|

| Reducing Current through Timer COntacts |

| Author |

Message |

miro forest

Senior Member

Username: miro

Post Number: 605

Registered: 11-2001

| | Posted on Saturday, March 10, 2012 - 09:56 pm: |

|

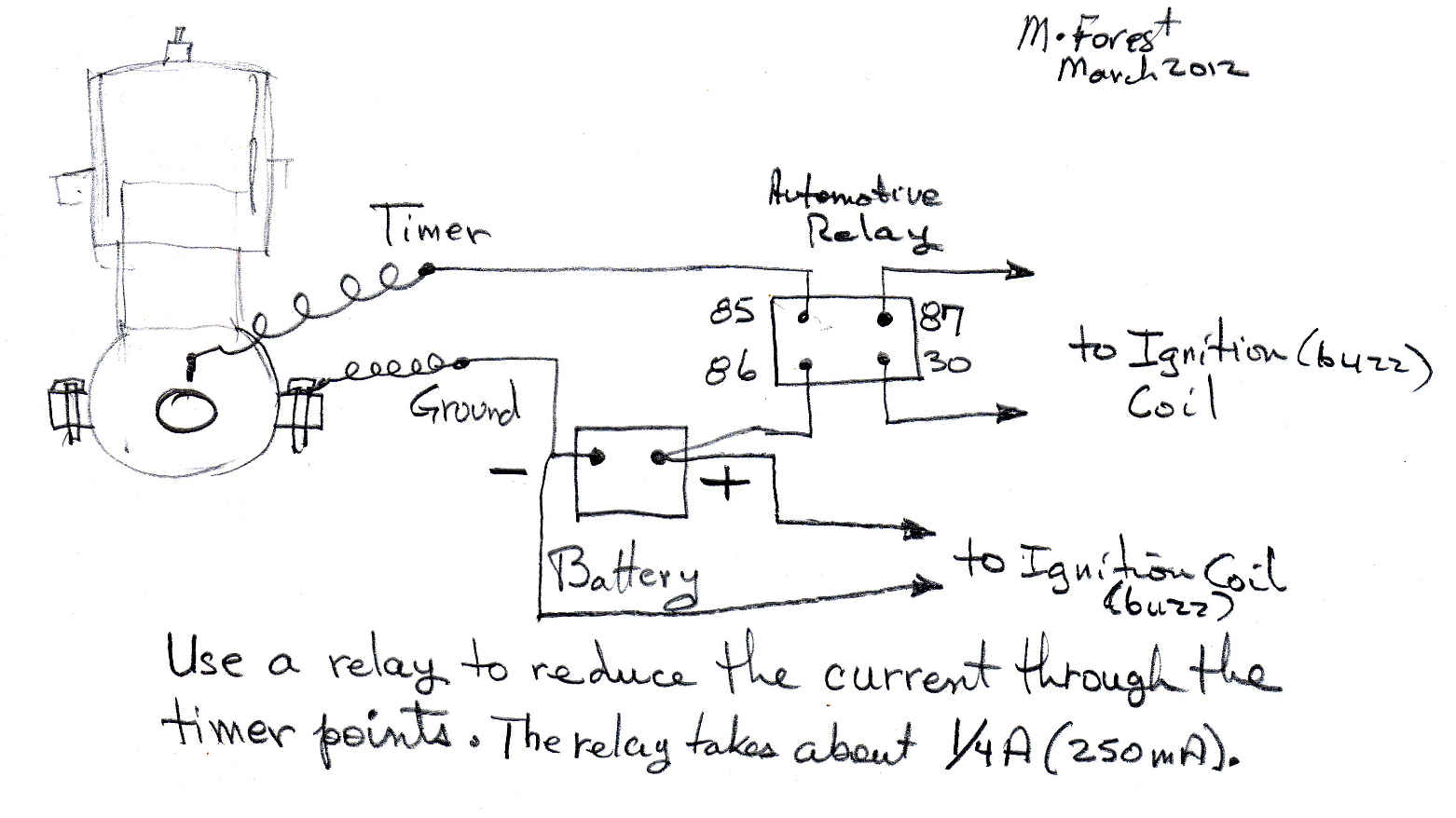

I've thought about ways to reduce the amount of current that flows through the timer

contacts in order to extend their life.

There are a number of solid state circuits that will

do the job, but these need special protection

against voltage spikes coming back from the

coil.

Others use devices where the original parts must be removed.

I came up with the idea of using the normally OPEN contact of the relay

used in the "JB coil".

The normally OPEN contacts are a proxy for the ( ancient and sometimes fragile) timer contacts.

Here is the circuit.

The relay takes about 1/4 A ( 250 mA) to close.

The speed of action of the armature in the relay

could be a limit on the speed of the engine.

But in most cases the engines run under about 1000 RPM, so it should be OK.

1000 RPM is 16 rev per second.

The buzz coils "sing" at about 500 cps or more.

In any event, the original timer parts can be left unchanged, but are less stressed by the current going through them.

The current for the buzz coils is usually about 1.0 to 1.5 A, so there is a 4 fold reduction

in the current.

This means there is a 16 fold reduction in the power the timer contacts are being asked to handle ( power is a square of the current).

In any event, I propose that this idea could be tried out at JB's camp visit in a couple of weeks

where there are engines and boats available.

It should be straight forward to do.

miro |

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 668

Registered: 07-2002

| | Posted on Wednesday, March 14, 2012 - 06:18 am: |

|

Miro, I keep spare relays and connectors, I'll try to make up a set, if I don't get it done it will be a good project for Thursday when y'all arrive. |

Ernie

Senior Member

Username: ernie

Post Number: 1480

Registered: 01-2002

| | Posted on Wednesday, March 14, 2012 - 08:39 am: |

|

I'm confused...

