| Author |

Message |

walt_ansel

New member

Username: walt_ansel

Post Number: 2

Registered: 12-2011

| | Posted on Sunday, January 08, 2012 - 10:12 pm: |

|

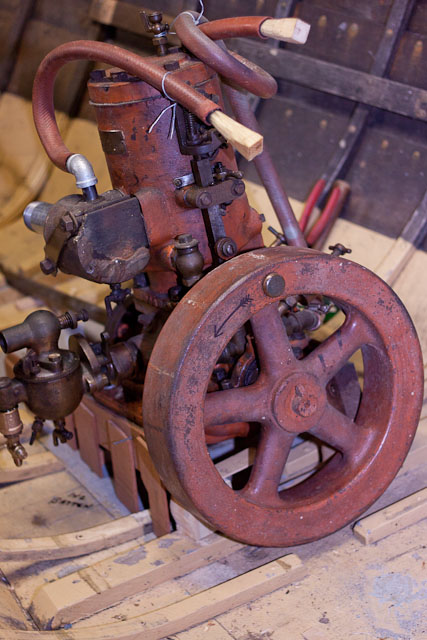

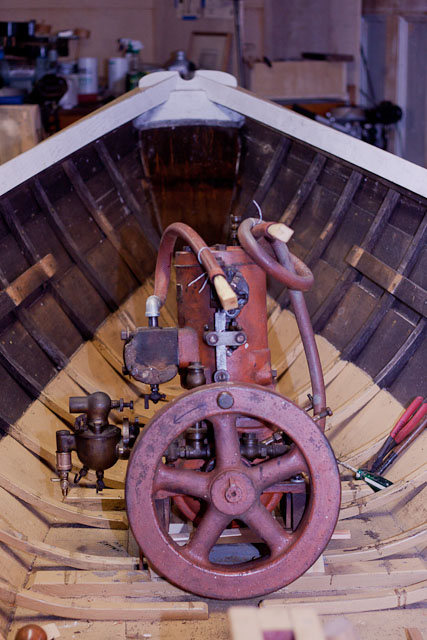

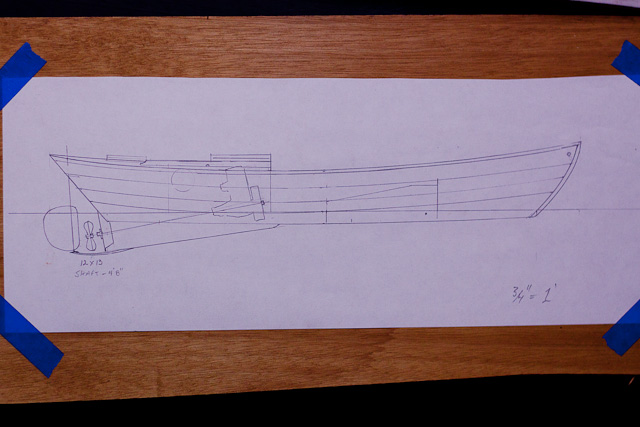

Here are pictures of patterning for a skeg/shaft log and beds for installing Ansel's 3 hp Mianus in an 18' dory

|

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 644

Registered: 07-2002

| | Posted on Monday, January 09, 2012 - 09:54 pm: |

|

I'd go ahead with it. Is this a new installation or a repair? |

walt_ansel

New member

Username: walt_ansel

Post Number: 3

Registered: 12-2011

| | Posted on Tuesday, January 10, 2012 - 08:54 pm: |

|

Hi JB,

Its a new installation. The dory had an outboard well that my dad removed. Thats what the square hole is from in the last picture-I've got to plug this with 1" pine.

Could I use a dry exhaust vented underwater? I was going to cool the engine with fresh water in a copper pipe keel cooler.

Thank you - Walt |

solarrog

Senior Member

Username: solarrog

Post Number: 510

Registered: 03-2002

| | Posted on Tuesday, January 10, 2012 - 09:57 pm: |

|

Hi Walt

You have peaked my interest. What type of outboard was on this boat?

