| Author |

Message |

bcm

Advanced Member

Username: bcm

Post Number: 39

Registered: 11-2009

| | Posted on Wednesday, September 19, 2012 - 09:25 am: |

|

I�m looking for information about methods used for two cycle engines with reciprocating water pumps to regulate cooling water flow to increase operating temperature.

This to increase engine output, reduce carbon build-up etc.

thanks

Barry |

Audie

Visitor

| | Posted on Wednesday, September 19, 2012 - 01:19 pm: |

|

Barry, On our Louisiana Bateau's we use a simple in line water valve on the discharge side of the engine. You could put a "T" in the line if you want to put a temp gauge and set the water valve to the temp you want. Hope this helps, Audie |

audie

Visitor

| | Posted on Wednesday, September 19, 2012 - 11:05 pm: |

|

Barry, I must apologize for some incorrect information. I have my own bateau piped the way I earlier explained and have seen others this way but will change it to the inlet side. After talking to a friend he made me realize that it was better to put it on the inlet. That way if the valve gets totally closed it won't cause the pump to build high pressure in the engine and possibly damage something. |

mullins13

Member

Username: mullins13

Post Number: 21

Registered: 11-2008

| | Posted on Thursday, September 20, 2012 - 09:56 pm: |

|

Audie,

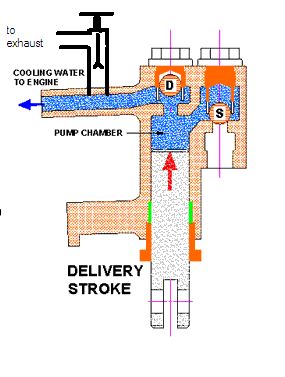

A friend of mine, who also uses a two cycle engine to power his boat suggests a cooling water by-pass set up as illustrated in the attached picture. He wonders if arrangement would allow the cooling water pump to supply maximum amount of water with out the risks associated with suction or discharge pipe restrictions.

Excess water not circulated through the engine could be piped and sprayed into the exhaust and used to provide additional exhaust cooling. Maybe this would help to dampen exhaust noise and at the same time reduce or maybe eliminate visible white water vapor exhaust.

What's your take on this?

|

audie

Visitor

| | Posted on Friday, September 21, 2012 - 05:51 pm: |

|

Problem I see here is valve would have be on the discharge side of the pump. Most two cycle engines have the water pump discharge bolted to the block and there is no way to install a bypass valve on those. My engine is a Lockwood Ash 8 hp and there would be no way to attach a valve that way to it. Any type restriction you put to control engine temperature would have to be closely monitored so as not to cause damage to the engine whether it's over heating or to much restrictive pressure. |

mullins13

Member

Username: mullins13

Post Number: 22

Registered: 11-2008

| | Posted on Friday, September 21, 2012 - 11:17 pm: |

|

Thanks for your input Audie. Certainly, there have been multiple variations on water pump design and thus would restrict installation of such a device. I agree that such a change in water flow would require close monitoring of engine temperature. However, it is fun to think about such things and potential design changes to accomplish optimal performance. |

mullins13

Member

Username: mullins13

Post Number: 23

Registered: 11-2008

| | Posted on Sunday, September 23, 2012 - 01:51 am: |

|

I was reminded that the very same water pump was used on single and multi cylinder engines....

Makes me think that my single cylinder would likely do well with half of its current flow. |

bcm

Advanced Member

Username: bcm

Post Number: 40

Registered: 11-2009

| | Posted on Sunday, September 23, 2012 - 02:38 pm: |

|

Wonder if any old two cycle engines exhibit factory installed systems to control cooling water flow, thus engine temperature.

Barry |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 724

Registered: 07-2002

| | Posted on Sunday, September 23, 2012 - 07:13 pm: |

|

The multiple cylinder engines with individual cylinders were hard to keep adjusted, temperature affected mixture and the cylinders seldom ran the same. Manufacturers started casting cylinders "en bloc" to reduce problems. In summer waters the cylinders ge hot enough around here, but the bases usually stay cold, this allows a lot of fuel to condense in there. |

bcm

Advanced Member

Username: bcm

Post Number: 41

Registered: 11-2009

| | Posted on Sunday, September 23, 2012 - 09:14 pm: |

|

I have two 3 � B x 4 S twin St Lawrence, circa 1925. The cooling water exit from the cylinder closest to water pump, to exhaust manifold is very restricted whereas front cylinder water exit is not restricted, apparently to balance cylinder temperature.

