| Author |

Message |

George Coates

Senior Member

Username: george_iv

Post Number: 93

Registered: 07-2003

| | Posted on Tuesday, August 27, 2013 - 04:11 pm: |

|

Look what I got!

|

Searcher

Senior Member

Username: searcher

Post Number: 574

Registered: 10-2004

| | Posted on Tuesday, August 27, 2013 - 05:59 pm: |

|

WOW! That is the elusive YT-2 aft cylinder head that has been impossible to find! Wonderful! I didn't realize the complexity of the YT head castings. Congratulations. |

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 826

Registered: 07-2002

| | Posted on Tuesday, August 27, 2013 - 08:40 pm: |

|

Looks great George, a lot of work. When are you going to pour? Looks like a cylinder in the background. |

Ernie

Senior Member

Username: ernie

Post Number: 1714

Registered: 01-2002

| | Posted on Wednesday, August 28, 2013 - 02:06 pm: |

|

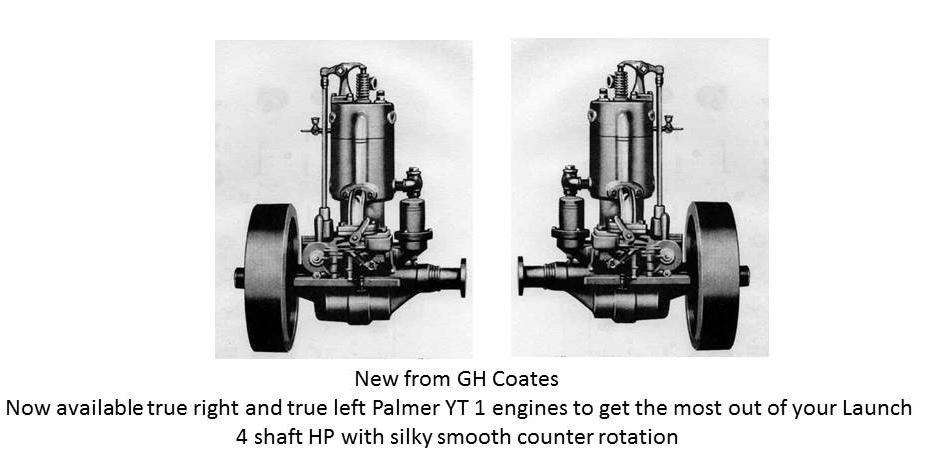

With a YT2 head you can also make a true left and true right pair of YT1s for twin screw operation The cam timing is symetrical so there would be no internal changes needed. Just use a YT2 rear head and install the cylinder backwards.

The timer and water pump would not be opposite but everything else would.

|

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 1075

Registered: 11-2003

| | Posted on Wednesday, August 28, 2013 - 02:44 pm: |

|

Congratulations George, A remarkable effort. A twin screw YT-1 hull will be most interesting. |

George Coates

Senior Member

Username: george_iv

Post Number: 94

Registered: 07-2003

| | Posted on Wednesday, August 28, 2013 - 08:01 pm: |

|

I've got some adjusting to do to the water jacket cores in the head but with luck possibly 2 weeks for a test pour.

I have made patterns and cores for the YT with dry exhaust, the YT2 fore and aft with wet exhaust. Some of the YT1's may have the raised boss for the dry exhaust on top of the head. I have 5 heads for YT and YT2 and some have the raised bosses and some don't. I'll probably machine the raised boss heads (dry exhaust style) for wet exhaust and put a threaded plug in the hole in the exhaust flange so they can be used either way.

Cylinders will be done soon too but I have to do some figuring on the water jacket core for them as well.

Soon. |

Paul Gray

Senior Member

Username: paulgray

Post Number: 144

Registered: 05-2003

| | Posted on Thursday, August 29, 2013 - 06:25 pm: |

|

You may wish to try putting some thick wire in the core supports/prints to keep them from floating during the pour if the thin core prints break off. Could not tell if you did this from the pix. Great job and good luck with the casting. |

George Coates

Senior Member

Username: george_iv

Post Number: 95

Registered: 07-2003

| | Posted on Monday, October 21, 2013 - 12:22 pm: |

|

First rough head is back from the foundry. Looks good! Hopefully get it machined this week but that may be optimistic. I don't have a cost yet, but am starting to take orders. The cost will be directly affected by the number of orders I have and I probably won't do another run of them. There will be standard YT with the raised boss for dry exhaust, YT with no boss for wet exhaust and YT2. Send me an email with desires and I'll start working on costs.