I collect very early outboards

Roger |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 645

Registered: 07-2002

| | Posted on Wednesday, January 11, 2012 - 06:27 am: |

|

Dry exhaust gets very hot, venting under water will have back pressure possibly making it hard to start. Outboards have a vent above water to relieve pressure when sarting, water exits with this to quiet it while running. We had an outboard at my dad's shop when I was young, Tuned it up, ran fine. Wouldn't start when launched, bees had plugged the vent. I would consider a second pump driven from the prop shaft for exhaust cooling water. A piston pump would pump forward and reverse, a gear pump can be plumbed with four check valves to pump the same direction with either rotation, do you plan to reverse the motor? |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 646

Registered: 07-2002

| | Posted on Wednesday, January 11, 2012 - 06:33 am: |

|

These engines shake quite a bit, looking at your engine support I would make then longer and notch and fit them around the ribs, bed them in with a filler, maybe epoxy. |

kerrigan

Advanced Member

Username: kerrigan

Post Number: 41

Registered: 06-2008

| | Posted on Wednesday, January 11, 2012 - 06:38 pm: |

|

How do you plan to mount the rudder? There are many ideas on http://www.google.com/search?q=rudder+post&hl=en&sa=G&prmd=imvns&tbm=isch&tbo=u& source=univ&ei=1xc

I have surplus rudder components from a dismantled 26' sailboat with a 1.25" diameter rudder shaft. Depending on your design you may find some parts useful. |

walt_ansel

Member

Username: walt_ansel

Post Number: 4

Registered: 12-2011

| | Posted on Wednesday, January 11, 2012 - 10:27 pm: |

|

Hi Folks,

This dory is only about four years old. The linseed oil finish makes it look a lot older. My dad cut a scale model, then cut 5 station molds thru the model. He then traced the sections, scaled up and built full sized molds. He's an experienced boatbuilder, now retired.

The outboard was a Forty Plus Seagull. You could not tilt it up in the well and this was less than ideal.

The first photo of the engine in the boat shows a mahogany glued up pattern below the Schebler. This for the engine beds that I'm going to make out of 3" oak. They will notch over the frames and be well bolted.

The rudder is a copy of a Toppan power dory rudder at the Seaport. I have a 3/4" monel shaft for a post and the bronze strap in the photo to hold a bottom bearing. The blade will be wood, cross bolted to the post.

Thank you for your help and interest- Walt |

miro

Senior Member

Username: miro

Post Number: 590

Registered: 11-2001

| | Posted on Friday, January 13, 2012 - 10:31 pm: |

|

I suggest that you make the engine bed as big and beefy as you can.

Notching the engine bed lumber to account for the ribs and fastening it very strongly to the hull is important. And, for sure, you've got to use some kind of bedding compound eg Sikaflex

Epoxy might be a bit brittle

On your boat it might take some fussing and fitting to get the bed lumber tight - but the effort will be well worth it.

On these videos you can see the engine beds are big and beefy.

http://www.youtube.com/watch?v=XNG9gI_6b7s&feature=related

http://www.youtube.com/watch?v=7Iirpza4iqc

See if you can figure out some way of getting water into the exhaust ( as per JB's suggestion)- preferably as close to the engine as you can. Again, it's worth the effort.

I think you'll also find that the engine will run cool - that's OK for a while, but after a number of years of running, an overly cooled engine will have a lot of carbon gunk built up inside .

A small control valve on the cooling water will help you keep regulate the engine temperature.

Miro |

walt_ansel

Member

Username: walt_ansel

Post Number: 5

Registered: 12-2011

| | Posted on Sunday, January 15, 2012 - 06:59 pm: |

|

Hi Miro,

Thank you for the advice-the videos are fantastic!

I milled a bunch of 7/4 and 8/4 angelique (South American hardwood) yesterday for beds, floors and shaft log. I had this left over from rebuilding an 1880's oyster dredger about 14 years ago.

I made a split shaft log with splines on the table saw which I think I'll glue together with epoxy. Its a 1 1/4" hole for a 1" shaft. Tricky drilling ahead! Walt |