Cooling water from back cylinder flows into front cylinder so water temperature is already hot.

As reported by Mullins13, water pump is identical to pumps used with single cylinder engines so twins run hotter, as a result probably cleaner and more efficient. |

doctorbigdaddy

Member

Username: doctorbigdaddy

Post Number: 4

Registered: 10-2011

| | Posted on Monday, September 24, 2012 - 10:21 pm: |

|

I have a 2 cylinder 2 cycle Lockwood Ash and plan to install it in a 1920 St Lawrence Launch 18 feet waterline length. The boat has the exhaust coming out the stern . It is a typical St Lawrence canoe sterned craft . the exhaust is currently piped higher than the engine manifold by about 8 inches. Can I still inject the cooling water into the exhaust pipe or would it drown the motor? |

mullins13

Member

Username: mullins13

Post Number: 24

Registered: 11-2008

| | Posted on Monday, September 24, 2012 - 11:15 pm: |

|

Hello Doctor,

I would vote drown. See Subject 11 at goslowboat.com. Water lift muffler should work. |

doctorbigdaddy

Member

Username: doctorbigdaddy

Post Number: 5

Registered: 10-2011

| | Posted on Tuesday, September 25, 2012 - 07:11 pm: |

|

thanks for the help . the water lift muffler was something that i had never heard about. The timing of the water discharge to the engine exhaust was also a pearl that i would have never figured out in a million years. Thank you mullins13! |

mullins13

Member

Username: mullins13

Post Number: 25

Registered: 11-2008

| | Posted on Tuesday, September 25, 2012 - 09:57 pm: |

|

Pass the word about this very informative web site. Do you have thoughts on water flow? |

bcm

Advanced Member

Username: bcm

Post Number: 42

Registered: 11-2009

| | Posted on Wednesday, September 26, 2012 - 09:03 am: |

|

Doctor David,

Am attaching an image of a 1920s -1930 St Lawrence canoe stern launch. These were made by Doucet in Smith Falls Ontario,Canada and often used on the Rideau waterway between Kingston and Ottawa. Many are still operating in that area. St Lawrence twin 3 1/4B x 3 1/2S 2 stroke engines were/are the usual power plant, image attached. Wonder if this boat is the same as yours.

|

mullins13

Member

Username: mullins13

Post Number: 26

Registered: 11-2008

| | Posted on Wednesday, September 26, 2012 - 10:00 am: |

|

What am I seeing along the waterline on the port side (just below the captain's left hand)? There seems to be two water bumpers hanging off further aft. Maybe this is just another bumper with a reflection in the image??? |

doctorbigdaddy

Member

Username: doctorbigdaddy

Post Number: 6

Registered: 10-2011

| | Posted on Wednesday, September 26, 2012 - 01:32 pm: |

|

Dear BCM,

My boat is identical to the ones pictured.As it turns out i bought the boat from a gentleman in Kingston ,Ontario. it had been in dry storage for 30 years. The engine was gone . I have a 6 HP Lockwood- Ash that I have restored and plan to put in the boat. The hull is sound except the sternpost will need partial replacing and I plan to put in a cutlass bearing in place of the 3/4 inch galvanzed pipe that had been used HaHA.The hull required replcement of most of the ribs which i have done with white oak. There is some discoloration around the fasteners which I am hoping can be removed by oxalic acid and then revarnishing. I dont want to put glass over the wood , but below the waterline there is a "rock injury' that may have to be fixed with discreet dynel glass and epoxy. I would appreciate any information on the way the drive shaft was placed in these boats. My engine is far forward with a 7 foot X 3/4 inch Diameter shaft passing through three sets of bearings.The exhaust comes out above the waterline and engine manifold 8 inches! I would like to know how the boats pictured were arranged as to exhaust and drive shaft. Thank you so much for the information and especially the picture! |

rogerd

Member

Username: rogerd

Post Number: 9

Registered: 01-2010

| | Posted on Wednesday, September 26, 2012 - 04:43 pm: |

|

Just a little clarification. The skiff in the forground of the picture is a Dowsett built by the Dowsett Company of Portland Ontario. Pictured in Put Put are former owners Joe and Irene Fossey of Dispro fame. The boat in the background is a Dispro. Regards Roger. |

bcm

Advanced Member

Username: bcm

Post Number: 43

Registered: 11-2009

| | Posted on Wednesday, September 26, 2012 - 05:12 pm: |

|

Roger,

Thanks for clarification. Using correct spelling for Dowsett, found images on Clarion site of Joe's boat that show St Lawrence engine/exhaust installation.