George

Ps. Cylinders to follow but not until next month.   |

George Coates

Senior Member

Username: george_iv

Post Number: 96

Registered: 07-2003

| | Posted on Monday, October 21, 2013 - 12:29 pm: |

|

Here's a cutaway of an old head and a new casting. Notice the erosion around the valve passages.

|

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 836

Registered: 07-2002

| | Posted on Monday, October 21, 2013 - 08:31 pm: |

|

Congratulations George, looks great, quite a bit of work. There should be a lot of YT's back in service. |

Richard Alcock

Senior Member

Username: raa

Post Number: 64

Registered: 02-2007

| | Posted on Monday, October 21, 2013 - 10:24 pm: |

|

That is one terrific bit of work George. I would like to see how you developed the cores. Were there any paste up work required? Did you make a positive and then cast a negative core box? |

Robert

Senior Member

Username: robert

Post Number: 615

Registered: 07-2003

| | Posted on Tuesday, October 22, 2013 - 01:08 am: |

|

Fascinating! Your core location is better than that original; the clearance for the water port from the cylinder jacket looks barely adequate on the original head. |

billyrimfire

Visitor

| | Posted on Tuesday, October 22, 2013 - 08:08 pm: |

|

Very nice. Who's your foundry? |

George Coates

Senior Member

Username: george_iv

Post Number: 97

Registered: 07-2003

| | Posted on Wednesday, October 23, 2013 - 03:13 pm: |

|

I have drawn the entire head outside and inside with cores. Then we machined core boxes and filled them with no bake core sand. We assemble the entire mold and send it to the foundry. The mold consists of 8 parts. The heads are as close to the originals as the originals; meaning the variations of the new heads are the same in the 7 samples of YT heads I have to work from and copy. It's pretty amazing how different the original heads are actually.

Here are the latest pictures. All of the rough machining is done.

|

Searcher

Senior Member

Username: searcher

Post Number: 582

Registered: 10-2004

| | Posted on Wednesday, October 23, 2013 - 03:40 pm: |

|

WOW! It looks great. |

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 1083

Registered: 11-2003

| | Posted on Wednesday, October 23, 2013 - 05:32 pm: |

|

I am sure Julius Ulrich the Palmer chief designer and life long employee will be very proud of this incredible effort. The YT was his design in 1920/21. One of the most desirable 1 lungers of pre WWII era. The last came off the line in 1948. It looks like that design will live on long after we are all gone. |

Searcher

Senior Member

Username: searcher

Post Number: 583

Registered: 10-2004

| | Posted on Tuesday, October 29, 2013 - 10:03 pm: |

|

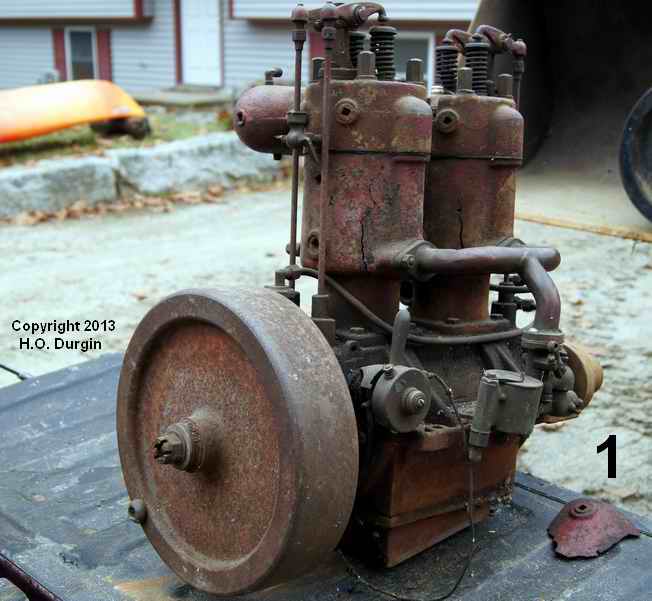

I should have posted the story and photos behind this YT-2 a long time ago. I think it took a while before the reality set in that George was actually going to tackle and solve the foundry pattern equivalent of Rubik�s Cube.

