| Author |

Message |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2759

Registered: 11-2001

| | Posted on Sunday, February 19, 2012 - 03:11 pm: |

|

*

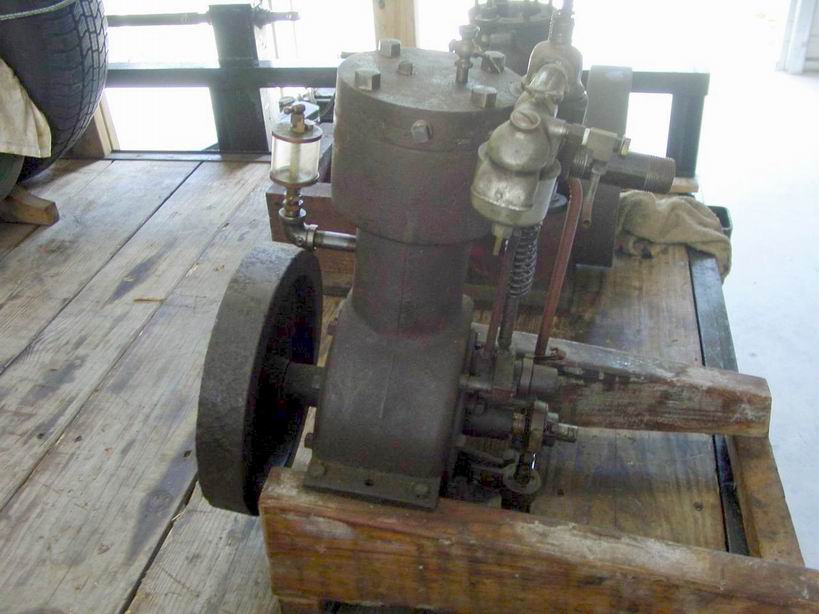

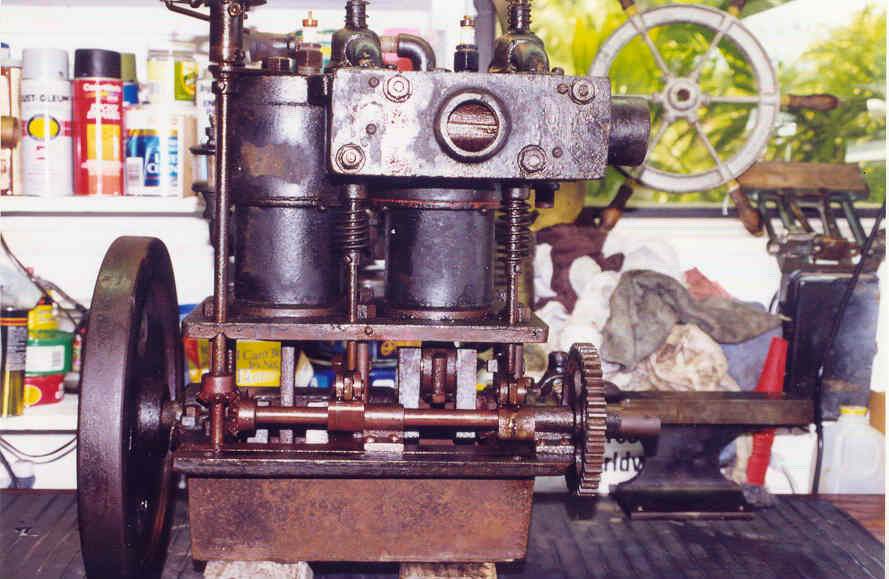

This engine has been a challenge to put a mfgrs date on for the last 10 years ?

1906 is the earliest photo from an ad or catalog i've seen and the common design is the spark plug in the head vertically, this eng has the plug horizontal in the valve chamber ?

Dunn first mfgrd engs in 1902 and quite a bit of info to substantiate that but no photos or illustrations have come to light yet ! Have to assume this eng falls in that 1902-05 era ??

Any info would be appreciated !