In the last 30 years I have never lost any timer contacts in a show engine or in actual use in my boats.

Additionally by dropping timer contact current you may have an issue with resistance at the contacts that doesn't show up with the higher current flow.

Why over complicate something? |

miro forest

Senior Member

Username: miro

Post Number: 608

Registered: 11-2001

| | Posted on Wednesday, March 14, 2012 - 09:30 am: |

|

Well, Ernie, over the past number of years, both the DisPro engine and the St Lawrence have had enough erosion of the timer points, that the engine speed declined .

I initially thought it was a carb problem, but as I later found out, it was an ignition issue traced to the timer points.

It is not a sudden failure, but a gradual, slow decline until one day, you say to yourself, - heck this engine used to work better.

The engine starts OK but won't get up to speed like it used to.

I agree with you , at shows, this really isn't an issue, but in a boat, it is.

In my boats, there little enough horsepower as it is - I didn't want to lose any more by having a lower top engine speed (850 RPM)

Removing a flywheel, while the engine is in the boat , is an experience, I'd rather not repeat (I've done it twice) so I undertook to find a way to protect the timer points.

Close inspection of the points ( the second time I took the flywheel off) revealed erosion on the points.

miro |

Ernie

Senior Member

Username: ernie

Post Number: 1481

Registered: 01-2002

| | Posted on Wednesday, March 14, 2012 - 12:17 pm: |

|

Miro,

I would rather maintain the timer contacts then add a bunch of electrics. Once a year should be often enough to inspect the contacts. However that is my preference as I live in a world FULL of automotive electronics and refuse to have my toys electrically complicated. My newest boat (1970) is diesel with totally mechanical everything except the starter and alternator.

My current launch with a Gray single cyinder has not had any attention to the timer in the last 4 years so timer style may come into play too.

Just my 2 cents worth

Ernie |

Keith Billet

Senior Member

Username: keith

Post Number: 351

Registered: 02-2002

| | Posted on Wednesday, March 14, 2012 - 02:02 pm: |

|

From what I've been told, you need to keep a little oil on the contacts of a Dippy motor. Reduces arcing and thus erosion. |

Allen Flux

Member

Username: allenf

Post Number: 11

Registered: 02-2011

| | Posted on Wednesday, March 14, 2012 - 05:19 pm: |

|

The biggest advantage point systems have is their simplicity. There are very few components and it�s mostly mechanical so you can see how everything works. It�s easy to wire up and the engine looks clean without extra wires and boxes. Rarely will a points ignition leave you stranded looking for parts. It most cases you can scratch the points clean with a pocket knife and gap them with a matchbook and be on your way. Since there are no electronics, a points system is not affected by electrical interference. You can run solid core plug wires and the engine won�t miss a beat.

http://www.gofastforless.com/ignition/points.htm |

miro forest

Senior Member

Username: miro

Post Number: 609

Registered: 11-2001

| | Posted on Wednesday, March 14, 2012 - 11:38 pm: |

|

I have religiously use light oil on the DisPro engine points, and yet, over the years, the points did erode. Maybe I use the boat too much.

The ground point on the DisPro is mounted on a fibre insulating ring BEHIND the flywheel. It is flat, about the diameter of an Aspirin pill, and rubs against the fixed point on the timer arm.

The only way to get at the the points is to pull the flywheel off while the engine is in the boat, - as I said - it ain't a job I relish.

I think Ernie made a very good point ( pun intended) about the style of the timer - the Gray timer is wonderful, and easy to work on.

The DisPro - not so much. The St Lawrence is a bit better, but not by much.

miro |

John Davis

Senior Member

Username: johnny

Post Number: 442

Registered: 03-2006

| | Posted on Thursday, March 15, 2012 - 11:38 am: |

|

What type of material are you using for contact points?

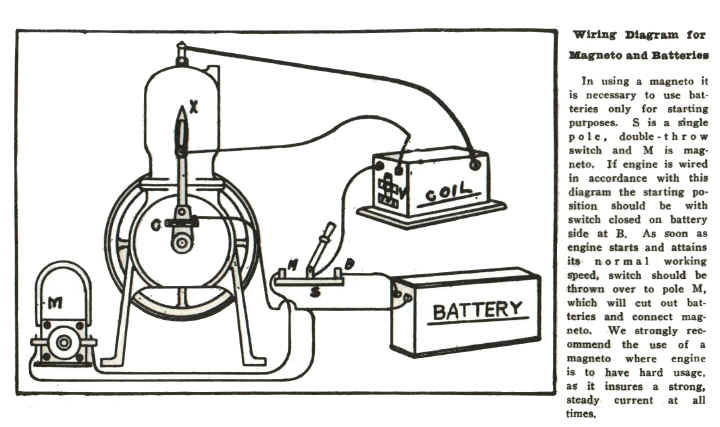

You could always get you one of the old Wizzard magnetos & drive it off the flywheel or crank. They put out (AC) alternating current. Points last much longer using AC. You start the engine with a battery then switch over to the magneto.

|

miro forest

Senior Member

Username: miro

Post Number: 611

Registered: 11-2001

| | Posted on Thursday, March 15, 2012 - 11:56 am: |

|

The material for the contact is brass. That's what the originals used.

I like the idea of a motor driven power source ( and AC no less), but there is precious little room in the engine area of the DisPro. Heck, there's little room enough for the passengers / captain.

Maybe I should leave a note in the boat for the next guy / gal that will own it, to use bronze for the contact, when they eventually

pull the flywheel :=}

miro |

|

|

|

|