I acquired this poor YT-2 along with some related documentation in the fall of 2011. To get it, I had to buy four other marine engines as part of a package deal. Three engines in the lot were rather sorry affairs, the other two, a Lockwood Ash twin and a tiny Fairfield were reasonably good but not engines I would have purchased by choice. My wife looked at the lot and I caught a fleeting grimace cross her face followed immediately by an equally fleeting expression every husband recognizes intuitively as the �quid pro quo new sofa� look.

After dismantling the YT-2, it became increasingly apparent that it wasn�t as salvageable as I had hoped. I sent the heads and cylinders to George Coates to have them �cooked� and to have him assess the restoration potential. In due time, George called me with the bad news that it would be easier to start from scratch than try to restore the heads and cylinders. At that point, I figured the YT-2 was going to end up as a parts engine.

Photos 1 - 6

As the photos show, the heads and water jackets of this YT-2 were badly damage by salt water. The water jackets and heads are crazed with cracks (the really fine cracks don�t show in the photos) and pieces of the water jacket are missing. Also, I expect there was very little solid metal left in the cylinder walls. Previous efforts at restoration, undertaken in the early 1950�s, included drilling holes to arrest the cracks in the water jacket and �gluing� the water jackets together by brazing. Those efforts had no chance of success because the salt problem was not addressed first.

