| Author |

Message |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1825

Registered: 11-2001

| | Posted on Thursday, September 25, 2008 - 09:17 pm: |

|

*

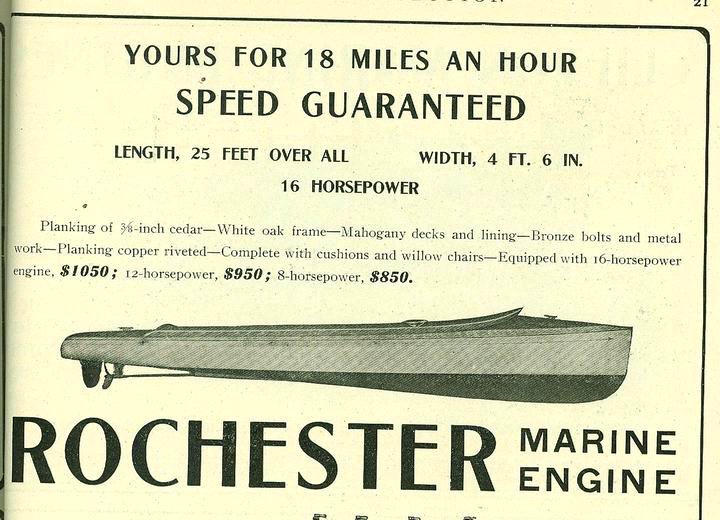

Rochester 1907

* |

bill_loveland

Member

Username: bill_loveland

Post Number: 4

Registered: 08-2009

| | Posted on Thursday, November 15, 2012 - 03:55 pm: |

|

Richard - did we ever figure out how the timer worked on this engine? |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2938

Registered: 11-2001

| | Posted on Friday, November 16, 2012 - 06:25 am: |

|

*

I looked through my info and couldn't find any

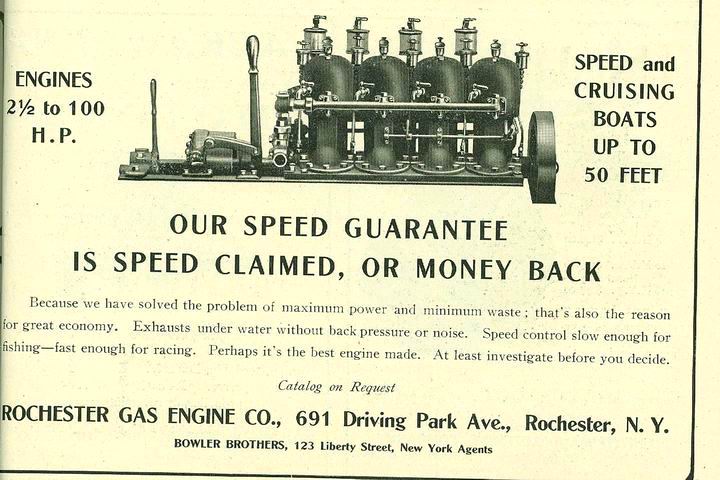

reference to the timers on these Rochester Multi's ? I could not find a photo of that side of the engine. it appears that the timer was on the aft port side and driven by the auxilliary shaft that drives the water pump ?

This is an early syracuse engine that may have similar set up ?