* |

ernie

Senior Member

Username: ernie

Post Number: 1468

Registered: 01-2002

| | Posted on Monday, February 20, 2012 - 02:29 pm: |

|

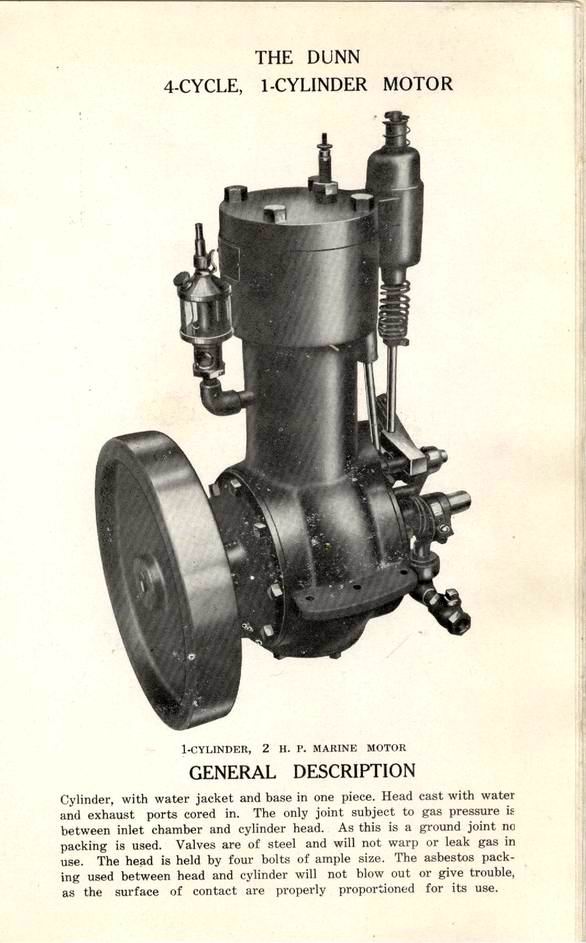

Richard to confuse you more...the casting quality in your pics doesn't even look like a Dunn. Most of them looked like they used dirt or mud and not casting sand. Compare your pics to the ones below. Also note the radius on the bottom of the water jacket. The one in the pics below is so sharp you could cut your finger on it. Not a nice radius like the one above. Also note the counterweighted flywheel. The water pipe on yours looks like a modern replacement. Note the differences in the 2 pipes. Flywheel is counterwieghted too.

This isn't my engine I just picked it up for another OME guy. Looks original and I am sure it would run like it is. It has so much compression it wll be hard to start. I suspect the blue is factory. The tag is just Dunn Ogensburg, NY

Enjoy the pics

Ernie

|

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2760

Registered: 11-2001

| | Posted on Tuesday, February 21, 2012 - 12:23 pm: |

|

*

Ernie

Thanks for the response and photos !

I have 1908 catalog a 1910 and a 1916, in all of those the single engs all have solid flywheels, I scanned all of my photo files and all single dunns were also with a solid flywheel,