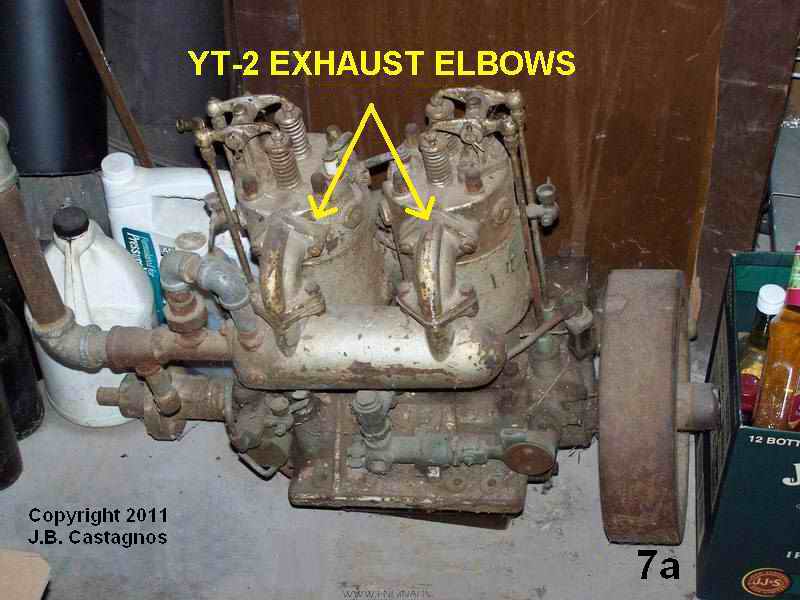

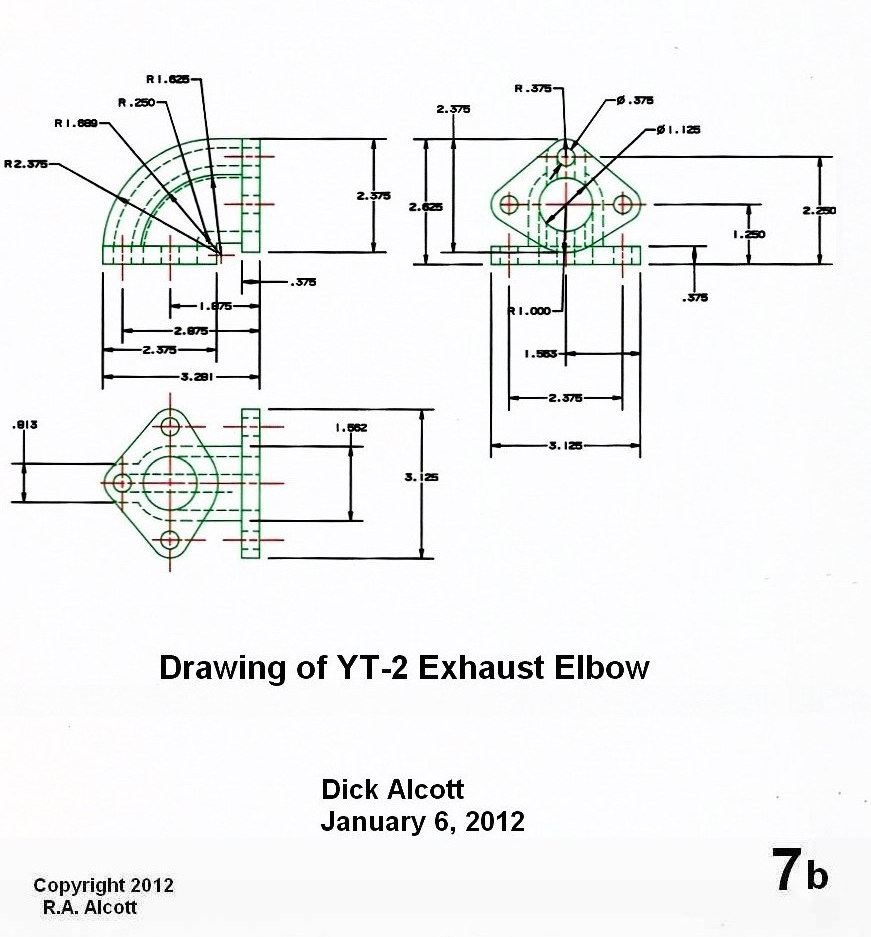

Photos 7a - 8

Unfortunately, the exhaust elbows that bolt between the heads and the cast iron wet muffler were missing when I got this engine. As you can see in Photo 7a (JB�s YT-2), the elbows add a great deal of character to the YT-2. Eventually, word got back to me that George was working on foundry patterns for the YT-2 heads and cylinders. I could hardly believe it. That got me thinking about the exhaust elbows. Naturally, my first thought was to e-mail Dick Day. Dick didn�t have any elbows and didn�t know of any available. I mentioned to Dick Alcott my intention to make some exhaust elbows out of two sizes of black iron pipe and the next thing I knew he was working out the details of making a foundry pattern for an elbow. Using an elbow borrowed from JB�s YT-2 as the guide, Dick made a drawing of the critical dimensions (Photo 7b). Photo 8 shows the foundry patterns Dick made from the drawing and the three elbows he had cast from those patterns.