Doesn't look like engine is as far forward as Doctorbd's boat. Also exhaust exit is not below LWL and not at stern as reported by Doctorbd ???

http://www.clarionboats.com/26-Dowsett-Motor-Skiff.html

Barry |

macspud

Member

Username: macspud

Post Number: 14

Registered: 03-2009

| | Posted on Wednesday, September 26, 2012 - 10:28 pm: |

|

BCM,

Sorry to butt in from nowhere. Having studied those photographs, I would say that the dimentions seem similar. It would appear that the engine sits amidships which would be about 7" forward of the stern tube, though the exhaust looks to exit the hull at the level of the manifold a few inches above the water line. It's hard to tell from the photos but would seem to me to be similar. |

jim_parrott

Senior Member

Username: jim_parrott

Post Number: 56

Registered: 06-2009

| | Posted on Tuesday, October 30, 2012 - 10:27 am: |

|

This is how Dick Gibbens would set up a cooling system. He always told me he wanted his engine running around 210-215 degrees. As you can see there is a valve at the pump inlet, and a thermometer near the outlet. There is another valve which regulates how much water dumps overboard. With this valve he could tune his exaust and verify that it was pumping water.

Jim   |

ernie

Senior Member

Username: ernie

Post Number: 1581

Registered: 01-2002

| | Posted on Tuesday, October 30, 2012 - 10:53 am: |

|

Neat plumbing however for salt water use you can't go above 147 deg F as the salt will start to participate out of the water above that temp.

Hope this helps

Ernie |

doctorbigdaddy

Member

Username: doctorbigdaddy

Post Number: 7

Registered: 10-2011

| | Posted on Tuesday, October 30, 2012 - 09:56 pm: |

|

Thanks Jim Parrot for the great pics. How does the valve on the pump overboard discharge keep the manifold pressure from exceeding the discharge pressure on the pump , especially in its suction stroke? What is the real purpose of pumping water into the exhaust ? Is it simply to cool the exhaust pipe as it travels through the boat? Or is the cooling effect of the discharge water creating a below atmospheric pressure in the exhaust like in a steam engine condenser and improving engine efficiency and power? |

mullins13

Member

Username: mullins13

Post Number: 27

Registered: 11-2008

| | Posted on Tuesday, October 30, 2012 - 10:16 pm: |

|

I like the thermometer that Jim has in place. Where would one get something like that? Or, was it fabricated?

Water in the exhaust quiets things down a bit.

I have never heard that salt would precipitate at higher temperatures. I thought that more salt would go into solution as the temperature rises. What happens at 147 F? |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 735

Registered: 07-2002

| | Posted on Wednesday, October 31, 2012 - 01:28 am: |

|

The thermometer is the type used to check air conditioner performance, they are available at auto parts stores, it held in place with a compression fitting and a ferule, the fitting must be drilled through. |

ernie

Senior Member

Username: ernie

Post Number: 1583

Registered: 01-2002

| | Posted on Wednesday, October 31, 2012 - 11:38 am: |

|

From the net on a marine diesel message board

The main problem with raw water cooling in a salt water environment is that the salt will begin to leach out of the water at about 160deg F. Most marine motors, especially diesel ones, want to run up around 180-190deg F. If you try and use salt water as a coolant at that temp the water channels inside the motor will eventually get clogged with salt/mineral deposits. The other choice is to run the motor at a lower temp, but with diesels, you invite all manner of other issues related to running too cold.

Yanmar salt/raw water cooled engines all have 147 deg thermostats in them as well as most outboards that have thermostats also use a 147 deg.

I remember as a kid on my Dads boat which had a 4 cylinder Gray which was raw/salt water cooled we used a valve to regulate engine temp. Everyone we talked to said DO NOT ever go above 150 deg f for the above reason. |

bruce

Senior Member

Username: bruce

Post Number: 334

Registered: 07-2002

| | Posted on Wednesday, October 31, 2012 - 02:04 pm: |

|

Contact dial thermometers held by spring tension around pipe are available through wholesale heating suppliers and graingers supply. Also,Petes-plugs are a male 1/4 pipe thread to neoprene gland that allows the insertion of a thermometer probe which can be left in place or removed at will with out leaking water. Also available from commercial heating supply houses. |