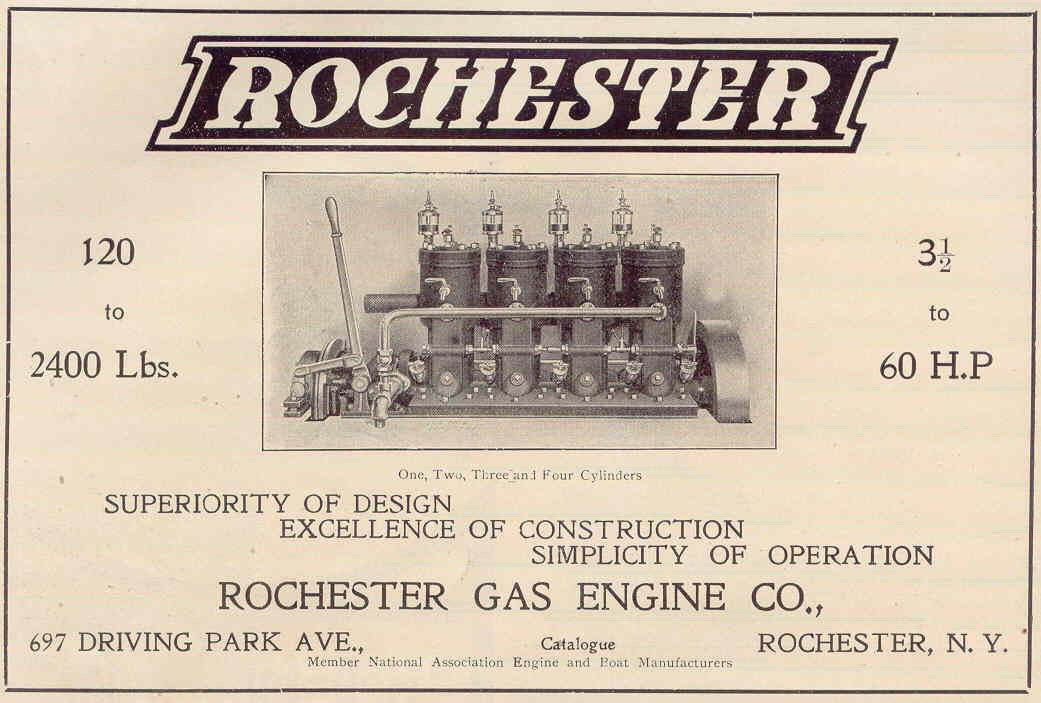

Looking at early Rochester eng info I found 1897

ad

first engines had removable heads 1904 ad

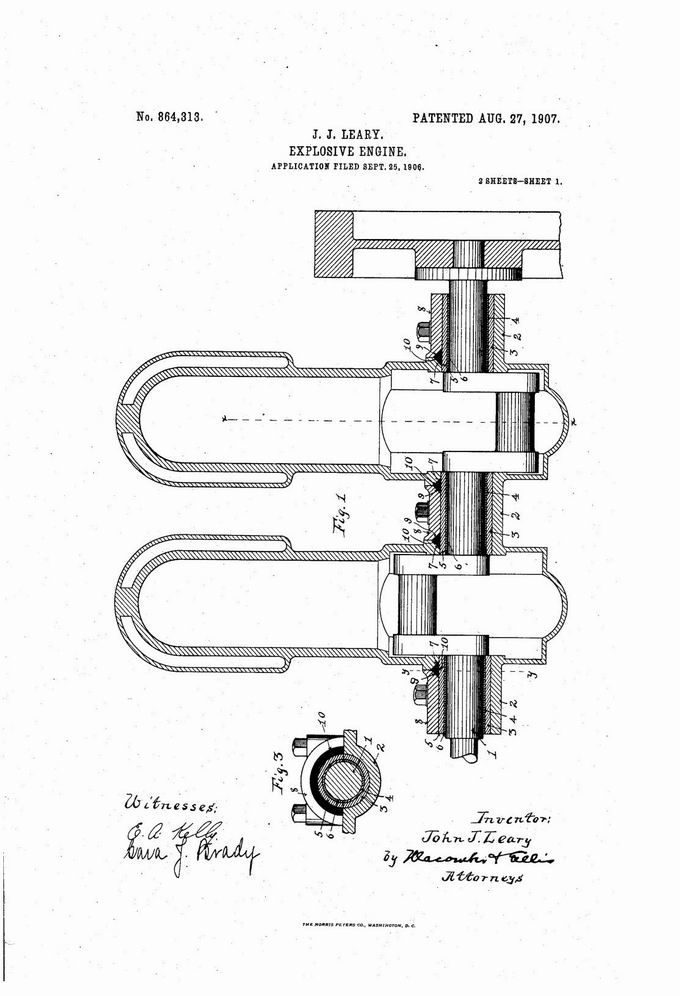

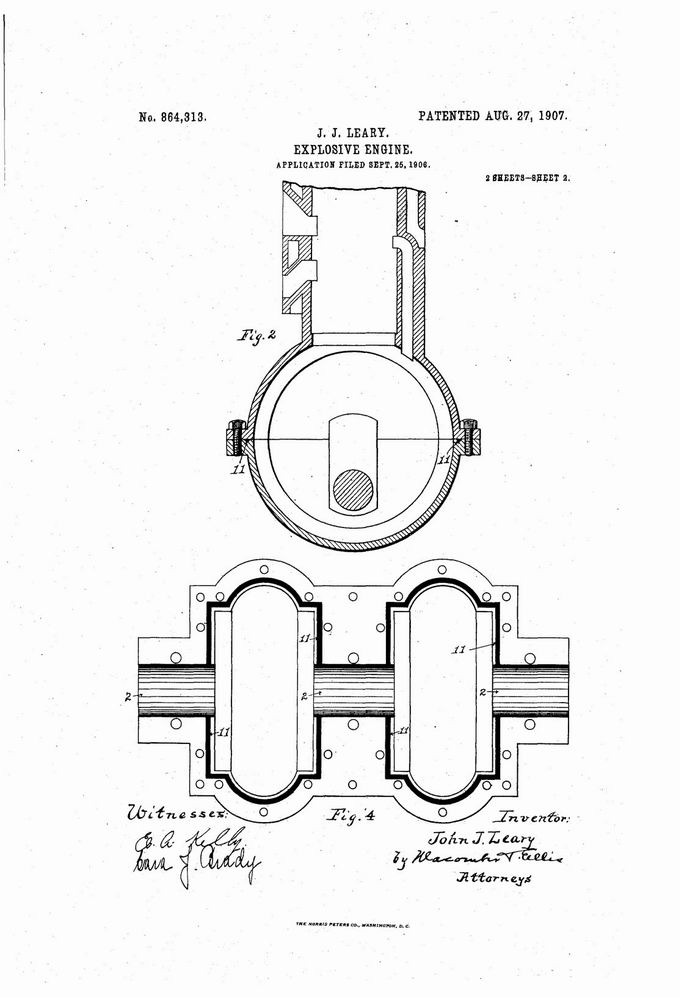

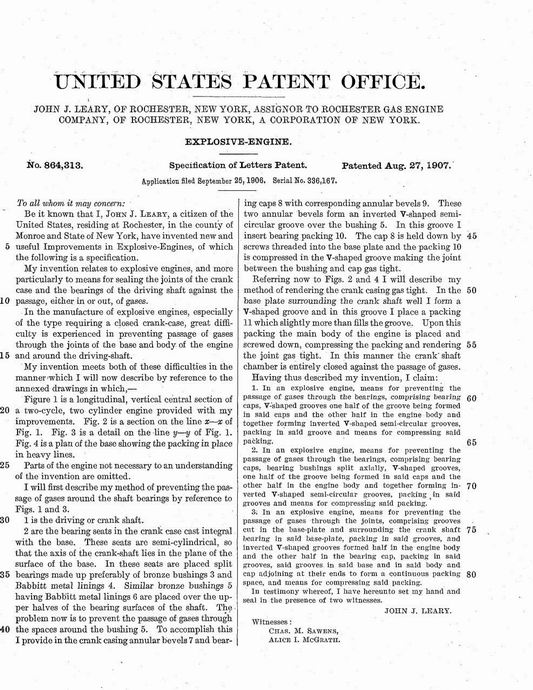

By 1906 John leary was vice president and engine designer at Rochester, he designed the headless

engine in the post above, applied for patent 1906.

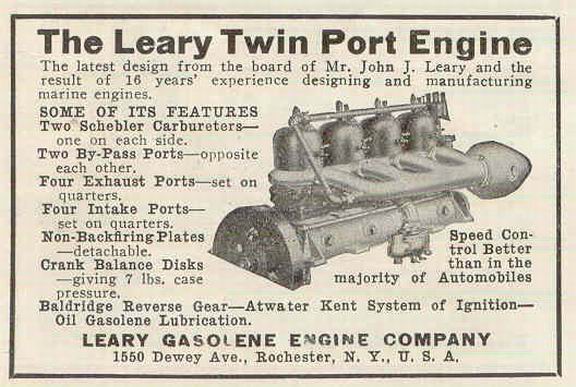

By 1910 John leary had left Rochester and mfgrd

a two port marine eng under his own name

Rochester's last year of production 1912 ca ?

How about few photos of your 6 cyl, I believe I may have seen that engine about 12 years ago in a warehouse on Long Island ??

* |

bill_loveland

Member

Username: bill_loveland

Post Number: 5

Registered: 08-2009

| | Posted on Friday, November 16, 2012 - 09:43 am: |

|

Richard - thanks for the info - I'll bet you're right about the timer and water pump drive.

The pic of the 1907 four cylinder shows a horizontal rod spanning cylinders 1,2 and 3, just under the water manifold. It appears to actuate a rod that disappears (in the photo) between cylinders 2 and 3. Any idea what that might be for? Possibly a cutout to open the priming cups on 2 and 3 to make starting easier?