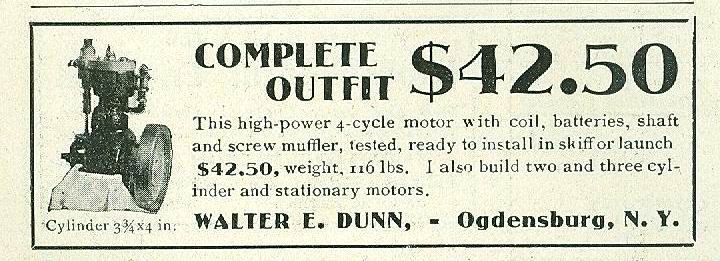

this is earliest ad so far 1905

This is 1916 catalog single{c16single}

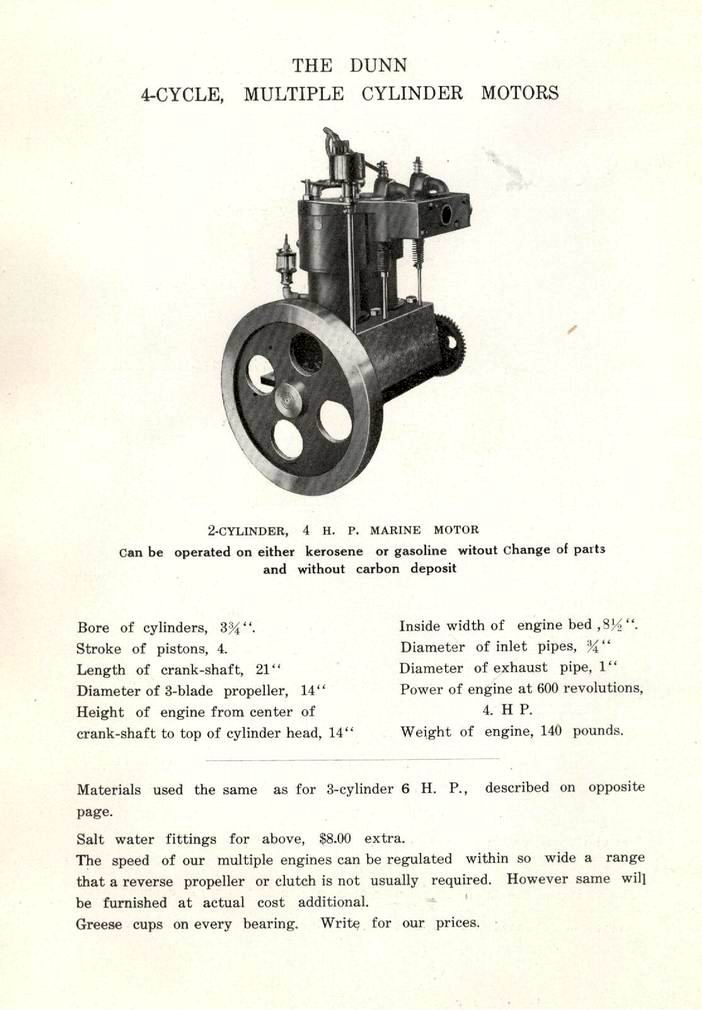

The 4 hole wheels show up in the 1916 catalog

on all of the multi's .

I will try to find ads with a single with 4 hole wheel !

Some of the rather crudeness of the castings on the engine in question may be surface rust that is accentuated by the flash when photo was taken, although some of these early castings were

rough, look at the crankcase on the blue single above ?

This is 4 hole twin that I have, The crankcase looks as if it was poured in a shovel dug hole in the garden ?

I found some of the very same blue on this twin that is on the single in above photos!

Without a lot of detail Walter Dunn probably got his machinist training at local steam engine mfgr and made engs while not yet formally in Business in 1902 its possible the eng in question was one of his earliest attempts prior to 1902 ??

In need of a special broom that can sweep confusion away !

* |

ernie

Senior Member

Username: ernie

Post Number: 1469

Registered: 01-2002

| | Posted on Wednesday, February 22, 2012 - 08:43 am: |

|

Richard,

You state assume which is correct. I don't think the year should even enter into it until someone comes up with an add with a good pic.

Earlier or later or whatever??? It could have simply been one they built to confirm the easiest way to make the castings. Or it could be the first style or a later style and they decided that there was way too much iron used in each engine with the larger crankcase. As to the flywheel does yours have counterweights inside? If so that would equate to a non counterweighted flywheel. The castings are for sure a lot nicer. Simply put your engine has a completly different crankcase, head and flywheel. Note the differences from the pics you posted to these. The crankcase is a lot larger. Note difference compared to the end housings. Also note the bulge on the blue engine in front of the timer etc. This is for cam gear clearance inside due to the smaller dia crankcase. Oh and if the water pipe on yours is original it is a late engine...chuckle chuckle you do have some nice old fittings to put on it when you restore I hope

|

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2765

Registered: 11-2001

| | Posted on Wednesday, February 22, 2012 - 05:26 pm: |

|

*

I think the answer is finding earlier than 1905 info ?

I don't believe the eng was a casting test etc because it had a tag on it and the dimensions of it and screw holes match other Dunns, seems they wouldn't have tagged it unless sold on the market ?

The crankcase is larger than any I have seen so far but then again technology advances moved to smaller or less volume two stroke crankcases, some even had machined fillers that restricted volume resulting in better RPM and power ?

I have not had this one apart to see crankshaft, in fact I dont think the lower end of this engine has ever been apart. Another tell tale is the square headed bolts on the crank flanges and timer-they all match-look original,all technolgy on these old timers seemed to progress away from the square head bolts in first few yrs of 1900's ??

