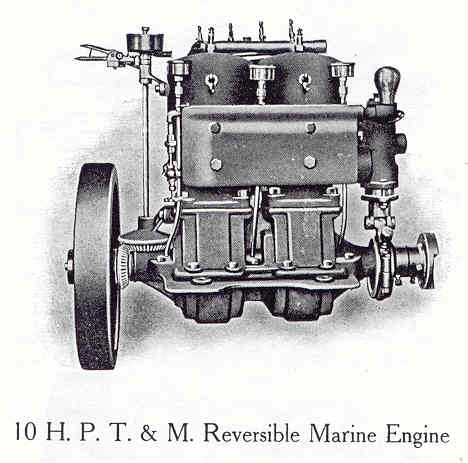

Quote:... some pictures of my Clift and

others. If you please feel free to post on the discussion site. Thank You for a great site.

The Clift is the engine from Bellingham, WA that was featured in Gas engine mag here a while back

The pictures of the Thrall is the engine that I need the timer for. (picture was not sent) Any help would be great.

The T&M is the one that is nearly done.

Best regards,

Matt Montague

North WET Washington

Clift

T&M

|

Matt Montague

| | Posted on Friday, January 02, 2004 - 07:45 pm: |

|

Thank You Andrew, Sorry about the missing picture thing. I am a little new at pictures! The Clift is last winters project, the T&M is this winters, putting the finish on the skid for it now.

Best wishes and Happy New Year, Matt |

andrew

| | Posted on Friday, January 02, 2004 - 10:24 pm: |

|

Matt,

Great looking engines!

You could try posting the Thrall picture yourself... see the instructions in the "formatting" section on left. |

richarddurgee

| | Posted on Saturday, January 03, 2004 - 07:38 pm: |

|

Matt

The Clift is a great looking engine !

The Termaat has me wondering why the by pass piping from top of w/pump to lower water jacket fitting ?? The factory pumped water into jacket through top mount of w/pump and out at top of wet muffler, some water went in exhaust and steamed and rest flowed out bottom fitting of muffler. Maybe hot spot in lower jacket? havent seen one altered like this ?? |

Ernie

| | Posted on Saturday, January 03, 2004 - 08:50 pm: |

|

Neat stuff Matt!

Good job

Ernie |

Richard Day

| | Posted on Saturday, January 03, 2004 - 09:21 pm: |

|

Further to Dick's comment I have three of this style engine and all are slightly different. One the exhaust outlet is opposite the engine exhaust port. One has the exhaust as shown in the photo and one has the exhaust outlet the same except it is near the bottom of the expansion chamber. The internal water pipe from the top of the exspansion chamber is 1/8" as I recall and it has two about 3/16" dia.water outlets drilled in the pipe at the same level as the engine exhaust port but arranged to shoot perpendicular to the exhaust port to cool the exspansion chamber and the exhaust line. The bottom of this pipe is not sealed with the bottom water drain so water build up in the expansion chamber cannot be sucked back into the cylinder in the event the exspansion chamber were to become full of water. The bottom drain of the exspansion chamber was simply connected to a through hull to allow the discharge water to drain overboard. I have also seen one version of the exspansion chamber that had a cast water jacket to cool the exspansion chamber. I am also puzzeled at the strange piping between the cylinder water jacket drain plug and the top of the pump. Why do I suspect that it is some add on by a previous owner. By the way watch for glass marbles as the top check. They don't work well as the are too light and bounce. |

J.B. Castagnos

| | Posted on Saturday, January 03, 2004 - 10:11 pm: |

|

I think that may be a home made water pump, doesn't look factory, should be hollow at the bottom mounting point, usually has a nut to hold the packing instead of the two bolt flange. |

Matt Montague

| | Posted on Saturday, January 03, 2004 - 10:46 pm: |

|

Thank You all for your kind comments, I found it odd that the ell on the bottom of the cylinder was brazed to the cylinder, However I have been restoring farm hit & miss for 10 years and tractors for over 20 and found many odditys. It would not surprise me if some enterprising soul re-engineered the cooling system. The water pump is a very nice cast iron casting that bolts nicely to the cylinder, the packing gland also fits nicely into it's counter bore. The top of the exhaust manifold has a pipe that runs down inside the expansion chamber and ends at the fitting on the bottom. I am certainly NO expert.

