| Author |

Message |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 648

Registered: 07-2002

| | Posted on Friday, January 20, 2012 - 07:39 pm: |

|

Dave Deardorf sent this engine home with me to get it running. It had been converted from a piston trip igniter to spark ignition. I was able to start it on the spark plug by putting oil in the cylinder, once stopped it wouldn't start until you added oil. Compression was low. I fabbed up a piston trip and was able to start it with the oil. You could see the piston flopping if you moved the crank with the head off. After removing the piston I measured and found it 3.515", the bore was 3.535". I honed the cylinder to 3.540" and made a new piston and rod. Modern automotive rings sealed well, after assembling it started first crank. The next problem is getting it to slow down, with the piston trip you need some advance to get the ignitor to open quick enough, with the throttle closed it still runs fast. I'll start checking for air leaks. Below is a youtube of it running.

http://www.youtube.com/watch?v=qqdIdbom1pk&NR=1&feature=endscreen |

gregoryan

Senior Member

Username: gregoryan

Post Number: 90

Registered: 09-2004

| | Posted on Friday, January 20, 2012 - 08:30 pm: |

|

OMG! I have observed putt putt engines for nearly 30 yrs, and Never knew of an oscillating combustion engine!! - only knew that model steam engines used this design as it allows a simple construction of a double-ended cylinder [sealed chamber each end], as a simple connecing-rod can exit thru the bottom chamber's gland.

From what i can imagine from the angle the vid is shot from; the exhaust, and inlet come thru the pivot point bearings, so-as to allow a still boss to pipe the exhaust from, and to keep the carbie still.

Are there other engines around like this? I would like to see more pics if possible please.

I can imagine reasons to this design;

*The crankcase and it's bearings are not needed to deal with aspiration's compression/ vacuum, and the presence of [inadvertent] anti-lubricating petrol.

*It is a lower profile engine than the cross-headed type [ articulated piston/connecting-rod thru a gland] which also avoids it's aspiration thru the crankcase.

Thanks for making the vid! |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 649

Registered: 07-2002

| | Posted on Friday, January 20, 2012 - 08:44 pm: |

|

It's my guess that this was manufactured by a steam engine company that saw the end of steam coming and tried to get into the gas engine business. The intake and exhaust are on the frame part of the bearing. There's a check valve on the intake side, it's a two port design. I brought the camera to the shop when I was assembling it, battery went dead after the first shot. I wanted to take pictures of the ignitor and piston. I'll get some tomorrow. |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2741

Registered: 11-2001

| | Posted on Friday, January 20, 2012 - 10:13 pm: |

|

*

Excellent work J.B. !

You've used your special magic once again to bring another rare and unique old engine back to life !

* |

kkinney

Member

Username: kkinney

Post Number: 16

Registered: 04-2011

| | Posted on Friday, January 20, 2012 - 11:21 pm: |

|

I remember seeing that engine on your trailer at Portland last summer. Really great to see it running. Thanks for sharing.

Keith |

ernie

Senior Member

Username: ernie

Post Number: 1463

Registered: 01-2002

| | Posted on Saturday, January 21, 2012 - 09:25 am: |

|

Glad to see it fixed! Nice work. I owned it for years and just never had the time to make it right. There is a story on it in GEM from back in 86 or 87. From what history I could find it was made in Copper Cliff, Ontario by a rather eccentric inventor and there were 6 of them. As the story goes the gent that made them ultimatly electrocuted himself attempting to recreate one of Nikola Tesla's devices. They were made to be put in "lumber pointers" of about 26 feet. JB keep your eye open for a casting mark that looks like an Eiffel Tower with 1 straight leg. The casting mark was on the bottom head and possibly other places. On this engine the bottom head was replaced long before I got it. I also have a couple of extra pistons somewhere. The water pump is from a 3 hp Acacia. There was no pump on it when I got it.

Ernie |

robert

Senior Member

Username: robert

Post Number: 468

Registered: 07-2003

| | Posted on Saturday, January 21, 2012 - 03:04 pm: |

|

Very interesting. With the water pump moving at that speed it must have run awfully cold and worn out the packing awfully quickly as well! And of course it shakes worse than any other two cycle. |

ernie

Senior Member

Username: ernie

Post Number: 1464

Registered: 01-2002

| | Posted on Saturday, January 21, 2012 - 03:57 pm: |

|

Finally dug the guys name out of the cobwebs in the back of my brain

Henry LaTour

Actually the water pump doesn't move any faster than it did on the Acadia. As to shaking it needed to be attached to something or on something soft. |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2742

Registered: 11-2001

| | Posted on Saturday, January 21, 2012 - 06:26 pm: |

|

*

2003 Post. Odd Ball Engines

http://www.oldmarineengine.com/discus/messages/1/2338.html

* |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2744

Registered: 11-2001

| | Posted on Monday, January 23, 2012 - 12:11 am: |

|

*

J.B.'s post

The first photo shows the piston trip externally, next the old piston, the staionary point of the ignitor, insulated and angled so timing can be adjusted, then the moving arm and the top of the new piston.