Yes, mine is the motor that came from LI along with the four cylinder. It was headed to Doug Morin's shop when I just missed it at the Clayton Boat Show. Chased it the next day after work to Dave Rydell's home in Fredonia (?)(Dave hauls for the ABM, and others) and took a good long look. I had all my spare money at the time tied up in a Packard 4M2500, so I swung the lead to Steve Fox. So this Rochester went from LI to Clayton to Fredonia to NE Ontario. Eventually, Steve got my Buffalo and the Rochester landed in my garage at the cottage (near Clayton) where it got buried. Finally dug it out this fall and got some wheels under it and put all the loose pieces back on it so it's together and put it in more accessible storage. If I can ever dig out from under in my shop at home, I'll bring it back to Rochester and take it apart. It's missing internal components and the crankcase is probably a lost cause.

As for pics, I'm afraid these are the only ones I took on moving day.

|

sfxman

Visitor

| | Posted on Friday, November 16, 2012 - 09:35 pm: |

|

The base appears to be aluminum, not so. It's solid lead. Someone cast poured a lead base on directly under the original aluminum crankcase base which probably added 300 pounds of weight. If you could get the lead out (so to speak) without melting the babbitt bearings it would probably be worth something at the local recycler. I don't know what the current price per pound is for lead. |

bill_loveland

Member

Username: bill_loveland

Post Number: 6

Registered: 08-2009

| | Posted on Monday, November 19, 2012 - 11:23 am: |

|

Steve's right - the crankcase on this motor has been reinforced with lots of lead. Readily visible where the lead is absent are big cracks in the aluminum. I suspect that, once it's stripped and the lead is off, what's left will be good for nothing more than a pattern. To remove the lead, I hope to thermally cycle it and crack the bond. It's possible that the exposed aluminum will be robust enough to be welded but if not, how hard could it be to have another cast and machined? Besides, I suspect that any welding sufficient to the purpose will require line boring afterwards.

I'll take some pics this weekend when I'm up at the cottage and post them when I return.

Heck, I'll take pics of all my inboards. Put on your thinking caps, I've got lots of questions coming. |

ernie

Senior Member

Username: ernie

Post Number: 1593

Registered: 01-2002

| | Posted on Monday, November 19, 2012 - 11:50 am: |

|

Back in the 80's there was one in eastern CT with the lead reinforcement. If I remember correctly it had a 6 cyl Atwater Kent distributor vertical behind the flywheel. I wonder where it went and if this is the one. Or did they have crankcase problems and the standard repair was to bed them in lead. |

sfxman

Visitor

| | Posted on Tuesday, November 27, 2012 - 09:58 pm: |

|

The problem may well have been with the multi cylinders themselves. I talked to a guy who had worked at St Lawrence in the 1950's and he told me they did actually build 20 or so 4 cylinder 5X5 bore engines in 1918 or so but they were very hard to start and unless you had the timing set up perfectly they wouldn't catch. St Lawrence did build an experimental one off 6 cylinder (two three cylinder 5X5's joined on a common crankcase but the crankshaft was not strong enough or thick enough to handle the added stress and could actually twist while running so the timing would always be off. They tested one on the back of the shop truck with an airplane propellor and drove it around the streets of Brockville until the crankshaft broke. Aside from ruining the engine they also got a big fine from the police for public endangerment. I think with the sixes the builders did not change the dimensions or the strength of the crankshaft metal (which was viable for the smaller 1-2-3 cylinders) but simply couldn't handle the heavy loads of the 4-6 cylinders. |

bill_loveland

Member

Username: bill_loveland

Post Number: 10

Registered: 08-2009

| | Posted on Tuesday, November 27, 2012 - 11:09 pm: |

|

Maybe, but the Rochester only has these dinky little 3.75" pistons.

And Ernie? Must be a different Rochester six. No distributor drive on the front on mine. Instead, the rear cylinder is a different casting from the front five, with a big squared off boss for mounting something substantial, and two bolts above that on the water jacket.

|

bill_loveland

Member

Username: bill_loveland

Post Number: 11

Registered: 08-2009

| | Posted on Tuesday, November 27, 2012 - 11:17 pm: |

|

doggone it. I keep forgetting I can't add pics when editing.

Here's the rear cylinder:

|