As me and the camera become better friends I will send pictures of some of the other marine engines. I enjoy this forum. Thank you again and Happy New Year.

Matt In North WET Washington

It's 10F w\a 50 mph wind from the interior of BC and 6 inches of snow right now. |

andrew

| | Posted on Saturday, January 03, 2004 - 11:59 pm: |

|

Here are the pictures of Matt's Thrall engine. See his comments above in the first post:

|

Dick Gibbens

| | Posted on Sunday, January 04, 2004 - 08:05 am: |

|

Good job! If you would like the swing timer lever for the Thrall I can loan you one to use as a pattern for casting. Dick Gibbens |

richarddurgee

| | Posted on Sunday, January 04, 2004 - 06:58 pm: |

|

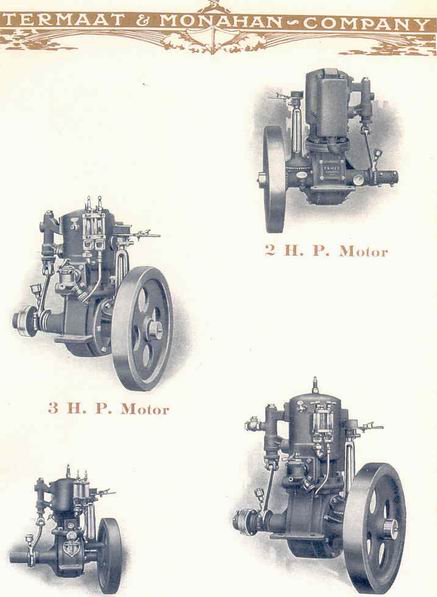

Matt

Seems we all like to put a Mfg date on our old iron, and part of the fun of this pastime for me !

My notes on T & M engs say the wet muffler was patented in 1906, and show two styles of packing glands used on their w/ pumps that also help date these old engines.

1906 and earlier use the flat flange type with two adjusting screws (like your eng above pic)

1907 and later use the threaded nut style.

pic of a twin Of mine with older style.

|

Matt Montague

| | Posted on Sunday, January 04, 2004 - 11:28 pm: |

|

Richard, Thank You for the picture. The Wet manifold has a PAT Date cast in it as 06. Looks like from the picures mine has a home made pump rod. And the dual oiler is different, mine after looking has a plug in the port just at the cylinder split line. That must be for the rod bearing? The upper port has has a very nice little groove for lubing the piston skirt. I have a dual oiler that I can put on it. This engine set up to run on 40:1 mix or ? Mine also was set up with a Shebler carb like the one on the Thrall only a 1" npt. This was by the way purchased in a 5 gallon bucket all apart so I guess atfer 90 some years one would expect a part or two to be missing. Hey it's warming up here, it is up to 19 F and the winds have slowed down to 15 or so. The weather man says 40 by wed yippee. Just get the pipes thawed out .. wifey's happy now. Thank you for all your help.