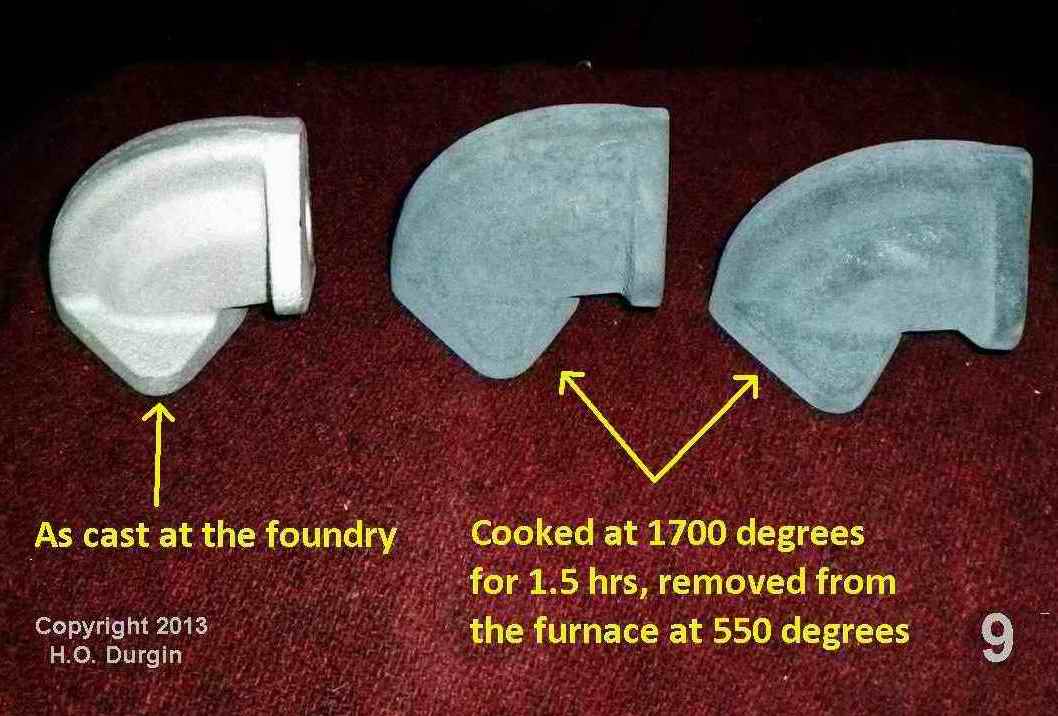

Photos 9 � 10

Dick quickly discovered that the newly cast elbows were so hard they couldn�t be machined. He surmised that the foundry removed them from the mold too soon after pouring. Rather than have new elbows made right away, I wanted to try heat treating the ones we already had in hand to see if they could be made amenable to machining. Dick conferred with a metallurgist who suggested the following recipe: Heat the elbows to 1700 degrees for 1.5 hours; turn the heat off, do not open the furnace, and wait for the furnace and elbows to slowly cool down to 550 degrees; remove the elbows from the furnace at 550 degrees. I loaded two of the elbows into my laboratory grade muffle furnace, dialed up 1700 degrees, and then followed through with the rest of the recipe. The heat treatment resulted in two easily machinable elbows. The end product is the two beautiful, new, YT-2 exhaust elbows shown in Photo 10.

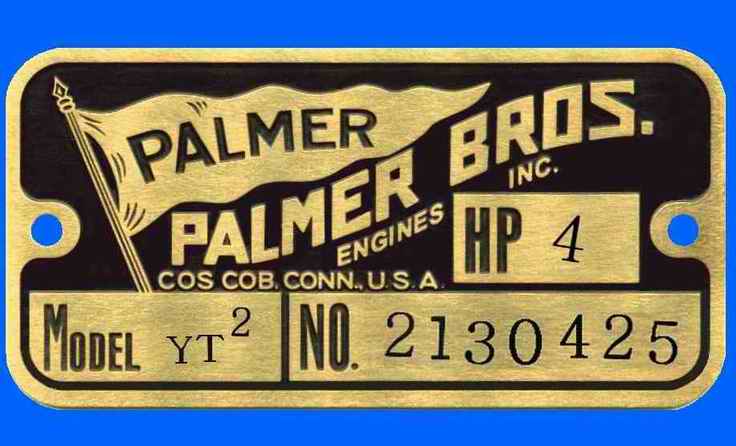

About a year ago, Jamie Hurry suggested going to PMA PhotoMetals in Phoenix for reproduction tags. I had PMA make some reproduction Knox tags for me several months ago and those came out just great. A few weeks ago I sent them some other tags to reproduce including the correct tag for a YT-2. The original tag was present on this engine in 1950 but apparently got lost later when pieces of the water jacket started falling off. Fortunately, I have 1950 documentation to and from Palmer indicating the original serial number for the engine. That documentation came to me along with the engine. PMA will stamp that serial number into the reproduction tag. I will post photos of the tag when I get it.

At one point, I was convinced this poor old piece of iron would never run again and was considering parting it out. Now here I am ordering a tag for it. I am very fortunate. |

Robert

Senior Member

Username: robert

Post Number: 618

Registered: 07-2003

| | Posted on Tuesday, October 29, 2013 - 11:12 pm: |

|

Dick, do we know roughly what proportion of the YT's had reverse gears? It surprises me that most of those we see do not, given that there is no way of reversing the engine and the only options would therefore be an adjustable pitch prop or an aftermarket reverse gear. |

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 838

Registered: 07-2002

| | Posted on Wednesday, October 30, 2013 - 01:49 am: |

|

Some engines are restored, this one is being resurrected, the Coates are known to make this happen. Bob Legnon straightened the copper manifold on his YT1. He welded a flange to a piece of pipe, welded a nut on the other end of the pipe. Filled the pipe with ball bearings to fit the ID of the manifold, greased things up bolted it to the manifold and pushed the bearings through, adding bearings as necessary. Smaller bearings pushed the larger ones out.If you try this on the twin manifold I would make a "spreader plate" bolted to the two flanges to keep the manifold from trying to straighten out. It would be best to anneal it first. |

George Coates

Senior Member

Username: george_iv

Post Number: 98

Registered: 07-2003

| | Posted on Monday, January 27, 2014 - 09:57 am: |

|

Update:

Thursday this week I will pick up 1/2 ton of casting sand, resin binder and start making and assembling 20 head molds of different flavors.