Refering to the anachronistic brass water pipe fittings I haven't seen a Dunn single with the inlet in the starboard aft side, all catalogs and photos of later engs show port aft side ??

Still seems the more I learn the less I know !

Thanks again for photos and input !

* |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2766

Registered: 11-2001

| | Posted on Wednesday, February 22, 2012 - 08:30 pm: |

|

*

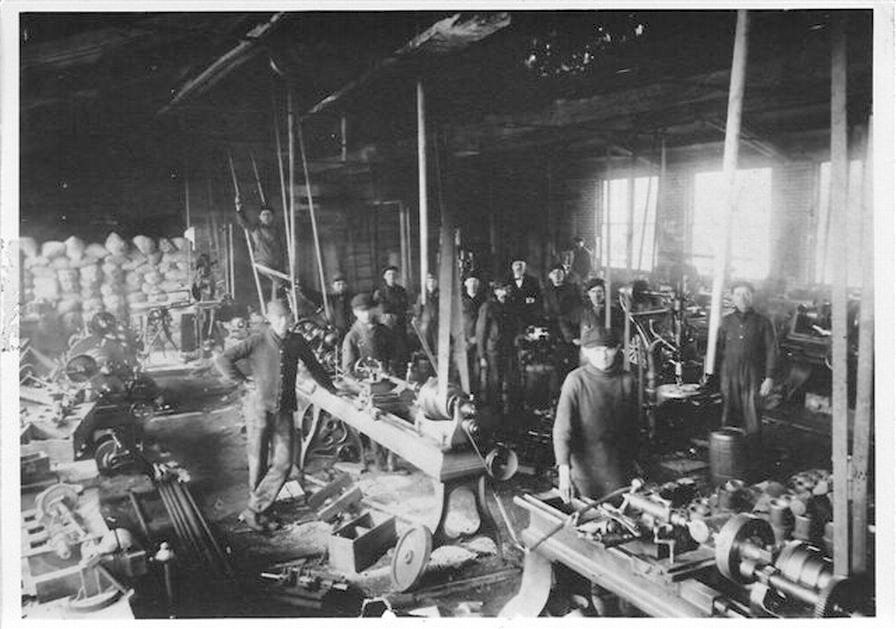

Have been looking through a lot of early Dunn history.

Thought many here would like these photos.

Walter Dunn in the auto he made 1915

Dunn factory works 1909

Dunn Foundry

Walter Dunn Headstone Ogdensburg, New York

* |

ernie

Senior Member

Username: ernie

Post Number: 1470

Registered: 01-2002

| | Posted on Wednesday, February 22, 2012 - 09:17 pm: |

|

Keep looking you are good at it

Ernie |

speleausmining

Member

Username: speleausmining

Post Number: 28

Registered: 10-2010

| | Posted on Wednesday, February 22, 2012 - 09:45 pm: |

|

Varriation in casting could be the difference in Foundary or materials. Is it at all possible that the early, or late, engines had the castings outsourced to another foundary. Also changing your souce of supply for casting sand can have a direct result on the quality of the finished castings. Even different people packing the sand can result in different casting quality. Of course the other possibility is a difference in the ammount of finishing that was done on the castings. Though theres deffinately differences in the two engines I think theres enough similarity to be fairly confident they share the same DNA. |

john_archibald

Senior Member

Username: john_archibald

Post Number: 180

Registered: 08-2006

| | Posted on Thursday, February 23, 2012 - 08:09 pm: |

|

Ernie,

In 1973 I worked for the New Jersey Zinc Company at their Sterling Mine in Ogdensburg, New Jersey. I was 23 at the time. Seems like yesterday in some sense.

It is now an underground mushroom farm producing some really good quality mushrooms. Mine is not operating. The mineral of interest was wilhemite which is a silicate of zinc. ZnSiO4 if I'm not mistaken. It's been a long time since I had mineralogy. Too lazy to Google it right now, but you can. Under UV light it glows with a very bright "stop and go light" green color. It is a deep brown color without the UV light. Lots of somewhat rare minerals in that mine.

I actually did "square set mining" there. That's quite rare as a mining method these days, but we did it there with 10 X 10 timbers 7 feet long and you had to be able to carry one of those around yourself. Brute force mining at its level best. I worked on the 2350 Level; 2,350 feet below the surface.

Archibald |