* |

billschaller

Senior Member

Username: billschaller

Post Number: 483

Registered: 12-2003

| | Posted on Monday, February 06, 2012 - 11:21 am: |

|

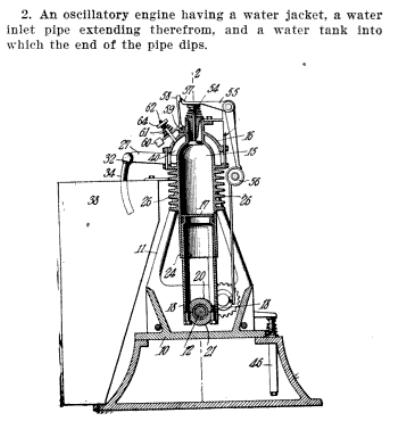

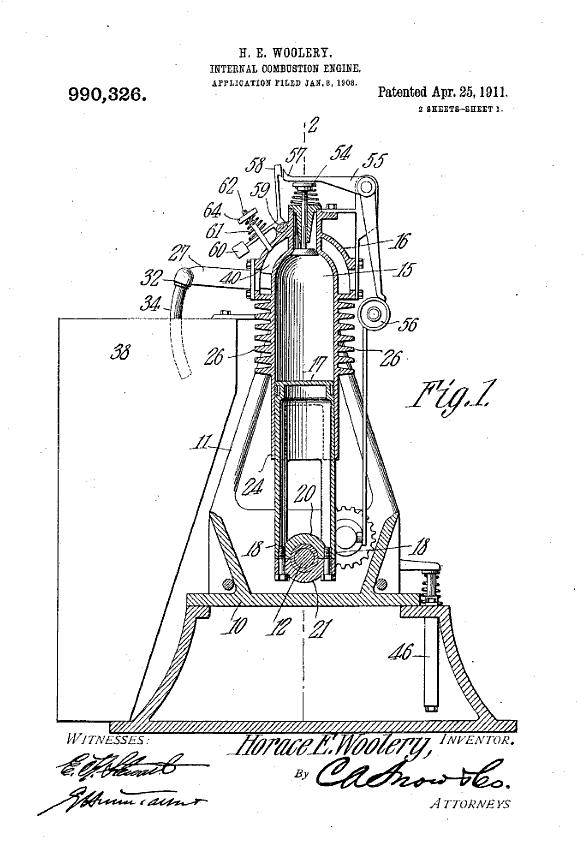

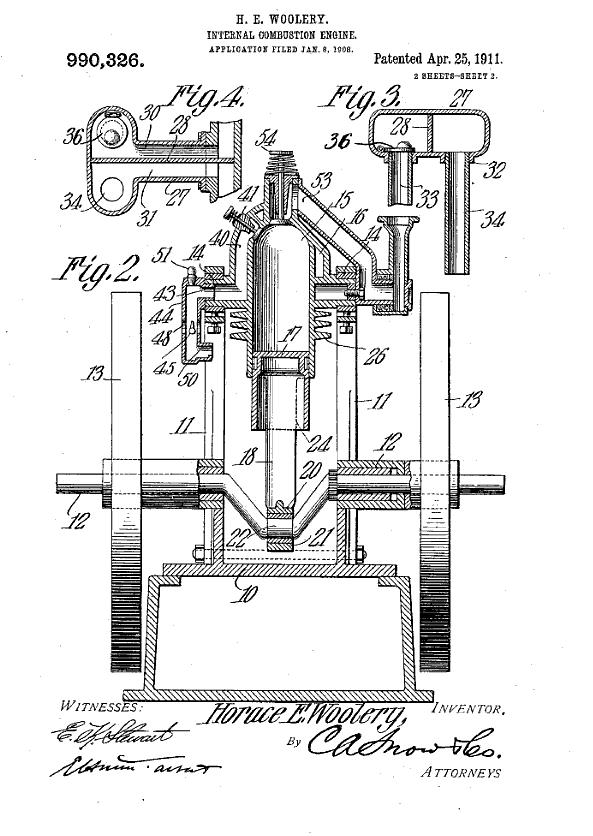

Horace Woolery, who worked for Fairmont motors, who made a number of marine engines, and then started his own company in Minneapolis to make Railroad motors, patented the following:

|