Its taken a little longer to get going, but it always does...

George IVy |

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 866

Registered: 07-2002

| | Posted on Monday, January 27, 2014 - 03:48 pm: |

|

Glad it's moving along George, keep us posted. |

Searcher

Senior Member

Username: searcher

Post Number: 601

Registered: 10-2004

| | Posted on Tuesday, January 28, 2014 - 02:17 pm: |

|

Here is the tag that will eventually be installed on this YT-2. The tag is a scan of one Ernie has for sale. I generated the letters indicating the model and the serial numbers on the computer but they are the correct numbers for this engine. I am trying to find a set of antique stamps in order to stamp the numbers and letters into the actual tag. Note that I tipped and skewed the numbers a bit. After looking at nine Palmer tags, I realized that eight of the nine had letters stamped in the model space that either tended to tip to the left or were vertical. The serial numbers, on the other hand, tended to tip to the right as does the number in the hp block (nerdy or what?). I suppose this indicates right handedness on the part of the people who stamped the tags?

I do have a point in mentioning the above though. If you ever have tags professionally made at PMA Photometals in Phoenix (and probably other shops) you can also have the shop etch the model letters, serial number, and hp onto the tag at the same time. They can easily duplicate the font and look of the hand stamped letters and numbers and even the flaws if you wish. You need to specify exactly what you want. Otherwise, the shop is apt to etch letters and numbers perfectly upright, evenly spaced, and all on the same line (yup, I wasn�t paying attention once). The hand stamping on old tags is never perfectly vertical and aligned and a tag loses a lot of character when the letters and numbers are perfect.

I recently sent three original tags to PMA Photometals to be duplicated. The tags have to be flattened so the shop can scan them into the computer. One tag I wanted copied was borrowed and it was also very fragile. Flattening the tag would certainly have broken it. I took a couple of very clear close up photos of the tag and provided dimensions. PMA did a great job working from the photos. In the future, I would probably opt to go the photo route rather than risk the loss of original tags.

As an experiment, I sent PMA a cast brass tag to see how well they could duplicate it using the etching process. The letters on a cast brass tag tend to be much more deeply defined than those created by etching on sheet brass. Most sheet brass tags are 0.032� thick with shallow lettering. For this experiment, PMA used 0.064� sheet brass which was very close to the thickness of the cast tag that I sent. The tag came out great and I was really pleased with it.

One other thing I learned, PMA stocks only naval (admiralty) brass and yellow brass. They will also make tags in red brass and bronze but you have to supply them with metal of the correct thickness.

|

rick intravia

Member

Username: everafter

Post Number: 25

Registered: 07-2011

| | Posted on Tuesday, January 28, 2014 - 02:53 pm: |

|

Nice work. Any chance one of the flavors might be for a bh-25 head? |

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 1089

Registered: 11-2003

| | Posted on Tuesday, January 28, 2014 - 07:54 pm: |

|

Henry Zerbarini, Palmer Bros. 1922-1964 worked in engine final test and he was charged with putting the serial number on the engine tag. They had a machine which could be used but he preferred to stamp the serial numbers by hand. He was not the only one who stamped the tags. Raynal Bolling Jr,

Palmer 1934 to 1968 also worked in final test in his early years often stamped the tags. Never did find out from Henry why he didn't use the tag stamping machine for all tags. |

Searcher

Senior Member

Username: searcher

Post Number: 603

Registered: 10-2004

| | Posted on Tuesday, January 28, 2014 - 09:56 pm: |

|

Neat piece of Palmer history. I'm glad they did stamp them by hand. Thanks |

George Coates

Senior Member

Username: george_iv

Post Number: 99

Registered: 07-2003

| | Posted on Wednesday, January 29, 2014 - 10:16 am: |

|

Dick, Your depth of knowledge of Palmer history never ceases to amaze me!