Best Regards Matt |

Richard Day

| | Posted on Monday, January 05, 2004 - 07:19 am: |

|

They didn't discover mixing the lube oil in the fuel until 1909/10. It soon took off and makers would not garantee their engines unless you mixed oil in the fuel. They continued for a few years to leave threaded but plugged holes for oilers but only supplied an oiler if the buyer demanded one. That practice ended in later years although some engine castings still had the bosses from the earlier years. This practice helps to a degree in dating an engine. Some big Canadian makers recommended one pint to 4 gallons whereas American makers recommended one pint to 5 gallons. Don't know why but that was the practice of Arcadia and I believe Lunenburg right up to the end of production. I leave the oilers in place if they are on the engine but fill them half full of oil but don't let them drip as it adds to the oil in the fuel and causes carbon to buld up faster in the upper chamber. I position the control to it look like they are dripping so helpful visitors don't have to warn me they are not dripping. Lathrop never did believe in mixing oil in the fuel but his customers did as they didn't want to bother with the weekly cleaning and daily servicing of the oilers. With regard to the water pump on Matt's T & M, I have five sets of casting for the pump body and gland that appear to me to be the same. The odd ball piping I don't understand but my castings have a built in water return passage from the top of the pump to the bottom inlet to the cylinder where the pump body bolts to the cylinder. I guess there has to be a number of pump body styles from the comments and photos we see on this thread. |

richarddurgee

| | Posted on Monday, January 05, 2004 - 11:36 am: |

|

While on the topic, my Termaat twin above is missing the brass elongated ball shaped fitting on the pipe from the water/pump. believe it's a pulsation dampener, the thread is a straight, 1 inch X 14 thread. Any one have one to sell or any ideas to get one

|

miro

| | Posted on Monday, January 05, 2004 - 12:46 pm: |

|

The mix ratio is almost the same ( within10%) USA and Canada.

The USA gallon is 4 litres ,the Canadian gallon is 4.5 litres. I dunno why - must have been something about winning the War of 1812.

miro |

olarry

| | Posted on Tuesday, January 06, 2004 - 12:10 pm: |

|

The way I was told is that 1 us gallon equalled four QUARTS and one canadian gallon equalled 5 QUARTS.So that would make the rate exactly the same as one pint for 20 Quarts. |

Andrew

| | Posted on Monday, April 26, 2004 - 12:18 am: |

|

Your T&M was built using Middleditch patents. Benjamine Middleditch had patented many items relating to marine engines, and later on, stationary engines. Most notable were the water cooling of the exhaust gasses to aid engine scavinging and cooling of the exhaust, low pressure fuel injection, pressurized oiling of engine lubrication (using crankcase pressure differential), and more. He had business relations with at least 9 manufacturers in the Detroit area, over a span of about 35 years or more. To name a few - both marine and stationary - T&M, Columbia, Detroit Engine Works -Builders of Marine Engines, Detroit Engine Works -Builders of Stationary Engines (seperate manufacturing facilities), Sandow, Detroit Motor Car, Detroit Auto, Bessemer, and others. His patents start about 1896 , With T&M using them, and his designs were used under various manufacturers until Bessemer discontinued them in the 1930's |

ron layman

| | Posted on Sunday, May 09, 2004 - 02:19 pm: |

|

I have a 4hp clift, as you probabley know they have a model t piston which can still be purchased new !! I am willing sell it but what should I ask it looks to be complete the push rod is chromed I brought it fromm a collecter mainley because of the ford part in it I also have a detroit 2 cycle which also has a model t piston thx

Ronlayman |

Matt Montague

| | Posted on Sunday, May 09, 2004 - 09:51 pm: |

|

Ron, I am interested in both of your units. I tried to e-mail but it came back as not deliverable. Please contact me at

kc7uhn at cs.com. Convert the "at" to a @and delete the spaces. Or feel free to call me on my land line in Western Washington at 360-966-3884. I look forward to hearing from you.

Matt Montague |

r layman

| | Posted on Monday, May 10, 2004 - 04:49 pm: |

|

I need to know what the value is on a 4 hp clift |

Matt Montague

| | Posted on Monday, May 10, 2004 - 05:41 pm: |

|

Ron, The one that is pictured here I paid $375 for. It was a local engine. It was complete less the Cuno timer. It is probibly worth a little more but that is what the man wanted. It did run but it was not all polished and painted. Does this engine run?

Where are you located?

Matt |

|

|

|

|