George IVy |

George Coates

Senior Member

Username: george_iv

Post Number: 100

Registered: 07-2003

| | Posted on Thursday, July 17, 2014 - 05:16 pm: |

|

|

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 938

Registered: 07-2002

| | Posted on Thursday, July 17, 2014 - 11:12 pm: |

|

You'd think Palmer was back in business, they look great. Is that a pair of YT-2 heads in the back? |

Engine Silo

Member

Username: enginesilo

Post Number: 4

Registered: 07-2014

| | Posted on Friday, July 18, 2014 - 12:29 am: |

|

Amazing work! I've always wondered what it would be like to have something patterned and remade, and now I know. Curious what something like that would cost to have remade from start to finish with the pattern and all. |

George Coates

Senior Member

Username: george_iv

Post Number: 101

Registered: 07-2003

| | Posted on Friday, July 18, 2014 - 09:08 am: |

|

Yep, there's one set of YT2s in the picture. More to come. I've got another 5 heads at the foundry of various flavors. First cylinder is there too. Hopefully the cylinders will go faster as far as machining and learning curve.

As far as cost, which is different than price of course, I've got 18 months invested in reverse engineering and pattern and mould making. I guess I'm worth $60k a year so at $18,000 each for the 5 usable heads in the picture, I'll never break even. And Dad is working for less than the Chinese do!! What are you willing to pay for a exact duplicate YT head? For sure, supporting the hobby is why we do what we do.

George IVy |

RichardDurgee

Senior Member

Username: richarddurgee

Post Number: 3346

Registered: 11-2001

| | Posted on Friday, July 18, 2014 - 10:42 am: |

|

*

It's Math

Outstanding talent + excellent work = beautiful cylinder heads !

* |

Richard Alcock

Senior Member

Username: raa

Post Number: 81

Registered: 02-2007

| | Posted on Friday, July 18, 2014 - 11:36 am: |

|

That is sure a great job you have done George. Hats off to you for a lot of work.

Dick |

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 1105

Registered: 11-2003

| | Posted on Saturday, July 19, 2014 - 12:45 pm: |

|

Congratulation George for a job very well done. A number of YT-1 and YT-2 should come back to life. It seems to me the YT-1 and YT-2 are much

desired by collectors. |

George Coates

Senior Member

Username: george_iv

Post Number: 102

Registered: 07-2003

| | Posted on Tuesday, August 05, 2014 - 03:01 pm: |

|

First one! |

Paul Gray

Senior Member

Username: paulgray

Post Number: 148

Registered: 05-2003

| | Posted on Tuesday, August 05, 2014 - 04:44 pm: |

|

Wow! Very nice. There is a bit of thought that went into the core boxes. And get a successful casting. Bravo... |

David W Flowers

Member

Username: aonemarine

Post Number: 18

Registered: 01-2011

| | Posted on Thursday, October 30, 2014 - 12:15 am: |

|

I just love the palmer YT engines, is there any part I can help reproduce? I would also like to buy a fixer upper to model off of to produce a model engine casting. |

Searcher

Senior Member

Username: searcher

Post Number: 625

Registered: 10-2004

| | Posted on Thursday, November 13, 2014 - 11:21 am: |

|

Here are some photos of one of the George Coates heads I have for my YT-2. The photos do not adequately depict the quality, fit, finish, and visual aesthetics of these heads � they are beautiful. They easily surpass the original Palmer heads in every way. The more I look at and handle them, the more I appreciate the complex pattern making, moulds, machine work, and care that went into manufacturing them. George, these are absolutely the best workmanship one could ask for. Thank you.

The last photo depicts a little surprise hidden in these heads. There is a capital G cast into the bottom of the spark plug chamber. It can only be seen by removing the spark plug and then looking straight down into the chamber. That is a real neat bit of detail.

|

Searcher

Senior Member

Username: searcher

Post Number: 626

Registered: 10-2004

| | Posted on Thursday, November 13, 2014 - 11:24 am: |

|

Last 2 of 6

|

George Coates

Senior Member

Username: george_iv

Post Number: 114

Registered: 07-2003

| | Posted on Friday, May 20, 2016 - 02:09 pm: |

|

Second mold set for the cylinders. Worked out a few bugs.

George

|

Bill Stoltz

New member

Username: 7bill

Post Number: 1

Registered: 05-2018

| | Posted on Monday, May 28, 2018 - 08:36 pm: |

|

Wow, great work. Did you achieve the finish product?

I have just recently acquired a YT-1 that needs a cylinder.

are any available? |